New Holland TL70A, TL80A, TL90A, TL100A Tractors Factory Service & Shop Manual

Catalog:

Model:

Complete workshop repair service manual with electrical wiring diagrams for New Holland TL70A, TL80A, TL 90A, TL100A Tractors. It's the same service manual used by dealers that guaranteed to be fully functional and intact without any missing page.

New Holland TL70A, TL80A, TL 90A, TL100A Tractors service & repair manual (including maintenance, overhaul, disassembling & assembling, adjustment, tune-up, operation, inspecting, diagnostic & troubleshooting…) is divided into different sections. Each section covers a specific component or system with detailed illustrations. A table of contents is placed at the beginning of each section. Pages are easily found by category, and each page is expandable for great detail. The printer-ready PDF documents work like a charm on all kinds of devices.

1,621 + 2,080 pages, bookmarked, Searchable, Printable, high quality PDF

FILE LIST:

603.54.491.00 - New Holland Tractors TL70A, TL80A, TL 90A, TL100A Service Manual.pdf; 1,621 pages, searchable, printable, bookmarked, high quality PDF w/ TOC.

603.54.511.00 - New Holland Tractors TL70A, TL80A, TL 90A, TL100A Service Manual.pdf; 2,080 pages, searchable, printable, bookmarked, high quality PDF w/ TOC.

EXCERPT:

SECTION 33 − BRAKING SYSTEM − CHAPTER 1

DESCRIPTION AND OPERATION

SERVICE BRAKES (see fig. 4)

The service brakes are the hydraulically operated wet disk type.

The two control pumps (one for each pedal) are located in the front part of the cab and are connected to their pedals (3) by means of tie−rods.

The pumps can be operated on their own by each pedal, or as a pair with both pedals (connected by a pin).

The connecting pipe (6) between the two pumps ensures balanced braking, even when the brake disks are not equally worn.

The control pumps are fed from a single reservoir installed on the pumps.

The brake disks (one for each rear wheel) are located between the rear transmission casing and the final drive casing. The disks are mounted on the differential drive shafts.

PARKING BRAKE (see fig. 2)

The parking brake is operated by a control lever on the left−hand side of the operator.

When acting on the control lever, a flexible tie−rod operates the lever (12) inside the parking brake support (13), bearing the brake sector assembly (10 and 11) and the brake disks (8) keyed onto the driven gear (7) and locking it.

Locking the rear bevel pinion shaft intermediate gear (7), locks the rear bevel pinion shaft too and therefore the tractor cannot move.

…

SECTIONS................1

INTRODUCTION................2

IMPORTANT WARNINGS................2

CONTENTS................3

SECTION 00 - GENERAL INSTRUCTIONS................12

IMPORTANT NOTICE................12

SHIMMING................12

ROTATING SHAFT SEALS................12

“O−RING” SEALS................12

SEALING COMPOUNDS................12

BEARINGS................13

SPRING PINS................13

SPARE PARTS................13

TOOLS................13

IMPORTANT NOTES................13

MOVING THE TRACTOR WITH THE BATTERY REMOVED................13

SAFETY REGULATIONS................14

CONSUMABLES................17

SECTION 10 − ENGINE................18

Chapter 1 − Engine................18

General specifications................19

Data................22

Tightening torques................28

Tools................30

Engine views................31

Lubrication diagram................33

Cooling system diagram................34

Fault diagnosis................38

Engine R.I.................42

Engine D.A. Checks, measurements and repairs................62

Crankshaft front seal − Replacement................114

Crankshaft rear seal − Replacement................117

Valve tappet and rocker arm clearance − Adjustment................120

Engine injector R.I................123

Bosch injection pump R.I. Timing. Air bleed................126

Coolant pump R.I.................134

Thermostat valve R.I.................136

Radiator R.I.................138

Coolant pump and generator drive belts. Tension adjustment................144

SECTION 18 − CLUTCH................146

Chapter 1 − Clutch................146

Clutches. General specifications................147

Tightening Torques................148

Tools................148

Cross−sectional views................149

Fault diagnosis................150

Checks, dimensions and repairs................151

Main transmission clutch release − Adjustment................153

Clutch R.I.................154

Dual Clutch 12”/12” − Test bench overhaul and adjustment................157

SECTION 21 − TRANSMISSIONS................162

Chapter 1 − Transmission and range gear (12 x 4)................162

Transmission and range gear. Data................163

Tightening Torques................164

Tools................165

Cross−sectional views................167

Description and Operation................169

Fault diagnosis................169

Chapter 2 − Reverser................171

Transmission with range gear and reverser. Data................172

Tightening Torques................173

Tools................174

Cross−sectional views................174

Description and Operation................176

Fault diagnosis................176

Clutch−reverser casing. Disassembly−Assembly................177

Chapter 3 − Dual Command (2 Speed Power Shift)................183

Data................184

Tightening Torques................186

Tools................187

Cross−sectional views................188

Description and Operation................192

Fault diagnosis................198

Clutch casing with Dual Command (2 Speed Power Shift) R.I................200

Clutch casing with Dual Command (2 Speed Power Shift) D.A.................209

Dual Command (2 Speed Power Shift) linkage adjustment................218

Dual Command (2 Speed Power Shift) solenoid valve R.I.................219

Dual Command (2 Speed Power Shift) control valve R.................223

Dual Command (2 Speed Power Shift) control valve D.A.................227

Chapter 4 − Reverser and creeper unit................230

Data................231

Tightening Torques................232

Tools................233

Cross−sectional views................235

Description and Operation................237

Fault diagnosis................237

Reverser−clutch casing and creeper unit D.A.................238

Chapter 5 − Power Shuttle transmission with Dual Command................245

Data................246

Tightening Torques................248

Tools................250

Cross−sectional views................252

Description and Operation................255

Clutch casing with Power Shuttle and Dual Command (2 Speed Power Shift) units D.A.................262

Clutch (a) D.A.................269

Clutch (B) D.A.................274

SECTION 23 − DRIVE LINES................275

Chapter 1 − Drive lines................275

Data................276

Tightening Torques................277

Tools................277

Cross−sectional views................278

Description of operation and hydraulic diagrams................279

Fault diagnosis................280

Services control valve R.I.................281

Services control valve D.A.................284

Drive gear housing R.I.................286

Drive gear housing D.A.................291

SECTION 25 − FRONT AXLE MECHANICAL TRANSMISSION................295

Chapter 1 − Front axle mechanical transmission................295

Data................296

Tightening Torques................298

Tools................300

Cross−sectional views................303

Rules for correctly fitting the axle support to the engine................307

Description of LIM−SLIP self−locking differential operation................309

Description of front differential lock operation................310

Fault diagnosis................311

Front axle R.I.................312

Front axle D.A. − Overhaul................316

Front axle differential with LIM−SLIP unit − Overhaul................325

Front axle differential with LIM−SLIP unit − Overhaul................326

Differential lock clutch assembly − Overhaul................328

Front epicyclic final drive without brake D.A.................330

Front epicyclic final drive with brake D.A.................334

Steering knuckle pins and bearings................337

Adjustments................338

SECTION 27 − REAR AXLE MECHANICAL TRANSMISSION................347

Chapter 1 − Rear axle mechanical transmission................347

Data................348

Tightening Torques................349

Tools................351

Cross−sectional views................356

Description and Operation................361

Fault diagnosis................362

Gearbox−transmission casing R.I.................364

Gearbox/transmission casing D.A. and adjustments................378

Adjustments − differential lock control pedal travel................397

Final drive casing R.I.................398

Epicyclic final drive D.A.................401

Drive wheel shaft D.A.................402

SECTION 31 − POWER TAKE−OFF................404

Chapter 1 − Mechanical power take−off................404

Data................405

Tools................408

Tightening Torques................409

Cross−sectional views................410

Description of operation................413

Fault diagnosis................414

Power take−off housing R.I.................415

Power take−off driving shaft D.A.................418

Driven shaft and other parts D.A.................418

Chapter 2 − Electro−hydraulic power take−off................421

Data................422

Tools................425

Tightening Torques................426

Cross−sectional views................427

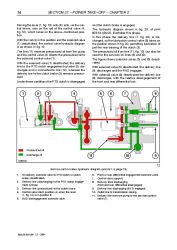

Description, operation and hydraulic diagrams................433

Fault diagnosis................444

Power take−off clutch brake Replacement................445

Electro−hydraulic power take−off housing R.I.................447

Speed selection control device D.A.................451

Power take−off driving shaft D.A.................451

PTO driven shaft D.A.................451

SECTION 33 − BRAKES................458

Chapter 1 − Brakes................458

Data................458

Tightening Torques................459

Cross−sectional views................460

Description and Operation................461

Fault diagnosis................464

Handbrake control. Travel adjustment................465

Parking brake casing. R.I.................466

Parking brake casing. D.A.................466

Brake hydraulic system. Air bleed................469

Service brake pump. R.I.................470

Service brake cylinder. R.I.................472

SECTION 35 − HYDRAULIC SYSTEMS................477

Chapter 1 − Rear mechanical hydraulic lift................477

Data................478

Tightening Torques................483

Tools................485

Cross−sectional views................486

Description and Operation................488

Fault diagnosis................492

Rear lift oil pump D.A.................495

Lift−O−Matic control D.A.................496

Rear lift linkage adjustments................497

Rear lift external controls D.A. and adjustments................500

Rear lift R.I.................501

Rear hydraulic lift internal controls D.A. and adjustments................508

Arm shaft and lifting cylinder D.A.................508

Lift shaft bushings − Replacement................508

Lift control valve R.I.................519

Lift control valve D.A.................521

Lift pressure relief valve R.I.................526

Lift pressure relief valve − Setting................526

Chapter 2 − Open centre system auxiliary control valves................527

Data − Tools................527

Tightening Torques................528

Cross−sectional views................529

Description and Operation................532

Troubleshooting................492

Auxiliary control valves D.A.................536

Flow control valve D.A.................539

Chapter 3 − Auxiliary control valves for remote control (BOSCH)................542

Data................543

Tools................543

Tightening Torques................544

Description and Operation................545

Auxiliary control valve components................547

Control valve inter−connection................551

Lifting oil flow (Cylinder extension)................552

Lowering oil flow (Cylinder retraction)................554

Neutral oil flow................555

Float mode oil flow................556

Automatic release pressure regulating valve operation................557

Operation of two or more control valves simultaneously................558

Auxiliary control valves R.I.................560

Auxiliary control valves. D.A.................563

Chapter 4 − Trailer brake auxiliary control valves................568

Cross−sectional views................568

Description and Operation................568

Trailer brakes control valve hydraulic circuit diagram with KONTAK control valves................569

Trailer brake control valve hydraulic circuit diagram with BOSCH control valves................570

Functional testing and troubleshooting................577

Chapter 5 − Supplementary cylinder................580

Data................580

Cross−sectional views................580

Description and Operation................580

Supplementary cylinder R.I.................581

Supplementary cylinder D.A.................581

Chapter 6 − Electronic draft control................582

Data................583

Tightening Torques................585

Tools................585

Details of electronic lift components................586

Description and Operation................589

Lift electronic control centre − Replacement................593

Electronic lift control panel R.I.................594

Lift arm potentiometer − Replacement................595

Draft sensor R.I.................596

Electronic lift calibration................598

Electronic draft control R.I.................600

Hydraulic control valve R. I.................606

Chapter 7 − Ventral control valves for Walvoil−type open centre system................608

Ventral control valve specifications................608

Tightening torques................609

Ventral control valve diagrams................610

Ventral control valve joystick................612

Control valve circuit................615

Hydraulic diagram................616

Description and operation of ventral control valve................617

Chapter 8 − Front Loader................626

Features................627

Maximum permissible front axle weights................628

Tightening torques................629

Diagrams................630

Ventral control valve specifications................633

Ventral control valve joystick................635

Switching full / dipped beam headlights on lights fitted on handrails................638

Ballasting the tractor for front loader operation................642

Loader general description................643

Loader installation − removal................653

Attachment installation − removal................658

Lift arm types and functions................662

“Smooth ride control”................671

Multi Quick coupler connection − disconnection................674

Hydraulic functions and flow diagram of loaders................686

Hydraulic flow diagrams................697

Repair instructions................714

Hydraulic components................720

Fault finding................725

SECTION 41 − STEERING................731

Chapter 1 − Steering................731

Data................732

Tightening Torques................735

Components and operating diagrams................736

Fault diagnosis................741

Tools................742

Hydrostatic steering control valve R.I.................743

Hydrostatic steering control valve D.A.................748

Hydrostatic steering control valve bench tests................762

Hydrostatic steering oil pump D.A.................765

Front axle steering cylinder R.I.................766

Front axle steering cylinder R.I.................767

SECTION 44 − AXLES AND WHEELS................768

Chapter 1 − Axles and wheels................768

Data................768

Cross−sectional views................770

Tightening Torques................771

Fault diagnosis and equipment................772

Front axle hub D. A.................773

Front axle R.I.................776

Stub axle Overhaul................779

Checking 2 WD front wheel camber and toe−in................782

Checking 4 WD front wheel alignment................783

SECTION 50 − AUXILIARY UNITS................784

Chapter 1 − Auxiliary units................784

Safety regulations................785

General specifications................786

Tools................787

Operating principles................788

Main components of the cab air conditioning system................790

Warnings for air conditioning system repair operations................794

Cab controls................795

Instructions for use − air conditioning system................798

Refrigerant recovery − recycling and evacuation − charging stations................798

Electronic leak detector 380000314................799

Air conditioning system maintenance................800

Air conditioning system troubleshooting................801

Air conditioning system troubleshooting................802

Cab air conditioning system functional testing................806

Checking for gas leaks with leak detector 380000314................807

Compressor drive belts. Tension adjustment................808

Air conditioner compressor. R.I.................810

Heating pipes. Replacement................813

Air conditioning pipes. Replacement................815

Air conditioner condenser. Replacement................821

Dryer filter. Replacement................822

Cab heater unit. R.I.................824

Air conditioner evaporator. Replacement................827

Electric cab fan. R.I.................830

SECTION 55 − ELECTRICAL SYSTEM................832

Chapter 1 − INSTRUMENTS................832

Control panel................833

Analog/Digital Instruments................835

Instruments................835

Liquid crystal displays................836

Central display................837

Using the advanced keypad................841

Transmitters, sensors, switches................843

Maintenance................851

Chapter 2 − COMPONENTS................852

Introduction................852

Description of components................853

Advanced Keypad................857

Controls on right−hand mudguard................860

Cab controls................862

Controls on right−hand cab upright................864

Maintenance................866

Chapter 3 − STARTING SYSTEM................868

Technical data................868

Tightening torques................868

Description and operation................869

Troubleshooting................871

System testing................872

Removal−Installation................874

Bench tests................877

Chapter 4 − CHARGING SYSTEM................879

Technical data................879

Tightening torques................879

Description and Operation................880

Chapter 5 − BATTERY................897

Technical data................897

Description and operation................897

Removal−Installation................898

Battery checking and maintenance................900

Tests................902

Chapter 6 − ELECTRICAL CIRCUITS................905

Electrical circuit components................907

Fuses and relays (version with cab)................912

Maxi fuse box (version with cab)................917

Fuse and relay layout (North America version without cab −................920

Fuse and relay layout (ISO version without cab −................922

Fuse and relay layout (North America version without cab −................924

Maxi fuse box (ISO − North America version without cab)................926

Power sockets................927

Operator safety circuit................928

Grid heater relay................929

Grid heater control module................929

Electronic flasher module................929

Ground location points................930

Symbols used in electrical circuits................932

Electric wire colour code................933

Electrical circuits................934

Wiring DIAGRAMS A − A/1................935

Starter and recharging circuit − DIAGRAM A/1................944

Battery cut−out circuit − DIAGRAM B................950

Wiring DIAGRAM C................957

Wiring DIAGRAMS D − E................967

Wiring DIAGRAM F................983

Wiring DIAGRAMS G − H................993

Wiring DIAGRAMS I − L − M................1007

Wiring DIAGRAMS N/1 − N/2 − O/1 − O/2................1027

Wiring DIAGRAMS P − Q − R/1 − R/2................1057

Wiring DIAGRAM S................1083

Wiring DIAGRAM T................1095

Electronic transmission control unit input/output circuit (TCM) − DIAGRAM U................1104

Measuring device control unit input/output circuit (ADIC) − DIAGRAM V................1106

Electronic rear lift control unit input/output circuit − DIAGRAM W................1108

Measuring device (ADIC) and transmission control unit (TCM) connection diagram −................1110

Chapter 7 − Components Testing................1112

Low transmission oil pressure switch Brake fluid level switch Air filter clogged switch Differential lock indicator switch Lift status switch................1113

Italia version trailer brake valve pressure switches Brake light switch Engine coolant temperature sensor Fuel sediment filter switch ................1115

Handbrake status switch Dual Command (2 Speed Power Shift) switch Gear/Range lever position sensors................1117

Engine oil pressure sensor Switch and clutch pedal potentiometer Speed sensors Clutch pressure switches A and B and oil temperature sensor Alternator ................1120

Radar 4WD pressure switch Fuel level indicator Power Shuttle lever................1124

Electronic lift arm position potentiometer Seat safety switch Draft pin sensors PTO speed sensor ................1126

Front windscreen wiper motor. R.I.................1128

Chapter 8 − Fault Codes................1129

Introduction................1130

Special Tools................1131

Wiring Harness Repairs................1131

Digital Multi−Meter − Basic Operation................1134

Electrical Test Procedures................1137

Circuit Components − Basic Description................1140

Controller Area Network (CAN) System................1150

Fault Code Displays................1151

H−Menu Diagnostic Mode................1153

Fault Code Lists................1154

Calibration U−Codes................1161

2001−3000 (Transmission)................1165

5001−6000 (Rear Power Take−Off)................1367

6001−7000 (Four Wheel Drive)................1385

7001−8000 (Differential Lock)................1395

14001−15000 (Analog Digital Instrument Cluster)................1409

Electronic Draft Control (EDC)................1477

Chapter 9 − HH MENU AND CALIBRATIONS................1553

HH MENU access................1554

HH MENU of the control panel................1556

HH MENU of the transmission................1563

HH MENU of the advanced keypad................1576

SECTION 90 − BODYWORK AND DRIVING POSITION................1578

Chapter 1 − Removal of components................1578

Platform. R.I.................1579

Bonnet. R.I.................1587

Driver’s seat. R.I.................1589

Cabt. R.I.................1590

Cab right− or left−hand door. R.I.................1603

Cab windscreen. Repl.................1604

Cab RH or LH bottom front window. Repl.................1604

Cab rear window. Repl.................1606

Left−hand upright strip. Repl.................1609

Right−hand upright strip. Repl.................1610

Fixed padding on right−hand wall. Repl.................1612

Fixed padding on left−hand wall. Repl.................1615

Hydraulic control lever guard. Repl.................1617

Cab ceiling trim. Repl.................1619

New Holland TL70A, TL80A, TL 90A, TL100A Tractors Factory Service & Shop Manual