John Deere Tractors 5050E, 5055E, 5065E, 5075E Diagnostics and Repair Service Manual (TM900319)

Catalog:

Model:

Complete All Inclusive Technical Manual with electrical wiring diagrams for John Deere Tractors 5050E, 5055E, 5065E, 5075E, with all the shop information to maintain, diagnose, repair, and service like professional mechanics (Diagnosis, Operation, Tests, Repair, Service, Troubleshooting).

John Deere 5050E, 5055E, 5065E, 5075E workshop diagnosis repair technical manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

TM900319 - John Deere 5050E, 5055E, 5065E and 5075E Tractors Technical Manual.pdf

Total Pages: 1,531 pages

File Format: PDF (PC/Mac/Android/Kindle/iPhone/iPad; bookmarked, ToC, Searchable, Printable)

Language: English

MAIN SECTIONS

Foreword

General Information

Safety

General Specifications

Fuel and Lubricants

Serial Number Locations

Features and Accessories

Engine Repair

Engine

Cylinder Head and Valves

Cylinder Block, Liners, Pistons and Rods

Crankshaft, Main Bearings and Flywheel

Camshaft and Timing Gear Train

Lubrication System

Cooling System

Fuel and Air Intake System Repair

Fuel System

Air Intake and Exhaust System

Speed Control Linkage

Electrical Repair

Battery, Starter and Alternator

Electrical System Components

Wiring Harness

Power Train Repair

Clutch Housing

Clutch Assembly

Transmission

Rear PTO Drive Shaft

Differential

Final Drives

Mechanical Front Wheel Drive – If Equipped

Steering and Brake Repair

Steering Repair

Brake Repair

Hydraulic Repair

Hydraulic Pump and Filter

JD Rockshaft

Selective Control Valve (SCV)

Miscellaneous Repair

Front Axle

Wheels

3-Point Hitch

Hood

Ballast

Operator Station Repair

Seat and Support

Right Console

Roll-Gard™

Center Console

Operator Station

Fenders

Operational Checkout Procedures

Operational Checkout Procedures

Engine Operation, Tests and Adjustments

Component Location

Theory of Operation

Diagnosis, Tests and Adjustments

Fuel/Air Operation, Tests and Adjustments

Component Location

Theory of Operation

Diagnosis, Tests and Adjustments

Electrical System Operation, Tests and Adjustments

Component Location

Theory of Operation

Diagnosis, Tests and Adjustments

Wiring Schematics

Component Information-Connectors

Power Train Operation, Tests and Adjustments

Component Location

Theory of Operation

Diagnosis, Tests and Adjustments

Steering and Brake Operation, Tests & Adjustments

Component Location

Theory of Operation

Diagnosis, Tests and Adjustments

Hydraulic System Operation, Tests and Adjustments

Component Location

Theory of Operation

Diagnosis

Hydraulic Tests-With SCV

Hydraulic Tests-With Mid-Mount Control Valve

Hydraulic Tests-Whole System

Adjustments-Hitch

Hydraulic Schematics

TABLE OF CONTENTS

Section 10: General Information................1550

Group 05: Safety................31

Recognize Safety Information................35

Understand Signal Words................36

Follow Safety Instructions................37

Prepare for Emergencies................38

Wear Protective Clothing................39

Protect Against Noise................40

Handle Fuel Safely—Avoid Fires................41

Fire Prevention................42

Use Foldable ROPS and Seat Belt Properly................43

Stay Clear of Rotating Drivelines................44

Use Steps and Handholds Correctly................46

Read Operator Manuals for ISOBUS Implements................47

Use Seat Belt Properly................48

Vibration................49

Operating the Tractor Safely................50

Avoid Backover Accidents................52

Limited Use in Forestry Operation................53

Operating the Loader Tractor Safely................54

Keep Riders Off Machine................55

Passenger Seat................56

Use Safety Lights and Devices................57

Towing Trailers/Implements Safely (Mass)................58

Use Caution On Slopes and Uneven Terrain................59

Freeing a Mired Machine................60

Avoid Contact with Agricultural Chemicals................61

Handle Agricultural Chemicals Safely................62

Handling Batteries Safely................64

Avoid Heating Near Pressurized Fluid Lines................66

Remove Paint Before Welding or Heating................67

Handle Electronic Components and Brackets Safely................68

Practice Safe Maintenance................69

Avoid Hot Exhaust................70

Clean Exhaust Filter Safely................71

Work In Ventilated Area................74

Support Machine Properly................75

Prevent Machine Runaway................76

Park Machine Safely................77

Transport Tractor Safely................78

Service Cooling System Safely................79

Service Accumulator Systems Safely................80

Service Tires Safely................81

Service Front-Wheel Drive Tractor Safely................82

Tightening Wheel Retaining Bolts/Nuts................83

Avoid High-Pressure Fluids................84

Do Not Open High-Pressure Fuel System................85

Store Attachments Safely................86

Dispose of Waste Properly................87

Group 10: General Specifications................1018

Machine Specifications................1018

Ground Speed Estimates................94

Service Recommendations for O-Ring Boss Fittings................98

Service Recommendations for Flat Face O-Ring Seal Fittings................100

Metric Bolt and Screw Torque Values................102

Unified Inch Bolt and Screw Torque Values................104

Group 20: Fuel and Lubricants................32

Diesel Fuel................108

Fuel Storage................110

Do Not Use Galvanized Containers................111

Fill Fuel Tank................112

Diesel Engine Oil................113

Heavy Duty Diesel Engine Coolant................115

Transmission and Hydraulic Oil................116

Grease (Specific Application)................117

Grease................118

Lubricant Storage................119

Group 25: Serial Number Locations................33

Serial Numbers................121

Product Identification Number Location................122

Engine Serial Number Location................123

Fuel Injection Pump Serial Number Location................124

Alternator Serial Number Location................125

Power Steering Valve Serial Number Location................126

Transmission Serial Number Location................127

Front Axle Serial Number Location- 2WD................128

Front Axle Serial Number Location—MFWD................129

Record ROPS Serial Number................130

Group 30: Features and Accessories................132

Features and Accessories................132

Standard Features................133

Factory Installed Optional Kits................136

Field Installed Optional Kits and Accessories................137

Section 20: Engine Repair................138

Group 05: Engine................138

Service Equipment and Tools................761

Specifications................1018

John Deere Engine Repair................147

Remove Engine................148

Install Engine................156

Engine Disassembly Sequence................163

Sealant Application Guidelines................165

Engine Re-Assembly Sequence................166

Engine Break-In Guidelines................168

Perform Engine Break-In................169

Diesel Engine Break-In Oil................170

Group 10: Cylinder Head and Valves................138

Special or Essential Tools................1019

Specifications................1018

Torques for Hardware................383

Cylinder Head - Exploded View................232

Check Valve Lift................183

Remove Cylinder Head................184

Clean Injection Nozzle Bores................187

Valve Actuating Parts................188

Remove Valves and Valve Springs................189

Checking Cylinder Head Flatness................190

Clean Valve Guides................191

Measure Valve Guides................192

Knurl Valve Guides................194

Clean and Inspect Valve Seats................195

Lapping Valve Seats................196

Check Valve Recess................197

Remove Valve Seat Inserts................198

Valve Seat Insert Installation................200

Check Valves................201

Grind Valves................202

Check Valve Spring Compression................203

Inspect Valve Rotators................204

Install Valves................205

Install Cylinder Head................207

Torque Turn Tightening Method................209

Disassembling and Checking Rocker Arm Shaft................211

Reassembling Rocker Arm Shaft................213

Install Rocker Arm Assembly................214

Valve Clearance................215

Valve Adjustment Sequence................216

Install Rocker Arm Cover................218

Final Work................219

Group 15: Cylinder Block, Liners, Pistons and Rods................139

Special or Essential Tools................1019

Specifications................1018

Torques for Hardware................383

Exploded View................232

Connecting Rods - General Information................1550

Remove Pistons and Connecting Rods................235

Measure Cylinder Liner Bore................237

Remove Cylinder Liners................238

Cylinder Liner Deglazing................239

Cylinder Block Cleaning................240

Check Piston Cooling Jets................241

Cam Follower Bore Measure................242

Measure Camshaft Bore................243

Remove Camshaft Bushing................244

Install Camshaft Bushing................245

Measure Crankshaft Bore................246

Replace Crankshaft Bearing Caps................247

Cylinder Block Top Desk Flatness................248

Measure Cylinder Liner Protrusion................249

Liner Packing Installation................251

Liner O-Ring Installation................252

Install Cylinder Liners................253

Measure Connecting Rod Bearing................254

Rod Bearing Clearance................256

Measure Connecting Rod Bushing................257

Replace Connecting Rod Bushing (3029D)................258

Replace Connecting Rod Bushing (3029T)................259

Measure Piston Pin................262

Clean and Inspect Pistons................263

Measure Piston Pin Bore................264

Piston Top Ring Groove................265

Second and Third Piston Ring Grooves................266

Piston Head and Skirt Checking................267

Install Piston Rings................268

Piston Rings Staggering................270

Piston/Liner Set Information................271

Assemble Piston and Connecting Rod................272

Install Piston and Connecting Rod................274

Measure Piston Protrusion................278

Complete Final Assembly................280

Group 20: Crankshaft, Main Bearings and Flywheel................140

Special or Essential Tools................1019

Specifications................1018

Torques For Hardware................416

Remove Crankshaft Pulley................289

Install Crankshaft Pulley................290

Flywheel Removal................291

Flywheel Ring Gear Replacement................292

Install Ball Bearing................293

Install Flywheel................294

Remove Crankshaft Rear Oil Seal................295

Flywheel Housing Replacement................298

Install Oil Seal/Wear Sleeve................300

Crankshaft End Play Measure................301

Remove Crankshaft................303

Crankshaft Inspection................304

Check Crankshaft Journal Diameter................305

Determine Crankshaft Main Bearing Clearance Using PLASTIGAGE PLASTIGAGE is a trademark of DANA Corp.................141

Regrind Crankshaft................308

Crankshaft Regrinding Guidelines................309

Micro-Finishing Specifications................1018

Replace Crankshaft Gear................311

Install Main Bearing Inserts................313

Install 2-Piece Thrust Bearing................314

Crankshaft Installation................315

Group 25: Camshaft and Timing Gear Train................141

Special or Essential Tools................1019

Specifications................1018

Torques for Hardware................383

Remove Crankshaft Front Oil Seal................324

Remove Timing Gear Cover................325

Measure Timing Gear Backlash................326

Camshaft End Play Measure................327

Remove Camshaft................328

Measure Camshaft Journal................329

Measure Height of Cam Lobe................330

Replace Camshaft Gear................331

Install Camshaft................332

Check Cam Follower................333

Idler Gear End Play Measure................334

Remove Front Plate................335

Idler Gear Bushing and Shaft Measure................337

Idler Gear Bushing Replacement................339

Remove Idler Shaft................340

Install Idler Shaft Spring Pin................341

Install Idler Shafts................342

Install Front Plate................343

Install Upper Timing Gear Train................345

Install Lower Timing Gear Train................347

Install Oil Deflector................348

Timing Gear Cover Identification................349

Install Timing Gear Cover................350

Install Crankshaft Front Oil Seal................352

Install Wear Ring................353

Install Auxiliary Equipment................354

Group 30: Lubrication System................142

Special or Essential Tools................1019

Specifications................1018

Torques for Hardware................383

Oil Cooler Identification................359

Remove Oil Cooler................360

Replace Oil Cooler Nipple................361

Install Oil Cooler................362

Replace Oil Cooler/Filter Bracket on Engine with Auxiliary Drive................363

Remove Oil Pressure Regulating Valve................365

Replace Oil Pressure Regulating Valve Seat................366

Install Oil Pressure Regulating Valve................367

Replace Oil Dipstick Guide................368

Replace Oil By-Pass Valve................369

Replace Oil Pump Strainer................370

Remove Oil Pump................371

Oil Pump Gear Axial Clearance................372

Oil Pump Gear Radial Clearance................373

Oil Pump Specifications................1018

Oil Pump Installation................375

Install Oil Pan................378

Group 35: Cooling System................142

Special or Essential Tools................1019

Specifications................1018

Torques for Hardware................383

Remove and Inspect Radiator................384

Water Pump — Exploded View................390

Remove Water Pump................391

Disassemble Water Pump................392

Assemble Water Pump................394

Install Water Pump................397

Inspect Thermostat................398

Cooling System Deaeration................400

Check Fan/Alternator Belt Tension................401

Install Radiator................403

Replace Thermostat................407

Section 30: Fuel and Air Intake System Repair................410

Group 05: Fuel System................410

Special or Essential Tools................1019

Self-Manufactured Tool Template For Front Plate Replacement................415

Torques For Hardware................416

Injection Pump, Nozzle and Governor Repair—Use CTM................417

Remove, Inspect and Install Fuel Tank................418

Replace Fuel Filter................422

Remove and Install Fuel Filter/Primer Pump Assembly................423

Remove Fuel Injection Nozzle................424

Clean Fuel Injection Nozzle................426

Fuel Injection Nozzle Disassembly................427

Install Fuel Injection Nozzle................428

Group 10: Air Intake and Exhaust System................410

Remove, Inspect, and Install Air Cleaner Elements................435

Check Air Inlet Pipe................439

Remove Turbocharger................443

Exhaust Manifold Inspection................445

Turbocharger Cut-Away View (Borge Warner)––If Equipped................447

Check Radial Clearance––If Equipped................449

Check Axial Clearance––If Equipped................450

Repair Turbocharger––If Equipped................451

Prelube Turbocharger––If Equipped................452

Install Turbocharger––If Equipped................453

Turbocharger Break-In––If Equipped................456

Recommendations for Turbocharger Use––If Equipped................457

Group 15: Speed Control Linkage................410

Inspect and Repair Speed Control Linkage................460

Section 40: Electrical Repair................462

Group 05: Battery, Starter and Alternator................462

Starter Repair—Use CTM................465

Remove and Install Battery................466

Remove and Install Starter................468

Alternator/Regulator Repair—Use CTM................470

Replace Alternator/Regulator................471

Group 10: Electrical System Components................462

Service Equipment and Tools................761

Other Material................803

Replace Air Filter Restriction Sensor................477

Replace Coolant Temperature Sensor................478

Replace Engine Speed Sensor................479

Replace Engine Oil Pressure Sensor................480

Replace Key Switch................482

Replace Light Switch................484

Replace Beacon Lamp Switch................486

Replace Turn Signal Switch................487

Replace Instrument Panel................489

Replace Rear PTO Switch................492

Replace Neutral Start Switch................494

Replace Differential Lock Switch................495

Replace MFWD Switch................497

Replace 7 Pin Connector................498

Replace Brake Switch................500

Replace Park Brake Switch................502

Replace Horn................504

Replace Fuel Level Sender................505

Replace Rotating Beacon Lamp................507

Group 15: Wiring Harness................462

Special or Essential Tools................1019

Service Parts Kits................787

Remove Connector Body from Blade Terminals................512

Replace WEATHER PACK WEATHER PACK is a trademark of Packard Electric. Connector................463

Install WEATHER PACK WEATHER PACK is a trademark of Packard Electric. Contact................463

Replace Battery Positive Cable................517

Replace Hood Wiring Harness................518

Replace Beacon Lamp Wiring Harness................520

Replace Engine Wiring Harness................522

Replace Console Wiring Harness................524

Replace Rear Wiring Harness................526

Replace 7 Pin Connector Wiring Harness................529

Section 50: Power Train Repair................530

Group 05: Clutch Housing................530

Service Equipment and Tools................761

Other Material................803

Specifications................1018

Separate Engine from Clutch Housing................537

Install Engine to Clutch Housing................543

Replace Clutch Housing Seal................549

Inspect and Repair Clutch Pedal and Linkage................551

Group 10: Clutch Assembly................530

Essential Tools................1019

Service Equipment and Tools................761

Other Material................803

Specifications................1018

Remove and Install Clutch Assembly................560

Disassemble and Inspect Clutch Assembly................563

Assemble Clutch Assembly................571

Traction Clutch Finger Adjustment................577

PTO Clutch Finger Adjustment................579

Remove and Inspect Clutch Release Mechanism and Shafts................581

Install Clutch Release Mechanism and Shafts................585

Group 15: Transmission................530

Specifications................1018

Separate Clutch Housing from Transmission................590

Install Clutch Housing to Transmission................593

Inspect and Repair Gear Shift Lever................596

Inspect and Repair Range Shift Lever................598

Remove Transmission................600

Disassemble and Inspect Transmission — SyncShuttle™................605

Assemble Transmission — SyncShuttle™................612

Install Transmission................619

Disassemble, Inspect and Assemble Gear Shift Shaft Assemblies................623

Disassemble, Inspect, and Assemble Transmission Top Shaft—SyncShuttle™ Transmission................625

Disassemble, Inspect, and Assemble Range Reduction Shaft................628

Disassemble, Inspect and Assemble Driven Shaft................630

Remove, Inspect, and Install Range Gears................632

Remove, Inspect, and Install Reverse Idler Shaft................634

Inspect and Repair Park Brake Lever................636

Remove, Inspect and Repair Park Brake................638

Group 20: Rear PTO Drive Shaft................531

Other Material................803

Specifications................1018

Remove, Inspect and Install Rear PTO Lever and Linkage................643

Remove and Install Standard Rear PTO Drive Shaft Assembly................645

Disassemble, Inspect and Assemble Standard Rear PTO Drive Shaft Assembly................647

Remove, Inspect and Install 540/540E Shift Lever and Linkage................650

Remove and Install 540/540E Rear PTO Drive Shaft Assembly – If Equipped................652

Disassemble, Inspect and Assemble Rear 540/540E PTO Drive Shaft Assembly – If Equipped................654

Group 25: Differential................531

Essential Tools................1019

Service Equipment and Tools................761

Other Material................803

Specifications................1018

Service Parts Kits................787

Remove and Install Differential Assembly................664

Disassemble, Inspect, and Assemble Differential Assembly................666

Remove and Inspect Differential Drive Shaft................668

Install Differential Drive Shaft................672

Remove, Inspect, and Install Differential Lock Assembly................677

Differential Cone Point Adjustment................679

Differential Backlash Adjustment................681

Group 30: Final Drives................531

Service Equipment and Tools................761

Other Material................803

Specifications................1018

Remove and Install Final Drive Assembly................687

Remove and Inspect Planetary Drive Assembly................689

Install Planetary Drive Assembly................692

Remove, Inspect, and Install Axle Shaft Assembly................695

Group 35: Mechanical Front Wheel Drive – If Equipped................532

Service Equipment and Tools................761

Essential Tools................1019

Other Material................803

Specifications................1018

MFWD Axle Repair................707

Inspect and Repair MFWD Lever and Linkage................708

Remove and Install MFWD Drop Gearbox................709

Disassemble and Inspect MFWD Drop Gear box................711

MFWD Drop Gearbox Cross Section................714

Assemble MFWD Drop Gearbox................716

Remove, Inspect and Install MFWD Drive Shaft................722

Remove and Install MFWD Axle Housing Assembly................723

Remove, Inspect and Install MFWD Axle Supports (Without Paddy Seal)................725

Section 60: Steering and Brake Repair................727

Group 05: Steering Repair................727

Other Material................803

Specification................936

Service Parts Kits................787

Remove and Install Steering Wheel................732

Remove and Install Steering Column and Valve................736

Disassemble and Inspect Steering Valve - Eaton................741

Assemble Steering Valve - Eaton................746

Remove and Install Steering Cylinder—2WD Axle................752

Disassemble, Inspect and Assemble Steering Cylinder—2WD Axle................754

Remove, Inspect and Install Tie Rod Assembly—2WD................756

Inspect and Replace Steering Hydraulic Lines................758

Group 10: Brake Repair................727

Service Equipment and Tools................761

Other Material................803

Specification................936

Remove and Install Brake Valve................764

Disassemble and Inspect Brake Pedals and Valve................766

Brake Valve Cross Section................769

Assemble Brake Valve................771

Remove and Inspect Brakes................774

Install Brakes................777

Inspect and Replace Brake Hydraulic Lines................780

Section 70: Hydraulic Repair................782

Group 05: Hydraulic Pump and Filter................782

Essential Tools................1019

Specification................936

Service Parts Kits................787

Remove, Inspect, and Install Hydraulic Oil Pick-Up Screen................788

Remove and Install Hydraulic Pump................789

Remove Hydraulic Pump External Components................791

Disassemble and Inspect Hydraulic Pump................792

Assemble Hydraulic Pump................795

Install Hydraulic Pump External Components................797

Remove and Install Hydraulic Oil Filter/Manifold................799

Inspect and Replace Hydraulic Supply and Suction/Return Lines................800

Group 10: JD Rockshaft................782

Other Material................803

Specification................936

Inspect and Repair Rockshaft Control Lever Assembly................805

Inspect and Repair Rockshaft Control Linkage................810

Inspect and Repair Draft Sensing Support Assembly................814

Replace Main Relief Valve................816

Replace Rockshaft Surge Relief Valve................818

Remove, Inspect, and Install Rate-of-Drop Valve................820

Replace Rockshaft Control Valve................823

Remove and Install Rockshaft Case................827

Remove, Inspect, and Install Rockshaft Lift Arms................830

Remove, Inspect, and Install Rockshaft Piston and Cylinder................832

Group 15: Selective Control Valve (SCV)................782

Specification................936

Inspect and Repair SCV Lever and Linkage................837

Remove and Install EATON Selective Control Valve................839

Remove and Install Rear Coupler Bracket................843

Remove and Install SCV Oil Lines................846

Disassemble, Inspect and Assemble Dual Mid-Mount Selective Control Valve (SCV)................847

Section 80: Miscellaneous Repair................853

Group 05: Front Axle................853

Specification................936

Remove and Install Front Axle—2WD................856

Remove and Install Front Axle — MFWD................859

Inspect and Replace Pivot Pin and Bushings—2WD Axle................863

Remove and Install Spindle Assembly—2WD................864

Inspect and Replace Spindle Shaft Bushings—2WD Axle................866

Group 10: Wheels................853

Specifications................1018

Remove and Install Front or Rear Wheels................869

Inspect and Replace Front Wheel Bearings................870

Tighten Bolts—Rear Axle (M-20 Bolt)................872

Tighten Nuts—Front Axle (MFWD)................873

Tighten Cap Screws—Front Axle (2WD)................874

Group 15: 3-Point Hitch................853

Specification................936

Inspect and Repair Fixed Draft Links................877

Inspect and Repair Lift Link................878

Inspect and Repair Center Link................880

Remove and Install Wagon Hitch and Support................881

Group 20: Hood................853

Specification................936

Remove and Install Hood................884

Group 25: Ballast................853

Specifications................1018

Remove and Install Front Ballast................889

Remove and Install Rear Ballast—For 5055E, 5065E and 5075E Turkey Tractors Only................893

Section 90: Operator Station Repair................895

Group 05: Seat and Support................895

Specifications................1018

Remove and Install Seat and Support................898

Group 06: Right Console................895

Remove and Install Right-Side Control Console................903

Group 10: Roll-GardRoll-Gard is a trademark of Deere & Company.................895

Specification................936

Remove ROLL-GARD™................909

Install ROLL-GARD™................915

Group 15: Center Console................895

Specification................936

Remove Center Console Assembly................923

Install Center Console Assembly................929

Group 20: Operator Station................895

Specification................936

Remove Isolated Open Operator Station................937

Install Isolated Open Operator Station................948

Remove and Install Left and Right Side Steps................960

Group 25: Fenders................895

Remove and Install Fenders................965

Section 210: Operational Checkout Procedures................968

Group 10: Operational Checkout Procedures................968

Operational Checkout Procedure Information................970

Engine Oil Level and Condition Check................971

Coolant Level and Condition Check................973

Transmission and Hydraulic Oil Check................974

Fan and Belt Check................975

Fuel System Check................976

Air Intake System Check................977

Electrical System Check................979

Hydraulic System Check................981

Indicator Light Check................982

Engine Start Check................984

Transmission Neutral Start Check................986

Engine Fast and Slow Idle Operation................987

Power Steering Check................988

Differential Lock Check................989

Clutch Check................990

Transmission Shift Check................991

Range-Shift Lever Check................992

Brake Check................994

Park Brake Check................995

Hitch Check................996

Selective Control Valve Check................998

Miscellaneous Checks................1000

Section 220: Engine Operation, Tests and Adjustments................1001

Group 05: Component Location................1001

Component Location Information................1476

Engine External Components—Left-Hand Side................1005

Engine External Components—Right-Hand Side................1007

Group 10: Theory of Operation................1001

Theory of Operation Information................1480

Engine Lubrication System Operation................1011

Engine Cooling System Operation................1015

Group 15: Diagnosis, Tests and Adjustments................1001

Specifications................1018

Essential Tools................1019

Diagnostic Information................1522

Engine Turns Over But Will Not Start or Starts Hard................1021

Engine Runs Irregularly or Stalls Frequently................1022

Engine Runs Rough................1023

Engine Low Power................1024

Engine Smokes—Black or Gray................1026

Engine Smokes Excessively—White................1027

Engine Uses Excess Fuel................1028

Engine Has Excess Noise or Vibration................1029

Engine Uses Excess Oil or Smokes Blue................1030

Engine Has Low Oil Pressure................1031

Engine Coolant Operating Temperature Incorrect................1032

Oil In Coolant or Coolant in Oil................1034

Radiator Bubble Test................1035

Cooling System Test................1038

Radiator Cap Pressure Test................1039

Engine Oil Pressure Test................1040

Cylinder Compression Pressure Test................1042

Fuel Shutoff Solenoid Check................1044

Throttle Lever Adjustment................1045

Rotary Fuel Injection Pump Timing Adjustment................1046

Rotary Fuel Injection Pump Slow Idle Adjustment................1047

Rotary Fuel Injection Pump Fast Idle Adjustment................1049

Valve Clearance Adjustment................1051

Fan/Alternator Drive Belt Adjustment................1053

Bleeding Fuel System – Rotary Pump................1055

Section 230: Fuel/Air Operation, Tests and Adjustments................1058

Group 05: Component Location................1058

Component Location Information................1476

Fuel System Components................1061

Air System Components................1063

Group 10: Theory of Operation................1058

Theory of Operation Information................1480

Fuel System Operation................1068

Fuel Filter Operation................1071

Fuel Injection Nozzle Operation................1073

Air System Operation................1076

Turbocharger Operation––If Equipped................1080

Check Turbocharger Boost Pressure––If Equipped................1081

Diagnosing Turbocharger Malfunctions––If Equipped................1082

Viscous Fan Clutch Operation................1083

Stanadyne Rotary Fuel Injection Pump Operation................1085

Cold Weather Starting Aid Operation................1087

Group 15: Diagnosis, Tests and Adjustments................1058

Diagnostic Information................1522

Fuel/Air Diagnosis, Tests and Adjustments................1091

Section 240: Electrical System Operation, Tests and Adjustments................1092

Group 05: Component Location................1092

Component Location Information................1476

Engine Electrical Components—Right-Hand Side................1099

Engine Electrical Components—Left-Hand Side................1100

Dashboard and Center Control Console Electrical Components................1101

Tractor Electrical Components................1103

Group 10: Theory of Operation................1092

Theory of Operation Information................1480

Fuse Block and Fuses................1107

Relays................1109

Starting System Operation—Normal................1110

Starting System Operation—Bypass Attempt................1112

Charging System Operation................1114

Turn Signal and Warning Light Operation................1116

Parking Light Operation................1119

Headlights and Instrument Lights Operation................1121

Tachometer/Hour Meter Operation................1123

Fuel Gauge Operation................1125

Temperature Gauge Operation................1127

PTO Indicator Operation................1129

Air Filter Restriction Indicator Operation................1131

7-Pin Trailer Outlet Connector Operation................1092

Horn Operation................1135

Flood Light Operation................1137

Beacon Light Operation................1139

MFWD Indicator and Differential Lock Indicator Operation................1141

Fuel Pump Operation................1143

Brake Switch Operation................1145

Engine Oil Pressure Indicator Operation................1147

Park Brake Indicator Operation................1149

Manifold Heater Operation................1151

Group 15: Diagnosis, Tests and Adjustments................1093

Diagnostic Information................1522

Starting System Test Points................1155

Charging System Test Points................1158

Turn Signals Test Points................1161

Warning Light Test Points................1165

Flood Light Test Points................1167

Beacon Light Test Points................1170

Headlight and Instrument Light Test Points................1173

Tachometer/Hourmeter Test Points................1176

Fuel Gauge Test Points................1178

PTO Indicator Test Points................1181

Park Brake Indicator Test Points................1184

Temperature Gauge Test Points................1187

Engine Oil Pressure Indicator Test Points................1190

Air Filter Restriction Indicator Test Points................1193

MFWD and Differential Lock Indicator Test Points................1196

Manifold Heater Test Points................1199

Brake Switch Test Points................1202

Fuel Pump Test Points................1204

Horn Test Points................1206

Accessory Relay and Trailer Connector Test Points................1208

Battery Voltage and Specific Gravity Tests................1211

Charge Battery................1213

Battery Load Test................1215

Starter Amp Draw/RPM Test................1217

Starter No-Load amp Draw/RPM Test................1219

Alternator/Regulator Test................1221

Starter Solenoid Test................1223

Starter Relay Test................1224

Key Switch Test................1226

Plug-In Relay Test................1228

Mini Plug-In Relay................1230

Diode Pack Test................1232

Fuse Test................1234

Neutral Start Switch Test................1235

PTO Switch Test................1237

Park Brake Switch Test................1238

Light Switch Test................1239

Turn Signal Switch Test................1241

Fuel Shut-Off Solenoid Test................1243

Group 20: Wiring Schematics................1094

Schematic Information................1245

Component Identification Table................1246

Quick Reference Table................1248

Reference Tables................1250

SE01—Starting Motor, Charging Circuit, Jump Start and Back EMF Protection................1252

SE01A—Starting Aid (Heater Manifold and Fuel Pump)................1253

SE02—Instrument Gauges, Sensors and Switches................1254

SE03—Turn Signals and Hazard Switch................1255

SE04—Light Switch, Left and Right Headlights, and Beacon Light................1256

SE05—Horn................1257

SE06—Trailer Connector................1259

Group 25: Component Information—Connectors................1094

Component Location—Connectors (Summary of Information)................1262

X1—6-Pin Connector for Electronic Flasher................1263

X2 and X3—12-Pin Connectors for Front to Console Wiring Harness................1264

X4 and X5—3-Pin Connectors for Console to Hood Wiring Harness................1266

X6—2-Pin Connector for Trailer Connector................1268

X7—1-Pin Connector for Junction Box................1269

X8—6-Pin Connector for Trailer Connector................1270

X9 and X10—12-Pin Connectors for Console to Rear Wiring Harness................1271

X11 and X12—6-Pin Connectors for Console to Rear Wiring Harness................1273

X13—60-Pin Connector for Fuse Box................1275

XA01—16-Pin Connector for Instrument Cluster................1278

XA02—6-Pin Connector for Instrument Cluster................1280

XB02—2-Pin Connector for Engine Speed Sensor................1281

XB03—2-Pin Connector for Fuel Level Sensor................1282

XB04—1-Pin Connector for Coolant Temperature Sensor................1283

XB05—1-Pin Connector for Engine Oil Pressure Switch................1284

XB06—2-Pin Connector for Air Filter Restriction Sensor................1285

XE01/1—1-Pin Connector for License Plate................1286

XE01/2—1-Pin Connector for License Plate................1287

XE02—2-Pin Connector for Left Front Turn Signal................1288

XE03—3-Pin Connector for LH Rear Fender Light................1289

XE04—2-Pin Connector for Right Front Turn Signal................1290

XS04—2-Pin Connector for Park Brake Switch................1291

XY01—1-Pin Connector for Fuel Shutoff Solenoid................1292

XS02—6-Pin Connector for PTO Switch................1293

XE14—2-Pin Connector for Beacon Light Switch................1294

XK03/1—1-Pin Connector for Manifold Heater Relay................1295

XK03/2—1-Pin Connector for Manifold Heater Relay................1296

XM01/1—1-Pin Connector for Starter Motor Solenoid................1297

XM01/2—1-Pin Connector for Starter Motor Solenoid................1298

XG02/1—2-Pin Connector for Alternator................1299

XG02/2—1-Pin Connector for Alternator................1300

XH01/1—1-Pin Connector for Horn................1301

XH01/2—1-Pin Connector for Horn................1302

XE05—3-Pin Connector for RH Rear Fender Light................1303

XE12—3 Pin Connector for Right Headlight................1304

XE13—3-Pin Connector for Left Headlight................1305

XE15—2-Pin Connector for Flood Light................1306

XS03—2-Pin Connector for Neutral Start Switch................1307

XY02/1—1-Pin Connector for Differential Lock Switch................1308

XY02/2—1-Pin Connector for Differential Lock Switch................1309

XY03—2-Pin Connector for Fuel Pump................1310

XS06—6-Pin Connector for Hazard Switch................1311

XS10—6-Pin Connector for Light Switch................1312

XS07—3-Pin Connector for Turn Signal Switch................1313

XS11/1—1-Pin Connector for Horn Switch................1314

XS11/2—1-Pin Connector for Horn Switch................1315

XS09—3 Pin Connector for Beacon Light Switch................1316

XS01—8-Pin Connector for Key Switch................1317

XS08/1—1-Pin Connector for Brake Switch................1318

XS08/2—1-Pin Connector for Brake Switch................1319

XK11/1—2-Pin Connector for Starter Relay................1320

XK11/2—1-Pin Connector for Starter Relay................1321

XK11/3—1-Pin Connector for Starter Relay................1322

XV01—9-Pin Connector for Diode Module................1323

XS05/1—1-Pin Connector for MFWD Switch................1324

XS05/2—1-Pin Connector for MFWD Switch................1325

XGND1—Ground (Left Front Turn Signal)................1326

XGND2—Ground (Left Rear Fender Light)................1327

XGND3—Ground (Front Wiring Harness)................1328

XGND4—Ground (Right Front Turn Signal)................1329

XGND5—Ground (Right Rear Fender Light)................1330

XGND6—Ground (Rear Wiring Harness)................1331

XGND7—Ground (Body Earthing)................1332

XGND8—Ground (Console Wiring Harness)................1333

Section 250: Power Train Operation, Tests and Adjustments................1334

Group 05: Component Location................1334

Component Location Information................1476

Power Train Components................1338

Clutch Components—Dual................1339

Transmission Components—SyncShuttle™................1341

Final Drive Components................1343

Park Brake Components................1344

Rear 540 PTO Components................1346

Rear 540/540E PTO Components––If Equipped................1347

Group 10: Theory of Operation................1334

Theory of Operation Information................1480

Clutch Operation—Dual Clutch................1350

Transmission Lubrication System................1358

SyncShuttle™ Transmission—Gear Shift Power Flow................1360

SyncShuttle™ Transmission Synchronizer Operation—Reverse and 2nd Gear (Disk-and-Plate Type Synchronizer)................1362

SyncShuttle™ Transmission Synchronizer Operation - 1st and 3rd Gear (Cone-Type Synchronizer)................1364

SyncShuttle™ Transmission—Range Shift Power Flow................1366

Mechanical Front Wheel Drive (MFWD) Operation (If Equipped)................1368

Rear 540 PTO Operation................1370

Rear 540/540E PTO Operation––If Equipped................1372

Differential Power Flow................1373

Differential Lock Operation................1375

Final Drive Operation................1377

Group 15: Diagnosis, Tests and Adjustments................1334

Diagnostic Information................1522

Isolate the Problem Area................1381

Traction Clutch Slips................1383

Traction Clutch Dragging................1384

Traction Clutch Does Not Engage................1385

Traction Clutch Grabs................1386

Traction Clutch Squeaks................1387

Traction Clutch Does Not Release................1388

Traction Clutch Chatters................1389

Traction Clutch Rattles................1390

Traction Clutch Engagement Is Noisy................1391

Excessive Vibration in Traction Clutch................1392

Clutch Pedal Does Not Return................1393

Clutch Pedal Loose................1394

Clutch Pedal Pulsates................1395

Jerky or Rough Transmission of Power................1396

Low Transmission Oil Level (Excessive Oil Leakage)................1397

Gears Clash, Shift Hard, or Will Not Engage................1398

Two Speeds Engage Together................1399

Transmission Will Not Stay in Gear................1400

Transmission Noisy................1401

PTO Noisy................1402

PTO Hard to Engage................1403

PTO Will Not Operate................1404

PTO Will Not Stay Engaged................1405

Excessive Differential Noise................1406

Differential Does Not Work................1407

No Differential Lock................1408

Differential Chatters................1409

Axle Noise................1410

Axle Shaft Will Not Turn................1411

Check and Adjust Clutch Pedal Free Play................1412

Adjust PTO Clutch Lever Linkage Adjustment................1413

Adjust 540E PTO Lever Linkage................1415

Section 260: Steering and Brake Operation, Tests Section 260: Steering and Brake Operation, Tests & Adjustments{pgNO}1417 Adjustments................1417

Group 05: Component Location................1417

Component Location Information................1476

Steering System Components................1421

Brake System Components................1422

Trailer Brake System Components................1424

Group 10: Theory of Operation................1417

Theory of Operation Information................1480

Steering System Operation................1427

Steering Valve Operation—Neutral and Manual Turning................1429

Steering Valve Operation—Power Turning................1431

Brake System Operation................1433

Brake Valve Operation................1435

Trailer Brake System Operation................1439

Trailer Brake Valve Operation................1441

Group 15: Diagnosis, Tests and Adjustments................1417

Diagnostic Information................1522

Isolate the Problem—Steering System................1449

Steering Sluggish or Loss of Steering................1450

Isolate the Problem—Brakes................1451

Excessive Brake Pedal Leak-Down................1452

Excessive Brake Chatter................1453

Trailer Brake Valve Operational Check................1454

Trailer Brake Valve Troubleshooting................1455

Steering Pump Flow Test................1457

Steering Valve Relief Test................1459

Steering Cylinder Leakage Test................1460

Steering Valve Leakage Test................1461

Check Toe-In—Two-Wheel Drive Tractor................1463

Adjust Toe-In (Two-Wheel Drive Tractor)................1464

Check Toe-In—MFWD Tractor................1465

Adjusting Toe-In—MFWD Tractor................1466

Brake Pedal Adjustment................1467

Bleed Brake System................1469

Park Brake Linkage Adjustment................1470

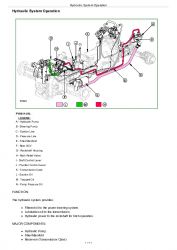

Section 270: Hydraulic System Operation, Tests and Adjustments................1472

Group 05: Component Location................1472

Component Location Information................1476

Hydraulic System Components................1477

Group 10: Theory of Operation................1472

Theory of Operation Information................1480

Hydraulic System Operation................1481

Hydraulic Filter Operation................1483

Hydraulic Pump Operation................1485

Hitch Valve Operation—Neutral Phase................1487

Hitch Valve Operation—Delivery Phase................1489

Hitch Valve Operation—Discharge Phase................1491

Hitch Rate-of-Drop Valve (Implement Lock) Operation................1493

JD Rockshaft Draft-Sensing Operation................1495

JD Rockshaft Surge Relief Valve Operation................1497

Hitch Main Relief Valve Operation................1499

Functioning of Position Control................1501

Functioning of Draft Control................1503

Combined Functioning of Position and Draft Control................1505

Hydraulics - Dual Mid-Mount SCV Extend and Retract Operation................1506

Hydraulics - Dual Mid-Mount SCV Float Operation................1508

Hydraulics - Dual Mid-Mount SCV Neutral Operation................1510

EATON Selective Control Valve—Neutral Position................1513

EATON Selective Control Valve—Retract Position................1515

EATON Selective Control Valve—Extend Position................1517

EATON Selective Control Valve—Float Position................1519

Group 15: Diagnosis................1472

Diagnostic Information................1522

Preliminary Hydraulic System Inspection................1523

Entire Hydraulic System Fails to Function/No Hydraulic Pump Output................1524

Insufficient Pump Delivery................1525

Hydraulic Functions Too Slow................1526

Excessive Pump Pressure................1527

Slow Hydraulic Pump Response................1528

Excessive Pump Noise During Operation................1529

Rockshaft Does Not Lift or Lifts Slowly................1530

Rockshaft Does Not Lower or Lowers Slowly................1531

Park Position Unstable, Rockshaft Drops after Engine Shut Down................1532

SCV Control Lever Does Not Return to Neutral Position................1533

SCV Does Not Return to Neutral Position-SCV With Detent Position................1534

SCV Does Not Remain In Detent Position-SCV With Detent Position................1535

Remote Cylinder Does Not Extend or Retract................1536

Remote Cylinder Settles Under Load................1537

Remote Cylinder Operates Too Fast or Too Slow................1538

Group 20: Hydraulic Tests—With SCV................1473

Hydraulic System Tests—With SCV................1541

Pump Flow Test—With SCV................1543

Main Relief Valve Test—With SCV................1545

SCV Leakage Test................1547

Group 25: Hydraulic Tests—With Mid-Mount Control Valve................1473

General Information................1550

Hydraulic System Tests—With Mid-Mount Control Valve................1551

Pump Flow Test—With Mid-Mount Control Valve................1553

Main Relief Valve Test—With Mid-Mount Control Valve................1555

Mid-Mount Control Valve Leakage Test................1557

Group 30: Hydraulic Tests—Whole System................1473

Hitch Leakage Test................1560

Rockshaft Lift Cycle Test................1562

Group 40: Adjustments—Hitch................1473

Rockshaft Lever Friction Adjustment................1565

Rockshaft Position-Sensing Feedback Linkage Adjustment................1566

Rockshaft Draft-Sensing Feedback Linkage Adjustment................1570

Rear SCV Lever Cable Adjustment................1572

Mid-Mount Control Valve Joystick Cable Adjustment................1573

Group 45: Hydraulic Schematics................1474

Hydraulic Circuit Symbols................1576

Hydraulic System—Standard Tractor with Second Rear SCV and Trailer Brake Valve................1578

Hydraulic System—Standard Tractor with Mid-Mount SCV................1580

John Deere Tractors 5050E, 5055E, 5065E, 5075E Diagnostics and Repair Service Manual (TM900319)