Hyundai Construction Backhoe Loader H930C, H930CB, H930S, H930ST, H940C, H940CB, H940S, H940ST Factory Service & Shop Manual

Catalog:

Model:

Complete workshop repair service manual with electrical wiring diagrams for Hyundai Construction Backhoe Loader H930C, H930CB, H930S, H930ST, H940C, H940CB, H940S, H940ST. It's the same service manual used by dealers that guaranteed to be fully functional and intact without any missing page.

This Hyundai Construction Backhoe Loader H930C, H930CB, H930S, H930ST, H940C, H940CB, H940S, H940ST service & repair manual (including maintenance, overhaul, disassembling & assembling, adjustment, tune-up, operation, inspecting, diagnostic & troubleshooting…) is divided into different sections. Each section covers a specific component or system with detailed illustrations. A table of contents is placed at the beginning of each section. Pages are easily found by category, and each page is expandable for great detail. The printer-ready PDF documents work like a charm on all kinds of devices.

EXCERPT:

CONTENTS

SECTION 1 GENERAL

Group 1 Safety Hints - - 1-1

Group 2 Specifications - - - 1-10

Group 3 Operational Checkout Record Sheet - - - 1-17

SECTION 2 ENGINE

Group 1 Structure - - 2-1

Group 2 Engine Speed and Stall rpm - - - 2-11

SECTION 3 POWER TRAIN SYSTEM

Group 1 Structure and Function - - 3-1

Group 2 Operational Checks and Troubleshooting - - - 3-15

Group 3 Test and Adjustments - - 3-23

Group 4 Disassembly and Assembly - - 3-25

SECTION 4 BRAKE SYSTEM

Group 1 Structure and Function - - 4-1

Group 2 Operational Checks and Troubleshooting - - - 4-13

Group 3 Tests and Adjustments - - 4-17

Group 4 Disassembly and Assembly - - - 4-18

SECTION 5 STEERING SYSTEM

Group 1 Structure and Function - - 5-1

Group 2 Operational Checks and Troubleshooting - - - 5-9

Group 3 Tests and Adjustments - - 5-16

Group 4 Disassembly and Assembly - - - 5-23

SECTION 6 WORK EQUIPMENT

Group 1 Structure and Function - - 6-1

Group 2 Operational Checks and Troubleshooting - - - 6-65

Group 3 Tests and Adjustments - - 6-78

Group 4 Disassembly and Assembly - - - 6-90

SECTION 7 ELECTRICAL SYSTEM

Group 1 Component Location - - 7-1

Group 2 Electrical Circuit - - 7-3

Group 3 Monitoring System - - 7-24

Group 4 Switches - - 7-29

Group 5 Electrical Component Specification - - 7-38

Group 6 Connectors - - 7-44

…

SECTION 3 POWER TRAIN SYSTEM

Group 1 Structure and Function - - 3-1

Group 2 Operational Checks and Troubleshooting - - - 3-15

Group 3 Test and Adjustments - - 3-23

Group 4 Disassembly and Assembly - - 3-25

…

SECTION 3 POWER TRAIN SYSTEM

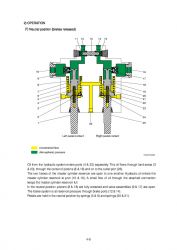

GROUP 1 STRUCTURE AND FUNCTION

1. POWER TRAIN COMPONENT OVERVIEW

Front drive shaft Rear drive shaft

Engine Transmission

Front axle Rear axle

The power train consists of the following components:

·Transmission

·Front and rear drive shafts

·Front and rear axles

Engine power is transmitted to the transmission through the torque converter.

The transmission is a hydraulically engaged four speed forward, three speed reverse countershaft type power shift transmission. A multi-disc type parking brake is located in the rear axle.

The transmission outputs through universal joints to two drive shaft assemblies. The front drive shaft is a telescoping shaft which drives the front axle. The front axle is mounted directly to the loader front frame. The front axle is equipped with conventional differential.

The rear axle is equipped with hydraulic lock differential.

The power transmitted to front axle and rear axle is reduced by the pinion gear and ring gear of differential. It then passes from the differential to the sun gear shaft (axle shaft) of final drive.

The power of the sun gear is reduced by a planetary mechanism and is transmitted through the planetary hub to the wheel.

…