Iveco EuroTrakker & Trakker Trucks Repair & Service Manual

Catalog:

Model:

Complete service repair manual for Iveco EuroTrakker & Trakker Trucks, with all the shop information to maintain, diagnose, repair, and rebuild like professional mechanics.

Iveco EuroTrakker & Trakker Trucks workshop service & repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

03.43.461 - Iveco EuroTrakker Cursor 8 (18-72T) REPAIR MANUAL_MECHANICAL_ELECTRIC_ELECTRONIC ('93-'04 ).pdf

03.43.811 - Iveco EuroTrakker Cursor 13 (18-72T) REPAIR MANUAL_MECHANICAL_ELECTRIC_ELECTRONIC ('93-'04).pdf

03.93.121 - Iveco EuroTrakker_EuroTech_EuroStar Cursor 8-10-13 REPAIR MANUAL_ELECTRIC_ELECTRONIC_SYSTEM.pdf

03.93.641 - Iveco Trakker Euro 4-5 (18-72T) REPAIR MANUAL_MECHANICAL_ELECTRIC_ELECTRONIC ('04-'13).pdf

03.93.641 - Iveco Trakker Euro 4-5 ELECTRIC_ELECTRONIC SYSTEM.pdf

PTO GUIDE FOR DEEC 2_2008_EN.pdf

TABLE OF CONTENTS

General 1

Engines 2

Clutch 3

Gearboxes 4

Power take-off 5

Transfer box TC 1800-TC 2200 6

Propeller shafts 7

Axles 8

Front axles 9

Suspensions 10

Wheels and tyres 11

Steering 12

Pneumatic system - Brakes 13

Bodywork and Chassis frame 14

Programmed maintenance 15

Electric/electronic system 16

PRODUCT DETAILS:

Total Pages: 4,021 pages

File Format: PDF

Language: English

603.43.461 - Iveco EuroTrakker Cursor 8 (18-72T) REPAIR MANUAL_MECHANICAL_ELECTRIC_ELECTRONIC ('93-'04 )...2

EUROTRAKKER CURSOR...2

REPAIR MANUAL...2

NOTE...4

Graphs and symbols...5

INDEX...6

SECTION 1 - General...7

General...7

GENERAL...9

COMPOSITION OF THE MODELS...9

P.I.C. CODE NUMBERS...14

VEHICLE IDENTIFICATION DATA...20

FILLING UP...21

International designations of lubricants and fluids...22

SECTION 2 - Engine...23

Engine...23

VIEWS OF THE ENGINE...28

TECHNICAL DESIGNATION...31

GENERAL CHARACTERISTICS...37

ASSEMBLY CLEARANCE DATA...40

FAULT DIAGNOSIS...46

DESCRIPTION...46

DIAGNOSTIC INSTRUMENTS...46

CONTROL UNIT TEST...47

ENGINE TEST...47

AUXILIARY FUNCTIONS...47

TIGHTENING TORQUES (PROVISIONAL)...51

TOOLS...55

ENGINE REMOVAL - REFITTING...65

Removal...65

Refitting the engine...66

DISMANTLING THE ENGINE ON THE BENCH...69

REPAIR OPERATIONS...75

CYLINDER BLOCK...75

Checks and measurements...75

CYLINDER LINERS...76

Replacing cylinder liners...77

Removal...77

Fitting and checking protrusion...77

CRANKSHAFT...78

Measuring main journals and crank pins...79

SELECTING THE MAIN HALF-BEARINGS AND BIG END HALF-BEARINGS...81

DETERMINATION OF PRELIMINARY DATA FOR SELECTION...82

Replacing the timing control gear and the oil pump...91

Checking main journal installation clearance...91

Checking crankshaft end float...93

PISTON-CONNECTING ROD ASSEMBLY...94

Removal...94

Measuring the diameter of the pistons...95

Conditions for correct gudgeon pin-piston coupling...95

Piston rings...96

CONNECTING ROD...97

Checking connecting rod alignment...98

Mounting the connecting rod - piston assembly...98

Mounting the piston rings...98

Fitting the connecting rod-piston assembly into the piston liners...99

Piston protrusion check...99

Checking assembly clearance of big end pins...100

CYLINDER HEAD...100

Taking down the valves...100

Checking the planarity on cylinder head...100

VALVE...100

Removing deposits and checking the valves...100

VALVE GUIDES...101

Replacing of valve guides...102

Replacing - Reaming the valve seats...102

REPLACING INJECTOR HOLDER CASES...102

Removal...102

Checking protrusion of injectors...104

TIMING GEAR...105

Checking cam lift and pin alignment...105

Camshaft...106

Bushes...106

Replacing camshaft bushes using beater 99360487...107

VALVE SPRINGS...108

Fitting the valves and oil seal ring...108

ROCKER SHAFT...109

ROCKERS...109

LUBRICATION...110

Oil pump...110

Overpressure valve...110

Oil pressure control valve...113

Heat exchanger...113

By-pass valve...114

Thermostatic valve...114

Engine oil filters...114

COOLING...115

Water pump...115

Thermostat...115

TURBOCHARGING...119

Turbocharger HOLSET HX40V...121

Actuator adjustment...122

VGT control solenoid valve...122

Turbocharger HOLSET HY40V...127

Actuator...130

Working principle...130

Solenoid valve for VGT control...130

FUEL FEED...131

Fuel pump...132

Injector-pump...132

Pumping element...132

Nozzle...132

Solenoid valve...132

Replacing injectors-pump...132

Injector Phases...133

Filling phase...133

Injection phase...134

Pressure Reduction phase...134

ASSEMBLING THE ENGINE ON THE BENCH...135

DIAGRAM SHOWING THE UNDERBLOCK FIXING SCREWS TIGHTENING ORDER...137

Fitting the connecting rod-piston assembly into the cylinder liners...138

ENGINE FLYWHEEL...141

Replacing the toothed crown of the engine flywheel...141

Fitting engine flywheel...141

Fitting camshaft...142

Fitting pump-injectors...143

Fitting rocker-arm shaft assembly...143

Camshaft timing...144

Phonic wheel timing...146

Intake and exhaust rocker play adjustment and pre-loading of rockers controlling pump injectors...147

ENGINE COMPLETION...148

SECTION 3 - Clutch...149

Clutch...149

DESCRIPTION...151

Clutch...151

SPECIFICATIONS AND DATA...151

DIAGNOSTICS...153

TIGHTENING TORQUES...156

REMOVAL AND REFITTING...157

Removal...157

Refitting...157

REMOVING-REFITTING THE THRUST BEARING...157

REPLACING CLUTCH SHAFT SUPPORT BEARING ...157

CHECKS...158

CLUTCH DISENGAGEMENT CONTROL...159

REMOVING-REFITTING THE PEDAL ASSY ...159

Removal...159

Refitting...159

STRIP-DOWN AND REASSEMBLY...160

CHECKING AND ADJUSTING CLUTCH PEDAL STOPS (excluded vehicles with EuroTronic gearbox)...162

Clutch stop...162

Clutch pedal idle stroke...162

Pedal timing gear stroke...162

HYDRAULIC CONTROL vehicles with gearboxes: 2895.9-ZF 9/16 S 109-ZF 16 S 151...163

CLUTCH ACTUATOR FOR ZF 16 S 151 GEARBOXES...164

Refitting and adjusting thewear clutch indicator...164

Push rod adjustment (new clutch)...165

CLUTCH ACTUATOR FOR EUROTRONIC AUTOMATED GEARBOX...166

Clutch actuator push rod adjustment (new clutch)...166

Fitting the clutch actuator...166

Replacing the clutch actuator...166

SECTION 4 - Gearboxes...167

Gearboxes...167

Gearbox 2895.9...170

DESCRIPTION...172

Gearbox...172

CHARACTERISTICS AND DATA...173

FAULT DIAGNOSIS...174

TIGHTENING TORQUES...176

TOOLS...177

DISMANTLING TRANSMISSION...184

CHECKS...187

ASSEMBLING THE TRANSMISSION...188

ADJUSTING SECONDARY SHAFT BEARING PRELOAD...188

DISMANTLING PRIMARY SHAFT...193

FITTING THE PRIMARY SHAFT...195

TAKING DOWN THE INPUT SHAFT...195

ASSEMBLING INPUT SHAFT...196

SECONDARY SHAFT...196

Replacing the bearings...196

DISMANTLING INTERNAL GEAR CHANGE SHAFT...196

ASSEMBLING INTERNAL GEAR CHANGE SHAFT...197

DISMANTLINGEXTERNALGEARCHANGE CASING...197

Assembly...198

EPICYCLIC REDUCTION GEAR UNIT...200

DISMANTLING...202

CHECKS...206

INSTALLATION...207

Gearbox ZF 9 S 109...213

GENERAL SPECIFICATIONS...215

Description of gearbox 9 S 109...215

SPECIFICATIONS AND DATA...217

DIAGNOSTICS...220

TIGHTENING TORQUE...223

EQUIPMENT...224

REMOVAL...227

Removing the E.R.U.box...227

Reassembling the E.R.U.box...227

DISASSEMBLING THE E.R.U. BOX...228

DISASSEMBLING THE E.R.U...228

CHECKS...230

ASSEMBLING THE E.R.U...232

ASSEMBLING THE E.R.U. BOX...233

ADJUSTING THE AXIAL BACKLASH OF THE REAR BEARING...233

DISASSEMBLING THE GEARBOX...235

REMOVING THE INPUT SHAFT...238

REMOVING THE MAIN SHAFT...238

REMOVING THE TRANSMISSION SHAFT...241

REMOVING THE GEARCHANGE CASE OF GEARBOX...241

OIL PUMP...243

CHECKS...244

ASSEMBLING THE GEARCHANGE CASE...244

ASSEMBLING THE TRANSMISSION SHAFT...246

ASSEMBLING THE INPUT SHAFT...249

ASSEMBLING THE GEARBOX...249

ADJUSTING THE TRANSMISSION SHAFT BEARINGS...251

Adjusting the main shaft bearings...252

Gearbox ZF 16 S 109...256

DESCRIPTION...258

CHARACTERISTICS AND DATA...260

FAULT DIAGNOSIS...263

TIGHTENING TORQUES...266

TOOLS...267

DISMANTLING...270

Removing E.R.U. case...270

Refitting E.R.U. case...270

Dismantling E.R.U. case...271

Dismantling E.R.U...271

CHECKS...273

Assembling E.R.U. case...276

Dismantling transmission case...278

Dismantling the input shaft...281

Assembling the drive input shaft...281

Dismantling the main shaft...282

CHECKS...283

Assembling the main shaft...284

Dismantling the countershaft...287

Taking down the gear change control case...287

OIL PUMP...289

CHECKS...290

Assembling gear change control case...290

Assembling the countershaft...292

Assembling transmission case...292

Adjusting the countershaft bearings...294

Adjusting the main shaft bearings...295

Gearbox ZF 16 S 151...299

DESCRIPTION...301

OPERATION...303

CHARACTERISTICS AND DATA...307

FAULT DIAGNOSIS...311

TIGHTENING TORQUES...314

TOOLS...315

REMOVING-FITTING THE ZF GEAR CHANGE...320

Removal...320

Reassembly...321

DISMANTLING...322

Removing Epicyclic Reduction Unit (E.R.U.) assembly...322

Taking down the transmission case...323

Dismantling countershaft...326

Dismantling main shaft and drive input shaft...326

Dismantling Epicyclic Reduction Unit (E.R.U.)...330

CHECKS AND INSPECTIONS...334

Cleanliness and inspection of bearings...334

Refitting...336

Assembling Epicyclic Reduction Unit (E.R.U.)...338

Assembling main shaft and input shaft...341

Assembling the countershaft...344

Assembling the transmission case...344

Refitting Epicyclic Reduction Unit (E.R.U.)...347

Gearbox EUROTRONIC...350

INTRODUCTION...352

CHARACTERISTICS AND DATA...354

TIGHTENING TORQUE...357

EQUIPMENT...358

MECHANICAL FAULTS DIAGNOSIS...364

REPAIRS...367

Removal of front box removal...367

Removal of central box...368

Removal of rear box and epicyclic reduction unit...370

Installation of rear box and epicyclic reduction unit...372

Axial clearance regulation on epicyclic reduction gear bearing...372

Removal of primary shaft...376

Primary shaft installation...377

Removal of Splitter synchroniser...379

Installation of Splitter synchroniser...379

Forks installation-disinstallation...379

Secondary shafts...379

Central box installation...380

Shafts timing...382

Disinstallation of movement input shaft...383

Installation of movement input shaft...384

Installation of front box...384

Disinstallation of front cover...385

Installation of front cover...385

Regulation of axial clearance on movement input shaft bearing...386

Regulation of axial clearance on secondary shaft bearings...386

EUROTRONIC IT (INTARDER)...390

CHARACTERISTICS AND DATA...390

REPAIRS...391

Disinstallation of rear box...391

Rear box installation...392

Regulation of axial clearance on epicyclic reduction gear bearing...392

Regulation of axial clearance on stator...393

CLUTCH ACTUATOR...394

Description...394

CHARACTERISTICS AND DATA...394

SAFETY RULES...395

Disinstallation...396

Installation...398

Operating checks...399

Measure of piston stroke...399

Gearbox EuroTronic 12 AS 2301 D.D...401

DESCRIPTION...403

SPECIFICATIONS AND DATA...404

TIGHTENING TORQUES...407

TOOLS...408

OVERHAULING THE GEARBOX...413

Checks...413

Gearbox actuator...413

Removal...413

Refitting...414

Removing the rear box...414

Removing the rear box...415

Removing the epicyclic reduction gear train (E.R.G.)...416

Fitting the epicyclic reduction gear train (E.R.G.)...418

Adjusting epicyclic reduction gear train bearing end float...419

Adjusting main shaft end float...420

Synchronizing device assembly for engaging normal or reduced gears...422

Removal...422

Removing the middle box...425

Removing the main shaft...427

Removing the drive input shaft...429

Removing the splitter synchronizing device...430

Fitting the splitter synchronizing device ...431

Fitting the main shaft...432

Fitting the drive input shaft...432

Splitter control fork...435

Disassembly - Assembly...435

Gear control forks...435

Removal...435

Fitting...436

Transmission shafts...437

Disassembly - Assembly...437

Fitting the middle box...437

Fitting the front box...440

Front cover...442

Removal...442

Fitting the front cover...442

Adjusting drive input shaft bearing end float...442

Adjusting transmission shaft bearing end float...443

Clutch release lever...445

Gearbox EuroTronic 12 AS 2301 D.D. with Intarder (IT)...448

SPECIFICATIONS AND DATA...450

OVERHAULING THE GEARBOX...451

Removing the hydraulic retarder...451

Refitting the hydraulic retarder...452

Adjusting epicyclic reduction gear train bearing end float...452

Adjusting stator end float...453

Removing the rear box...454

Removing the E.R.G...455

Fitting the E.R.G...456

EXPERIMENTAL TOOLS...461

Epicyclic reduction gear unit TC 700...463

DESCRIPTION...465

SPECIFICATIONS AND DATA...465

REDUCTION GEAR UNIT OPERATION...467

On road...467

Off road...468

Motion transmission diagram: on road...469

Motion transmission diagram: off road...470

TIGHTENING TORQUES...471

EQUIPMENT...472

REMOVING AND REFITTING THE REDUCTION GEAR UNIT...474

Removal...474

Refitting...474

DISASSEMBLING THE REDUCTION GEAR UNIT AT THE BENCH...475

DISASSEMBLING THE INPUT SHAFT (Operation to be performed under hydraulic press)...476

DISASSEMBLING THE COUNTERSHAFT...477

DISASSEMBLING THE EPICYCLIC REDUCTION GEAR UNIT...477

CLEAN OUT AND CHECKS...478

REPLACING THE SEALING RINGS ON DRIVING AND INPUT SHAFT COVERS...478

REFITTING THE COUNTERSHAFT...480

REFITTING THE EPICYCLIC REDUCTION GEAR UNIT (Differential)...480

SHAFT BEARINGS PRELOAD ADJUSTMENT...482

DRIVING SHAFT...482

Indicator switch adjustment...483

Pulse transmitter adjustment...484

Transfer case TC 1800...486

DESCRIPTION...488

SPECIFICATIONS AND DATA...488

TRANSFER CASE OPERATION...490

On-road...490

Off road...491

Transmission of motion pictorial diagram: on-road...492

Transmission of motion pictorial diagram: off-road...493

TIGHTENING TORQUE...494

EQUIPMENT...495

TRANSFER CASE REMOVALRE- FITTING IN PLACE...498

Removal...498

Re-fitting in place...498

DISMANTLING THE TRANSFER CASE AT THE BENCH...498

DISMANTLING THE INPUT SHAFT...500

DISMANTLING THE COUNTERSHAFT...501

DISMANTLING THE EPICYCLIC TRANSFER CASE...501

REPLACING THE SEAL RINGS ON THE DRIVING SHAFT COVERS...502

CLEAN OUT AND CHECK...502

FITTING IN PLACE THE INPUT SHAFT...502

FITTING IN PLACE THE COUNTERSHAFT...503

FITTING IN PLACE THE EPICYCLIC TRANSFER CASE...503

ASSEMBLING THE TRASFER CASE AT THE BENCH...504

ADJUSTING SHAFT BEARING PRELOADING...506

Prod switch adjustment...508

Pulse sender adjustment...508

Power take off...511

Power take off HYDROCAR...514

POWER TAKE OFF HYDROCAR...516

SPECIFICATIONS AND DATA...516

TIGHTENING TORQUES...518

Power take off ZF...521

POWER TAKE OFF ZF...523

SPECIFICATIONS AND DATA...523

TIGHTENING TORQUES...525

Power take off (Optional 2395)...528

DESCRIPTION...530

FEATURES AND DATA...531

TIGHTENING TORQUE...532

EQUIPMENT...533

Operation (power take off disengaged)...537

REMOVING - REFITTING TOTAL POWER TAKE-OFF ASSEMBLY...539

Removal...539

Refitting...539

OVERHAULING...540

Removing main box...540

Removing drive assembly...540

Removing bearing for shaft with gear wheel...540

Removing oil pump...541

Cleaning and checking parts...542

Fitting bearing for shaft with gear wheel...543

Fitting drive assembly...543

Adjusting drive output shaft tapered bearings...545

Adjusting ball bearing...546

SECTION 5 - Intarder - ZF hydraulic retarder...548

Intarder - ZF hydraulic retarder...548

LOCATION OF INTARDER HYDRAULIC RETARDER DESCRIPTION PLATE...550

GENERAL INFORMATION...551

OPERATION...551

Retarder engaged...552

Retarder disengaged...553

LAYOUT OF MAIN SYSTEM COMPONENTS ON THE RETARDER...554

REMOVING AND REFITTING THE RETARDER ON THE ZF S 151-OD GEARBOX...555

Removal...555

Refitting...556

Filling with oil...556

SPECIFICATIONS AND DATA...557

TIGHTENING TORQUES...558

TOOLS...559

FAULT DIAGNOSIS...561

OVERHAULING THE INTARDER HYDRAULIC RETARDER...565

Hydraulic accumulator...565

Removal...565

Fitting...565

Removing hydraulic retarder...565

Checking the component parts of the hydraulic retarder...570

Fitting the hydraulic retarder...571

Stator end float adjustment...576

SECTION 6 - Propeller shafts...578

Propeller shafts...578

SPECIFICATIONS AND DATA...580

DIAGNOSTIC...585

TIGHTENING TORQUES...587

EQUIPMENT...587

REMOVING AND RE-FITTING IN PLACE THE PROPELLER SHAFT...588

REPAIR OPERATIONS...588

REMOVING THE UNIVERSAL JOINT...588

FITTING IN PLACE THE UNIVERSAL JOINT...588

CHECKING THE PROPELLER SHAFTS ON THE VEHICLE...589

SECTION 7 - Axles...590

Axles...590

AXLES...592

DIAGNOSTIC...594

REMOVING - RE-FITTING IN PLACE THE FRONT DRIVE AXLE (4x4 - 6x6 Vehicles)...596

Removal...596

Re-fitting in place...597

REMOVING REAR AXLES (4x2 - 4x4 Vehicles)...598

REMOVING THE REAR AXLE 6x4 - 6x6 - 8x4x4 Vehicles...600

REMOVING THE INTERMEDIATE AXLE 6x4 - 6x6 - 8x4x4 Vehicles...601

Instructions to adjust and check the functioning of the transmitter that controls the engagement of differential and reduction gear unit locking...602

REFITTING IN PLACE THE AXLE - Vehicles : all versions...602

Front drive axleD 1385 (5985) D 8185 (5985/2D)...605

DESCRIPTION...607

SPECIFICATIONS AND DATA...609

TIGHTENING TORQUE...611

EQUIPMENT...615

REPAIRING THE AXLE ANDWHEEL HUBS...620

Removal...620

Removing the fork support...627

Removing the stub axle...627

Removing the epicyclic reduction gear...628

CLEAN-OUT AND CHECKS...629

CHECKING THE AXLE CASING CAMBER ANGLE AND CASTER ANGLE...629

Fitting in place the fork support...632

Fitting in place the stub axle...633

Fitting in place the epicyclic reduction gear support...638

GREASING THE STUB AXLE PINS...639

EPICYCLIC UNITS LUBRICATION...639

REMOVING THE DIFFERENTIAL (with axle on stand 99322215)...640

Axle casing check...640

RE-FITTING IN PLACE THE DIFFERENTIAL (with axle on stand 99322215)...640

REPAIRING THE DIFFERENTIAL...642

Removal...642

REMOVING THE BEVEL PINION SUPPORT...644

REMOVING THE GEAR HOUSING...644

CHECKING THE DIFFERENTIAL COMPONENTS...644

FITTING IN PLACE THE GEAR HOUSING...645

FITTING IN PLACE THE BEVEL PINION SUPPORT...646

FITTING IN PLACE THE DIFFERENTIAL HOUSING...648

Adjusting the gear housing bearings rolling torque...649

Intermediate axles R 9274 (452191) R 9189 (453291) R 9274 (452191/2D) R 9189 (453291/2D)...654

DESCRIPTION...656

SPECIFICATIONS AND DATA...658

TIGHTENING TORQUES...659

EQUIPMENT...663

REMOVAL-RE-FITTING IN PLACE THE DIFFERENTIAL-REDUCTION GEAR UNIT (with axle on vehicle) ...671

Removal...671

Re-fitting...671

INTERMEDIATE AXLE ASSEMBLY REPAIR OPERATIONS...673

Removal...673

Dis-assembling the epicyclic reduction unit...673

Removing the wheel hubs...674

CHECKS ON THEWHEEL HUBS AND EPICYCLIC REDUCTION GEAR COMPONENTS...676

Fitting in place the wheel hubs...676

Fitting in place the epicyclic reduction unit...679

REMOVAL-RE-FITTING IN PLACE OF THE DIFFERENTIALREDUCTION GEAR UNIT (with axle on stand 99322215)...681

Removal...681

Refitting in place...681

DIFFERENTIAL-REDUCTION GEAR UNIT REPAIR OPERATIONS ...682

Removal...682

Removing the gear housing...687

Removing the differential-reduction gear unit...689

CHECKS ON DIFFERENTIAL-REDUCTION GEAR UNIT COMPONENTS...690

FITTING IN PLACE THE BEVEL PINION HOUSING...693

Procedure to determine the adjusting ring thickness for the bevel pinion rolling torque...693

FITTING IN PLACE THE DIFFERENTIAL HOUSING...695

FITTING IN PLACE THE GEAR HOUSING...696

Adjusting gearing box bearing rolling torque...697

DRIVING SHAFT...701

Removal...701

Checks...702

Refitting in place...702

Intermediate axle R 9174 (452146) R 9174 (452146/2D)...705

DESCRIPTION...707

REPAIRS...707

SPECIFICATIONS AND DATA...709

TIGHTENING TORQUES...710

EQUIPMENT...714

DIFFERENTIAL - REDUCTION GEAR UNIT REPAIR OPERATIONS...722

Removing the bevel pinion support...724

Removing the gear housing...724

Removing the differential - reduction gear unit...725

DIFFERENTIAL - REDUCTION GEAR UNIT COMPONENTS CHECK...728

Assembling the differential - reduction gear unit...728

Assembling the gear housing...730

Assembling the bevel pinion support...731

Procedure to determine the adjusting ring thickness for the bevel pinion rolling torque...731

DIFFERENTIAL HOUSING ASSEMBLY...733

Adjusting the rolling torque for the gear housing bearings...735

Rear axles R 8284 (451391) R 8274 (452191) R 8298 (453291) R 8284 (451391/2D) R 8274 (452191/2D) R 8298 (453291/2D)...740

DESCRIPTION...742

SPECIFICATIONS AND DATA...745

TIGHTENING TORQUE...746

DRIVING TORQUES...747

EQUIPMENT...750

REAR AXLE ASSEMBLY OVERHAUL OPERATIONS...756

Removing the epicyclic reduction gear...756

Removing the wheel hubs...759

CHECKING WHEEL HUB AND EPICYCLIC REDUCTION GEARCOMPONENTS...760

FITTING IN PLACE THEWHEEL HUBS...760

Fitting in place the epicyclic reduction gear...763

REMOVAL AND RE-FITTING IN PLACE THE DIFFERENTIAL...766

RE-FITTING IN PLACE...767

REMOVING THE DIFFERENTIAL HOUSING...768

Removing the gear housing...769

REMOVING THE BEVEL PINION SUPPORT...770

DIFFERENTIAL COMPONENTS CHECK...772

FITTING IN PLACE THE GEAR HOUSING...773

FITTING IN PLACE THE BEVEL PINION SUPPORT...774

Procedure to determine the thickness of the bevel pinion rolling torque adjusting ring...774

FITTING IN PLACE THE DIFFERENTIAL HOUSING...776

Adjusting the rolling torque of the gear housing bearings...777

Rear axle R 8174 (452146) R 8174 (452146/2D)...783

DESCRIPTION...785

REPAIR OPERATIONS...785

SPECIFICATIONS AND DATA...787

TIGHTENING TORQUES...788

EQUIPMENT...792

DIFFERENTIAL REPAIR OPERATIONS...797

Removal...797

REMOVING THE GEAR HOUSING...798

REMOVING THE BEVEL PINION SUPPORT...799

DIFFERENTIAL COMPONENTS CHECK...799

FITTING IN PLACE THE GEAR HOUSING...800

FITTING IN PLACE THE BEVEL PINION SUPPORT...801

FITTING IN PLACE THE DIFFERENTIAL HOUSING...803

Adjusting the rolling torque of the gear housing bearings...804

Axles in Tandem Meritor SR 145 E/2D...807

Axles in tandem (Intermediate) Meritor RD 145 E (R 2478)...809

DESCRIPTION...811

SPECIFICATIONS AND DATA...811

TIGHTENING TORQUES...813

TOOLS...817

EXPERIMENTAL TOOLS...824

! SERVICING INTERMEDIATE AXLEASSEMBLYRD145E(R2478)...827

AIR BREATHER REMOVAL-REFITTING...827

SERVICINGWHEEL HUBS...827

Checking wheel hub components...828

ASSEMBLINGWHEEL HUBS...829

REMOVING DIFFERENTIAL GEAR — TRANSFER BOX(with rear axle on stand 99322215) ...832

REFITTING DIFFERENTIAL GEAR — TRANSFER BOX (with rear axle on stand 99322215)...832

REPAIRING INTER-AXLE UNIT...833

Dismantling inter-axle unit...833

Checking inter-axle unit components...835

Fitting inter-axle unit...835

Adjusting drive input shaft bearing end float...837

Adjusting differential lock and inter-axle control pin end-stop...837

REPAIRING MAIN DIFFERENTIAL - DISMANTLING DIFFERENTIAL CASING...838

Dismantling gear cage...841

Checking differential components...841

Assembling gear cage...842

ASSEMBLING DIFFERENTIAL CASING...843

Calculatingbevel pinion positionin differential casing...843

COMPUTATIONAL EXAMPLES...844

Adjusting the cap gap...847

CORRECTING THE CROWNWHEEL AND PINION CONTACTS (AFTER ASSEMBLY)...849

REMOVING-SERVICING-REFITTING INTER-AXLE OUTPUT SHAFT...852

Axles in tandem (Rear) Meritor RR 140 E (R 0878)...855

DESCRIPTION...857

SPECIFICATIONS AND DATA...857

TOOLS...861

SERVICING REAR AXLE ASSEMBLY RR 140 E (R 0878)...866

AIR BREATHER REMOVAL/ INSTALLATION...866

REMOVING DIFFERENTIAL (with axle on stand 99322215) ...866

REFITTING DIFFERENTIAL (with axle on stand 99322215)...866

REPAIRING DIFFERENTIAL...867

Removing differential lock...867

Dismantling differential casing...868

Dismantling gear cage...869

Dismantling bevel pinion support...869

Checking differential components...873

Assembling gear cage...873

Specimen calculations...875

Assembling differential casing...875

ADJUSTING THE CAP GAP...877

CORRECTING THE CROWNWHEEL AND PINION CONTACTS (AFTER ASSEMBLY)...880

Axles in Tandem Meritor RT 153 E/2D...883

Axles in Tandem (Intermediate) Meritor RP 153 E...885

DESCRIPTION...887

SPECIFICATIONS AND DATA...887

TIGHTENING TORQUES...889

TOOLS...893

EXPERIMENTAL TOOLS...900

SERVICING INTERMEDIATE AXLE ASSEMBLY RP 153 E...903

WHEEL HUB OVERHAULING...903

Removing...903

Checks on wheel hub components...904

Refitting...904

REMOVING DIFFERENTIAL ...908

REFITTING DIFFERENTIAL (axle on stand 99322215) ...908

REPAIRING INTER-AXLE UNIT...909

Dismantling inter-axle unit...909

Checking inter-axle unit components...911

Fitting inter-axle unit...911

Adjusting drive input shaft bearing end float...913

Adjusting differential lock and inter-axle control pin end-stop...913

REPAIRING MAIN DIFFERENTIAL - DISMANTLING DIFFERENTIAL CASING...914

Removing the gear housing...917

Checking the differential components...918

Refitting the gear housing...918

ASSEMBLING DIFFERENTIAL CASING...920

Calculating bevel pinion position in differential casing...920

EXAMPLES...920

ADJUSTING THE CAP ANGLE...923

CORRECTING THE BEVEL GEAR PAIR CONTACTS (AFTER FITTING IN PLACE)...926

REMOVING-SERVICING-REFITTING INTER-AXLE OUTPUT SHAFT...930

Axles in tandem (rear) MERITOR RR 167...933

DESCRIPTION...935

CHARACTERISTICS AND DATA...936

TIGHTENING TORQUES...937

TOOLS...938

REMOVING AND REFITTING THE DIFFERENTIAL (with axle on stand 99322215) ...944

Removal...944

Checking axle housing...944

Refitting...944

REPAIRING THE DIFFERENTIAL...945

Removing the differential...945

Removing the gearcase...946

REMOVING THE BEVEL PINION FROM THE SUPPORT...948

Differential component check...948

Fitting the gear housing...949

FITTING THE MOUNT ON THE BEVEL PINION...950

Reassembling the differential housing...952

ADJUSTING THE CAP GAP...954

CORRECTING THE CROWNWHEEL AND PINION CONTACTS (AFTER ASSEMBLY)...957

WORK ON THE VEHICLE...960

REPLACING THE BEVEL PINION MOUNT SEAL...960

Disassembly...960

Assembly...961

SECTION 8 - Axles...963

Axles...963

Axles 5886 (F9021) 5886/2D (F9021)...965

DESCRIPTION...967

Front axle...967

SPECIFICATIONS AND DATA...968

DIAGNOSTIC...970

TIGHTENING TORQUE...973

TOOL...975

REMOVING AND RE-FITTING THE AXLE...981

Removal...981

Refitting in place...982

VEHICLE CHECKS...983

Kingpins...983

Tie rods...983

TRACK ROD AND DRAG LINK KINGPINS SLACK CHECK...983

FRONT AXLE ASSEMBLY OVERHAUL...984

REMOVING AND RE -FITTING IN PL ACE THE WHEEL HUBS...984

Removal...984

Re-fitting in place the wheel hubs...986

Wheel hub bearings end play adjustment...986

Finding the rolling torque...986

WHEEL HUB BEARINGS REPLACEMENT...987

Wheel bolts replacement...988

REMOVAL AND RE-FITTING IN PLACE THE TRACK ROD...988

REPLACING TRANSVERSE TIE ROD SWIVEL HEADS...989

REMOVING AND REFITTING LEVERS FOR TRANSVERSE TIE ROD...989

REMOVING AND REFITTING LEVER FOR LONGITUDINAL TIE ROD...989

REMOVING AND REFITTING PIN FOR STUB AXLE...989

Removal...989

REMOVAL AND RE-FITTING IN PLACE THE DRAG LINK...990

Replacing kingpin bearing...990

Re-fitting...991

Stub axle-axle end play check and adjustment...992

AXLE BODY CHECKS AND MEASUREMENTS...992

Checking leaf spring supporting surface levelness with reference to kingpin holes using proper equipment...992

Kingpin holes camber angle check...994

Front axle 5886/D (F9021)...995

DESCRIPTION...997

Front axle 5886 / D...997

SPECIFICATIONS AND DATA...998

TIGHTENING TORQUES...1000

FRONT AXLE ASSEMBLY OVERHAUL...1001

REMOVING - REFITTINGWHEEL HUBS...1001

Removal...1001

Refitting wheel hubs...1002

Wheel geometry...1003

GENERAL INFORMATION...1005

Steering wheel angles...1005

FRONTWHEEL GEOMETRY (4X2 VEHICLES)...1006

Positioning clips and headlights...1006

Electronic compensation of rim eccentricity...1007

Wheel alignment...1007

Checking wheel toe-in...1008

Checking wheel deviation...1008

Checking camber...1008

Checking kingpin angle and caster...1009

Checking rear axle alignment...1010

WHEEL GEOMETRY OF VEHICLES WITH ADDED CENTRAL AXLE (8X4X4)...1010

Checking steering angles...1012

SECTION 9 - Suspensions...1013

Suspensions...1013

FRONT AND REAR SUSPENSIONS...1015

Description...1015

SPECIFICATIONS AND DATA FRONT SUSPENSIONS 4X2 - 6X4 - 6X6 - 4X4 MODELS...1025

FRONT SHOCK ABSORBERS...1030

REAR SHOCK ABSORBERS...1031

AIR SUSPENSION...1032

Chassis frame lifting, lowering and self-levelling with remote control ...1032

Saving Levels...1032

AIR SUSPENSION SYSTEM DIAGRAMS...1033

Rear air suspension main diagram for 4x4W/P vehicles...1033

Working diagram of pneumatic rear suspensions for 6x4 HB/P, 8x4 H/P, 8x4 HB/P vehicles...1034

CHARACTERISTICS AND DATA...1035

Pneumatic system...1035

MAIN COMPONENTS OF THE PNEUMATIC SYSTEM...1036

Relief valve...1036

Fault diagnosis...1036

Level sensor...1036

Electropneumatic distributor...1037

Air low pressure manometer switch...1037

Air spring...1037

Pneumatic rear suspension 4x4W/P vehicles...1038

Pneumatic rear suspension 8x4 H/P - HB/P vehicles...1039

FAULT DIAGNOSIS...1041

Diagnosis Instruments...1041

TIGHTENING TORQUE...1047

EQUIPMENT...1048

REMOVAL-REFITTING OF FRONT LEAF SPRING...1053

Removal...1053

Refitting...1053

REMOVAL-REFITTING OF INTERMEDIATE AXLE LEAF SPRING (8X4 VEHICLES)...1054

Removal...1054

Refitting...1054

REMOVAL-REFITTING OF REAR LEAF SPRING (4X2 - 4X4 vehicles)...1055

Removal...1055

Refitting...1055

REMOVAL-REFITTING OF REAR LEAF SPRING ON CANTILEVER TYPE SUSPENSIONS (6X4 - 6X6 - 8X4 vehicles)...1056

Removal...1056

Refitting...1056

Procedure for assembly of the slipper block and mounting brackets for the longitudinal bars...1057

Tightening theU-bolts clamping the leaf spring to the central pivot...1057

REAR CANTILEVER SUSPENSION (6x4 - 6x6 - 8x4 vehicles)...1058

Removal-refitting of central pivot...1058

Removal-refitting of central pivot shaft !...1058

Renewal of bearings...1058

Removal-refitting of hanger bracket...1058

Removal of the central pivot...1058

Removal of the central pivot shaft...1058

Removal of the hanger bracket...1058

Renewal of the bearings...1058

Refitting the hanger bracket...1059

Refitting the central pivot shaft...1060

Refitting the central pivot...1060

REMOVAL-REFITTING OF REAR AXLE LONGITUDINAL ARM...1062

REMOVAL-REFITTING OF INTERMEDIATE AXLE LONGITUDINAL ARM...1062

REMOVAL-REFITTING OF REAR AXLE TRIANGULAR ARM FOR VEHICLES WITH AIR SUSPENSION...1062

Removal...1062

Refitting...1062

REPLACEMENT OF THE FLEXIBLE PINS OF LONGITUDINAL/TRIANGULAR ARMS...1063

Disassembly...1063

Assembly...1063

SHOCK ABSORBERS...1064

Removal...1064

Refitting...1064

ANTI-ROLL BARS...1064

ANTI-ROLL BAR...1065

FRONT ANTI-ROLL BAR...1065

AUXILIARY AXLE ANTI-ROLL BAR (8X4 VEHICLES)...1065

REAR ANTI-ROLL BAR ...1065

INTERMEDIATE AXLE ANTI-ROLL BAR (6X4 - 6X6 - 8X4 VEHICLES)...1065

Removal...1065

Refitting...1065

SECTION 10 - Wheels and tyres...1069

Wheels and tyres...1069

DESCRIPTION...1071

CHARACTERISTICS AND DATA...1071

Tyre inflation pressure data...1071

TOOLS...1072

DIAGNOSTIC...1072

WHEEL STATIC BALANCING...1075

CORRECTING RESIDUAL STATIC UNBALANCE...1076

TYRE PRESSURE...1076

BEHAVIOUR OF TYRES DEPENDING ON INFLATION PRESSURE...1077

SECTION 11 - Steering gear...1079

Steering gear...1079

DESCRIPTION...1081

SPECIFICATIONS AND DATA...1082

DIAGNOSTIC...1083

TIGHTENING TORQUE...1088

EQUIPMENT...1089

Steering control diagram for 4x2 - 6x4 vehicles (ZF 8098 power steering)...1091

Steering control diagram for 4x4 - 6x6 vehicles (ZF 8098 power steering)...1092

Steering control diagram for 8x4x4 vehicles (ZF 8099/1 power steering)...1093

Steering hydraulic control circuit diagram for 8x4x4 vehicles (8099/1 power steering)...1095

HYDRAULIC GUIDE...1097

Mounting steering wheel lever...1097

REMOVING AND REFITTING IN PLACE THE STEERING CONTROL ASSEMBLY...1098

Removal...1098

Fitting in place...1099

MAIN OPERATIONS...1100

Bleeding the air from the power steering circuit...1100

Measuring plays in the steering box detected on the steering wheel ...1100

Checking the power steering system maximum pressure...1100

Adjusting the hydraulic steering limiting device...1100

Checking the steering hydraulic modulation device with the vehicle running...1102

Setting the automatic hydraulic steering limit...1102

Check...1102

SECTION 12 - Pneumatic system - Brakes...1103

Pneumatic system - Brakes...1103

SYMBOLS FOR AIR/HYDRAULIC SYSTEM CIRCUIT DIAGRAMS (MISCELLANEOUS AND GENERATORS)...1106

SYMBOLS FOR AIR/HYDRAULIC SYSTEM CIRCUIT DIAGRAMS (VALVES)...1107

SYMBOLS FOR AIR/HYDRAULIC SYSTEM CIRCUIT DIAGRAMS (TANKS AND ACCUMULATORS)...1113

SYMBOLS FOR AIR/HYDRAULIC SYSTEM CIRCUIT DIAGRAMS (CALIPERS AND CYLINDERS)...1114

SYMBOLS FOR AIR/HYDRAULIC SYSTEM CIRCUIT DIAGRAMS (HALF-JOINTS AND COUPLING HEADS)...1116

SYMBOLS FOR AIR/HYDRAULIC SYSTEM CIRCUIT DIAGRAMS (INDICATORS AND SWITCHES)...1118

SYMBOLS FOR AIR/HYDRAULIC SYSTEM CIRCUIT DIAGRAMS (BRAKES)...1119

PIPES AND COUPLINGS...1120

General...1120

End forming on rigid pipes...1120

Bending rigid pipes...1121

Cutting rigid pipes...1121

Replacing flexible hoses with threaded couplings ...1122

Replacing flexible hoses with quick-connection couplings...1123

BRAKING SYSTEM...1125

Wiring diagram for 4x2 - 4x4 vehicles...1125

6x4 vehicles wiring diagram (the tractor version)...1126

6x4 vehicles wiring diagram (only outside Europe)...1127

6x6 vehicles wiring diagram...1128

8x4x4 vehicles wiring diagram...1129

ABS system wiring diagram (for 4x2 - 4x4 vehicles)...1130

ABS - ASR system wiring diagram (for 4x2 - 4x4 vehicles)...1131

ABS system wiring diagram (for 6x4 - 6x6 vehicles)...1132

ABS - ASR system wiring diagram (for 6x4 - 6x6 vehicles)...1133

ABS system wiring diagram (for 8x4x4 vehicles)...1134

ABS - ASR system wiring diagram (for 8x4x4 vehicles)...1135

Working diagram for 4x2 - 4x4 vehicles designed for towing with EBL device...1136

Working diagram for 6x4 vehicles isolated with an EBL device...1137

Working diagram for 6x4 - 6x6 vehicles designed for towing with EBL device...1138

Working diagram for 8x4x4 vehicles isolated with an EBL device...1139

Working diagram for 8x4x4 vehicles designed for towing with EBL device...1140

BRAKING SYSTEM...1141

Working diagram for 4x2 - 4x4 vehicles designed for towing with ABS-ASR device (without braking corrector)...1141

Working diagram for 6x4 - 6x6 vehicles designed for towing with ABS-ASR device (without braking corrector)...1142

Working diagram for isolated 6x4 vehicles with ABS-ASR device (without braking corrector)...1143

Working diagram for isolated 8x4x4 vehicles with ABS-ASR device (without braking corrector)...1144

Working diagram for 8x4x4 vehicles designed for towing with ABS-ASR device (without braking corrector)...1145

Braking system main components layout on the vehicle...1146

ABS - ASR system main components layout on the vehicle...1147

DESCRIPTION...1148

Service braking...1148

Emergency braking...1148

Retarding braking...1148

Parking braking...1148

BRAKES...1148

Front disc brakes SB7 - SN7 type (for vehicles with partial traction)...1148

Drum brakes...1148

FAULT DIAGNOSIS...1149

Diagnosis Instruments...1149

ABS Troubleshooting...1151

TIGHTENING TORQUES...1169

TOOLS...1172

SPECIFICATIONS AND DATA - PNEUMATIC SYSTEM...1181

SPECIFICATIONS AND DATA - BRAKES...1186

BRAKING SYSTEM MAIN COMPONENTS CHECK...1193

BRAKING SYSTEM MAIN COMPONENTS...1196

Compressor...1196

Head fastening screws tightening torque...1196

Diagnostic...1196

Drier...1197

Diagnostic...1197

Four-way safety valve...1197

Diagnostic...1197

Duplex distributor...1198

Diagnostic...1198

Pressure reducer...1199

Diagnostic...1199

Setting at the bench...1199

Triple control servo distributor...1199

Diagnostic...1199

Predominance adjustment...1199

KNORR BREMSE AC 597B...1200

KNORR BREMSE AC 597B WABCO 973 009 013...1200

Diagnostic...1200

Coupling heads...1201

Check valve (towing vehicles)...1201

Parking brakes control hand distributor (for towing vehicles)...1201

Diagnostic...1201

Parking brakes control hand distributor (stand-alone vehicles)...1202

Diagnostic...1202

Relay valves...1203

Diagnostic...1203

Engine brake control pedal valve...1203

Diaphragm brake cylinder...1203

Combined brake cylinder...1204

Combined cylinder emergency relief device...1204

REPAIR OPERATIONS...1204

Diagnostic...1204

BRAKING CONTROL...1205

For 6x4 - 6x6 - 8x4x4 vehicles...1206

Diagnostic...1207

ANTI-SKID SYSTEM...1207

ABS (Anti-Lock Brake System)...1207

ASR (Anti-Slip Regulator) system...1207

EBL (Electronic Brakes Limiter)...1207

Electronic control unit...1208

Brake anti-lock distributor...1208

Electropneumatic valve for ASR...1208

Rpm sensors...1208

Phonic wheels...1208

BRAKE REPAIRS...1209

FRONT DISC BRAKES SB7 TYPE (VEHICLESWITH PARTIAL TRACTION)...1209

DISC BRAKES SN7 TYPE...1210

Brakes SB7 type operation...1211

CHECKS...1211

Efficiency of automatic clearance recovery...1211

Brake lining thickness...1212

Replacing brake linings...1213

Removing and refitting SB7 brake callipers...1215

Removal...1215

Refitting...1215

Removing and refitting wheel hubs...1216

Removal...1216

Refitting...1216

OVERHAULING SB7 BRAKECAL - LIPERS...1217

Cleaning and checking component parts...1218

Assembly...1218

OVERHAULING BRAKE DISCS...1219

TURNING AND GRINDING BRAKE DISCS ON THE BENCH ...1220

TURNING AND GRINDING BRAKE DISCS ON THE VEHICLE...1220

DRUM BRAKES...1221

FRONT BRAKES...1222

REAR BRAKES...1222

Disassembly...1222

Drum turning...1227

Replacing brake linings...1227

Turning brake linings...1228

Assembly...1228

SECTION 13 - Body work - Chassis...1235

Body work - Chassis...1235

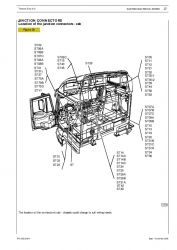

CAB...1237

Specifications...1237

TIGHTENING TORQUE...1237

EQUIPMENT...1237

ANCHORAGE CAB...1238

REPAIR OPERATIONS...1240

REPLACING CAB SUSPENSION FRONT AND REAR SHOCK ABSORBERS ...1240

REMOVING AND RE-FITTING INPLACE THEFRONTSUPPORTS AND CAB STABILIZER BARS...1240

REPLACING THE CAB TIPPING HYDRAULIC CYLINDER...1241

REPLACING THEWINDSCREEN...1241

REPLACING LOWERABLE DOOR WINDOWS...1242

REPLACING THEWINDOW CLOSING DEVICE...1243

REPLACINGTHEFIXEDWINDOW...1243

Replacing the roof air vent hatch...1245

CAB HEATING AND VENTILATION UNIT...1245

CHASSIS...1246

REPAIR OPERATIONS...1246

CHECKS...1246

Finding chassis bending up and down...1247

Finding chassis lateral bending...1247

Finding chassis displacement...1247

Finding chassis twist...1248

PRECAUTIONS...1248

Welds on the chassis...1250

SECTION 14 - Scheduled maintenance...1251

SCHEDULED MAINTENANCE...1253

Description...1253

Maintenance services specifications...1253

EXTRA PLAN OPERATIONS...1253

Maintenance servicing table (time intervals)...1257

CHECK AND/OR MAINTENANCE POINTS SCHEME...1259

603.43.811 - Iveco EuroTrakker Cursor 13 (18-72T) REPAIR MANUAL_MECHANICAL_ELECTRIC_ELECTRONIC ('93-'04)...1261

EUROTRAKKER CURSOR 13...1261

REPAIR MANUAL...1261

NOTE...1263

Graphics and Symbols...1264

CONTENTS OF SECTIONS...1265

SECTION 1 - General...1266

General...1266

VEHICLE IDENTIFICATION DATA...1268

Vehicle Identification Plate...1269

Production identification plate...1269

P.I.C. NUMBER CODING...1270

COMPOSITION OF MODELS...1274

REPLENISHING FLUIDS...1280

International lubricant and fluid names...1282

SECTION 2 - Engine...1284

Engine...1284

VIEWS OF THE ENGINE...1288

TECHNICAL DESCRIPTION...1291

CHARACTERISTIC CURVES...1292

GENERAL SPECIFICATIONS...1296

ASSEMBLY DATA - CLEARANCE...1299

FAULT DIAGNOSIS...1305

Blink Code...1305

Check procedures / troubleshooting...1305

Procedures to delete faultmemory fromdriving seat...1305

EDC MS 6.2 control unit blink code table...1306

FAULT DIAGNOSIS INSTRUMENTS...1307

MODUS - IT2000...1307

I.W.T...1308

TROUBLESHOOTING...1309

Introduction...1309

Troubleshooting with Blink Code...1310

Troubleshooting by symptoms...1318

TIGHTENING TORQUES...1325

DIAGRAMS OF TIGHTENING SEQUENCE OF MAIN ENGINE COMPONENTS...1328

TOOLS...1332

ENGINE REMOVAL-REFITTING...1342

Removal...1342

Refitting...1345

Filling the cooling system...1346

Bleeding air from the supply system...1347

Checks and tests...1347

STRIPPING THE ENGINE ON THE BENCH...1350

REPAIRS...1358

Cylinder block...1358

Checks and measurements...1358

Cylinder liners...1359

Replacing the cylinder liners...1360

Crankshaft...1361

Measuring the main journals and crankpins...1362

Selecting the main bearing and big end bearing shells...1363

Preliminary measurement of data to select main bearing and big end bearing shells...1364

Replacing the timing gear and oil pump...1371

Checking main journal assembly clearance...1371

Checking crankshaft end float...1372

Connecting rod piston assembly...1373

Piston rings...1375

Connecting rod...1376

Checking connecting rods...1377

Mounting the connecting rod - piston assembly...1377

Mounting the piston rings...1377

Fitting connecting rod piston assembly in the cylinder liners to check assembly clearances...1378

Checking assembly clearance of big end pins...1379

Cylinder head...1379

Removing valves...1379

Checking head bearing surface on cylinder block...1379

Valves...1379

Decarbonizing and checking valves...1379

Valve guides...1380

Replacing valve guides...1381

Replacing - Regrinding valve seats...1381

Replacing injector cases...1381

Checking injector protrusion...1383

Timing system...1384

Checking cam lift and pin alignment...1384

Camshaft...1385

Bushings...1385

Valve springs...1388

Rocker arm shaft...1389

Rocker arms...1389

ENGINE ASSEMBLY ON BENCH...1390

Fitting connecting rod piston assemblies in cylinder liners...1393

Fitting cylinder head...1394

Fitting flywheel box...1395

ENGINE FLYWHEEL...1396

Fitting engine flywheel...1396

Fitting camshaft...1397

Fitting pump-injectors...1398

Rocker arm holder shaft assembly...1398

Camshaft timing...1399

Phonic wheel timing...1401

Adjusting rocker armclearance, intake, exhaust and pre-load of pump injector governing rocker arms...1402

Completing assembly...1403

LUBRICATION...1405

Oil pump...1405

Overpressure valve...1405

Oil pressure control valve...1406

Heat exchanger...1406

By-pass valve...1407

Thermostatic valve...1407

Engine oil filters...1407

Lubrication circuit...1408

COOLING...1410

Water pump...1410

View of thermostat operation...1410

Cooling circuit...1412

TURBOCHARGING...1414

Turbocharger...1414

HOLSET HY55V (VGT Turbine)...1415

Actuator...1418

Working principle...1418

Solenoid valve for VGT control...1418

HOLSET HX 50W (Wastegate Turbine)...1420

Pressure relief valve...1420

FEEDING...1422

Fuel pump...1423

Injector-pump...1423

Replacing injectors-pump...1423

Injector Phases...1424

HYDROCAR PRESSURE TAKE-OFF ON TIMING SYSTEM - P.T.O. (OPTIONAL)...1426

Specifications and data...1427

Tightening torques...1428

Engaging power take-off...1429

Removing-refitting power take-off...1429

SECTION 3 - Clutch...1430

Clutch...1430

DESCRIPTION...1432

Clutch...1432

SPECIFICATIONS AND DATA...1432

FAULT DIAGNOSIS...1434

TIGHTENING TORQUES...1437

TOOLS...1437

REMOVING AND REFITTING THE CLUTCH...1438

Removal...1438

CHECKS...1438

Refitting...1439

REMOVING-REFITTING THE THRUST BEARING...1439

CLUTCH DISENGAGEMENT CONTROL (vehicles with ZF 16 S 151/181/221 O.D. gearboxes)...1440

REMOVING-REFITTING THE PEDAL UNIT...1440

Removal...1440

Refitting...1440

PEDAL UNIT...1441

REMOVAL-ASSEMBLY...1441

CHECKING AND ADJUSTING STOPS ON CLUTCH PEDAL (vehicles with ZF 16 S 151 O.D./181 O.D./221 O.D. gearboxes)...1442

Clutch stop...1442

Idle travel of clutch pedal...1442

Pedal control valve stroke...1442

HYDRAULIC CONTROL (vehicles with ZF 16 S 151 O.D./181 O.D./221 O.D. gearboxes)...1443

CLUTCH ACTUATOR FOR ZF 16 S 151 O.D./181 O.D./221 O.D. GEARBOXES...1444

Fitting and adjusting the clutch wear indicator...1444

Push rod adjustment (new clutch)...1445

Push rod adjustment (vehicles with PTO opt. 2395 only)...1445

BLEEDING THE AIR FROM THE CLUTCH CIRCUIT...1445

CLUTCH ACTUATOR FOR THE EUROTRONIC 16 A S 2601 O.D. GEARBOX...1446

Clutch actuator push rod adjustment (new clutch)...1446

Fitting the clutch actuator...1446

Replacing the clutch actuator...1446

SECTION 4 - Gearbox...1448

Gearbox...1448

Gearboxes ZF 16 S 151 O.D. - ZF 16 S 181 O.D. - ZF 16 S 221 O.D...1450

LOCATION OF GEARBOX DESCRIPTION PLATE...1452

DESCRIPTION...1453

GEARBOX AIR-OPERATED CONTROL...1455

OPERATION...1456

Slow range...1456

Fast range...1457

EPICYCLIC REDUCTION GEAR CONTROL...1458

Reduced speeds...1458

Normal speeds...1459

SPECIFICATIONS AND DATA...1460

TIGHTENING TORQUES...1464

TOOLS...1465

GEARBOX FAULT DIAGNOSIS...1470

REMOVING-REFITTING THE GEARBOX...1474

Removal...1474

Refitting...1475

OVERHAULING THE GEARBOX...1476

Servoshift gear box...1476

Removal...1476

Refitting...1476

Disassembly...1476

Assembly...1478

Removing the rear box...1482

Removing the epicyclic reduction gear unit (ERG)...1482

Fitting the epicyclic reduction gear unit (ERG)...1484

Refitting the epicyclic reduction gear unit (ERG) rear box ...1487

Removing the gearbox...1487

Removing the main shaft...1490

Removing the drive input shaft...1493

Removing the transmission shaft...1494

CHECKS...1494

Gearbox...1494

Hubs - sliding sleeves - forks...1494

Bearings...1494

Shafts - gears...1494

Synchronizing devices...1494

BK-type single-cone synchronizing devices...1494

Fitting the transmission shaft...1495

Fitting the drive input shaft...1495

Fitting the main shaft...1496

Adjusting the main shaft...1498

Fitting the gearbox...1499

Oil pump...1500

Adjusting the transmission shaft bearing end float...1500

Drive input shaft cover...1501

ZF gearboxes with INTARDER hydraulic retarder, types: 16 S 151 O.D. - 16 S 181 O.D. - 16 S 221 O.D...1504

SPECIFICATIONS AND DATA...1506

TOOLS...1507

Removing the hydraulic retarder from the gearbox on the stand...1514

Refitting the hydraulic retarder...1514

Removing the epicyclic reduction gear unit (ERG) rear box...1515

Removing the epicyclic reduction gear unit (ERG)...1515

Component parts of the epicyclic reduction gear unit...1518

Fitting the epicyclic reduction gear unit (ERG)...1519

Refitting the epicyclic reduction gear unit (ERG) rear box...1521

Gearbox: EuroTronic 16 AS 2601 O.D...1523

DESCRIPTION...1525

SPECIFICATIONS AND DATA...1526

TIGHTENING TORQUES...1529

TOOLS...1530

OVERHAULING THE GEARBOX...1535

Checks...1535

Gearbox actuator...1535

Removal...1535

Refitting...1536

Removing the rear box...1536

Removing the rear box...1537

Removing the epicyclic reduction gear train (E.R.G.)...1538

Fitting the epicyclic reduction gear train (E.R.G.)...1540

Adjusting epicyclic reduction gear train bearing end float...1541

Adjusting main shaft end float...1542

Synchronizing device assembly for engaging normal or reduced gears...1544

Removal...1544

Removing the middle box...1547

Removing the main shaft...1549

Removing the drive input shaft...1551

Removing the splitter synchronizing device...1552

Fitting the splitter synchronizing device...1553

Fitting the main shaft...1554

Fitting the drive input shaft...1554

Splitter control fork ...1557

Disassembly - Assembly...1557

Gear control forks...1557

Removal...1557

Fitting...1558

Transmission shafts...1559

Disassembly - Assembly...1559

Fitting the middle box...1559

Fitting the front box...1562

Front cover...1564

Removal...1564

Fitting the front cover...1564

Adjusting drive input shaft bearing end float...1564

Adjusting transmission shaft bearing end float...1565

Clutch release lever...1567

Gearbox: EuroTronic 16 AS 2601 O.D. with Intarder...1570

EuroTronic Automated 16 AS 2601 O.D. with intarder...1572

SPECIFICATIONS AND DATA...1572

OVERHAULING THE GEARBOX...1573

Removing the hydraulic retarder...1573

Refitting the hydraulic retarder...1574

Adjusting epicyclic reduction gear train bearing end float...1574

Adjusting stator end float...1575

Removing the rear box...1576

Removing the E.R.G...1577

Fitting the E.R.G...1578

EXPERIMENTAL TOOLS...1583

SECTION 5 - Intarder - ZF hydraulic retarder...1584

Intarder - ZF hydraulic retarder...1584

LOCATION OF INTARDER HYDRAULIC RETARDER DESCRIPTION PLATE...1586

GENERAL INFORMATION...1587

OPERATION...1587

Retarder engaged...1588

Retarder disengaged...1589

LAYOUT OF MAIN SYSTEM COMPONENTS ON THE RETARDER...1590

REMOVING AND REFITTING THE RETARDER ON THE ZF S 151/181/221-OD GEARBOX...1591

Removal...1591

Refitting...1592

Filling with oil...1592

SPECIFICATIONS AND DATA...1593

TIGHTENING TORQUES...1594

TOOLS...1595

FAULT DIAGNOSIS...1597

OVERHAULING THE INTARDER HYDRAULIC RETARDER...1601

Hydraulic accumulator...1601

Removal...1601

Fitting...1601

Removing hydraulic retarder...1601

Checking the component parts of the hydraulic retarder...1606

Fitting the hydraulic retarder...1607

Stator end float adjustment...1612

SECTION 6 - Total power take-off (Option 2395)...1614

Total power take-off (Option 2395)...1614

DESCRIPTION...1616

SPECIFICATIONS AND DATA...1617

TIGHTENING TORQUES...1618

TOOLS...1619

Operation (power take off disengaged)...1623

Operation (power take off engaged)...1624

REMOVING - REFITTING TOTAL POWER TAKE-OFF ASSEMBLY...1625

Removal...1625

Refitting...1625

OVERHAULING...1626

Removing main box...1626

Removing drive assembly...1626

Removing bearing for shaft with gear wheel...1626

Removing oil pump...1627

Cleaning and checking parts...1628

Fitting oil pump...1628

Fitting bearing for shaft with gear wheel...1629

Fitting drive assembly...1629

Adjusting drive output shaft tapered bearings...1631

Fitting main box...1632

Adjusting ball bearing...1632

SECTION 7 - Reduction gear - Divider TC 1800-TC 2200...1634

Reduction gear - Divider TC 1800-TC 2200...1634

DESCRIPTION OF REDUCTION GEAR - DIVIDER ASSEMBLY TC 1800 - TC 2200...1636

SPECIFICATIONS AND DATA...1636

VERSION WITH P.T.O. (OPT. 391-392)...1638

P.T.O. SPECIFICATIONS...1638

USING THE REDUCTION GEAR - DIVIDER...1639

On-road driving (normal ratio)...1639

Diagram of drive transmission with normal ratio...1640

Off-road driving (reduced ratio)...1641

Diagram of drive transmission with reduced ratio...1642

Version with P.T.O...1643

TORQUE DIVIDER...1646

Division ratio calculation...1646

Control locking divider and differential gears...1647

TIGHTENING TORQUES...1649

TOOLS...1653

LUBRICATION...1656

REMOVING AND REFITTING REDUCTION GEAR - DIVIDER ...1657

Removal...1657

Refitting...1657

REMOVING THE REDUCTION GEAR - DIVIDER ON THE BENCH...1657

CLEANING AND CHECKING PARTS...1661

REPLACING OUTPUT SHAFT COVER SEALS...1661

REPLACING INPUT SHAFT COVER SEAL...1661

INPUT SHAFT...1662

Removal...1662

Fitting...1662

EPICYCLIC DIVIDER UNIT...1663

Removal...1663

Fitting...1664

COUNTERSHAFT...1664

Removal...1664

Fitting...1664

FITTING THE REDUCTION GEAR - DIVIDER ON THE BENCH...1665

ADJUSTING THE BEARING PRE-LOAD...1668

Input shaft...1668

Countershaft...1668

Output shaft...1669

COMPLETING ASSEMBLY...1670

Adjusting push-rod switch signalling divider locking and P.T.O. engagement (if applicable)...1671

Adjusting pulse transmitter...1671

Replenishing oil...1671

SECTION 8 - Propeller shafts...1672

Propeller shafts...1672

SPECIFICATIONS AND DATA...1674

FAULT DIAGNOSIS...1674

TIGHTENING TORQUES...1676

TOOLS...1676

PROPELLER SHAFT REMOVAL AND REFITTING...1677

Removal...1677

Refitting...1677

REPAIRS...1677

Removing the universal joint...1677

Fitting the universal joint...1677

CHECKING PROPELLER SHAFTS ON VEHICLES...1678

SECTION 9 - Axles...1680

Axles...1680

FAULT DIAGNOSIS...1682

REAR AXLE REMOVAL - REFITTING...1684

Removing the intermediate axle ( 6x4 - 8x4 - 8x8 vehicles)...1684

Removing the rear axle ( 6x4 - 8x4 - 8x8 vehicles) ...1685

Refitting the rear axle...1686

Instructions for adjustments and checks on differential lock and flow divider engagement transmitter operation...1686

Front Axle 5985/2D (D1385)...1689

DESCRIPTION...1691

SPECIFICATIONS AND DATA...1692

TIGHTENING TORQUES...1694

TOOLS...1696

OVERHAULING THE FRONT AXLEE...1702

Wheel hub disassembly...1702

Stub axle disassembly...1703

Drive shaft disassembly...1705

Fork support disassembly...1705

Stub axle disassembly...1706

Wheel hub disassembly...1706

Epicycloid gear disassembly...1706

CLEANING AND CHECKING PARTS...1707

CHECKING THE AXLE HOUSING ANGLE AND INCIDENCE...1707

ASSEMBLY...1710

Fork support assembly...1711

Drive shaft assembly...1712

Stub axle assembly...1712

Epicycloid reduction gear assembly...1717

Greasing the stub axle pins...1718

Epicycloid gear unit lubrication...1718

REMOVING THE DIFFERENTIAL (with the rear axle mounted on stand 99322215)...1719

Checking the axle housing...1719

REFITTING THE DIFFERENTIAL (with the axle mounted on stand 99322215)...1719

DIFFERENTIAL REPAIR...1721

Disassembly...1721

Disassembling the gear housing...1722

Disassembling the bevel pinion support...1723

CHECKING THE DIFFERENTIAL COMPONENTS...1723

Assembling the gear housing...1724

Assembling the bevel pinion support...1725

Differential...1727

Adjusting the rolling torque on the gear housing bearings...1728

Intermediate axles 452191/2D (R 9274) 453291/2D (R 9189)...1732

DESCRIPTION...1734

SPECIFICATIONS AND DATA...1735

TIGHTENING TORQUES...1736

TOOLS...1738

REMOVING-REFITTING THE FLOW DIVIDER DIFFERENTIAL (with the axle mounted on the vehicle)...1745

Removal...1745

Refitting...1745

INTERMEDIATE AXLE ASSEMBLY REPAIRS...1746

Disassembly...1746

Epicycloid reduction gear disassembly...1746

Wheel hub disassembly...1747

Wheel hub disassembly...1750

Assembling the epicycloid reduction gear...1752

REMOVING-REFITTING THE FLOW DIVIDER DIFFERENTIAL (with the axle mounted on stand 99322215)...1754

Removal...1754

Refitting...1754

REPAIRING THE FLOW DIVIDER-DIFFERENTIAL...1755

Flow divider differential unit disassembly...1755

Gear housing disassembly...1758

Flow divider-differential disassembly...1760

Flow divider differential unit assembly...1764

Gear housing assembly...1765

Flow divider differential unit assembly...1767

Procedure to follow to determine the thickness of the bevel pinion rolling torque adjusting ring...1767

Adjusting the rolling torque on the gear housing bearings...1771

DRIVE SHAFT...1775

Disassembly...1775

Checking parts...1776

Assembly...1776

Intermediate axle 452146/2D (R 9174)...1779

DESCRIPTION...1781

SPECIFICATIONS AND DATA...1782

TIGHTENING TORQUES...1783

TOOLS...1785

REPAIRING THE FLOW DIVIDERDIFFERENTIAL ASSEMBLY...1791

Disassembly...1791

REPAIRING THE FLOW DIVIDER DIFFERENTIAL...1791

Flow divider differential unit disassembly...1791

Removing the bevel pinion from the support...1794

Gear housing disassembly...1794

Differential - flow divider disassembly...1795

CHECKING THE DIFFERENTIAL - FLOW DIVIDER COMPONENTS...1799

Flow divider - differential unit assembly...1799

Gear housing assembly...1801

Assembling the bevel pinion support...1802

Procedure to follow to determine the thickness of the bevel pinion rolling torque adjusting ring...1802

Differential housing assembly...1804

Gear housing bearings rolling torque adjustment...1806

Rear axles 451391/2D (R 8284) 452191/2D (R 8274) 453291/2D (R 8298)...1812

DESCRIPTION...1814

SPECIFICATIONS AND DATA...1815

TIGHTENING TORQUES...1816

TOOLS...1818

REAR AXLES ASSEMBLY OVERHAUL...1823

Disassembly...1823

Epicycloid reduction gear disassembly...1823

Wheel hub disassembly...1824

CLEANING AND CHECKING WHEEL HUB AND EPICYCLOID GEAR PARTS...1826

WHEEL HUB ASSEMBLY...1827

Assembling the epicycloid reduction gear...1829

REMOVING-REFITTING THE DIFFERENTIAL...1832

REFITTING...1833

REPAIRING THE DIFFERENTIAL...1834

Removal...1834

Gear housing disassembly...1835

Removing the bevel pinion from the support...1836

CHECKING THE DIFFERENTIAL COMPONENTS...1838

Gear housing assembly...1839

Assembling the bevel pinion support...1840

Procedure to follow to determine the thickness of the bevel pinion rolling torque adjusting ring...1840

Differential housing assembly...1842

Gear housing bearings rolling torque adjustment...1843

Rear axle 452146/2D (R 8174)...1849

DESCRIPTION...1851

SPECIFICATIONS AND DATA...1852

TIGHTENING TORQUES...1853

TOOLS...1855

REAR AXLE ASSEMBLY OVERHAUL...1860

REPAIRING THE DIFFERENTIAL...1860

Disassembly...1860

Disassembling the gear housing...1861

Disassembling the bevel pinion support...1862

CHECKING THE DIFFERENTIAL COMPONENTS...1862

Assembling the gear housing...1863

Assembling the bevel pinion support...1864

Differential housing assembly...1866

Adjusting the rolling torque on the gear housing bearings...1867

Axles in Tandem MERITOR RT 153E/2D...1872

Axles in Tandem (Intermediate) Meritor RP 153E...1874

DESCRIPTION...1876

SPECIFICATIONS AND DATA...1876

TIGHTENING TORQUES...1878

TOOLS...1882

EXPERIMENTAL TOOLS...1889

SERVICING INTERMEDIATE AXLE ASSEMBLY RP 153E...1892

WHEEL HUB OVERHAULING...1892

Removing...1892

Checks on wheel hub components...1893

Refitting...1893

REMOVING DIFFERENTIAL (AXLE ON STAND 99322215) ...1897

REFITTING DIFFERENTIAL (axle on stand 99322215)...1897

REPAIRING INTER-AXLE UNIT...1898

Dismantling inter-axle unit...1898

Checking inter-axle unit components...1900

Fitting inter-axle unit...1900

Adjusting drive input shaft bearing end float...1902

REPAIRING MAIN DIFFERENTIAL - DISMANTLING DIFFERENTIAL CASING...1903

Removing the gear housing...1906

Checking the differential components...1907

Refitting the gear housing...1907

ASSEMBLING DIFFERENTIAL CASING...1909

Calculating bevel pinion position in differential casing...1909

ADJUSTING THE CAP ANGLE...1912

CORRECTING THE BEVEL GEAR PAIR CONTACTS (AFTER FITTING IN PLACE)...1915

REMOVING-SERVICING-REFITTING INTER-AXLE OUTPUT SHAFT...1919

Rear Axle MERITOR U 177 E...1922

DESCRIPTION...1924

CHARACTERISTICS AND DATA...1925

TIGHTENING TORQUES...1926

TOOLS...1927

REMOVING AND REFITTING THE DIFFERENTIAL (with axle on stand 99322215) ...1933

Removal...1933

Checking axle housing...1933

Refitting...1933

REPAIRING THE DIFFERENTIAL...1934

Removing the differential...1934

Removing the gearcase...1935

REMOVING THE BEVEL PINION FROM THE SUPPORT...1937

Differential component check...1937

Fitting the gear housing...1938

FITTING THE MOUNT ON THE BEVEL PINION...1939

Reassembling the differential housing...1941

ADJUSTING THE CAP GAP...1943

CORRECTING THE CROWN WHEEL AND PINION CONTACTS (AFTER ASSEMBLY)...1946

WORK ON THE VEHICLE...1949

REPLACING THE BEVEL PINION MOUNT SEAL...1949

Disassembly...1949

Assembly...1950

SECTION 10 - Front axles...1952

Front axles...1952

Front axle 5886/D (F9021)...1955

DESCRIPTION...1957

Front axle 5886 / D...1957

SPECIFICATIONS AND DATA...1958

TIGHTENING TORQUES...1960

FAULT DIAGNOSIS...1961

TOOLS...1964

REMOVING AND REFITTING FRONT AXLE...1969

Removal...1969

Refitting...1969

REMOVING AND REFITTING MIDDLE AXLE (8X4 - 8X8 VEHICLES)...1970

Removal...1970

Refitting...1970

VEHICLE CHECKS...1971

Tie rods...1971

Swivel heads...1971

CHECKING SWIVEL HEAD PLAY...1971

FRONT AXLE ASSEMBLY OVERHAUL...1972

REMOVING - REFITTINGWHEEL HUBS...1972

Removal...1972

Replacing wheel hub bearings...1973

Replacing wheel fixing pins...1974

Refitting wheel hubs...1974

Checking wheel hub bearing end float...1974

Measuring rolling torque...1975

REMOVING AND REFITTING TRANSVERSE TIE ROD...1975

REPLACING TRANSVERSE TIE ROD SWIVEL HEADS ...1976

REMOVING AND REFITTING PIN FOR STUB AXLE ...1976

Removal...1976

Replacing kingpin bearing...1977

Checking and adjusting clearance between stub axle and axle...1978

CHECKING AND MEASURING THE AXLE BODY...1979

Checking angle of holes for kingpins...1980

Front axle 5886/2D (F9021)...1982

DESCRIPTION...1984

Front axle 5886 / 2D...1984

SPECIFICATIONS AND DATA...1985

TIGHTENING TORQUES...1987

FRONT AXLE ASSEMBLY OVERHAUL...1988

REMOVING - REFITTING WHEEL HUBS...1988

Removal...1988

Refitting wheel hubs...1989

Wheel geometry...1992

GENERAL INFORMATION...1994

Steering wheel angles...1994

FRONT WHEEL GEOMETRY (4X2 VEHICLES)...1995

Positioning clips and headlights...1995

Electronic compensation of rim eccentricity...1996

Wheel alignment...1996

Checking wheel toe-in...1997

Checking wheel deviation...1997

Checking camber...1997

Checking kingpin angle and caster...1998

Checking rear axle alignment...1999

WHEEL GEOMETRY OF VEHICLES WITH ADDED CENTRAL AXLE (8X4X4)...1999

Checking steering angles...2001

SECTION 11 - Suspensions...2002

Suspensions...2002

FRONT AND REAR MECHANICAL SUSPENSIONS...2004

Description...2004

SPECIFICATIONS AND DATA...2015

FRONT SHOCK ABSORBERS...2025

REAR SHOCK ABSORBERS...2026

AIR SUSPENSION...2027

Chassis frame lifting, lowering and self-levelling with remote control ...2027

Saving Levels...2027

Working diagram of pneumatic rear suspensions for 8x4 H/P, 8x4 HB/P vehicles...2028

CHARACTERISTICS AND DATA...2029

Pneumatic system...2029

MAIN COMPONENTS OF THE PNEUMATIC SYSTEM...2030

Relief valve...2030

Fault diagnosis...2030

Level sensor...2030

Electropneumatic distributor...2031

Air low pressure manometer switch...2031

Air spring...2031

Rear pneumatic suspension for vehicles 8x4 H/P - HB/P...2032

FAULT DIAGNOSIS...2033

Diagnosis Instruments...2033

TIGHTENING TORQUES...2038

TOOLS...2039

REMOVAL-REFITTING OF FRONT LEAF SPRING...2044

Removal...2044

Refitting...2044

REMOVAL-REFITTING OF INTERMEDIATE AXLE LEAF SPRING (8X4 VEHICLES)...2045

Removal...2045

Refitting...2045

REMOVAL-REFITTING OF REAR LEAF SPRING (4X2 - 4X4 VEHICLES)...2046

Removal...2046

Refitting...2046

REMOVAL-REFITTING OF REAR LEAF SPRING ON CANTILEVER TYPE SUSPENSIONS (6X4 - 6X6 - 8X8 VEHICLES)...2047

Removal...2047

Refitting...2047

Procedure for assembly of the slipper block and mounting brackets for the longitudinal bars...2048

Tightening theU-bolts clamping the leaf spring to the central pivot...2048

REAR CANTILEVER SUSPENSION (6x4 - 6x6 - 8x4 - 8x8 vehicles)...2049

Removal-refitting of central pivot...2049

Removal-refitting of central pivot...2049

Renewal of bearings...2049

Removal-refitting of hanger bracket...2049

Removal of the central pivot...2049

Removal of the central pivot shaft...2049

Removal of the hanger bracket...2049

Renewal of the bearings...2049

Refitting the hanger bracket...2050

Refitting the central pivot shaft...2051

Refitting the central pivot...2051

REMOVAL-REFITTING OF REAR AXLE LONGITUDINAL ARM...2053

REMOVAL-REFITTING OF INTERMEDIATE AXLE LONGITUDINAL ARM...2053

REMOVAL-REFITTING OF REAR AXLE TRIANGULAR ARM FOR VEHICLES WITH AIR SUSPENSION...2053

Removal...2053

Refitting...2053

REPLACEMENT OF THE FLEXIBLE PINS OF LONGITUDINAL/TRIANGULAR ARMS...2054

Disassembly...2054

Assembly...2054

SHOCK ABSORBERS...2055

Removal...2055

Refitting...2055

ANTI-ROLL BARS...2055

ANTI-ROLL BAR...2056

FRONT ANTI-ROLL BAR...2056

AUXILIARY AXLE ANTI-ROLL BAR (8X4 VEHICLES)...2056

REAR ANTI-ROLL BAR...2056

INTERMEDIATE AXLE ANTI-ROLL BAR (6X4 - 6X6 - 8X4 - 8X8 VEHICLES)...2056

Removal...2056

Refitting...2056

SECTION 12 - Wheels and tyres...2060

Wheels and tyres...2060

DESCRIPTION...2062

SPECIFICATIONS AND DATA...2062

Tyre inflation pressures...2062

TOOLS...2063

FAULT DIAGNOSIS...2063

STATICWHEEL BALANCING...2066

CORRECTION OF RESIDUAL STATIC IMBALANCE...2067

TYRE INFLATION PRESSURES...2067

RELATIONSHIP OF INFLATION PRESSURE TO TYRE BEHAVIOUR...2068

SECTION 13 - Steering...2070

Steering...2070

DESCRIPTION...2072

STEERING BOX/VEHICLE COMBINATIONS...2073

SPECIFICATIONS AND DATA...2074

Vehicles: 4X2 - 4X4 - 6X4 - 6X6...2074

Vehicles: 8x4x4 - 8x8...2074

FAULT DIAGNOSIS...2075

TOOLS...2080

TIGHTENING TORQUES...2081

Steering gear arrangement for 4x2 - 6x4 vehicles (ZF 8098 steering box)...2082

Steering gear arrangement for 4x4 - 6x6 vehicles (ZF 8098 steering box)...2083

Steering gear arrangement for 8x4x4 - 8x8 vehicles (ZF 8099/1.5 steering box)...2084

Hydraulic circuit diagram for 8x4x4 - 8x8 vehicles (ZF 8099/1.5 steering box)...2085

HYDRAULIC POWER STEERING...2086

Steering lever assembly...2086

REMOVAL AND REFITTING OF COMPLETE STEERING COLUMN...2087

Removal...2087

Refitting...2088

MAIN OPERATIONS...2089

Bleeding the power steering system...2089

Measuring steering box play at the steering wheel ...2089

Checking the maximum pressure of the power steering wheel...2089

Adjustment of hydraulic steering limiting valves...2089

Testing the hydraulic steering limiting valves with the vehicle in motion...2090

Setting the automatic hydraulic steering limit...2090

Checking...2090

SECTION 14 - Air system - Brakes...2092

Air system - Brakes...2092

GRAPHIC SYMBOLS FOR AIR-HYDRAULIC SYSTEM DIAGRAMS (MISCELLANEOUS AND GENERATORS)...2096

GRAPHIC SYMBOLS FOR AIR-HYDRAULIC SYSTEM DIAGRAMS (VALVES)...2097

GRAPHIC SYMBOLS FOR AIR-HYDRAULIC SYSTEM DIAGRAMS (TANKS AND ACCUMULATORS)...2103

GRAPHIC SYMBOLS FOR AIR-HYDRAULIC SYSTEM DIAGRAMS (CONVERTERS, CYLINDERS AND CALLIPERS)...2104

GRAPHIC SYMBOLS FOR AIR-HYDRAULIC SYSTEM DIAGRAMS (CALLIPERS AND CYLINDERS)...2105

GRAPHIC SYMBOLS FOR AIR-HYDRAULIC SYSTEM DIAGRAMS (HALF-COUPLINGS AND COUPLING HEADS)...2106

GRAPHIC SYMBOLS FOR AIR-HYDRAULIC SYSTEM DIAGRAMS (HALF-COUPLINGS AND COUPLING HEADS)...2107

GRAPHIC SYMBOLS FOR AIR-HYDRAULIC SYSTEM DIAGRAMS (INDICATORS AND SWITCHES)...2108

GRAPHIC SYMBOLS FOR AIR-HYDRAULIC SYSTEM DIAGRAMS (BRAKES)...2109

PIPES AND FITTINGS...2110

General information...2110

Flaring rigid pipes...2110

Bending rigid pipes...2111

Cutting rigid pipes...2111

Replacing the flexiblehoses withconventional fittings ...2112

Replacing flexible hoses with quick-coupling fittings...2113

BRAKING SYSTEM...2115

Working diagram for 4x2 - 4x4 vehicles designed for towing with ABS-ASR device...2115

Working diagram for isolated 6x4 vehicles with ABS-ASR device...2116

Working diagram for 6x4 - 6x6 vehicles designed for towing with ABS-ASR device...2117

Working diagram for isolated 8x4x4 - 8x8x4 vehicles with ABS-ASR device...2118

Working diagram for 8x4x4 - 8x8x4 vehicles designed for towing with ABS-ASR device...2119

BRAKING SYSTEM...2120

Working diagram for 4x2 - 4x4 vehicles designed for towing with ABS-ASR device...2120

Concept diagram for 6x4 vehicles isolated with EBL devices...2121

Working diagram for 6x4 - 6x6 vehicles designed for towing with EBL device...2122

Concept diagram for 8x4x4 - 8x8x4 vehicles isolated with EBL devices...2123

Working diagram for 8x4x4 - 8x8x4 vehicles designed for towing with EBL device...2124

Layout on vehicle of main components of braking system...2126

Layout on vehicle of main components of ABS-ASR system...2127

DESCRIPTION...2128

Service braking...2128

Emergency braking...2128

Retarding braking...2128

Parking brake...2128

ABS (Anti-Lock Brake System)...2128

ASR (Anti-Slip Regulator) system...2129

EBL (Electronic Brakes Limiter)...2129

BRAKES...2129

Front disc brakes type KNORR: SB7; SN7 (for vehicles with partial traction)...2129

Front brakes (for four-wheel drive vehicles) and rear brakes type MERITOR Duo - duplex Ø 410x180 and 410x200 ...2129

FAULT DIAGNOSIS...2130

Diagnosis Instruments...2130

ABS Troubleshooting...2132

TIGHTENING TORQUES...2152

TOOLS...2155

SPECIFICATIONS AND DATA - PNEUMATIC SYSTEM...2163

SPECIFICATIONS AND DATA - BRAKES...2168

CHECKS ON MAIN COMPONENTS OF THE BRAKING SYSTEM...2171

CHECKS ON MAIN COMPONENTS OF THE BRAKING SYSTEM...2172

MAIN COMPONENTS OF THE BRAKING SYSTEM...2174

Compressor...2174

Head locking screw tightness...2174

Electronic control unit...2175

A.P.U. (Air Processing Unit)...2175

Triple servo control valve...2176

Predominance control...2176

Predominance control...2176

Knorr Bremse AC 597B...2176

Wabco 973 009 013...2176

Duplex control valve...2177

Coupling heads...2178

Check valve (vehicles suited to towing)...2178

Parking brake hand control valve (vehicles suited to towing)...2178

Safety valve (”for Sweden”)...2179

Parking brake hand control valve (isolated vehicles)...2179

Diaphragm brake cylinder...2180

Combined brake cylinder...2180

Combined cylinder emergency braking device...2180

Repairs...2180

Relay valve...2181

Pressure reduction unit...2181

Engine brake switch...2182

Dual servo control valve...2182

Brake anti-lock control valve...2183

ASR electropneumatic valve...2183

Speed sensor...2183

Phonic wheels...2183

BRAKE REPAIRS...2184

FRONT DISC BRAKES SB7 TYPE (VEHICLESWITH PARTIAL TRACTION)...2184

TYPE SN7 DISK BRAKES...2185

SB7 type brake operation...2187

CHECKS...2187

Efficiency of automatic clearance recovery...2187

Brake lining thickness...2188

Replacing brake linings...2189

Removing and refitting brake callipers SB7...2191

Removal...2191

Refitting...2191

Removing and refitting wheel hubs...2192

Removal...2192

Refitting...2192

OVERHAULING BRAKE CALLIPERS SB7...2193

Disassembly...2193

Cleaning and checking component parts...2194

Assembly...2194

OVERHAULING BRAKE DISCS...2195

TURNING AND GRINDING BRAKE DISCS ON THE BENCH ...2196

TURNING AND GRINDING BRAKE DISCS ON THE VEHICLE...2196

DRUM BRAKES...2196

FRONT BRAKES...2197