John Deere Tractors 5220, 5320, 5420 & 5520 Diagnosis and Tests Service Technical Manual (TM2049)

Catalog:

Model:

Complete Diagnosis & Tests Technical Manual with electrical wiring diagrams for John Deere Tractors 5220, 5320, 5420, 5520, with all the technical information to maintain, diagnose, rebuild like professional mechanics.

John Deere Tractors 5220, 5320, 5420, 5520 workshop Diagnosis & Tests technical manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

tm2049 English - 5220, 5320, 5420, and 5520 Tractors Diagnostic Technical Manual - (388313-,420001-,-388312,-420000,-420001,388313-,420001-,-388312,-420000,-420001,388313-,420001-,-388312,-420000,-420001,388313-,420001-,-388312,-420000,-420001) Diagnosis and Tests

tm9110 French - Manuel technique de diagnostic des tracteurs 5220, 5320, 5420 et 5520 - (388313-,420001-,-388312,-420000,-420001,388313-,420001-,-388312,-420000,-420001,388313-,420001-,-388312,-420000,-420001,388313-,420001-,-388312,-420000,-420001)

PRODUCT DETAILS:

Total Pages: 1,666 pages

File Format: PDF (bookmarked, ToC, Searchable, Printable, high quality)

Language: English French

MAIN SECTIONS

Foreword

Operational Checkout Procedures

Operational Checkout Procedures

Engine Operation, Tests, and Adjustments

Component Location

Theory of Operation

Diagnosis, Tests, and Adjustments

Fuel/Air Operation, Tests, and Adjustments

Component Location

Theory of Operation

Diagnosis, Tests and Adjustments

Electrical System Operation, Test & Adjust

Component Location

Theory of Operation

Diagnosis, Test and Adjust

Wiring Schematics

Power Train Operation, Tests and Adjustments

Component Location-CollarShift/SyncShuttle™ Transmission

Component Location-PowrReverser™ Transmission

Theory of Operation-CollarShift/SyncShuttle™ Transmission

Theory of Operation-PowrReverser™ Transmission

Diagnosis, Tests, and Adjustments-CS/SS Transmission

Diagnosis, Tests, and Adjustments-PowrReverser™

Steering and Brake Operation, Test & Adjust

Component Location

Theory of Operation

Diagnosis, Tests and Adjustments

Hydraulic System Operation, Tests, and Adjustments

Component Location

Theory of Operation

Diagnosis

Hydraulic Tests-Without SCV

Hydraulic Tests-With SCV

Hydraulic Tests-All

Adjustments

Hydraulic Schematics

Operator Station

Component Location

Theory of Operation

Diagnosis, Tests, and Adjustments

Dealer Fabricated Tools

TABLE OF CONTENTS

Section 210: Operational Checkout Procedures................23

Group 10: Operational Checkout Procedures................23

Specifications................127

Operational Checkout Procedure Information................27

Engine Oil Level and Condition Check................28

Coolant Level and Condition Check................29

Transmission and Hydraulic Oil Check................31

3-Cylinder Fan and V-Belt Check................33

4-Cylinder Fan and Serpentine Belt Check................34

Compressor Belt Check................35

Fuel System Check (S.N. —420000)................37

Fuel System Check (S.N. 420001— )................39

Air Intake System Check................41

Electrical System Check (S.N. —420000)................43

Electrical System Check (S.N. 420001— )................45

Hydraulic System Check (S.N. —420000)................48

Hydraulic System Check (S.N. 420001— )................49

MFWD Oil Check................51

MFWD Differential Oil Check................52

Indicator Lamps Check (S.N. —420000)................53

Indicator Lamps Check (S.N. 420001— )................54

Cab Blower Motor Check (S.N. —420000)................55

Cab Blower Motor Check (S.N. 420001— )................56

A/C Compressor Clutch Check................76

Engine Start Check—Straddle Mount Tractors................58

Engine Start Check—Isolated Open Operator Station and Cab Tractors................60

Transmission Neutral Start Check—Straddle Mount Tractors................62

Transmission Neutral Start Check—Isolated Open Operator Station and Cab Tractors................64

PTO Neutral Start Check................66

Engine Fast and Slow Idle Operation................68

Foot Throttle Pedal Check—Isolated Open Operator Station and Cab Tractors................70

Power Steering Check................72

Differential Lock Check................73

PTO Engagement Check................74

Clutch Check................76

Transmission Shift Check................77

Range Lever Shift Check................79

MFWD Drive Check................81

Brake Check................82

Park Brake Check—CollarShift and SyncShuttle SYNCSHUTTLE is a trademark of Deere & Company Transmissions................24

Park Brake Check—PowrReverser POWRREVERSER is a trademark of Deere & Company Transmission................24

Rockshaft Check—Straddle Mount Tractors................87

Rockshaft Check—Isolated Open Operator Station and Cab Tractors................89

Selective Control Valve Check—Straddle Mount Tractors................91

Selective Control Valve Check—Isolated Open Operator Station and Cab Tractors................93

Front End Loader Joystick Control Check (Optional)................95

A/C System Operational Check................97

Cab Heater Valve Check................98

Miscellaneous Checks................99

Section 220: Engine Operation, Tests, and Adjustments................100

Group 05: Component Location................100

Component Location Information................1152

3-Cylinder Engine External Components—Left-Hand Side................104

3-Cylinder Engine External Components—Right-Hand Side................106

4-Cylinder Engine External Components—Left-Hand Side................108

4-Cylinder Engine External Components—Right-Hand Side................110

Group 10: Theory of Operation................100

Theory of Operation Information................1174

Engine Lubrication System Operation................114

Engine Lubrication System Operation—Continued................117

Engine Cooling System Operation—3-Cylinder................119

Engine Cooling System Operation—4-Cylinder................121

Group 15: Diagnosis, Tests, and Adjustments................1396

Service Equipment and Tools................125

Specifications................127

Diagnostic Information................1245

Engine Turns Over but Will Not Start or Starts Hard................129

Engine Runs Irregularly or Stalls Frequently................130

Engine Runs Rough................131

Engine Has Low Power................132

Engine Smokes—Black or Gray................134

Engine Smokes Excessively—White................135

Engine Uses Excess Fuel................136

Engine Has Excess Noise or Vibration................137

Engine Uses Excess Oil or Smokes Blue................138

Engine Has Low Oil Pressure................139

Engine Coolant Operating Temperature Incorrect................140

Oil In Coolant or Coolant in Oil................142

Radiator Bubble Test................143

Cooling System Test................145

Radiator Cap Pressure Test................146

Engine Oil Pressure Test................147

Cylinder Compression Pressure Test................149

Fuel Shut-Off Solenoid Check................151

Throttle Lever Adjustment—Straddle Mount Tractors................152

Throttle Lever Adjustment—Isolated Open Operator Station and Cab Tractors................153

Slow Idle Adjustment................155

Fast Idle Adjustment................157

Foot Throttle Pedal Stop Adjustment—Isolated Open Operator Station and Cab Tractors................159

Injection Pump Timing Adjustment................160

Check and Adjust Valve Clearance................162

Fan/Alternator V-Belt Adjustment—5220 and 5320 Tractors................166

Compressor Drive Belt Adjustment—3-Cylinder................168

Turbocharger Boost Pressure Test—5320 and 5520 Tractors................170

Bleed Fuel System................172

Section 230: Fuel/Air Operation, Tests, and Adjustments................175

Group 05: Component Location................175

Component Location Information................1152

Fuel System Components—Straddle Mount................178

Fuel System Components—Isolated Open Operator Station and Cab Tractors (S.N. —420000)................180

Fuel System Components—Isolated Open Operator Station and Cab Tractors (S.N. 420001— )................182

Air Intake System Components—Without Turbocharger................184

Air Intake System Components—With Turbocharger................186

Group 10: Theory of Operation................175

Theory of Operation Information................1174

Fuel System Operation—Straddle Mount................190

Fuel System Operation—Isolated Open Operator Station and Cab Tractors (S.N. —420000)................192

Fuel System Operation—Isolated Open Operator Station and Cab Tractors (S.N. 420001— )................194

Fuel Filter/Priming Pump Operation................197

Fuel Filter/Priming Pump Operation................197

Fuel Injection Nozzle Operation................200

Fuel Injection Nozzle Operation................200

Air Intake System Operation—Without Turbocharger................202

Air Intake System Operation—Without Turbocharger................202

Air Intake System Operation—With Turbocharger................204

Air Intake System Operation—With Turbocharger................204

Turbocharger Operation—5320 and 5520................205

Group 15: Diagnosis, Tests and Adjustments................175

Diagnostic Information................1245

Fuel/Air Diagnosis, Tests and Adjustments................209

Section 240: Electrical System Operation, Test Section 240: Electrical System Operation, Test & Adjust{pgNO}210 Adjust................210

Group 05: Component Location................210

Component Location Information................1152

Engine Electrical Components................220

Dash Electrical Components—Straddle Mount (S.N. —420000)................222

Dash Electrical Components—Straddle Mount (S.N. 420001— )................224

Dash Electrical Components—Isolated Open Operator Station and Cab Tractors (S.N. —420000)................226

Dash Electrical Components—Isolated Open Operator Station and Cab Tractors (S.N. 420001— )................229

Machine Electrical Components—Straddle Mount (S.N. —420000)................231

Machine Electrical Components—Straddle Mount (S.N. 420001— )................233

Machine Electrical Components—Isolated Open Operator Station (S.N. —420000)................235

Machine Electrical Components—Isolated Open Operator Station (S.N. 420001— )................237

Machine Electrical Components—Cab Tractors (S.N. —420000)................239

Machine Electrical Components—Cab Tractors (S.N. 420001— )................241

Cab Control Panel and Electrical Components................243

Group 10: Theory of Operation................210

Theory of Operation Information................1174

Fuse/Relay Block Assembly—Straddle Mount (S.N. —420000)................246

Fuse/Relay Block Assembly—Straddle Mount (S.N. 420001— )................248

Fuse/Relay Block Assembly—Early Model Cab Tractors (S.N. —420000)................250

Fuse/Relay Block Assembly—Isolated Open Operator Station and Late Model Cab Tractors (S.N. —420000)................253

Fuse/Relay Block Assembly—Isolated Open Operator Station and Cab Tractors (S.N. 420001— )................256

Electrical Load Center—Isolated Open Operator Station and Cab Tractors (S.N. 420001— )................258

HVAC/Wiper Relay Block Assembly—Isolated Open Operator Station and Cab Tractors (S.N. 420001— )................260

Starting System Operation—Normal (S.N. —420000)................262

Starting System Operation—Normal (S.N. 420001— )................265

Starting System Operation—Bypass Attempt (S.N. —420000)................268

Starting System Operation—Bypass Attempt (S.N. 420001— )................271

Air Intake Heater System Operation (S.N. —420000) (Optional)................274

Air Intake Heater System Operation (S.N. 420001— ) (Optional)................276

Charging System Operation (S.N. —420000)................278

Charging System Operation (S.N. 420001— )................280

Lighting System Operation—Turn Signals and Enhanced Tail Lights—Straddle Mount (S.N. —420000)................283

Lighting System Operation—Turn Signals—Isolated Open Operator Station (S.N. —420000)................286

Lighting System Operation—Turn Signals—Straddle Mount and Isolated Open Operator Station (S.N. 420001— )................289

Lighting System Operation—Turn Signals—Early Model Cab Tractors (S.N. —420000)................292

Lighting System Operation—Turn Signals—Late Model Cab Tractors (S.N. —420000)................295

Lighting System Operation—Turn Signals—Cab Tractors (S.N. 420001— )................298

Lighting System Operation—Warning Lights—Straddle Mount (S.N. —420000)................301

Lighting System Operation—Warning Lights—Isolated Open Operator Station (S.N. —420000)................303

Lighting System Operation—Warning Lights—Straddle Mount and Isolated Open Operator Station (S.N. 420001— )................305

Lighting System Operation—Warning Lights—Early Model Cab Tractors (S.N. —420000)................307

Lighting System Operation—Warning Lights—Late Model Cab Tractors (S.N. —420000)................310

Lighting System Operation—Warning Lights—Cab Tractors (S.N. 420001— )................313

Lighting System Operation—Tail Lights—All Tractors (S.N. —420000)................316

Lighting System Operation—Tail Lights—All Tractors (S.N. 420001— )................318

Lighting System Operation—Headlights and Instrument Lights—Straddle Mount (S.N. —420000)................320

Lighting System Operation—Headlights and Instrument Lights—Straddle Mount (S.N. 420001— )................322

Lighting System Operation—Headlights and Instrument Lights—Early Model Cab Tractors (S.N. —420000)................324

Lighting System Operation—Headlights and Instrument Lights—Isolated Open Operator Station and Late Model Cab Tractors (S.N. —420000)................327

Lighting System Operation—Headlights and Instrument Lights—Isolated Open Operator Station and Cab Tractors (S.N. 420001— )................330

Flood Light Operation—Straddle Mount (S.N. —420000)................333

Flood Light Operation—Isolated Open Operator Station (S.N. —420000)................335

Flood Light Operation—Cab Tractors (S.N. —420000)................337

Work Light Operation—Straddle Mount and Isolated Open Operator Station (S.N. 420001— )................339

Work Light and Beacon Operation—Cab Tractors (S.N. 420001— )................341

Instrument Panel System Operation—Tachometer/Hour Meter—All Tractors (S.N. —420000)................344

Instrument Cluster Operation—Tachometer/Hour Meter—All Tractors (S.N. 420001— )................346

Instrument Panel System Operation—Fuel Gauge—All Tractors (S.N. —420000)................348

Instrument Cluster Operation—Fuel Gauge—All Tractors (S.N. 420001— )................350

Instrument Panel System Operation—Coolant Temperature Gauge—All Tractors (S.N. —420000)................352

Instrument Cluster Operation—Coolant Temperature Gauge—All Tractors (S.N. 420001— )................354

PTO Warning System Operation—Straddle Mount (S.N. —420000)................356

PTO Warning System Operation—Early Model Cab Tractors (S.N. —420000)................358

PTO Warning System Operation—Isolated Open Operator Station and Late Model Cab Tractors (S.N. —420000)................361

PTO Warning System Operation—All Tractors (S.N. 420001— )................364

Air Filter Restriction Indicator Operation—All Tractors (S.N. —420000)................366

Air Filter Restriction Indicator Operation—All Tractors (S.N. 420001— )................368

Optional Horn Operation—All Tractors (S.N. —420000)—Isolated Open Operator Station and Cab Tractors (S.N. 420001— )................370

Optional Horn Operation—Straddle Mount Tractors (S.N. 420001— )................372

Accessory Relay and Electrical Outlet Operation—All Tractors (S.N. —420000)................374

Accessory Relay and Electrical Outlet Operation—Straddle Mount Tractors (S.N. 420001— )................376

Accessory Relay and Electrical Outlet Operation—Isolated Open Operator Station and Cab Tractors (S.N. 420001— )................378

Blower Motor Operation—Cab Tractors (S.N. —420000)................381

Blower Motor Operation—Cab Tractors (S.N. 420001— )................384

A/C Compressor Operation—Cab Tractors (S.N. —420000)................387

A/C Compressor Operation—Cab Tractors (S.N. 420001— )................390

Front Wiper/Washer Operation—Cab Tractors (S.N. —420000)................392

Front Wiper/Washer Operation—Cab Tractors (S.N. 420001— )................395

Rear Wiper/Washer Operation—Cab Tractors (S.N. —420000) (Optional)................398

Rear Wiper/Washer Operation—Cab Tractors (S.N. 420001— ) (Optional)................400

Dome Light Operation—Cab Tractors (S.N. —420000)................402

Dome Light Operation—Cab Tractors (S.N. 420001— )................404

Convenience Outlet Operation—Cab Tractors (S.N. —420000)................406

Convenience Outlet Operation—Cab Tractors (S.N. 420001— )................408

Group 15: Diagnosis, Test and Adjust................212

Diagnostic Information................1245

Wire Color Chart................412

Starting System Test Points—Normal Operation—Straddle Mount (S.N. —420000)................414

Starting System Test Points—Normal Operation—Straddle Mount (S.N. 420001— )................418

Starting System Test Points—Normal Operation (Isolated Open Operator Station and Cab Tractors) (S.N. —420000)................422

Starting System Test Points—Normal Operation (Isolated Open Operator Station and Cab Tractors) (S.N. 420001— )................426

Starting System Test Points—Bypass Attempt—Straddle Mount (S.N. —420000)................431

Starting System Test Points—Bypass Attempt—Straddle Mount (S.N. 420001— )................434

Starting System Test Points—Bypass Attempt (Isolated Open Operator Station and Cab Tractors) (S.N. —420000)................437

Starting System Test Points—Bypass Attempt (Isolated Open Operator Station and Cab Tractors) (S.N. 420001— )................440

Air Intake Heater Test Points—Straddle Mount (S.N. —420000)................443

Air Intake Heater Test Points—Straddle Mount (S.N. 420001— )................446

Air Intake Heater Test Points—Isolated Open Operator Station and Cab Tractors (S.N. —420000)................449

Air Intake Heater Test Points—Isolated Open Operator Station and Cab Tractors (S.N. 420001— )................452

Charging System Test Points—Straddle Mount (S.N. —420000)................455

Charging System Test Points—Straddle Mount (S.N. 420001— )................458

Charging System Test Points—Isolated Open Operator Station and Cab Tractors (S.N. —420000)................461

Charging System Test Points—Isolated Open Operator Station and Cab Tractors (S.N. 420001— )................464

Lighting System Test Points—Turn Signals and Enhanced Tail Lights—Straddle Mount (S.N. —420000)................468

Lighting System Test Points—Turn Signals and Enhanced Tail Lights—Straddle Mount (S.N. 420001— )................475

Lighting System Test Points—Turn Signal Switch Power (Isolated Open Operator Station and Cab Tractors) (S.N. —420000)................485

Lighting System Test points—Turn Signal Operation (Isolated Open Operator Station) (S.N. —420000)................487

Lighting System Test points—Turn Signals—Isolated Open Operator Station (S.N. 420001— )................493

Lighting System Test points—Turn Signals—Early Model Cab Tractors (S.N. —420000)................500

Lighting System Test points—Turn Signals—Isolated Open Operator Station and Late Model Cab Tractors (S.N. —420000)................507

Lighting System Test points—Turn Signals—Cab Tractors (S.N. 420001— )................514

Lighting System Test Points—Warning Lights—Straddle Mount (S.N. —420000)................521

Lighting System Test Points—Warning Lights—Straddle Mount (S.N. 420001— )................524

Lighting System Test Points—Warning Lights (Isolated Open Operator Station) (S.N. —420000)................529

Lighting System Test Points—Warning Lights (Isolated Open Operator Station) (S.N. 420001— )................534

Lighting System Test Points—Warning Lights—Early Model Cab Tractors (S.N. —420000)................540

Lighting System Test points—Warning Lights—Late Model Cab Tractors (S.N. —420000)................546

Lighting System Test points—Warning Lights—Cab Tractors (S.N. 420001— )................552

Lighting System Test Points—Flood Light(s)—Straddle Mount (S.N. —420000)................558

Lighting System Test Points—Work Lights—Straddle Mount (S.N. 420001— )................561

Lighting System Test Points—Flood Lights (Isolated Open Operator Station) (S.N. —420000)................565

Lighting System Test Points—Work Lights—Isolated Open Operator Station (S.N. 420001— )................569

Lighting System Test Points—Flood Lights (Cab Tractors) (S.N. —420000)................573

Lighting System Test Points—Work Lights—Cab Tractors (S.N. 420001— )................577

Lighting System Test Points—Tail Lights—Straddle Mount (S.N. —420000)................581

Lighting System Test Points—Tail Lights—Straddle Mount (S.N. 420001— )................584

Lighting System Test Points—Tail Lights (Isolated Open Operator Station and Cab Tractors) (S.N. —420000)................587

Lighting System Test Points—Tail Lights—Isolated Open Operator Station and Cab Tractors (S.N. 420001— )................590

Lighting System Test Points—Headlights and Instrument Lights—Straddle Mount (S.N. —420000)................593

Lighting System Test Points—Headlights and Instrument Lights—Straddle Mount (S.N. 420001— )................597

Lighting System Test Points—Headlights and Instrument Lights—Early Model Cab Tractors (S.N. —420000)................600

Lighting System Test points—Headlights and Instrument Lights—Isolated Open Operator Station and Late Model Cab Tractors (S.N. —420000)................605

Lighting System Test points—Headlights and Instrument Lights—Isolated Open Operator Station and Cab Tractors (S.N. 420001— )................610

Lighting System Test Points—Dome Light (Cab Tractors) (S.N. —420000)................615

Lighting System Test Points—Dome Light—Cab Tractors (S.N. 420001— )................618

Instrument Panel System Test Points—Tachometer/Hour Meter—Straddle Mount (S.N. —420000)................621

Instrument Cluster System Test Points—Tachometer/Hour Meter—Straddle Mount (S.N. 420001— )................624

Instrument Panel System Test Points—Tachometer/Hour Meter (Isolated Open Operator Station and Cab Tractors) (S.N. —420000)................627

Instrument Cluster Test Points—Tachometer/Hour Meter—Isolated Open Operator Station and Cab Tractors (S.N. 420001— )................630

Instrument Panel System Test Points—Fuel Gauge—Straddle Mount (S.N. —420000)................633

Instrument Cluster System Test Points—Fuel Gauge—Straddle Mount (S.N. 420001— )................636

Instrument Panel System Test Points—Fuel Gauge (Isolated Open Operator Station and Cab Tractors) (S.N. —420000)................639

Instrument Cluster Test Points—Fuel Gauge (Isolated Open Operator Station and Cab Tractors) (S.N. 420001— )................642

Instrument Panel System Test Points—Temperature Gauge—Straddle Mount (S.N. —420000)................645

Instrument Cluster System Test Points—Temperature Gauge—Straddle Mount (S.N. 420001— )................648

Instrument Panel System Test Points—Temperature Gauge (Isolated Open Operator Station and Cab Tractors) (S.N. —420000)................651

Instrument Cluster Test Points—Temperature Gauge (Isolated Open Operator Station and Cab Tractors) (S.N. 420001— )................654

Instrument Cluster System Test Points—Oil Pressure—Straddle Mount (S.N. —420000)................657

Instrument Cluster System Test Points—Oil Pressure—Straddle Mount (S.N. 420001— )................660

Instrument Panel System Test Points—Oil Pressure (Isolated Open Operator Station and Cab Tractors) (S.N. —420000)................663

Instrument Cluster Test Points—Oil Pressure (Isolated Open Operator Station and Cab Tractors) (S.N. 420001— )................666

PTO Warning System Test Points—Straddle Mount (S.N. —420000)................669

PTO Warning System Test Points—Straddle Mount (S.N. 420001— )................672

PTO Warning System Test Points—Early Model Cab Tractors (S.N. —420000)................675

PTO Warning System Test Points—Isolated Open Operator Station and Late Model Cab Tractors (S.N. —420000)................679

PTO Warning System Test Points—Isolated Open Operator Station and Cab Tractors (S.N. 420001— )................683

Air Filter Restriction Test Points—Straddle Mount (S.N. —420000)................686

Air Filter Restriction Test Points—Straddle Mount (S.N. 420001— )................689

Air Filter Restriction Test Points—Isolated Open Operator Station and Cab Tractors (S.N. —420000)................692

Air Filter Restriction Test Points—Isolated Open Operator Station and Cab Tractors (S.N. 420001— )................695

Optional Horn Test Points—Straddle Mount (S.N. —420000)................698

Optional Horn Test Points—Straddle Mount (S.N. 420001— )................700

Optional Horn Test Points—Cab Tractors and Isolated Open Operator Station (S.N. —420000)................703

Optional Horn Test Points—Isolated Open Operator Station and Cab Tractors (S.N. 420001— )................705

Accessory Relay and Electrical Outlet Test Points—Straddle Mount (S.N. —420000)................707

Accessory Relay and Electrical Outlet Test Points—Straddle Mount (S.N. 420001— )................711

Accessory Relay and Electrical Outlet Test Points—Early Model Cab Tractors (S.N. —420000)................715

Accessory Relay and Electrical Outlet Test Points—Isolated Open Operator Station and Late Model Cab Tractors (S.N. —420000)................720

Accessory Relay and Electrical Outlet Test Points—Isolated Open Operator Station and Cab Tractors (S.N. 420001— )................725

Blower Motor Test Points—Cab Tractors (S.N. —420000)................728

Blower Motor Test Points—Cab Tractors (S.N. 420001— )................734

A/C Compressor Clutch Coil Test Points—Cab Tractors (S.N. —420000)................739

A/C Compressor Clutch Coil Test Points—Cab Tractors (S.N. 420001— )................742

Front Wiper/Washer Test Points—Cab Tractors (S.N. —420000)................744

Front Wiper/Washer Test Points—Cab Tractors (S.N. 420001— )................748

Rear Wiper/Washer Test Points—Cab Tractors (S.N. —420000)................752

Rear Wiper/Washer Test Points—Cab Tractors (S.N. 420001— )................755

Convenience Outlet Test Points—Cab Tractors (S.N. —420000)................759

Convenience Outlet Test Points—Cab Tractors (S.N. 420001— )................762

Battery Voltage and Specific Gravity Tests................765

Charge Battery................767

Battery Load Test................769

Starter Amp Draw/RPM Test................771

Starter No-Load Amp Draw/RPM Test................773

Alternator/Regulator Test................775

Starter Solenoid Test................777

Starter Relay Test................778

Key Switch Test................780

Plug-In Relay Test................782

Diode Pack Test................784

Fuse Test................786

Neutral Start Switch Test................787

PTO Switch Test................788

PTO Seat Switch Test................790

Light Switch Test................792

Flasher Module Test—Isolated Open Operator Station and Cab Tractors................794

Turn Signal Controller Test—Straddle Mount (S.N. —420000)................795

Turn Signal Switch Test—All Tractors (S.N. 420001— )................796

Fuel Shut-Off Solenoid Test................798

Blower Switch Test................799

Start Resistor Test................801

Blower Motor Resistors................802

A/C Temperature Control Switch Test................803

Front Wiper/Washer Switch Test................804

Rear Wiper/Washer Switch Test................806

Door Switch Test................807

Dome Light Switch Test................808

Group 20: Wiring Schematics................217

Schematic Information................811

Component Identification Table................812

5220—5520 Straddle Mount Electrical Schematic (S.N. —420000)................814

5220—5520 Straddle Mount Electrical Schematic (S.N. 420001— )................821

5220—5520 Early Model Cab Tractors Electrical Schematic (S.N. —420000)................830

5220—5520 Isolated Open Operator Station and Late Model Cab Tractors Electrical Schematic (S.N. —420000)................844

5220—5520 Isolated Open Operator Station and Cab Tractors Electrical Schematic (S.N. 420001— )................860

Section 250: Power Train Operation, Tests and Adjustments................884

Group 05: Component Location—CollarShift/SyncShuttle™ Transmission................884

Component Location Information................1152

Power Train Components—Straddle Mount (CollarShift and SyncShuttle™)................890

Power Train Components—Isolated Open Operator Station and Cab Tractors (CollarShift and SyncShuttle™)................892

Clutch Components—CollarShift and SyncShuttle™ Transmissions................894

Transmission Components—CollarShift................896

Transmission Components—SyncShuttle™................898

Final Drive Components................917

Hi-Crop Final Drive Axle Components................901

Rear PTO Components................918

Rear 540/540E PTO Components (SyncShuttle™ Transmission Only)................904

Group 06: Component Location—PowrReverser™ Transmission................884

Component Location Information................1152

Power Train Components—Straddle Mount (PowrReverser™ Transmission)................907

Power Train Components—Isolated Open Operator Station and Cab Tractors (PowrReverser™ Transmission)................909

Clutch Components—PowrReverser™ Transmission................911

PowrReverser™ Components................913

Transmission Components—PowrReverser™ Transmission................915

Final Drive Components................917

Rear PTO Components................918

Group 10: Theory of Operation—CollarShift/SyncShuttle™ Transmission................884

Theory of Operation Information................1174

Clutch Operation—CollarShift and SyncShuttle™ Transmissions................921

Transmission Lubrication System................929

CollarShift Transmission—Gear Shift Power Flow................931

SyncShuttle™ Transmission—Gear Shift Power Flow................933

SyncShuttle™ Transmission Synchronizer Operation—Reverse and 2nd Gear (Disk-and-Plate Type Synchronizer)................935

SyncShuttle™ Transmission Synchronizer Operation—1st and 3rd Gear (Cone-Type Synchronizer)................937

CollarShift Transmission—Range Shift Power Flow................939

Rear PTO Operation................990

Rear PTO Operation................990

Rear 540/540E PTO Operation (SyncShuttle™ and PowrReverser™ Transmissions)................945

Rear 540/540E PTO Operation (SyncShuttle™ and PowrReverser™ Transmissions)................945

Differential Power Flow................947

Differential Power Flow................947

Hi-Crop Axle Differential Power Flow................950

Hi-Crop Axle Differential Power Flow................950

Differential Lock Operation................952

Differential Lock Operation................952

Final Drive Operation................991

Mechanical Front Wheel Drive (MFWD) Drop Gearbox Operation................956

Mechanical Front Wheel Drive (MFWD) Drop Gearbox Operation................956

Group 11: Theory of Operation—PowrReverser™ Transmission................885

Theory of Operation Information................1174

Clutch Operation—PTO Clutch Disengaged (PowrReverser™ Transmission)................959

Clutch Operation—PTO Clutch Engaged (PowrReverser™ Transmission)................961

PowrReverser™ General Information................963

PowrReverser™ Operation in Forward................964

PowrReverser™ Operation in Reverse................966

PowrReverser™ Power Flow................968

PowrReverser™ Control Valve Operation—Initial Engine Start-Up, Clutch Pedal Up................970

PowrReverser™ Control Valve Operation—F-N-R Lever in Neutral, Clutch Pedal Down................972

PowrReverser™ Control Valve Operation—F-N-R Lever in Neutral, Clutch Pedal Up................974

PowrReverser™ Control Valve Operation—F-N-R Lever in Forward, Clutch Pedal Up................976

PowrReverser™ Control Valve Operation—F-N-R Lever in Reverse, Clutch Pedal Up................979

PowrReverser™ Transmission—Gear Shift Power Flow................981

Gear Shift Synchronizer Operation................983

PowrReverser™ Transmission—Range Shift Power Flow................985

PowrReverser™ Transmission Lubrication System................988

Rear PTO Operation................990

Final Drive Operation................991

Differential Operation................992

MFWD Operation................993

Group 15: Diagnosis, Tests, and Adjustments—CS/SS Transmission................886

Diagnostic Information................1245

Isolate the Problem Area................996

Traction Clutch Slips................998

Traction Clutch Dragging................999

Traction Clutch Does Not Engage................1000

Traction Clutch Grabs................1001

Traction Clutch Squeaks................1002

Traction Clutch Does Not Release................1003

Traction Clutch Chatters................1004

Traction Clutch Rattles................1005

Traction Clutch Engagement Is Noisy................1006

Excessive Vibration in Traction Clutch................1007

Clutch Pedal Does Not Return................1043

Clutch Pedal Loose................1009

Clutch Pedal Pulsates................1010

Jerky or Rough Transmission of Power................1011

Low Transmission Oil Level (Excessive Oil Leakage)................1042

Gears Clash, Shift Hard, or Will Not Engage................1047

Two Speeds Engage Together................1048

Transmission Will Not Stay in Gear................1049

Transmission Noisy................1050

PTO Noisy................1017

PTO Hard to Engage................1018

PTO Will Not Operate................1019

PTO Will Not Stay Engaged................1020

Excessive Differential Noise................1021

Differential Does Not Work................1022

No Differential Lock................1023

Differential Chatters................1024

Axle Noise................1025

Axle Shaft Will Not Turn................1026

MFWD Lever Is Hard to Engage................1027

MFWD Lever Will Not Stay in ON Position................1028

Noisy Front Wheel Drive Operation................1029

Check and Adjust Clutch Pedal Free Play—CollarShift and SyncShuttle™ Transmissions (Straddle Mount)................1030

Check and Adjust Clutch Pedal Free Play—CollarShift and SyncShuttle™ Transmissions (Isolated Open Operator Station and Cab Tractors)................1032

Adjusting PTO Clutch Lever Linkage—Straddle Mount................1034

Adjusting PTO Clutch Lever Linkage—Isolated Open Operator Station and Cab Tractors................1036

Group 16: Diagnosis, Tests, and Adjustments—PowrReverser™................887

Diagnostic Information—PowrReverser™ Transmission................1039

Isolate the Problem Area—PowrReverser™ Transmission................1040

Low Transmission Oil Level (Excessive Oil Leakage)................1042

Clutch Pedal Does Not Return................1043

Tractor Does Not Move in Forward or Reverse................1044

PowrReverser™ Engages Too Quickly or Too Slowly................1045

PowrReverser™ Does Not Disengage................1046

Gears Clash, Shift Hard, or Will Not Engage................1047

Two Speeds Engage Together................1048

Transmission Will Not Stay in Gear................1049

Transmission Noisy................1050

PTO Troubleshooting................1051

Differential Troubleshooting................1052

Final Drive Axle Troubleshooting................1053

MFWD Troubleshooting................1054

PowrReverser™ Control Valve Tests................1055

Transmission Pump Flow Test................1061

Adjust Forward-Neutral-Reverse Cable................1063

Clutch Pedal Linkage Adjustment................1070

Park Brake Cable Adjustment................1072

PTO 540/540E Lever and Linkage Adjustment................1077

Section 260: Steering and Brake Operation, Test Section 260: Steering and Brake Operation, Test & Adjust{pgNO}1079 Adjust................1079

Group 05: Component Location................1079

Component Location Information................1152

Steering System Components—5220—5320 Straddle Mount................1083

Steering System Components—5420—5520 Straddle Mount................1085

Steering System Components—5220—5320 Isolated Open Operator Station................1087

Steering System Components—5420—5520 Isolated Open Operator Station and All Cab Tractors................1089

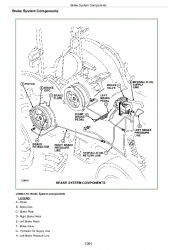

Brake System Components................1091

Group 10: Theory of Operation................1079

Theory of Operation Information................1174

Steering System Operation—5220—5320 Straddle Mount................1095

Steering System Operation—5420—5520 Straddle Mount................1097

Steering System Operation—5220—5320 Isolated Open Operator Station................1099

Steering System Operation—5420—5520 Isolated Open Operator Station and All Cab Tractors................1101

Steering Valve Operation—Neutral and Manual Turning................1103

Steering Valve Operation—Power Turning................1105

Brake System Operation................1107

Brake Valve Operation (S.N. —420000)................1109

Brake Valve Operation (S.N. 420001— )................1113

Group 15: Diagnosis, Tests and Adjustments................1079

Diagnostic Information................1245

Isolate the Problem—Steering System................1119

Steering Sluggish or Loss of Steering................1120

Isolate the Problem—Brakes................1121

Excessive Brake Pedal Leak-Down................1122

Excessive Brake Chatter................1123

Steering Pump Flow Test................1124

Steering Valve Relief Test................1126

Steering Cylinder Leakage Test................1127

Steering Valve Leakage Test................1128

Toe-In Check and Adjustment—Standard Axle................1130

Toe-In Check and Adjustment—MFWD................1132

MFWD Steering Stop Adjustment................1134

Brake Pedal Adjustment (S.N. —420000)................1136

Brake Pedal Adjustment (S.N. 420001— )................1138

Bleed Brake System................1140

Adjust Brake (S.N. 388313— )................1141

Adjust Brake (S.N. —388312)................1143

Section 270: Hydraulic System Operation, Tests, and Adjustments................1147

Group 05: Component Location................1147

Component Location Information................1152

Hydraulic System Components—Straddle Mount Tractors (Without Oil Cooler)................1153

Hydraulic System Components—Isolated Open Operator Station and Cab Tractors (Without Oil Cooler)................1155

Hydraulic System Components—Straddle Mount Tractors (With Oil Cooler)................1157

Hydraulic System Components—Isolated Open Operator Station and Cab Tractors (With Oil Cooler)................1159

Selective Control Valve Components—Straddle Mount Tractors without Mid-Mount SCV (S.N. —420000)................1161

Selective Control Valve Components—Straddle Mount Tractors without Mid-Mount SCV (S.N. 420001— )................1163

Selective Control Valve Components—Isolated Open Operator Station and Cab Tractors without Mid-Mount SCV................1165

Selective Control Valve Components—Cab Tractors with Mid-Mount SCV................1167

Selective Control Valve Components—Isolated Open Operator Station Tractors with Mid-Mount SCV................1169

Selective Control Valve Components—Straddle Mount Tractors with Mid-Mount SCV (S.N. 420001— )................1171

Group 10: Theory of Operation................1147

Theory of Operation Information................1174

Hydraulic System Operation—Straddle Mount Tractors (S.N. —420000)................1175

Hydraulic System Operation—Straddle Mount Tractors (S.N. 420001— )................1178

Hydraulic System Operation—Isolated Open Operator Station and Cab Tractors................1181

Hydraulic Filter Operation................1184

Hydraulic Pump Operation................1186

Rockshaft Control Valve Operation—Two Flow Regulator Valves (Early Model Straddle Mount)................1188

Rockshaft Control Valve Operation—Neutral Position (Early Model Straddle Mount)................1190

Rockshaft Control Valve Operation—Raise Position (Early Model Straddle Mount)................1192

Rockshaft Control Valve Operation—Lower Position (Early Model Straddle Mount)................1194

Rockshaft Control Valve Operation—Neutral Position (Isolated Open Operator Station, Cab Tractors and Late Model Straddle Mount)................1196

Rockshaft Control Valve Operation—Raise Position (Isolated Open Operator Station, Cab Tractors and Late Model Straddle Mount)................1198

Rockshaft Control Valve Operation—Flow Control Operation (Isolated Open Operator Station, Cab Tractors and Late Model Cab Tractors)................1200

Rockshaft Control Valve Operation—Lower Position (Isolated Open Operator Station, Cab Tractors and Late Model Straddle Mount)................1202

Surge Relief Valve Operation................1204

Main Relief Valve Operation—Straddle Mount Tractors................1206

Main Relief Valve Operation—Isolated Open Operator Station and Cab Tractors................1208

Rate-of-Drop Valve Operation—Full Open (Straddle Mount)................1210

Rate-of-Drop Valve Operation—Full Open (Isolated Open Operator Station And Cab Tractors)................1212

Rate-of-Drop Valve Operation—Partially Open (Straddle Mount)................1214

Rate-of-Drop Valve Operation—Partially Open (Isolated Open Operator Station and Cab Tractors)................1216

Rate-of-Drop Valve Operation—Full Closed (Straddle Mount)................1218

Rate-of-Drop Valve Operation—Full Closed (Isolated Open Operator Station And Cab Tractors)................1220

Rockshaft Draft-Sensing Operation................1222

SCV Operation—Straddle Mount Tractors (Neutral Position)................1224

SCV Operation—Straddle Mount Tractors (Extend and Retract Positions)................1226

Float SCV Operation—Straddle Mount Tractors (Float Position)................1228

Regenerative SCV Operation—Straddle Mount Tractors (Regenerative Position)................1230

SCV Operation—Isolated Open Operator Station and Cab Tractors (Neutral Position)................1232

SCV Operation—Isolated Open Operator Station and Cab Tractors (Extend and Retract Positions)................1234

Float SCV Operation—Isolated Open Operator Station and Cab Tractors (Float Position)................1236

Regenerative SCV Operation—Isolated Open Operator Station and Cab Tractors (Regenerative Position)................1238

Quick Disconnect Coupler Operation (Straddle Mount)................1240

Quick Disconnect Coupler Operation (Cab and IOOS)................1242

Group 15: Diagnosis................1148

Diagnostic Information................1245

Preliminary Hydraulic System Inspection................1246

Hydraulic Oil Warm-Up Procedure................1247

Entire Hydraulic System Fails to Function/No Hydraulic Pump Output................1248

Insufficient Pump Delivery................1249

Hydraulic Functions Too Slow................1250

Excessive Pump Pressure................1251

Slow Hydraulic Pump Response................1252

Excessive Pump Noise During Operation................1253

Rockshaft Does Not Lift or Lifts Slowly................1254

Rockshaft Does Not Lower or Lowers Slowly................1255

Neutral Position Unstable, Rockshaft Drops after Engine Shut Down................1256

Mid-Mount Joystick Does Not Return to Neutral Position—Mid-Mount SCV................1257

Mid-Mount Joystick Does Not Remain in Detent Position—Mid-Mount SCV................1258

Remote Cylinder Does Not Extend or Retract................1259

Remote Cylinder Settles Under Load................1260

Remote Cylinder Operates Too Fast or Too Slow................1261

Group 16: Hydraulic Tests—Without SCV................1149

Hydraulic System Tests—Without SCV (Straddle Mount Tractors)................1264

Hydraulic System Tests—Without SCV (Isolated Open Operator Station and Cab Tractors)................1266

Pump Flow Test—Without SCV................1268

Main Relief Valve Test—Without SCV (Straddle Mount Tractors)................1270

Main Relief Valve Test—Without SCV (Isolated Open Operator Station and Cab Tractors)................1272

Group 17: Hydraulic Tests—With SCV................1149

Hydraulic System Tests—With SCV (Straddle Mount Tractors) (S.N. —420000)................1276

Hydraulic System Tests—With SCV (Straddle Mount Tractors) (S.N. 420001— )................1278

Hydraulic System Tests—With SCV (Isolated Open Operator Station and Cab Tractors)................1280

Pump Flow Test—With SCV................1282

Main Relief Valve Test—With SCV................1285

SCV Leakage Test................1287

Group 18: Hydraulic Tests—All................1149

Rockshaft Leakage Test—Straddle Mount................1291

Rockshaft Leakage Test—Isolated Open Operator Station and Cab Tractors................1293

Rockshaft Lift Cycle Test................1295

Group 19: Adjustments................1149

Selective Control Valve (SCV) Cable Adjustment—Isolated Open Operator Station and Cab Tractors................1302

Rockshaft Draft-Sensing and Position Control Lever Cable Adjustment—Isolated Open Operator Station and Cab Tractors................1307

Rockshaft Lever Friction Adjustment................1308

Rockshaft Position-Sensing Feedback Linkage Adjustment................1309

Rockshaft Draft-Sensing Feedback Linkage Adjustment................1313

Main Relief Valve Adjustment—Straddle Mount Tractors................1315

Main Relief Valve Adjustment—Isolated Open Operator Station and Cab Tractors................1316

Group 20: Hydraulic Schematics................1150

Hydraulic Circuit Symbols................1319

Hydraulic Schematic—Straddle Mount Tractors (Without SCV) (S.N. —420000)................1321

Hydraulic Schematic—Straddle Mount Tractors (With SCV) (S.N. —420000)................1323

Hydraulic Schematic—Straddle Mount Tractors (With Mid-Mount Valve) (S.N. —420000)................1325

Hydraulic Schematic—Isolated Open Operator Station and Cab Tractors (Without SCV) (S.N. —420000)................1327

Hydraulic Schematic—Isolated Open Operator Station and Cab Tractors (With SCV) (S.N. —420000)................1329

Hydraulic Schematic—Isolated Open Operator Station and Cab Tractors (With Mid-Mount Valve) (S.N. —420000)................1331

Hydraulic Schematic—Straddle Mount Tractors (Without SCV) (S.N. 420001— )................1333

Hydraulic Schematic—Straddle Mount Tractors (With SCV) (S.N. 420001— )................1335

Hydraulic Schematic—Straddle Mount Tractors (With Mid-Mount Valve) (S.N. 420001— )................1337

Hydraulic Schematic—Isolated Open Operator Station and Cab Tractors (Without SCV) (S.N. 420001— )................1339

Hydraulic Schematic—Isolated Open Operator Station and Cab Tractors (With SCV and Mid Mount) (S.N.420001— )................1341

Hydraulic Schematic—Isolated Open Operator Station and Cab Tractors (With Mid-Mount Valve) (S.N. 420001— )................1343

Hydraulic Schematic—Isolated Open Operator Station and Cab Tractors (With Triple Rear SCV, Mid Mount, Power Beyond Coupler and Power Beyond Flow Control)................1345

Section 290: Operator Station................1347

Group 05: Component Location................1347

Air Conditioning System Components (S.N. —420000)................1350

Air Conditioning System Components (S.N. 420001— )................1352

Group 10: Theory of Operation................1347

Refrigerant R134a................1355

Air Conditioning System Air Flow................1356

Air Conditioning System Cycle................1358

Compressor................1360

Condenser................1361

Receiver-Dryer................1362

Expansion Valve................1363

A/C Temperature Control Switch................1364

Evaporator................1365

A/C ON/OFF Switch and Temperature Control Knob................1366

Heater Temperature Control Knob................1367

High and Low Pressure Switches (S.N. —420000)................1368

High/Low Pressure Switch (S.N. 420001— )................1369

Group 15: Diagnosis, Tests, and Adjustments................1396

Diagnosis, Tests, and Adjustments................1396

Adjust Heater Temperature Control Cable................1422

Adjust A/C Temperature Control Switch................1424

Section 299: Dealer Fabricated Tools................1426

Group 00: Dealer Fabricated Tools................1426

DFLV1A Final Drive Turning Tool................1428

DFRW20—Compressor Holding Fixture................1429

John Deere Tractors 5220, 5320, 5420 & 5520 Diagnosis and Tests Service Technical Manual (TM2049)