John Deere 5083E and 5093E Tractors Diagnosis and Test Service Technical Manual (TM608919)

Catalog:

Model:

Complete Diagnosis & Tests Technical Manual with electrical wiring diagrams for John Deer 5083E and 5093E Tractors, with workshop information to maintain, diagnose, and rebuild like professional mechanics.

John Deer 5083E and 5093E Tractors workshop Diagnosis & Tests technical manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

TM608919 English - John Deer 5083E and 5093E Tractors Diagnostic Technical Manual (February 2015).pdf

TM608980 Turkish - 5083E ve 5093E Traktörler Arıza Tanı Teknik El Kitabı.pdf

PRODUCT DETAILS:

Total Pages: 1,203 pages

File Format: PDF (bookmarked, ToC, Searchable, Printable)

Category: Diagnosis and Tests

Language: English Turkish

Published on 2015/02/26

TABLE OF CONTENTS................1

Section 210: General................22

Group 05: Safety................22

Recognize Safety Information................26

Understand Signal Words................27

Follow Safety Instructions................28

Prepare for Emergencies................29

Wear Protective Clothing................30

Protect Against Noise................31

Handle Fuel Safely—Avoid Fires................32

Fire Prevention................33

In Case of Fire................34

Use Foldable ROPS and Seat Belt Properly................35

Stay Clear of Rotating Drivelines................36

Use Steps and Handholds Correctly................38

Read Operator Manuals for ISOBUS Implements................39

Use Seat Belt Properly................40

Vibration................41

Operating the Tractor Safely................42

Avoid Backover Accidents................44

Limited Use in Forestry Operation................45

Operating the Loader Tractor Safely................46

Keep Riders Off Machine................47

Passenger Seat................48

Use Safety Lights and Devices................49

Towing Trailers/Implements Safely (Mass)................50

Use Caution On Slopes and Uneven Terrain................51

Freeing a Mired Machine................52

Avoid Contact with Agricultural Chemicals................53

Handle Agricultural Chemicals Safely................54

Handling Batteries Safely................56

Avoid Heating Near Pressurized Fluid Lines................58

Remove Paint Before Welding or Heating................59

Handle Electronic Components and Brackets Safely................60

Practice Safe Maintenance................61

Avoid Hot Exhaust................62

Clean Exhaust Filter Safely................63

Work In Ventilated Area................66

Support Machine Properly................67

Prevent Machine Runaway................68

Park Machine Safely................69

Transport Tractor Safely................70

Service Cooling System Safely................71

Service Accumulator Systems Safely................72

Service Tires Safely................73

Service Front-Wheel Drive Tractor Safely................74

Tightening Wheel Retaining Bolts/Nuts................75

Avoid High-Pressure Fluids................76

Do Not Open High-Pressure Fuel System................77

Store Attachments Safely................78

Dispose of Waste Properly................79

Group 15: General References................23

General References - Summary of References................81

Metric Bolt and Screw Torque Values................82

Unified Inch Bolt and Screw Torque Values................84

Glossary of Terms................87

Hydraulic Circuit Symbols................91

Wiring Diagram and Schematic Information................92

Electrical Schematic Symbols................93

Reading Wiring Schematics and Diagrams................96

Visually Inspect Electrical System................100

Electrical Procedure................101

Using a Probe Light................105

Circuit Types................107

Circuit Malfunctions................109

Understanding Electrical vs. Electronic Circuits................112

Relay Circuit Types................115

Using a Digital Multimeter................128

Troubleshooting Unresolved Electrical/Electronic Problems................130

Section 211: Diagnostic Trouble Codes................131

Group CCU: CCU Code Diagnostics................131

CCU 000629.12 - CCU Control Unit Fault................131

CCU 001638.00 - Hydraulic Oil Temperature Very Hot................131

CCU 001638.03 - Hydraulic Oil Temperature Sensor Circuit Voltage High................131

CCU 001638.04 - Hydraulic Oil Temperature Sensor Circuit Voltage Low................131

CCU 001883.00 - Rear PTO Overspeed................131

CCU 001883.01 - Rear PTO Underspeed................131

CCU 524016.04 - CCU Switched Supply Voltage Low................131

CCU 524037.02 - MFWD Switch Circuit Fault................131

CCU 524224.14 - Rear PTO Disabled................131

CCU 524235.05 - MFWD Solenoid Circuit Fault................131

CCU 524252.05 - Rear PTO Solenoid Circuit Fault................131

CCU 600006.31 - Default DTC................131

Group PTR: PTR Code Diagnostics................131

PTR 000168.01 - PTR Unswitched Supply Voltage Low................131

PTR 000190.18 - Engine Speed Low................131

PTR 000191.00 - Transmission Overspeed During Calibration................131

PTR 000191.17 - Transmission Underspeed................131

PTR 000598.02 - Clutch Pedal Switch/Sensor Circuit Conflict................131

PTR 000598.04 - Clutch Pedal Switch/Transmission Enable Sensor Circuit Conflict................131

PTR 000628.02 - EOL Data Fault................131

PTR 000630.07 - PTR Calibration Fault/Tractor Movement................131

PTR 000630.14 - PTR Not Calibrated................131

PTR 000734.05 - Forward Solenoid Circuit Fault................131

PTR 000735.05 - Reverse Solenoid Circuit Fault................131

PTR 000752.03 - Infinitely Variable Shuttle Control Circuit Voltage High................131

PTR 000752.04 - Infinitely Variable Shuttle Control Circuit Voltage Low................131

PTR 001079.03 - Sensor Reference Circuit Voltage High................131

PTR 001079.04 - Sensor Reference Circuit Voltage Low................131

PTR 001504.30 - Seat Switch Circuit Fault................131

PTR 523959.31 - Operator Left Seat with Directional Reverser Lever in Gear................131

PTR 523960.31 - Operator Not Seated During a Directional Reverser Lever Command................131

PTR 524017.07 - Gearshift Lever in Park with Directional Reverser Lever in Gear................132

PTR 524020.31 - Directional Reverser Lever in Gear at Power-Up................132

PTR 524021.31 - Directional Reverser Lever Switch Circuit Fault................132

PTR 524029.02 - Clutch Pedal Sensor Circuit Conflict................132

PTR 524029.15 - Clutch Pedal Sensor Circuit Voltage High................132

PTR 524029.16 - Clutch Pedal Sensor Circuit Voltage High, Neutral Recoverable................132

PTR 524029.17 - Clutch Pedal Sensor Circuit Voltage Low................132

PTR 524029.18 - Clutch Pedal Sensor Circuit Voltage Low, Neutral Recoverable................132

PTR 524060.03 - Transmission Enable Signal High During Operation................132

PTR 524060.04 - Transmission Enable Signal Low During Operation................132

PTR 524081.31 - Come Home Detected................132

PTR 524160.02 - Not Neutral Signal Conflicts with Neutral Signal................132

PTR 524230.05 - Enable Proportional Valve Circuit Fault................132

PTR 524230.07 - Enable Valve Stuck Open................132

PTR 524234.03 - Enable Pressure Sensor Circuit Voltage High................132

PTR 524234.04 - Enable Pressure Sensor Circuit Voltage Low................132

Section 212: Observable Symptoms................237

Group 20: Engines................237

Engine Problems................237

Group 30: Fuel and Air................237

Fuel and Air Problems................237

Group 40: Electrical................237

Starting and Charging Problems................237

Lighting Problems................237

Instrument Cluster Problems................237

Miscellaneous Electrical Problems................237

Group 45: Control Units................237

Control Unit Problems................237

Group 50: Transmission................237

PowrReverser™ Problems................237

Group 56: Drive Systems................237

Differential Lock Problems................237

MFWD Problems................237

Rear Mechanical PTO Problems................237

Group 60: Steering and Brakes................237

Steering Problems................237

Brake Problems................237

Group 70: Hydraulics................237

SCV Problems................237

Hitch Problems................237

Hydraulic Problems................237

Group 90: Operator Station................237

HVAC Problems................237

Radio Problems................237

Seat Problems................237

Wiper Problems................237

Section 213: System Diagnosis................267

Group 40: Electrical................267

Starting System Diagnosis................267

Group 50: Transmission................267

PowrReverser™ Transmission System Diagnosis................267

Group 56: Drive Systems................267

Differential Lock System Diagnosis................267

MFWD System Diagnosis................267

Rear Mechanical PTO System Diagnosis................267

Group 60: Steering and Brakes................267

Steering System Diagnosis................267

Rear Brake System Diagnosis................267

Group 70: Hydraulics................267

Single and Dual Rear SCV System Diagnosis................267

Dual Mid-Mount SCV System Diagnosis................267

Rear Mechanical Hitch System Diagnosis................267

Hydraulics - Hydraulic Trailer Brake System Diagnosis................267

Group 90: Operator Station................267

HVAC System Diagnosis................267

Section 220: Engines................314

Group 05: General Information................314

Engine General Information - Summary of References................316

John Deere Engine Repair—Use Component Technical Manual................317

General Engine Specifications................318

Tractor-Specific Engine Information................319

Group 15: Tests and Adjustments................314

Engine Tests and Adjustments - Summary of References................321

Throttle Lever Adjustment................322

Group 20: Theory of Operation................314

Engine Theory of Operation - Summary of References................324

Overview of Tractor Engines................325

Section 230: Fuel and Air................326

Group 05: General Information................326

Fuel and Air General Information - Summary of References................328

John Deere Engine Fuel Systems Repair—Use Component Technical Manual................329

Group 20: Theory of Operation................326

Fuel and Air Theory of Operation - Summary of References................331

Fuel System Operation—Cab................332

Fuel System Operation—OOS................334

Air Intake System Operation................336

Section 240: Electrical System................338

Group 05: General Information................338

Electrical System General Information - Summary of References................343

Load Center Fuses and Relays................344

Group SE01: SE01—Starting and Charging, SE02—Fuel Supply System................338

SE01—Starting and Charging System, SE02— Fuel System - Summary of References................352

Key Switch, Starter, Alternator and Starting Aid Functional Schematic................353

PTO and Fuel Supply System Functional Schematic................355

Air Heater Circuit Test................356

Battery Inspection Test................358

Cold Advance Circuit Test................367

Charging System Circuit Test................369

Fuel Flow Circuit Test................372

Key Switch Circuit Test................375

Rear PTO Lever Position Switch Circuit Test................377

Starter Circuit Test................378

Group SE03: SE03—Accessory Power, SE04—Horn................338

SE03—Accessory Power, SE04—Horn - Summary of References................381

Accessory Power and Horn Functional Schematic................382

Accessory Power Circuit Test................383

Horn Circuit Test................386

Group SE07A: SE07A, SE08A—Cab Lighting................338

SE07A, SE08A—Cab Lighting - Summary of References................390

Cab Lighting Functional Schematic................391

Headlight Circuit Test (Cab)................394

Tail Light Circuit Test (Cab)................402

Light Switch Circuit Test (Cab)................409

Right Turn Signal Light Circuit Test (Cab)................411

Left Turn Signal Light Circuit Test (Cab)................417

Warning Light Circuit Test (Cab)................423

Front Work Light Circuit Test (Cab)................429

Rear Work Light Circuit Test (Cab)................434

Beacon Light Circuit Test (Cab)................439

License Plate Light Circuit Test (Cab)................442

Group SE07B: SE07B, SE07C, SE08B—OOS Lighting................339

SE07B, SE07C, SE08B—OOS Lighting - Summary of References................447

OOS Lighting Functional Schematic................448

Headlight Circuit Test (OOS)................451

Tail Light Circuit Test (OOS)................457

Tail Light Circuit Test (OOS) (with Warning Light Switch)................461

Light Switch Circuit Test (OOS)................465

Right Turn Signal Light Circuit Test (OOS)................467

Right Turn Signal Light Circuit Test (OOS) (with Warning Light Switch)................473

Left Turn Signal Light Circuit Test (OOS)................479

Left Turn Signal Light Circuit Test (OOS) (with Warning Light Switch)................485

Warning Light Circuit Test (OOS)................491

Warning Light Circuit Test (OOS) (with Warning Light Switch)................498

Front Work Light Circuit Test (OOS)................507

Rear Work Light Circuit Test (OOS)................510

Rear Work Light Circuit Test (OOS) (with Rear Work Light Switch)................513

Beacon Light Circuit Test (OOS)................517

License Plate Light Circuit Test (OOS)................520

Group SE09: SE09—Junction Block................339

SE09—Junction Block - Summary of References................524

Junction Block Functional Schematic................525

Junction Block Power Circuit Test................526

Group SE11: SE11—Trailer Connector................339

SE11—Trailer Connector - Summary of References................531

Trailer Connector Functional Schematic................532

Trailer Power Circuit Check................533

Group SE13: SE13—BackUp Alarm, SE15—Power Outlet (Cab Only)................339

SE13—BackUp Alarm, SE15—Power Outlet - Summary of References................537

Backup Alarm and Power Outlet Functional Schematic................538

Backup Alarm Circuit Test................540

Convenience Outlet Circuit Test................542

Power Outlet Circuit Test................545

Auxiliary Power Strip Circuit Test................547

Group SE16: SE16—Heating and Air Conditioning................340

SE16—Heating and Air Conditioning - Summary of References................551

Heating and Air Conditioning Functional Schematic................552

Heater and Blower Circuit Test................553

Air Conditioner Control and Compressor Circuit Test................561

Group SE20: SE20—Front Wiper System, SE21—Rear Wiper System................340

SE20—Front Wiper System, SE21—Rear Wiper System - Summary of References................566

Front and Rear Wiper/Washer Functional Schematic................567

Front Wiper/Washer Circuit Test................569

Rear Wiper/Washer Circuit Test................574

Group SE22: SE22—Dome Light, Door Switch, and Radio (Cab Only)................340

SE22—Dome Light, Door Switch, and Radio (Cab Only) - Summary of References................580

Dome Light, Door Switch, and Radio Functional Schematic................581

Dome Light Circuit Test................582

Right Hand Console Light Circuit Test................586

Radio/Clock Circuit Test................588

Radio Speaker Circuit Test................593

Radio Antenna Circuit Test................595

Group SE24: SE24—Instrument Cluster................340

SE24—Instrument Cluster - Summary of References................598

Instrument Cluster Functional Schematic................599

Instrument Cluster Test................600

Engine Oil Pressure Input Circuit Test................604

Air Filter Restriction Switch Circuit Test................606

Fuel Level Sensor Circuit Test................608

Engine Coolant Temperature Sensor Circuit Test................610

Left Turn Signal Indicator Input Circuit Test................613

Right Turn Signal Indicator Input Circuit Test................615

High Beam Headlight Input Circuit Test................617

Flasher (Turn Signal Light and Warning Light) Output Circuit Test................619

Battery Charge Indicator Input Circuit Test................621

PTO Switch Input Circuit Test................623

Seat Switch Input Circuit Test................625

Secondary Brake Switch Circuit Test................627

Group SE25: SE25—Seat Switch, SE26—ELX Relay and Fuses, SE28—Brake Switch................341

SE25—Seat Switch, SE26—ELX Relay and Fuses, SE28—Brake Switch - Summary of References................630

Seat Switch, ELX Relay and Fuses, and Brake Switch Functional Schematic................631

Brake Light Circuit Test................632

Seat Switch Circuit Test................634

Group SE29: SE29—Electrohydraulic Control (EHC) Unit, SE33—Service ADVISOR™................341

SE29—Electrohydraulic Control (EHC) Unit, SE33—Service ADVISOR™/Power - Summary of References................638

Electrohydraulic Control (EHC) Unit and Service ADVISOR™ Functional Schematic................639

Electrohydraulic Control (EHC) Unit (CCU and PTR) Test................640

Clutch Enable Proportional Valve Circuit Test................646

Clutch Pedal Position Sensor Circuit Test................650

Enable Pressure Sensor Circuit Test................655

Engine Speed Sensor Circuit Test................661

Forward Neutral Reverser (FNR) Switch Circuit Test................665

Park Switch Circuit Test................669

Power Shuttle Control Circuit Test................674

Topshaft Speed Sensor Circuit Test................679

Transmission Forward Solenoid Circuit Test................684

Transmission Reverse Solenoid Circuit Test................687

Hydraulic Oil Temperature Sensor Circuit Test................690

Section 245: Control Units................695

Group 05: General Information................695

Control Units General Information - Summary of References................700

Electro-Hydraulic Controller General Information................701

Access Control Unit Addresses................718

Performance Monitor General Operation................709

Diagnostic Trouble Code Listing................713

PRF Code List................714

CCU Code List................715

PTR Code List................716

Control Unit Addresses................718

Address 223-251 — General Control Unit Data................870

CCU Address List................720

PTR Address List................722

Programming Control Units................725

CAN Communication System Theory of Operation................732

VIN Security Fault Diagnosis................734

CAN Network Voltage Checks................735

Group CCU: CCU - Chassis Control Unit................695

Control Units CCU - Summary of References................741

Chassis Control Unit (CCU) Calibration................742

CCU 000 — Initial Address................751

CCU 001 — Recall Diagnostic Codes................752

CCU 002 — System Beep Address With Speed Sensors................753

CCU 003 — System Beep Address Without Speed Sensors................756

CCU 004 — Engine and Rear PTO Speed Sensor Status................758

CCU 005 — Wheel Speed Sensor Status................759

CCU 006 — Rear PTO Switch Status................760

CCU 007 — MFWD Switch Status................761

CCU 008 — Secondary Hand Brake, Left Brake, Right Brake Switch Status................762

CCU 009 — Sensor Supply Status................763

CCU 010 — Hydraulic Oil Temperature Sensor Voltage................764

CCU 030 — System Voltage................765

CCU 031 — Sensor Reference Voltage................766

CCU 032 — Engine Speed................767

CCU 033 — Rear PTO Speed................768

CCU 034 — Wheel Speed................769

CCU 036 — Hydraulic Oil Temperature................770

CCU 060 — MFWD Configuration................771

CCU 061 — Rear PTO Setup 1................772

CCU 062 — Rear PTO Setup 2................773

CCU 063 — Engine Pulses Per PTO Shaft Revolution Configuration................774

CCU 064 — Rear PTO Pulses Per PTO Shaft Revolution Configuration................775

CCU 065 — Wheel Speed Pulses Per Axle Revolution Configuration................776

CCU 066 — Rear Tire Rolling Circumference................777

CCU 069 — Diagnostic Code Purge Setting................779

CCU - Beep Mode Test With Speed Sensors................780

CCU - Beep Mode Test Without Speed Sensors................782

CCU - Controller Theory of Operation................783

CCU - Hydraulic Oil Temperature Sensor Theory of Operation................785

CCU - Engine Speed Sensor Theory of Operation................786

Group PTR: PTR - Power Train Reverser................696

Control Units PTR - Summary of References................788

Power Train Reverser (PTR) Control Unit Configuration and Calibration................789

PTR 000 — Initial Address................814

PTR 001 — Recall Diagnostic Codes................815

PTR 002 — PTR System Beep Mode................816

PTR 003 — PTR System Beep Mode With Speed Sensors................818

PTR 004 — Engine and Countershaft Speed Sensor Status................820

PTR 005 — Come Home, Trans Enable, Clutch Pedal Switch, and Seat Switch Status................822

PTR 006 — Forward, Neutral, Not Neutral, and Reverse Switch Status................824

PTR 007 — High/Low Switch Status................825

PTR 008 — Park Switch Status................826

PTR 009 — Seat Switch Status................827

PTR 010 — Clutch Disengaged Switch Status................828

PTR 011 — Power Shuttle Input Voltage................829

PTR 012 — Trans Enable Pressure Sensor Voltage................830

PTR 013 — Clutch Pedal Potentiometer Channel A Voltage................832

PTR 014 — Clutch Pedal Potentiometer Channel B Voltage................833

PTR 022 — Clutch Pack Overfill Protection Status................834

PTR 030 — PTR Switched Supply Voltage................835

PTR 031 — PTR Sensor Supply Voltage................836

PTR 032 — Clutch Pedal Position................837

PTR 033 — Clutch Pedal Pressure Command................838

PTR 034 — Trans Enable Actual Pressure................839

PTR 035 — Countershaft Pulses Per Revolution................841

PTR 036 — Countershaft Speed................842

PTR 037 — Hydraulic Oil Temperature................843

PTR 060 — Transmission Type................844

PTR 061 — Hydraulic Oil Type Selection................845

PTR 062 — Temperature Offset For Alternate Hydraulic Oil................846

PTR 063 — Transmission Calibration................847

PTR 064 — Transmission Fill Pressure and Fill Time Calibration Values................849

PTR 065 — Forward Valve Fill Pressure Adjustment................851

PTR 066 — Reverse Valve Fill Pressure Adjustment................852

PTR 067 — Forward Valve Fill Time Adjustment................853

PTR 068 — Reverse Valve Fill Time Adjustment................854

PTR 069 — PowerShuttle Setup Status................855

PTR 070 — PowerShuttle Minimum Wheel Speed Fill Pressure................856

PTR 071 — PowerShuttle Minimum Wheel Speed................857

PTR 072 — Forward and Reverse Current Shift Pressure................858

PTR 073 — Coefficient for V◦2 Shift Logic (Non-PowrShuttle)................859

PTR 074 — Starting Shift Pressure for V◦2 Shift Logic (Non-PowrShuttle)................860

PTR 075 — Maximum Shift Pressure for V◦2 Shift Logic (Non-PowrShuttle)................861

PTR 076 — Vehicle model number................862

PTR 080 — Forward and Reverse Valves Test Mode................863

PTR 081 — Enable Valve Test Mode................864

PTR 082 — Enable Pressure................865

PTR 083 — Hi/Lo Switch Setup................866

PTR 084 — Park Switch Polarity................867

PTR 085 — Seat Switch Polarity................868

PTR 100 — Come Home Mode Enable................869

Address 223-251 — General Control Unit Data................870

PTR - Control Unit Beep Mode Test With Speed Sensors................871

PTR - Control Unit Beep Mode Test Without Speed Sensors................875

PTR—Clutch Pedal Switch Circuit Test................876

PTR - Control Unit Theory of Operation................878

PTR - Directional Reverser Switch Theory of Operation................882

PTR - Clutch Disengaged Switch Theory of Operation................883

PTR - Optional Infinitely Variable Shuttle Control Theory of Operation................884

PTR - Park Switch Theory of Operation................885

PTR - Seat Switch Theory of Operation................886

PTR - Forward Solenoid Theory of Operation................887

PTR - Reverse Solenoid Theory of Operation................888

PTR - Clutch Enable Proportional Valve Theory of Operation................889

PTR - Clutch Pedal Position Sensor Theory of Operation................890

PTR - Enable Pressure Sensor Theory of Operation................891

PTR - Countershaft Speed Sensor Theory of Operation................892

Section 250: Transmission................893

Group 10: Preliminary and Operational Checks................893

Transmission Preliminary and Operational Checks - Summary of References................895

Transmission Preliminary Checks................896

Transmission Operational Checks................898

Group 15: Tests and Adjustments................893

Transmission Tests and Adjustments - Summary of References................902

Install Test Equipment—PowrReverser™................903

PowrReverser™ Control Valve Tests................909

PowrReverser™ Pump Flow Test................1038

PowrReverser™ Main Pressure Relief Valve Adjustment................917

Group 20: Theory of Operation................893

Transmission Theory of Operation - Summary of References................920

PowrReverser™ Transmission Hydraulic Schematic................921

Power Train Components................923

Mechanical PTO Clutch Components................924

Mechanical PTO Clutch Operation—Clutch Disengaged................925

Mechanical PTO Clutch Operation—Clutch Engaged................927

PowrReverser™ General Information................929

PowrReverser™ Clutch Components................930

PowrReverser™ Clutch Operation in Forward................931

PowrReverser™ Clutch Operation in Reverse................933

PowrReverser™ Control Valve Operation—Electro-Hydraulic Directional Reverser in Neutral................935

PowrReverser™ Control Valve Operation—Electro-Hydraulic Directional Reverser in Forward................937

PowrReverser™ Control Valve Operation—Electro-Hydraulic Directional Reverser in Reverse................939

Transmission Components................941

PowrReverser™ Transmission—Gearshift Power Flow................943

PowrReverser™ Transmission—Range Shift Power Flow................945

Gearshift Synchronizer Operation................947

PowrReverser™ Transmission Lubrication System................949

Section 256: Drive Systems................950

Group 10: Preliminary and Operational Checks................950

Drive Systems Preliminary and Operational Checks - Summary of References................952

Drive Systems Preliminary Checks................953

Rear Differential Lock Operational Check................955

PTO Operational Checks................956

MFWD Operational Checks................958

Group 15: Tests and Adjustments................950

Drive Systems Tests and Adjustments - Summary of References................961

Adjust PTO Clutch Lever Linkage................962

Park Brake Band Adjustment................964

Park Brake Linkage Adjustment................966

Group 20: Theory of Operation................950

Drive Systems Theory of Operation - Summary of References................969

Final Drive Components................970

Differential Power Flow................971

Differential Lock Operation................973

Final Drive Operation................975

Mechanical Front Wheel Drive (MFWD) Drop Gearbox Operation................976

Standard Mechanical PTO Components................978

Standard Mechanical PTO Operation................979

540/540E Mechanical PTO Components................981

540/540E Mechanical PTO Operation................982

Park Brake Components................984

Park Brake Operation................986

Section 260: Steering and Brakes................988

Group 10: Preliminary and Operational Checks................988

Steering and Brakes Preliminary and Operational Checks - Summary of References................990

Steering Preliminary Check................991

Steering Operational Check................992

Rear Brakes Preliminary Check................993

Rear Brakes Operational Check................994

Group 15: Tests and Adjustments................988

Steering and Brakes Tests and Adjustments - Summary of References................997

Install Test Equipment—Steering and Brakes................998

Steering Pump Flow Test................1038

Steering Valve Relief Test................1002

Steering Leak Test................1003

Bleed Rear Brakes................1005

Rear Brake Valve Leak Test................1006

Brake Pedal Adjustment................1007

Adjust Brake Retractors................1009

Group 20: Theory of Operation................988

Steering and Brakes Theory of Operation - Summary of References................1011

Steering Valve Operation—Neutral and Manual Turning................1012

Steering Valve Operation—Power Turning................1014

Brake System Operation................1016

Brake Valve Operation................1018

Section 270: Hydraulics................1022

Group 10: Preliminary and Operational Checks................1022

Hydraulics Preliminary and Operational Checks - Summary of References................1025

Hydraulic System Preliminary Checks................1026

Rear Hitch System Operational Check................1028

Hydraulics - Hydraulic Trailer Brake System Operational Check................1030

Group 15: Tests and Adjustments................1022

Hydraulics Tests and Adjustments - Summary of References................1032

Hydraulic Oil Warm-Up Procedure................1033

Install Test Equipment—Hydraulics................1034

Pump Flow Test................1038

Main Relief Valve Test................1040

Rockshaft Load Sense Relief Valve Test................1042

SCV Leakage Test................1044

Rockshaft Leakage Test................1046

Mid-Mount Control Valve Cable Adjustment................1048

Rockshaft Draft-Sensing and Position Control Cable Adjustment................1050

Rockshaft Lever Friction Adjustment................1051

Rockshaft Position-Sensing Feedback Linkage Adjustment................1052

Rockshaft Draft-Sensing Feedback Linkage Adjustment................1056

Hydraulics - Hydraulic Trailer Brake Valve Test................1058

Group 20: Theory of Operation................1022

Hydraulics Theory of Operation - Summary of References................1062

Hydraulic System Operation................1063

Hydraulic Filter Operation................1067

Hydraulic Pump Operation................1069

Rockshaft Control Valve Operation—Two Flow Regulator Valves................1071

Rockshaft Control Valve Operation—Neutral Position................1073

Rockshaft Control Valve Operation—Raise Position................1075

Rockshaft Control Valve Operation—Lower Position................1077

Surge Relief Valve Operation................1079

Rate-of-Drop Valve Operation—Full Open................1081

Rate-of-Drop Valve Operation—Full Closed................1082

Rockshaft Draft-Sensing Operation................1083

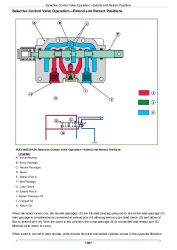

Selective Control Valve Operation—Neutral Position................1085

Selective Control Valve Operation—Extend and Retract Positions................1087

Selective Control Valve Operation—Boom Spool Float Position................1089

Dual Mid-Mount Control Valve Operation—Neutral Position................1091

Dual Mid-Mount Control Valve Operation—Extend and Retract Positions................1093

Dual Mid-Mount Control Valve Operation—Float Position................1095

Dual Mid-Mount Control Valve Operation—Regenerative Position................1097

Double-Acting Sleeve Coupler Operation................1099

Selective Control Valve Operation—Bucket Spool Regenerative Position................1101

Hydraulics - Hydraulic Trailer Brake Operation................1103

Section 290: Operator Station................1106

Group 10: Preliminary and Operational Checks................1106

Operator Station Preliminary and Operational Checks - Summary of References................1108

HVAC Preliminary Checks................1109

HVAC Operational Checks................1112

Group 15: Tests and Adjustments................1106

Operator Station Tests and Adjustments - Summary of References................1119

Install Test Equipment - A/C System................1120

A/C System Pressure Test................1121

A/C System Static Pressure Test................1129

Temperature Drop Test................1134

Group 20: Theory of Operation................1106

Operator Station Theory of Operation - Summary of References................1141

Refrigerant Circuit Layout................1142

Air Conditioning Refrigerant Circuit................1144

Air Conditioning Compressor Operation................1146

Air Conditioning Condenser Operation................1147

Air Conditioning Receiver/Dryer Operation................1148

Air Conditioning Expansion Valve Operation................1149

Air Conditioning Thermostat Switch Operation................1152

Air Conditioning Evaporator Operation................1153

Air Conditioning High/Low Pressure Switch Operation................1154

Air Conditioning ON/OFF Switch and Temperature Control Knob Operation................1155

Heater Temperature Control Knob Operation................1156

Heating and Ventilation Operation................1157

Section 299: Service Tools................1159

Group 05: Dealer Fabricated Tools................1159

Dealer Fabricated Tools - Summary of References................1162

DFRW126................1163

DFRW213 — Hydraulic Trailer Brake Test / Bleed Assembly................1165

Group 10: Service Tools and Kits................1159

Service Tools and Kits - Summary of References................1168

AR94522................1169

D01074AA................1170

FKM10002................1171

FKM10302................1172

FKM10303................1173

FKM10305................1174

JDG774................1175

JDG10466................1176

JT02051................1177

JT02063................1178

JT02153................1179

JT02178................1180

JT03044................1181

JT03051................1182

JT03059................1183

JT03110................1184

JT03262................1185

JT03345................1186

JT03364................1187

JT03367................1188

JT03368................1189

JT03481................1190

JT03481-1................1191

JT03481-3................1192

JT03481-4................1193

JT03520................1194

JT05469................1195

JT05473................1196

JT05494................1197

JT05498................1198

JT05634................1199

JT05685................1200

JT05791................1201

JT05843................1202

JT07032................1203

JT07041................1204

JT07148................1205

John Deer 5083E and 5093E Tractors Diagnosis and Test Service Technical Manual (TM608919)