John Deere Tractors 5055E, 5065E, 5075E Diagnosis and Tests Service Technical Manual (TM901419)

Catalog:

Model:

Complete Diagnosis & Tests Technical Manual with electrical wiring diagrams for John Deere Tractors 5075E, 5065E, 5055E (European), with all the shop information to maintain, diagnose, and service like professional mechanics.

John Deere Tractors 5055E, 5065E & 5075E workshop Diagnosis & Tests technical manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

tm901419 - 5055E, 5065E and 5075E Tractors Diagnostic Technical Manual (European Edition) Technical Manual.pdf

Total Pages: 1,395 pages

File Format: PDF (PC/Mac/Android/Kindle/iPhone/iPad; bookmarked, ToC, Searchable, Printable)

Language: English

MAIN SECTIONS

Foreword

General

Safety

General Specifications

General References

Diagnostic Trouble Codes

CCU Code Diagnostics

ICC Code Diagnostics

PTR Code Diagnostics

Observable Symptoms

Engines

Fuel and Air

Electrical

Control Units

PowrReverser™ Transmissions

Drive Systems

Steering and Brakes

Hydraulics

Operator Station

System Diagnosis

Starting, Charging and Start Aid

PowrReverser™ Transmission

Differential Lock

MFWD

PTO

Steering

Rear Brakes

Rear SCV System Diagnosis

Mid-Mount Control Valve System Diagnosis

Rear Hitch System Diagnosis

Air Conditioning

Engines

General Information

Tests and Adjustments

Engine System Theory of Operation

Fuel and Air

General Information

Fuel and Air Theory of Operation

Electrical System

Fuse/Relay Block

Tests and Adjustments

Theory of Operation

Functional Schematics (Cab)

Functional Schematics (IOOS)

Connector Information

Control Units

General References

Tests and Adjustments

CCU

ICC

PTR

PowrReverser™ Transmission

General Information

Preliminary and Operational Checks

Tests and Adjustments

Theory of Operation

Schematics and Diagrams

TSS Transmission

Tests and Adjustments

Theory of Operation

Schematics and Diagrams

Drive Systems

General Information

Preliminary and Operational Checks

Tests and Adjustments

Theory of Operation

Schematics and Diagrams

Steering and Brakes

General Information

Preliminary and Operational Checks

Test and Adjustments

Theory of Operation

Hydraulics

General Information

Preliminary and Operational Checks

Tests and Adjustments

Theory of Operation

Operator`s Station

General Information

Preliminary and Operational Checks

Tests and Adjustments

Theory of Operation

Service Tools

Dealer-Fabricated Tools

Service Tools and Kits

TABLE OF CONTENTS

Section 210: General................25

Group 05: Safety................25

Recognize Safety Information................29

Understand Signal Words................30

Follow Safety Instructions................31

Prepare for Emergencies................32

Wear Protective Clothing................33

Protect Against Noise................34

Handle Fuel Safely—Avoid Fires................35

Fire Prevention................36

In Case of Fire................37

Avoid Static Electricity Risk When Refueling................38

Use Foldable ROPS and Seat Belt Properly................40

Stay Clear of Rotating Drivelines................41

Use Steps and Handholds Correctly................43

Read Operator’s Manuals for ISOBUS Controllers................44

Use Seat Belt Properly................45

Vibration................46

Operating the Tractor Safely................47

Avoid Backover Accidents................49

Limited Use in Forestry Operation................50

Operating the Loader Tractor Safely................51

Keep Riders Off Machine................52

Passenger Seat................53

Use Safety Lights and Devices................54

Towing Trailers/Implements Safely (Mass)................55

Use Caution On Slopes and Uneven Terrain................56

Freeing a Mired Machine................57

Avoid Contact with Agricultural Chemicals................58

Handle Agricultural Chemicals Safely................59

Handling Batteries Safely................61

Avoid Heating Near Pressurized Fluid Lines................63

Remove Paint Before Welding or Heating................64

Handle Electronic Components and Brackets Safely................65

Practice Safe Maintenance................66

Avoid Hot Exhaust................67

Clean Exhaust Filter Safely................68

Work In Ventilated Area................71

Support Machine Properly................72

Prevent Machine Runaway................73

Park Machine Safely................74

Transport Tractor Safely................75

Service Cooling System Safely................76

Service Accumulator Systems Safely................77

Service Tires Safely................78

Service Front-Wheel Drive Tractor Safely................79

Tightening Wheel Retaining Bolts/Nuts................80

Avoid High-Pressure Fluids................81

Do Not Open High-Pressure Fuel System................82

Store Attachments Safely................83

Decommissioning — Proper Recycling and Disposal of Fluids and Components................84

Group 10: General Specifications................86

General Specifications................86

Group 15: General References................26

Bolt and Cap Screw Torque Values................88

Glossary of Terms................89

JIC Hydraulic Symbols................93

Wiring Diagram and Schematic Information................96

Electrical Schematic Symbols................97

Reading Wiring Schematics and Diagrams................100

Visually Inspect Electrical System................104

Seven-Step Electrical Procedure................105

Using a Probe Light................108

Circuit Types................110

Circuit Malfunctions................112

Troubleshooting Circuit Malfunctions................115

Understanding Electrical vs. Electronic Circuits................120

Intermittent Electronic Problems................122

Relay Circuit Types................126

Using a Digital Multimeter................139

Troubleshooting Unresolved Problems................141

Section 211: Diagnostic Trouble Codes................142

Group CCU: CCU Code Diagnostics................142

CCU - Non-Tractor CCU Codes................142

CCU 000096.03 - Fuel Level Sensor Circuit Voltage High................142

CCU 000096.04 - Fuel Level Sensor Circuit Voltage Low................142

CCU 000100.01 - Engine Oil Pressure Signal Extremely Low................142

CCU 000100.04 - Engine Oil Pressure Signal Out of Range Low................142

CCU 000110.00 - Engine Coolant Temperature Signal Extremely High................142

CCU 00110.03 - Engine Coolant Temperature Sensor Out of Range High................142

CCU 00110.04 - Engine Coolant Temperature Sensor Out of Range Low................142

CCU 000110.16 - Engine Coolant Temperature Signal Moderately High................142

CCU 000237.02 - VIN Security Data Conflict................142

CCU 000237.31 - VIN Security Messages Missing................142

CCU 000569.05 - Rear Differential Lock Solenoid Circuit Fault................142

CCU 000628.02 - CCU EOL Data Fault................142

CCU 000630.14 - Rear PTO Configuration Invalid................142

CCU 001638.00 - Hydraulic Oil Temperature Very Hot................142

CCU 001638.03 - Hydraulic Oil Temperature Sensor Circuit Voltage High................142

CCU 001638.04 - Hydraulic Oil Temperature Sensor Circuit Voltage Low................142

CCU 001638.16 - Hydraulic Oil Temperature High................142

CCU 001883.00 - Rear PTO Overspeed................142

CCU 001883.01 - Rear PTO Underspeed................142

CCU 002818.31 - Operator Presence Switch Not Activated................142

CCU 003509.03 - Sensor Supply Voltage Out of Range High................142

CCU 003509.04 - Sensor Supply Voltage Out of Range Low................142

CCU 523316.04 - CCU Switched Supply Voltage Low................142

CCU 523839.02 - Secondary Brake Switch Conflict................142

CCU 523844.12 - Differential Lock Braking Disabled................142

CCU 523907.02 - PTO Remote Enable Switch Conflict................142

CCU 523908.02 - Rear PTO External Switch Conflict................142

CCU 524037.02 - MFWD Switch Circuit Fault................142

CCU 524223.03 - Differential Lock Circuit Voltage High................142

CCU 524224.14 - PTO Switch Voltage Mismatch................142

CCU 524235.05 - MFWD Solenoid Circuit Fault................143

CCU 524252.05 - Rear PTO Solenoid Circuit Fault................143

CCU 524255.31 - Rear Remote PTO Enabled................143

CCU 600006.31 - Default DTC................143

Group ICC: ICC Code Diagnostics................143

ICC - Non-Tractor ICC Codes................143

ICC 000237.02 - ICC VIN Security Mismatch................143

ICC 000237.31 - ICC VIN Security Missing................143

ICC 000628.12 - ICC Programming Fault................143

ICC 000630.02 - ICC Calibration Memory Fault................143

ICC 002818.31 - Operator Presence Switch Not Activated................143

Group PTR: PTR Code Diagnostics................143

PTR 000084.07 - Excessive Wheel Speed Detected During Calibration................143

PTR 000158.01 - System Switched Voltage Low................143

PTR 000162.02 - High/Low Switch Circuit Conflict................143

PTR 000162.31 - High, Low Switch Stuck On................143

PTR 000190.18 - Engine Speed Missing During Shift................143

PTR 000191.17 - Top Shaft Speed Too Low................143

PTR 000598.02 - Clutch Switch Open With Pedal Up................143

PTR 000598.04 - Clutch Switch Signal Failed Low................143

PTR 000628.02 - EOL Check Sum Error................143

PTR 000630.14 - Tractor Model Out Of Range/Transmission Calibration Value High................143

PTR 000752.03 - Power Shuttle Potentiometer Input Voltage High................143

PTR 000752.04 - Power Shuttle Potentiometer Input Voltage Low................143

PTR 001504.10 - Seat Switch Closed Too Long................143

PTR 002820.31 - Operator Not Present During Shift................143

PTR 002825.07 - Not Valid Neutral Park Command................143

PTR 003509.03 - PTR Sensor Supply Voltage High................143

PTR 003509.04 - PTR Sensor Supply Voltage Low................143

PTR 521233.05 - High Valve Driver Fault................143

PTR 521234.05 - Low Valve Driver Fault................143

PTR 521235.05 - Reverse Valve Driver Fault................143

PTR 522456.07 - Speed Control Lever Park and Neutral Switch Conflict................143

PTR 522456.31 - Speed Control Lever Transition Without Using Clutch Pedal................144

PTR 523953.02 - Speed Control Lever Sensor Circuit Conflict................144

PTR 523959.31 - No Wheel Speed While in Gear................144

PTR 524020.31 - Reverser in Gear at Power-Up................144

PTR 524021.31 - Directional Reverser Lever Switch Circuit Fault................144

PTR 524160.02 - Not Valid Neutral/Not Neutral Switch................144

PTR 524173.02 - Clutch Pedal Compare Error................144

PTR 524173.14 - Sync Lever Shift Without Clutch Pedal Engaged................144

PTR 524173.15 - Clutch Pedal Voltage High................144

PTR 524173.16 - Both Clutch Pedals Voltage High................144

PTR 524173.17 - Clutch Pedal Voltage Low................144

PTR 524173.18 - Both Clutch Pedals Voltage Low................144

PTR 524230.05 - Enable Valve Driver Fault................144

PTR 524230.07 - Enable Valve Stuck................144

PTR 524234.03 - Pressure Sensor Voltage High................144

PTR 524234.04 - Pressure Sensor Voltage Low................144

PTR 524254.03 - Transmission Enable Valve Power High................144

PTR 524254.04 - Transmission Enable Valve Power Low................144

PTR 524267.15 - High Speed Shuttle Shift................144

Section 212: Observable Symptoms................275

Group 20: Engines................275

Engine Problems................275

Group 30: Fuel and Air................275

Fuel and Air Problems................275

Group 40: Electrical................275

12-Volt Electrical Problems................275

Group 45: Control Units................275

Electronic Problems................275

Group 55: PowrReverser™ Transmissions................275

PowrReverser™ Transmission Problems................275

Group 56: Drive Systems................275

Drive System Problems................275

Group 60: Steering and Brakes................275

Steering and Brake System Problems................275

Group 70: Hydraulics................275

Hitch Problems................275

Selective Control Valve Problems................275

Group 90: Operator Station................275

Air Conditioning Problems................275

Section 213: System Diagnosis................299

Group 40: Starting, Charging and Start Aid................299

Starting, Charging and Start Aid System Diagnosis................303

Group 55: PowrReverser™ Transmission................299

PowrReverser™ Transmission System Diagnosis................309

Group 56A: Differential Lock................299

Differential Lock System Diagnosis................314

Group 56B: MFWD................299

MFWD System Diagnosis................317

Group 56C: PTO................299

Rear Mechanical PTO System Diagnosis................320

EH PTO System Diagnosis................322

Group 60A: Steering................299

Steering System Diagnosis................327

Group 60B: Rear Brakes................299

Rear Brake System Diagnosis................333

Group 70A: Rear SCV System Diagnosis................299

Single and Dual Rear SCV System Diagnosis................339

Group 70B: Mid-Mount Control Valve System Diagnosis................299

Dual Mid-Mount Control Valve System Diagnosis................345

Group 70C: Rear Hitch System Diagnosis................299

Rear Mechanical Hitch System Diagnosis................352

EQRL Hitch System Diagnosis................356

Group 90: Air Conditioning................299

Air Conditioning System Diagnosis................362

Section 220: Engines................366

Group 05: General Information................366

John Deere Engine Repair—Use Component Technical Manual................368

General Engine Specifications................369

List of All Tractor-Specific Engine Information................370

Group 15: Tests and Adjustments................366

Throttle Lever Adjustment—Cab................372

Group 20: Engine System Theory of Operation................366

Overview of 5055E , 5065E , and 5075E Tractor Engines................374

Section 230: Fuel and Air................375

Group 05: General Information................375

John Deere Engine Fuel Systems Repair—Use Component Technical Manual................377

Group 20: Fuel and Air Theory of Operation................375

Fuel System Operation— 5055E, 5065E and 5075E................380

Air Intake System Operation................382

Section 240: Electrical System................384

Group 05: Fuse/Relay Block................384

Fuse/Relay Block Diagram Listing................389

Access Fuses and Relays................390

Load Center Fuses and Relays—Cab (sync shuttle Transmission)................392

Center Console Relay and Diode—Cab (sync shuttle Transmission)................394

Load Center Fuses and Relays—Cab (PowrReverser™ Transmission)................395

Center Console Relay and Diode—Cab (PowrReverser™ Transmission)................397

EEC Light Module Relays—Cab (PowrReverser™ Transmission)................398

Light Module Relay—Cab................399

Load Center - 1 Fuses and Relays—IOOS (PowrReverser™ Transmission)................400

Load Center - 2 Fuses and Relays—IOOS— (PowrReverser™ Transmission)................401

Center Console Relay and Diode—IOOS (PowrReverser™ Transmission)................402

Group 15: Tests and Adjustments................384

Starting Circuit Test................406

Fuel Shutoff Solenoid Circuit Test................409

Battery Inspection Test................411

Charging System Test................419

Warning Lights Circuit Test................421

Turn Signal Lights Circuit Test................427

Brake Lights Circuit Test................432

Accessory Power and Junction Block Circuit Test................435

Engine Speed Sensor Circuit Test................441

Engine Oil Pressure Switch Circuit Test................445

Air Filter Restriction Switch Circuit Test................449

Fuel Level Sender Circuit Test................453

Engine Coolant Temperature Sender Circuit Test................457

Tail Light Circuit Test................461

Front Work Light Circuit Test................464

Beacon Light Circuit Test................469

Rear Work Light Circuit Test................471

Headlight and Backlighting Circuit Test................476

Radio and Dome Light Circuit Test................485

HVAC Circuit Test................491

Wiper System Circuit Test................500

Key Switch Test................508

Switch Test................508

Fuel Transfer Pump Circuit Test................511

Group 20: Theory of Operation................385

Starting System Operation................517

Cold Start System Operation................518

Charging System Operation................520

Lighting System Operation—Turn Signals................521

Lighting System Operation—Warning Lights................522

Lighting System Operation—Tail Lights................523

Lighting System Operation—Headlights and Loader Lights................524

Work Light and Beacon Light Operation................527

Instrument Cluster Operation—Tachometer/Hour Meter................528

Instrument Cluster Operation—Fuel Gauge................529

Instrument Cluster Operation—Coolant Temperature Gauge................530

PTO Warning System Operation................531

Air Filter Restriction Indicator Operation................532

Accessory Power and Junction Block Power Operation................533

Blower Motor Operation................534

Front Wiper/Washer Operation................535

Rear Wiper/Washer Operation................536

Dome Light Operation................537

Wheel Speed Sensor Operation................538

Group 25: Functional Schematics (Cab)................385

Functional Schematics Listing (Cab)................540

Schematic and Component Identification Legend (Cab)................541

SE1—Key Switch, Starter, Alternator, Starting Aid And Fuel Pump Circuit................544

SE2A—Mechanical PTO, Neutral Start, Fuel Circuit (9/3 TSS), SE2B—EH PTO, Neutral Start, Fuel Circuit (12/12 PR), SE3—Accessory Power, SE4—Horn................545

SE7—Common Vehicle Lighting Section, Common Cab Work Lighting................546

SE8—Turn Signal Switch and Hazard Warning Lights................547

SE9—Power Source, SE11—Trailer Interfaces, SE12—Loader Lights , SE13A—Backup Alarm, SE13B—Beacon Lamp................548

SE15B—Power Outlet, SE16—Heater, SE17—Air Conditioning................549

SE20—Front Windshield Wiper And Washer System, SE21—Rear Windshield Wiper And Washer System, SE22—Dome Light, Door Switch And Radio Option, SE23—Air Seat Option................550

SE24A—Instrumentation (PR), SE24B—Instrumentation (TSS)................551

SE25—Seat Switch, Rear PTO Switch, SE26—ELX Relay And Fuses, SE27—MFWD, SE28—Brake Switch................552

SE29—PR Transmission Controller................553

SE30—EQRL Controller (PR)................554

SE32—CAN Terminators (PR)................555

Group 26: Functional Schematics (IOOS)................386

Functional Schematics Listing (IOOS)................557

Schematic and Component Identification Legend (IOOS)................558

SE01— Key Switch, Starter and Alternator................562

SE02— Light Circuit................563

SE03— Instrument Cluster................564

SE04— Transmission Controller................565

SE05— Transmission Controller and Service ADVISOR™ Unit................566

SE06— Trailer Circuit, Horn and Seat Switch................567

Group 30: Wiring Harnesses (Cab)................386

Wiring Harnesses Schematic Listing................589

Engine Wiring Harness................570

Hood Wiring Harness................590

Cab Wiring Harness................573

Transmission Wiring Harness (Cab)................577

Rear Wiring Harness................579

Wiring Harness Module EEC................583

Roof Wiring Harness................585

Group 30A: Wiring Harnesses (IOOS)................386

Wiring Harnesses Schematic Listing................589

Hood Wiring Harness................590

Transmission Wiring Harness (IOOS)................591

Front Wiring Harness................594

Alternator Supply Wiring Harness................596

Beacon Lamp Wiring Harness................597

Console PR Wiring Harness................598

Group 35: Connector Information................387

Front Console-to-Cab Harness Connector 1................603

Front Console-to-Cab Harness Connector 2................605

Front Console-to-Cab Harness Connector 3................607

Roof Harness-to-Cab Harness Connector 1................609

Roof Harness-to-Cab Harness Connector 2................611

Section 245: Control Units................612

Group 05: General References................612

Electro-Hydraulic Controller General Information................621

Performance Monitor General Operation................623

Recall, Record, and Clear Codes................627

Diagnostic Trouble Code Listing................632

CCU Code List................633

ICC Code List................635

PTR Code List................636

Control Unit Addresses................638

CCU Address List................639

ICC Address List................642

PTR Address List................644

Programming Control Units................647

CAN Network Voltage Checks................654

CAN Communication System Theory of Operation................657

CAN System Diagnosis................612

VIN Security Fault Diagnosis................662

Group 15: Tests and Adjustments................612

Electro-Hydraulic Controller Switched Supply Voltage and Ground Test................665

Electro-Hydraulic Controller Unswitched Supply Voltage and Ground Test................667

Open Circuit Load Test................669

EHC—Electrohydraulic Control Unit Test................672

ICC—Instrument Cluster Control Unit Test................676

Group CCU: CCU................612

Chassis Control Unit (CCU) Calibration................687

Chassis Control Unit (CCU) Configuration and Calibration................694

CCU—Hydraulic Oil Temperature Sensor Circuit Test (PR Transmission)................695

CCU—MFWD Solenoid Circuit Test (PR Transmission)................697

CCU—Sensor Excitation Circuit Test (PR Transmission)................699

CCU—Rear PTO Solenoid Circuit Test (PR Transmission)................702

CCU—Rear PTO Speed Sensor Circuit Test (PR Transmission)................704

CCU—Secondary Brake Switch Circuit Test (PR Transmission)................706

CCU—Differential Lock Switch Circuit Test (PR Transmission)................708

CCU—Differential Lock Solenoid Circuit Test (PR Transmission)................711

CCU—Fuel Level Sensor Circuit Test (PR Transmission)................713

CCU—Remote PTO Enable Switch Circuit Test (PR Transmission)................715

CCU—Right Fender PTO ON/OFF Switch Circuit Test (PR Transmission)................717

CCU—Left Fender PTO ON/OFF Switch Circuit Test (PR Transmission)................719

CCU 000 — Initial Address................721

CCU 001 — Recall Diagnostic Codes................722

CCU 002 — System Beep Address With Speed Sensors................723

CCU 003 — System Beep Address Without Speed Sensors................726

CCU 004 — Switched Supply Voltage................728

CCU 005 — Rear PTO Speed Signal Status................729

CCU 006 — Primary Wheel Speed Signal Status................730

CCU 007 — Rear PTO Switch Status................731

CCU 008 — Engine Speed Signal Status................732

CCU 010 — Hydraulic Oil Temperature Sensor Voltage................733

CCU 012 — Rear PTO Remote Enable/Remote Fender Switch Status................734

CCU 013 — Primary Fuel Level Sensor Voltage................735

CCU 014 — Primary Fuel Level Sensor Resistance................736

CCU 015 — Sensor Reference Voltage Status................737

CCU 024 — Secondary Hand Brake/Brake Pedal Switch Status................738

CCU 025 — MFWD Switch Status................739

CCU 050 — CCU Unswitched Supply Voltage................740

CCU 051 — Sensor Reference Voltage................741

CCU 052 — Hydraulic Oil Temperature................742

CCU 054 — Fuel Level Percent................743

CCU 055 — Primary Wheel Speed................744

CCU 058 — Rear PTO Speed................745

CCU 059 — Engine Speed................746

CCU 060 — Front PTO Speed................747

CCU 063 — Differential Drive Shaft Speed................748

CCU 064 — Engine Oil Pressure Switch Status................749

CCU 065 — Engine Coolant Temperature................750

CCU 066 — Engine Coolant Temperature Sensor Voltage................751

CCU 102 — Fuel Sensor Setup................752

CCU 103 — MFWD Configuration................753

CCU 104 — Rear PTO Configuration 1................754

CCU 105 — Rear PTO Configuration 2................755

CCU 106 — Rear PTO Speed Configuration................756

CCU 107 — Rear PTO Pulses Per Revolution................757

CCU 108 — Front PTO Pulses Per Revolution................758

CCU 109 —Front PTO Installed................759

CCU 111 — Rear Tire Rolling Circumference................760

CCU 115 — Differential Lock Configuration................762

CCU 116 — Differential Lock Switch................763

CCU 117 — Differential Lock Disengage Wheel Speed Configuration................764

CCU 120 — Rear PTO Valve Current................765

CCU 129 — MFWD Engaged with Battery Input................766

CCU 130 — Secondary Handbrake Configuration................767

CCU 134 — Engine Hours Display/Input................768

CCU 135 — Engine Function Configuration................769

CCU 180 — Not Used................770

CCU 200-251 — General Control Unit Data................771

CCU - Beep Mode Test With Speed Sensors................772

CCU - Beep Mode Test Without Speed Sensors................775

CCU - Hydraulic Oil Temperature Sensor Circuit Test................776

CCU - Engine Speed Sensor Circuit Test................780

CCU - Wheel Speed Sensor Circuit Test................785

CCU - Controller Theory of Operation................791

CCU - Hydraulic Oil Temperature Sensor Theory of Operation................793

CCU - Engine Speed Sensor Theory of Operation................794

CCU - Wheel Speed Sensor Theory of Operation................795

Group ICC: ICC................614

Instrument Cluster Control Unit (ICC) Configuration and Calibration................798

ICC 000 — Initial Address................800

ICC 001 — Recall Diagnostic Codes................801

ICC 002 — ICU System Beep Address................802

ICC 005 — Switch Status................804

ICC 006 — Indicator Status................805

ICC 010 — Fuel Level Sender Voltage................807

ICC 020 — Units Selection................808

ICC 021 — Auto Clear DTC Hours................809

ICC 022 — Backlight Dimming Percentage................810

ICC 031 — Revert to Hours Status................811

ICC 032 — ICC Flash Rate 1................812

ICC 033 — ICC Flash Rate 2................813

ICC 036 — Engine Coolant Warning Level................814

ICC 037 — Engine Coolant Stop Level................815

ICC 040 — Fuel Gauge Configuration................816

ICC 041 — Resistance Verses Fuel Level Gauge Constant 1................817

ICC 042 — Resistance Verses Fuel Level Gauge Constant 2................818

ICC 043 — Resistance Verses Fuel Level Gauge Constant 3................819

ICC 044 — Resistance Verses Fuel Level Gauge Constant 4................820

ICC 045 — Resistance Verses Fuel Level Gauge Constant 5................821

ICC 046 — Resistance Verses Fuel Level Gauge Constant 6................822

ICC 047 — Resistance Verses Fuel Level Gauge Constant 7................823

ICC 048 — Resistance Verses Fuel Level Gauge Constant 8................824

ICC 049 — Resistance Verses Fuel Level Gauge Constant 9................825

ICC 200-248 — General Control Unit Data................826

Group PTR: PTR................615

Power Train Reverser (PTR) Control Unit Calibration................848

Power Train Reverser (PTR) Control Unit Configuration and Calibration................869

PTR—Clutch Enable Pressure Sensor Circuit Test................871

PTR—Clutch Enable Solenoid Circuit Test................874

PTR—Clutch Pedal Position Circuit Test................876

PTR—Clutch Pedal Switch Circuit Test................879

PTR—Forward Neutral Reverse (FNR) Switch Circuit Test................881

PTR—High/Low Shifter Switch Circuit Test................883

PTR—Park Switch Circuit Test................885

PTR—Power Shuttle Control Circuit Test................887

PTR—Start Signal Circuit Test................890

PTR—Top Shaft Speed Sensor Circuit Test................892

PTR—Transmission Forward Solenoid Circuit Test (High)................894

PTR—Transmission Forward Solenoid Circuit Test (Low)................898

PTR—Transmission Reverse Solenoid Circuit Test................900

PTR—Speed Lever Neutral Switch Circuit Test................902

PTR 000 — Initial Address................904

PTR 001 — Recall Diagnostic Codes................905

PTR 002 — PTR System Beep Mode................906

PTR 003 — PTR System Beep Mode With Speed Sensors................908

PTR 004 — Engine and Countershaft Speed Sensor Status................910

PTR 005 — Come Home, Trans Enable, Clutch Pedal Switch, and Seat Switch Status................912

PTR 006 — Forward, Neutral, Not Neutral, and Reverse Switch Status................914

PTR 007 — Speed Lever Neutral, High, Low, and Park Switch Status................915

PTR 008 — Trans Enable Relay, High, Low, and Reverse Driver Command................916

PTR 009 — High, Low, and Reverse Driver Status................918

PTR 010 — Trans Enable Solenoid Current................919

PTR 011 — Power Shuttle Input Voltage................920

PTR 012 — Trans Enable Pressure Sensor Voltage................921

PTR 013 — Clutch Pedal Potentiometer Channel A Voltage................923

PTR 014 — Clutch Pedal Potentiometer Channel B Voltage................924

PTR 015 — Creeper Lever Position Sensor Voltage................925

PTR 022 — Clutch Pack Overfill Protection Status................926

PTR 032 — Clutch Pedal Position................927

PTR 033 — Clutch Pedal Pressure Command................928

PTR 034 — Trans Enable Actual Pressure................929

PTR 036 — Countershaft Speed................931

PTR 050 — PTR Switched Supply Voltage................933

PTR 051 — PTR Sensor Supply Voltage................934

PTR 052 — Hydraulic Oil Temperature................935

PTR 060 — Transmission Type................936

PTR 061 — Hydraulic Oil Type Selection................937

PTR 062 — Temperature Offset For Alternate Hydraulic Oil................938

PTR 063 — Transmission Calibration................939

PTR 064 — Transmission Fill Pressure and Fill Time Calibration Values................946

PTR 065 — Forward Valve High Fill Pressure Adjustment................948

PTR 066 — Forward Valve High Fill Time Adjustment................949

PTR 067 — Forward Valve Low Fill Pressure Adjustment................950

PTR 068 — Forward Valve Low Fill Time Adjustment................951

PTR 069 — Reverse Valve Fill Pressure Adjustment................952

PTR 070 — Reverse Valve Fill Time Adjustment................953

PTR 072 — Has Calibration been Completed................954

PTR 075 — PTR PowerShuttle Setup Status................955

PTR 076 — PowerShuttle Minimum Wheel Speed Fill Pressure................956

PTR 077 — PowerShuttle Minimum Wheel Speed................957

PTR 078 — PowerShuttle Pressure Offset................958

PTR 079 — High Speed Shuttle Shift Limit................959

PTR 084 — Engine Brake Torque................960

PTR 086 — Hi/Lo Switch Setup................961

PTR 087 — Park Switch Polarity................962

PTR 088 — Seat Switch Polarity................963

PTR 100 — Come Home Mode Enable................964

PTR 101 — Come Home Mode Relay Block Polarity................965

PTR 200-251 — General Control Unit Data................966

PTR - Control Unit Beep Mode Test With Speed Sensors................967

PTR - Control Unit Beep Mode Test Without Speed Sensors................971

PTR - Directional Reverser Switch Circuit Test................972

PTR - Clutch Disengaged Switch Circuit Test................976

PTR - Optional Infinitely Variable Shuttle Control Circuit Test................979

PTR - Park Switch Circuit Test................984

PTR - Seat Switch Circuit Test................988

PTR - Forward Solenoid Circuit Test................992

PTR - Reverse Solenoid Circuit Test................995

PTR - Clutch Enable Proportional Valve Circuit Test................998

PTR - Clutch Pedal Position Sensor Circuit Test................1002

PTR - Enable Pressure Sensor Circuit Test................1007

PTR - Countershaft Speed Sensor Circuit Test................1012

PTR - Control Unit Theory of Operation................1017

PTR - Directional Reverser Switch Theory of Operation................1021

PTR - Clutch Disengaged Switch Theory of Operation................1022

PTR - Optional Infinitely Variable Shuttle Control Theory of Operation................1023

PTR - Park Switch Theory of Operation................1024

PTR - Seat Switch Theory of Operation................1025

PTR - Forward Solenoid Theory of Operation................1026

PTR - Reverse Solenoid Theory of Operation................1027

PTR - Clutch Enable Proportional Valve Theory of Operation................1028

PTR - Clutch Pedal Position Sensor Theory of Operation................1029

PTR - Enable Pressure Sensor Theory of Operation................1030

PTR - Countershaft Speed Sensor Theory of Operation................1031

Section 255A: PowrReverser™ Transmission................1032

Group 05: General Information................1032

PowrReverser™ Transmission Identification................1034

Install Test Equipment - Transmission................1035

Group 10: Preliminary and Operational Checks................1032

PR Transmission Preliminary Checks................1045

PR Transmission Operational Checks................1047

Group 15: Tests and Adjustments................1032

PowrReverser™ Control Valve Tests................1058

PR Pump Flow Test................1064

PR Main Pressure Relief Valve Adjustment................1066

Transmission System Pressure Test................1068

PTO Clutch Leak Test................1070

Checking and Adjusting Clutch Pedal Free Play................1088

Group 20: Theory of Operation................1032

PowrReverser™ Transmission Theory of Operation................1076

Group 25: Schematics and Diagrams................1032

PowrReverser™ Transmission Component Location Listing................1078

PR Transmission Hydraulic Schematic................1079

Power Train Components................1081

PowrReverser™ Components................1082

Transmission Components................1083

Section 255B: TSS Transmission................1085

Group 15: Tests and Adjustments................1085

Checking and Adjusting Clutch Pedal Free Play................1088

Group 20: Theory of Operation................1085

TSS Transmission Theory of Operation................1091

Group 25: Schematics and Diagrams................1085

Component Location Information................1093

Transmission Components (TSS)................1094

Mechanical PTO Clutch Components................1098

Park Brake Components (TSS Transmission)................1099

Rear PTO Components................1101

Rear 540/540E PTO Components................1102

Section 256: Drive Systems................1103

Group 05: General Information................1103

Install Test Equipment - Drive System................1107

Group 10: Preliminary and Operational Checks................1103

Preliminary Checks - Drive System................1112

Rear Differential Lock Operational Check................1114

PTO Operational Checks................1115

MFWD Operational Checks................1117

Group 15: Tests and Adjustments................1103

MFWD Troubleshooting................1119

PTO Clutch Lever Linkage Adjustment................1120

PTO 540/540E Lever and Linkage Adjustment................1122

Group 20: Theory of Operation................1103

Drive Systems Theory of Operation Reference Listing................1125

Differential Power Flow................1126

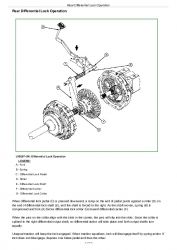

Rear Differential Lock Operation................1128

Final Drive Operation................1130

Mechanical Front Wheel Drive (MFWD) Drop Gearbox Operation (Mechanical)................1131

Mechanical PTO Operation................1133

540/540E Mechanical PTO Operation................1133

Electro-Hydraulic PTO Operation................1137

Electro-Hydraulic PTO Valve Operation................1138

Electro-Hydraulic PTO Clutch Operation................1140

Group 25: Schematics and Diagrams................1103

Drive Systems Component Location Listing................1144

Final Drive Components................1145

540/540E Mechanical PTO Components................1103

Section 260: Steering and Brakes................1147

Group 05: General Information................1147

Install Test Equipment - Steering and Brake................1151

Group 10: Preliminary and Operational Checks................1147

Steering Preliminary Check................1155

Steering Operational Check................1156

Rear Brakes Preliminary Check................1157

Rear Brake Operational Test................1159

Group 15: Test and Adjustments................1147

Steering Pump Flow Test................1162

Steering Valve Relief Test................1163

Steering Leak Test................1164

Checking Toe-In—MFWD Axle................1166

Adjusting Toe-In—MFWD Axle................1167

Set MFWD Steering Stops Turning Radius................1168

Bleed Rear Brakes................1169

Rear Brake Valve Leak Test................1170

Brake Pedal Adjustment................1171

Adjust Brake Retractors................1173

Group 20: Theory of Operation................1147

Steering Valve Operation—Park Position and Manual Turning................1176

Steering Valve Operation—Power Turning................1178

Hydraulic Brake System Operation................1180

Brake Valve Operation................1182

Section 270: Hydraulics................1186

Group 05: General Information................1186

Install Test Equipment - Hydraulics................1191

Warming Transmission/Hydraulic System Oil................1194

Group 10: Preliminary and Operational Checks................1186

Hydraulic System Preliminary Checks................1198

Hydraulic System Operational Checks................1200

Group 15: Tests and Adjustments................1186

Pump Flow Test (Tractors With SCV)................1207

Main Relief Valve Test (Tractors With SCV)................1209

SCV Leakage Test................1211

Rockshaft Leakage Test................1213

Rockshaft Lift Cycle Test................1215

Mid-Mount Control Valve Cable Adjustment................1217

Rear SCV Cable Adjustment................1219

Rockshaft Position-Sensing Feedback Linkage Adjustment................1220

Rockshaft Draft-Sensing Feedback Linkage Adjustment................1224

Rockshaft Lever Friction Adjustment................1226

Hitch Limit Adjustment for EQRL (If Equipped)................1227

Group 20: Theory of Operation................1186

Hydraulic System Theory of Operation Information Reference Listing................1230

Hydraulic System Operation................1231

Hydraulic Filter Operation................1235

Hydraulic Pump Operation................1237

Rockshaft Control Valve Operation—Neutral Phase................1239

Rockshaft Control Valve Operation—Delivery Phase................1241

Rockshaft Control Valve Operation—Discharge Phase................1243

Main Relief Valve Operation................1245

Rate-of-Drop Valve Operation................1247

Surge Relief Valve Operation................1249

Rockshaft Draft-Sensing Operation................1251

Selective Control Valve—Neutral Position................1253

Selective Control Valve—Retract Position................1255

Selective Control Valve—Extend Position................1257

Selective Control Valve—Float Position................1259

Dual Mid-Mount Control Valve Operation—Neutral Position................1261

Dual Mid-Mount Control Valve Operation—Extend and Retract Positions................1263

Dual Mid-Mount Control Valve Operation—Float Position................1265

Dual Mid-Mount Control Valve Operation—Regenerative Position................1267

Quick Disconnect Coupler Operation (Mid-Mount Control Valve)................1269

Quick Disconnect Coupler Operation (Rear SCV)................1271

Section 290: Operator's Station................1273

Group 05: General Information................1273

Operator Station— Install Test Equipment................1276

Group 10: Preliminary and Operational Checks................1273

A/C System Preliminary Checks................1281

Air Conditioning Operational Checks................1284

Group 15: Tests and Adjustments................1273

HVAC Circulation Blower Motor Circuit Test................1295

HVAC Compressor Clutch Engagement and Cycle Test................1299

HVAC System Pressure Check................1311

HVAC Temperature Drop Check................1320

Summary of A/C Testing................1325

A/C System Moisture Removal Procedure................1326

Adjust Heater Temperature Control Cable................1327

Adjust A/C Temperature Control Switch................1329

Group 20: Theory of Operation................1273

Air Conditioning Theory of Operation................1339

Section 299: Service Tools................1347

Group 05: Dealer-Fabricated Tools................1347

DFRW26—Test Lead for Automotive-Style Fuses................1350

DFRW51—Electronic Circuit Load Tester................1351

DFRW126—Modified Tap Out Harness................1352

DFRW133—Tap Out Harness................1353

Group 10: Service Tools and Kits................1347

AR94522—ISO SCV Coupler................1355

JDG774—Solenoid Test Harness................1356

JT02051—Manifold with Gauges................1357

JT02081—Halogen Leak Detector................1358

JT02153—Current Clamp-On Probe................1359

JT03043—Adapter 1/2 M NPT x 1-1/16 M 37°................1360

JT03044—Adapter 3/4 M NPT x 1-1/16 M 37°................1361

JT03051—Adapter 1-1/16 F 37° x 1-1/16 F 37°................1362

JT03059—90° Elbow, 1 1/16-12 M 37° x 1 1/16-12 F 37° Sw................1363

JT03110—Adapter................1364

JT03262—Adapter................1365

JT03345—Gauge................1366

JT03364—Hose with Coupler................1367

JT03367—Connector................1368

JT03481—Kit................1369

JT03481-1—Adapter Male Quick Coupler Plug x 1/4 M NPT................1370

JT03481-3—Straight Fitting 3/4-14 F NPT x M20 x 1.5 ORB................1371

JT03481-4—Straight Fitting 1/8 M BSPT X 1/8 F NPT................1372

JT03520—Special Adapter................1373

JT05473—Gauge w/Quick Coupler, 0-35,000 kPa (0-5000 psi)................1374

JT05494—7/16-20 M 37° x 3/4-16 M ORB................1375

JT05498—Hose 508 mm (20 in.)................1376

JT05634—Pressure Gauge................1377

JT05685—Battery Load Tester................1378

JT05690—1 1/16-12 M 37° x 1 3/16-12 F ORFS................1379

JT05791—Digital Multimeter................1380

JT05843—Hydrometer................1381

JT07032—Gauge 400 kPa (60 psi)................1382

JT07041—Gauge 2800 kPa (400 psi)................1383

JT07148—Digital Hydraulic Tester................1384

JDG10466................1385

JDG1478................1386

John Deere Tractors 5055E, 5065E, 5075E Diagnosis and Tests Service Technical Manual (TM901419)