Komatsu 68E, 74E, 78E, 82E, 84E, 88E, 94E, 98E Series Diesel Engine Repair Service Manuals

Catalog:

Model:

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Diesel Engines 68E, 74E, 78E, 82E, 84E, 88E, 94E, 98E Series, with all the technical information to maintain, diagnose, repair, and rebuild like professional mechanics.

Komatsu 68E, 74E, 78E, 82E, 84E, 88E, 94E, 98E Series Diesel Engines workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

SEBM011501 - 68E, 74E, 78E, 82E, 84E, 88E Series Diesel Engine Shop Manual.pdf

SEBM013001 - 94E, 98E Series Diesel Engine Shop Manual.pdf

SEBM035103 - 82E, 84E, 88E, 94E, 98E Series Diesel Engine Shop Manual.pdf

SEN04211-03 - 82E-6, 84E-6, 88E-6, 94E-6, 98E-6 Series Diesel Engine Shop Manual.pdf

PRODUCT DETAILS:

Total Pages: 927 pages

File Format: PDF

Language: English

MAIN SECTIONS

2. CROSS SECTIONAL VIEWS... 2-1

3. COOLING WATER, LUBRICATING OIL AND FUEL OIL ... 3-1

4. TROUBLESHOOTING ... 4-1

5. SPECIAL SERVICE TOOLS AND MEASURING INSTRUMENTS ... 5-1

6. MEASUREMENT, INSPECTION AND ADJUSTMENT ... 6-1

7. MEASURING PROCEDURES, SERVICE DATA AND CORRECTIVE ACTION... 7-1

8. DISASSEMBLY AND REASSEMBLY ... 8-1

9. SERVICE DATA ... 9-1

10. TIGHTENING TORQUE ... 10-1

11. FUEL INJECTION PUMP FOR INDIRECT INJECTION SYSTEM ... 11-1

12. FUEL INJECTION PUMP FOR DIRECT INJECTION SYSTEM ... 12-1

13. GOVERNOR ... 13-1

14. TURBOCHARGER ... 14-1

15. SERVICE INFORMATION FOR CARB ULG REGULATION ... 15-1

16. ATTACHED DRAWING... 16-1

20. EPA CERTIFIED ENGINE... 20-1

SEBM011501 - 68E, 74E, 78E, 82E, 84E, 88E Series Diesel Engine Shop Manual....2

COVER....2

CONTENTS....3

1. SPECIFICATIONS AND PERFORMANCE....8

1.1 2D68E....9

1.2 3D68E....10

1.3 3D74E....11

1.4 3D78AE....12

1.5 3D82AE....13

1.6 3D82E....14

1.7 3D84E....15

1.8 3D88E....16

1.9 4D82E....17

1.10 4D84E....18

1.11 4D88E....19

1.12 S3D84E....20

1.13 S4D84E....21

2. CROSS SECTIONAL VIEWS....22

2.1 SPECIAL SWIRL PRE-COMBUSTION CHAMBER SYSTEM (INDIRECT INJECTION SYSTEM)....23

2.2 DIRECT INJECTION SYSTEM....25

3. COOLING WATER, LUBRICATING OIL AND FUEL OIL....27

3.1 COOLING WATER....28

3.2 LUBRICATING OIL....29

3.3 FUEL OIL....31

4. TROUBLESHOOTING....33

4.1 TROUBLE CAUSES AND REMEDIES....34

4.2 TROUBLE DIAGNOSIS THROUGH MEASUREMENT OF COMPRESSION PRESSURE....38

5. SPECIAL SERVICE TOOLS AND MEASURING INSTRUMENTS....39

5.1 SPECIAL SERVICE TOOLS....40

5.2 MEASURING INSTRUMENTS....43

6. MEASUREMENT, INSPECTION AND ADJUSTMENT....47

6.1 MEASURING THE COMPRESSION PRESSURE....48

6.2 ADJUSTING THE VALVE HEAD CLEARANCE....50

6.3 CHECKING THE V-BELT TENSION....51

6.4 MEASURING AND CHECKING THE INJECTION PRESSURE AND SPRAY PATTERNS OF THE FUEL INJECTION VALVE....52

6.5 CHECKING AND ADJUSTING THE FUEL INJECTION TIMING....56

6.6 ADJUSTING THE NO-LOAD MAXIMUM (OR MINIMUM) REVOLUTIONS....59

6.7 CHECKING THE COOLING WATER SYSTEM AND RADIATOR FOR WATER LEAKAGE....59

6.8 CHECKING THE BATTERY....60

6.9 CHECKING THE SENSORS....63

6.10 CHECKING THE OIL COOLER....64

6.11 CHECKING THE PISTON COOLING NOZZLE....65

7. MEASURING PROCEDURES, SERVICE DATA AND CORRECTIVE ACTION....66

7.1 CYLINDER HEAD....67

7.2 CYLINDER BLOCK....75

7.3 VALVE ROCKER ARM....79

7.4 PISTON AND PISTON RING....82

7.5 CONNECTING ROD....88

7.6 CAMSHAFT....93

7.7 CRANKSHAFT....96

7.8 GEARS....99

7.9 TROCHOID PUMP....101

8. DISASSEMBLY AND REASSEMBLY....103

8.1 DISASSEMBLY....104

8.2 PRECAUTIONS BEFORE AND DURING REASSEMBLY....109

9. SERVICE DATA....114

9.1 CYLINDER HEAD....115

9.2 CYLINDER BLOCK....116

9.3 VALVE ROCKER ARM....116

9.4 PISTON....117

9.5 PISTON RING....118

9.6 CONNECTING ROD....119

9.7 CAMSHAFT....119

9.8 CRANKSHAFT....120

9.9 SIDE GAP AND BACKLASH....120

9.10 OTHERS....121

10. TIGHTENING TORQUE....122

10.1 MAIN BOLT/NUT....123

10.2 STANDARD BOLT AND NUT....124

11. FUEL INJECTION PUMP FOR INDIRECT INJECTION SYSTEM....125

11.1 EXPLODED VIEW (YPFR TYPE)....126

11.2 DISASSEMBLY....127

11.3 INSPECTION....129

11.4 REASSEMBLY....131

12. FUEL INJECTION PUMP FOR DIRECT INJECTION SYSTEM....133

12.1 EXPLODED VIEW (YPES TYPE)....134

12.2 SPECIAL SERVICE TOOLS FOR DISASSEMBLY AND REASSEMBLY....136

12.3 DISASSEMBLY....137

12.4 INSPECTION....142

12.5 REASSEMBLY....144

13. GOVERNOR....149

13.1 EXPLODED VIEWS OF GOVERNOR FOR INDIRECT INJECTION SYSTEM....150

13.2 EXPLODED VIEWS OF GOVERNOR FOR DIRECT INJECTION SYSTEM....152

13.3 DISASSEMBLY....154

13.4 INSPECTION....160

13.5 REASSEMBLY....162

14. TURBOCHARGER....166

14.1 SPECIFICATIONS....167

14.2 CONSTRUCTION....168

14.3 WASTE GATE VALVE ADJUSTING METHOD....170

14.4 EXPLODED VIEW OF TURBOCHARGER (WITH WASTE GATE)....172

14.5 TIGHTENING TORQUE....173

14.6 SERVICE STANDARDS....173

15. SERVICE INFORMATION FOR CARB ULG REGULATION....174

15.1 LIMITING THE HIGH IDLE AND LOW IDLE ADJUSTMENT SCREW....175

15.2 LIMITING THE FUEL VOLUME LIMITER SCREW....176

16. ATTACHED DRAWING....177

16.1 EXPLODED VIEWS OF ENGINE COMPONENTS....178

16.2 EXPLODED VIEWS OF ENGINE COMPONENTS....180

20. EPA CERTIFIED ENGINE....182

20.1 APPLICABLE MACHINE, SERIAL NUMBER (EPA CERTIFIED ENGINE)....183

20.2 EPA CERTIFICATION PLATE ATTACHING LOCATION....184

20.3 DIFFERENCES WITH THE CURRENT PRODUCTION MODEL....185

20.4 FUEL INJECTION TIMING ADJUSTMENT....186

20.5 SECIFICATIONS....197

SEBM013001 - 94E, 98E Series Diesel Engine Shop Manual....206

COVER....206

CONTENTS....207

1. GENERAL....212

1.1 SPECIFICATIONS....213

1.2 FUEL OIL, LUBRICATING OIL AND COOLING WATER....215

1.3 ENGINE EXTERNAL VIEWS....217

1.4 STRUCTURAL DESCRIPTION....219

1.5 HOW TO READ THIS MANUAL....221

1.6 PRECAUTIONS FOR SERVICE WORK....223

1.7 TIGHTENING TORQUES FOR STANDARD BOLTS AND NUTS....224

2. TROUBLESHOOTING....225

2.1 QUICK REFERENCE TABLE FOR TROUBLESHOOTING....226

2.2 TROUBLESHOOTING BY MEASURING COMPRESSION PRESSURE....230

3. INSPECTION AND ADJUSTMENT....232

3.1 OIL INSPECTION....233

3.2 COOLING WATER INSPECTION....233

3.3 INSPECTING WATER LEAK FROM COOLING WATER SYSTEM AND RADIATOR....233

3.4 FAN BELT TENSION INSPECTION AND ADJUSTMENT....234

3.5 ADJUSTING THE VALVE CLEARANCE....235

3.6 INSPECTING THE FUEL INJECTION NOZZLE INJECTION PRESSURE AND SPRAY PATTERN....236

3.7 FUEL INJECTION TIMING INSPECTION AND ADJUSTMENT....239

3.8 ADJUSTING THE NO-LOAD MAXIMUM (OR MINIMUM) REVOLUTIONS....240

3.9 SENSOR INSPECTION....241

3.10 BATTERY INSPECTION....242

3.11 ADJUSTING OPERATION....244

3.12 LONG STORAGE....245

3.13 PERIODIC MAINTENANCE SCHEDULE....246

4. ENGINE BODY....248

4.1 INTRODUCTION....249

4.2 CYLINDER HEAD....250

4.3 GEAR TRAIN AND CAMSHAFT....259

4.4 CYLINDER BLOCK....264

5. LUBRICATION SYSTEM....277

5.1 LUBRICATION SYSTEM DIAGRAM....278

5.2 TROCHOID PUMP COMPONENTS....278

5.3 DISASSEMBLY (REVERSE THE PROCEDURE BELOW FOR ASSEMBLY)....279

5.4 SERVICING POINTS....279

5.5 PARTS INSPECTION AND MEASUREMENT....280

6. COOLING SYSTEM....281

6.1 COOLING WATER SYSTEM....282

6.2 COOLING WATER PUMP COMPONENTS....283

6.3 DISASSEMBLY (REVERSE THE PROCEDURE BELOW FOR ASSEMBLY)....283

6.4 SERVICING POINTS....283

7. FUEL INJECTION PUMP/GOVERNOR....284

7.1 INTRODUCTION....285

7.2 FUEL INJECTION PUMP....285

7.3 FUEL INJECTION NOZZLE....292

7.4 FUEL FEED PUMP....292

7.5 GOVERNOR....294

7.6 SPECIAL SERVICE TOOLS FOR DISASSEMBLY/ASSEMBLY....295

8. STARTING MOTOR....297

8.1 SPECIFICATIONS....298

8.2 COMPONENTS....299

8.3 TROUBLESHOOTING....300

8.4 NAMES OF PARTS AND DISASSEMBLY PROCEDURE....301

8.5 INSPECTION AND MAINTENANCE....305

8.6 SERVICE STANDARDS....311

8.7 ASSEMBLY....312

8.8 CHARACTERISTIC TEST....314

9. ALTERNATOR....315

9.1 SPECIFICATIONS....316

9.2 SECTIONAL VIEW....317

9.3 TROUBLESHOOTING....318

9.4 PARTS NAMES AND DISASSEMBLY PROCEDURE....319

9.5 INSPECTION AN OVERHAUL....322

9.6 ASSEMBLY....326

9.7 SERVICE STANDARDS....327

9.8 PERFORMANCE TEST....328

10. SPECIAL SERVICE TOOLS....329

10.1 SPECIAL TOOLS....330

10.2 MEASURING INSTRUMENTS....332

11. SERVICE STANDARDS....335

11.1 ENGINE TUNING....336

11.2 ENGINE BODY....337

11.3 LUBRICATING OIL SYSTEM (TROCHOID PUMP)....341

11.4 TIGHTENING TORQUES FOR MAIN PARTS....342

20. EPA CERTIFIED ENGINE....344

20.1 APPLICABLE MACHINE, SERIAL NUMBER (EPA CERTIFIED ENGINE)....345

SEBM035103 - 82E, 84E, 88E, 94E, 98E Series Diesel Engine Shop Manual....346

COVER....346

CONTENTS....360

1. GENERAL ....361

1.1 SPECIFICATIONS....362

1.2 ENGINE EXTERNAL VIEWS....374

1.3 STRUCTURAL DESCRIPTION ....375

2. INSPECTION ANG ADJUSTMENT....376

2.1 PERIODIC MAINTENANCE SCHEDULE....377

2.2 PERIODIC INSPECTION AND MAINTENANCE PROCEDURE....378

2.2.1 CHECK BEFORE DAILY OPERATION ....378

2.2.2 INSPECTION AFTER INITIAL 50 HOURS OPERATION ....380

2.2.3 INSPECTION EVERY 50 HOURS ....383

2.2.4 INSPECTION EVERY 250 HOURS OR 3 MONTHS ....387

2.2.5 INSPECTION EVERY 500 HOURS OR 6 MONTHS ....390

2.2.6 INSPECTION EVERY 1000 HOURS OR ONE YEAR ....392

2.2.7 INSPECTION EVERY 2000 HOURS OR 2 YEARS ....401

2.3 ADJUSTING THE NO-LOAD MAXIMUM OR MINIMUM SPEED....404

2.4 SENSOR INSPECTION ....404

2.4.1 OIL PRESSURE SWITCH....404

2.4.2 THERMO SWITCH....404

2.5 WATER LEAK CHECK IN COOLING WATER SYSTEM ....405

2.6 RADIATOR CAP INSPECTION ....405

2.7 THERMOSTAT INSPECTION ....406

2.8 ADJUSTING OPERATION ....407

2.9 LONG STORAGE....407

3. TROUBLESHOOTING....408

3.1 PREPARATION BEFORE TROUBLESHOOTING....409

3.2 QUICK REFERENCE TABLE FOR TROUBLESHOOTING ....410

3.3 TROUBLESHOOTING BY MEASURING COMPRESSION PRESSURE....413

4. DISASSEMBLY, INSPECTION AND REASSEMBLY OF ENGINES....415

4.1 COMPLETE DISASSEMBLY AND REASSEMBLY....416

4.1.1 INTRODUCTION ....416

4.1.2 SPECIAL SERVICE TOOLS....417

4.1.3 COMPLETE DISASSEMBLY....422

4.1.4 PRECAUTIONS BEFORE AND DURING REASSEMBLY....426

4.1.5 ADJUSTING OPERATION ....426

4.2 CYLINDER HAED: DISASSEMBLY, INSPECTION AND REASSEMBLY....427

4.2.1 COMPONENTS(2-VALVE CYLINDER HAED)....427

4.2.2 DISASSEMBLY PROCEDURE....427

4.2.3 REASSEMBLY PROCEDURE....428

4.2.4 SERVICING POINTS....429

4.2.5 PARTS INSPECTION AND MEASUREMENT....433

4.2.6 VALVE SEAT CORRECTION ....437

4.2.7 VALVE GUIDE REPLACEMENT....438

4.2.8 VALVE STEM SEAL REPLACEMENT....439

4.3 GEAR TRAIN AND CAMSHAFT....440

4.3.1 COMPONENTS....440

4.3.2 DISASSEMBLY PROCEDURE....440

4.3.3 REASSEMBLY PROCEDURE....440

4.3.4 SERVICING POINTS....441

4.3.5 PARTS INSPECTION AND MEASUREMENT....444

4.3.6 OIL SEAL REPLACEMENT (GEAR CASE SIDE)....446

4.3.7 CAMSHAFT BUSHING REPLACEMENT....446

4.4 CYLINDER BLOCK....447

4.4.1 COMPONENTS....447

4.4.2 DISASSEMBLY PROCEDURE....447

4.4.3 REASSEMBLY PROCEDURE....447

4.4.4 SERVICING POINTS....448

4.4.5 PARTS INSPECTION AND MEASUREMENT....452

4.4.6 CYLINDER BORE CORRECTION ....463

4.4.7 PISTON PIN BUSHING REPLACEMENT....464

4.4.8 OIL SEAL REPLACEMENT (FLYWHEEL HOUSING SIDE)....464

5. LUBRICATION SYSTEM....465

5.1 LUBRICATION SYSTEM DIAGRAM....466

5.2 TROCHOID PUMP COMPONENTS....467

5.3 DISASSEMBLY (REVERSE THE PROCEDURE BELOW FOR ASSEMBLY)....467

5.4 SERVICING POINTS....467

5.5 PARTS INSPECTION AND MEASUREMENT....468

6. COOLING SYSTEM ....470

6.1 COOLING WATER SYSTEM ....471

6.2 COOLING WATER PUMP COMPONENTS....471

6.3 DISASSEMBLY (REVERSE THE PROCEDURE BELOW FOR ASSEMBLY)....472

6.4 SERVICING POINTS....472

7. FUEL INJECTION PUMP/GOVERNOR....473

7.1 INTRODUCTION ....474

7.2 FUEL INJECTION PUMP....474

7.2.1 FUEL SYSTEM DIAGRAM....474

7.2.2 EXTERNAL VIEW AND COMPONENTS....475

7.2.3 DISASSEMBLY PROCEDURE....475

7.2.4 ASSEMBLY PROCEDURE....476

7.2.5 SERVICING POINTS....476

8. TURBOCHARGER....478

8.1 STRUCTURE AND FUNCTIONS....479

8.1.1 MAIN SPECIFICATIONS....479

8.1.2 CONSTRUCTION....479

8.1.3 STRUCTURAL AND FUNCTIONAL OUTLINE....480

8.1.4 COMPONENTS....480

8.1.5 COMPONENTS....481

8.2 SERVICE STANDARDS AND TIGHTENING TORQUE....482

8.2.1 SERVICE STANDARDS....482

8.2.2 TIGHTENING TORQUE....483

8.3 PERIODIC INSPECTION PROCEDURE....484

8.3.1 PERIODIC INSPECTION INTERVALS....484

8.3.2 INSPECTION PROCEDURE....484

8.3.3 WASTE GATE VALVE ADJUSTMENT PROCEDURE....485

8.4 DISASSEMBLY PROCEDURE....487

8.4.1 PREPARATION FOR DISASSEMBLY....487

8.4.2 INSPECTION BEFORE DISASSEMBLY....488

8.4.3 DISASSEMBLY....488

8.5 WASHING AND INSPECTION PROCEDURE....489

8.5.1 WASHING....489

8.5.2 INSPECTION PROCEDURE....490

8.6 REASSEMBLY PROCEDURE....493

8.6.1 PREPARATION FOR REASSEMBLY....493

8.6.2 REASSEMBLY....493

8.7 HANDING AFTER DISASSEMBLY AND REASSEMBLY....496

8.7.1 INSTRUCTIONS FOR TURBOCHARGER INSTALLATION ....496

8.8 TROUBLESHOOTING....497

8.8.1 EXCESSIVELY EXHAUST SMOKE....497

8.8.2 WHITE SMOKE GENERATION ....497

8.8.3 SUDDEN OIL DECREASE....498

8.8.4 DECREASE IN OUTPUT....498

8.8.5 POOR (SLOW) RESPONSE (STARTING) OF TURBOCHARGER....498

8.8.6 ABNORMAL SOUND OR VIBRATION ....498

9. STARTING MOTOR....499

9.1 FOR 4D94LE/(S)4D98E....500

9.1.1 SPECIFICATIONS....500

9.1.2 COMPONENTS....501

9.1.3 TROUBLESHOOTING ....502

9.1.4 NAMES OF PARTS AND DISASSEMBLY PROCEDURE....503

9.1.5 INSPECTION AND MAINTENANCE....507

9.1.6 SERVICE STANDARDS....512

9.1.7 ASSEMBLY....513

9.1.8 CHARACTERISTIC TEST....515

10. ALTERNATOR....516

10.1 THE 40A ALTERNATOR FOR 3D84E AND OTHER MODELS....517

10.1.1 COMPONENTS....517

10.1.2 SPECIFICATIONS....518

10.1.3 WIRING DIAGRAM....518

10.1.4 STANDARD OUTPUT CHARACTERISTICS....519

10.1.5 INSPECTION ....519

10.1.6 TROUBLESHOOTING....520

11. ELECTRIC WIRING....521

11.1 ELECTRIC WIRING DIAGRAM....522

11.2 PRECAUTION ON ELECTRIC WIRING....524

11.2.1 ALTERNATOR....524

11.2.2 STARTING MOTOR....525

11.2.3 CURRENT LIMITER....526

11.2.4 SECTION AREA AND RESISTANCE OF ELECTRIC WIRE....527

12. SERVICE STANDARDS....528

12.1 ENGINE TUNING....529

12.2 ENGINE BODY....530

12.2.1 CYLINDER HEAD ....530

12.2.2 GEAR TRAIN AND CAMSHAFT....533

12.2.3 CYLINDER BLOCK....534

12.3 LUBRICATING OIL SYSTEM (TROCHOID PUMP)....539

13. TIGHTENING TORQUE FOR BOLTS AND NUTS....540

13.1 TIGHTENING TORQUES FOR MAIN BOLTS AND NUTS....541

13.2 TIGHTENING TORQUES FOR STANDARD BOLTS AND NUTS....542

SEN04211-03 - 82E-6, 84E-6, 88E-6, 94E-6, 98E-6 Series Diesel Engine Shop Manual....543

COVER....543

00 Index and foreword....544

Index....544

Composition of shop manual....545

Table of contents....546

Foreword and general information....550

Introduction....551

Applicable machine model and serial number....552

Safety Statements....553

Safety Precautions....554

01 Specification....576

Specification and technical data....576

Component identification....578

Function of major engine components....580

Main electronic control components and features....581

Function of cooling system components....583

Diesel fuel....584

Diesel fuel specifications....584

Filling the fuel tank....585

Priming the fuel system....587

Engine oil....587

Engine oil specifications....587

Engine oil viscosity....588

Checking engine oil....588

Adding engine oil....589

Engine oil capacity (typical)....589

Engine coolant....590

Engine coolant specifications....591

Filling radiator with engine coolant....591

Engine coolant capacity (typical)....592

Specifications....593

Description of Model Number....593

Engine speed specifications....593

Engine general specifications....594

Principal engine specifications....595

3D82AE (– EPA Tier2)....595

3D84E (– EPA Tier2)....596

S3D84E (– EPA Tier2)....597

3D88E (– EPA Tier2)....598

4D84E (– EPA Tier2)....599

S4D84E (– EPA Tier2)....600

4D88E (– EPA Tier2)....601

4D94LE (– EPA Tier2)....602

4D98E (– EPA Tier2)....603

S4D98E (– EPA Tier2)....604

3D82AE-B (complies with EPA Interim Tier4)....605

S3D84E-B (complies with EPA Interim Tier4)....606

3D88E-U (complies with EPA Interim Tier4)....607

3D88E-B (complies with EPA Interim Tier4)....608

S4D84E-Z (complies with EPA Interim Tier4)....609

4D88E-U (complies with EPA Interim Tier4)....610

4D88E-B (complies with EPA Interim Tier4)....611

4D98E-E (complies with EPA Interim Tier4)....612

4D98E-Z (complies with EPA Interim Tier4)....613

S4D98E-Z (complies with EPA Tier3)....614

Engine service standards....615

Tightening torques for standard bolts and nuts....616

Abbreviations and symbols....618

Abbreviations....618

Symbols....618

Unit conversions....619

Unit prefixes....619

Units of length....619

Units of volume....619

Units of mass....619

Units of force....619

Units of torque....619

Units of pressure....619

Units of power....619

Units of temperature....619

30 Testing and adjusting....622

Testing and adjusting, Part 1....622

Before you begin servicing....624

Introduction....637

The importance of periodic maintenance....637

Performing periodic maintenance....637

Komatsu replacement parts....637

Required EPA / ARB maintenance - USA only....637

EPA / ARB installation requirements - USA only....637

Periodic maintenance schedule....638

Periodic maintenance procedures....641

After initial 50 hours of operation....641

Every 50 hours of operation....645

Every 250 hours of operation....648

Every 500 hours of operation....653

Every 1000 hours of operation....657

Every 1500 hours of operation....660

Every 2000 hours of operation....662

Testing and adjusting, Part 2....664

Before you begin servicing....666

Introduction....669

Cylinder head specifications....669

Adjustment specifications....669

Cylinder head....669

Intake / exhaust valve and guide....670

Push rod....672

Rocker arm and shaft....672

Valve spring....673

Camshaft and timing gear train specifications....674

Camshaft....674

Idler gear shaft and bushing....676

Timing gear backlash....676

Crankshaft and piston specifications....677

Crankshaft....677

Thrust bearing....678

Piston....679

Piston ring....681

Connecting rod....684

Tappet....685

Cylinder block specifications....686

Cylinder block....686

Special torque chart....687

Torque for bolts and nuts....687

Special service tools....690

Measuring instruments....694

2-valve cylinder head....696

2-valve cylinder head components....696

Components of a two-valve cylinder head....697

Disassembly of 2-valve cylinder head....698

Cleaning of cylinder head components....702

Inspection of cylinder head components....702

Reassembly of cylinder head....706

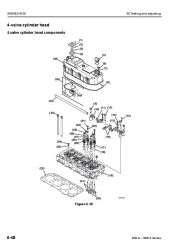

4-valve cylinder head....711

4-valve cylinder head components....711

Disassembly of 4-valve cylinder head....712

Cleaning of cylinder head components....717

Inspection of cylinder head components....718

Reassembly of cylinder head....723

Measuring and adjusting valve clearance....728

2-valve cylinder heads....729

4-valve cylinder heads....730

Crankshaft and camshaft components....733

Disassembly of engine....734

Disassembly of camshaft and timing components....735

Disassembly of crankshaft and piston components....740

Inspection of crankshaft and camshaft components....744

Honing and boring....750

Reassembly of crankshaft and piston components....751

Reassembly of camshaft and timing components....756

Final reassembly of engine....760

EGR system....761

EGR system....761

EGR system....763

Inspecting/cleaning EGR related components....766

Testing and adjusting, Part 3....772

Before you begin servicing....774

Introduction....779

Fuel injection pump....779

Stop solenoid....780

Cold start device....780

Trochoid fuel pump....781

Electronically controlled governor....781

Fuel system specifications....782

Special torque chart....782

Test and adjustment specifications....783

Special service tools....784

Measuring instruments....784

Fuel system diagram....785

Fuel system components....786

2-valve cylinder head....786

4-valve cylinder head....788

Fuel injection pump....790

Removal of fuel injection pump....790

Installation of fuel injection pump....795

Checking and adjusting fuel injection timing....801

Determining the fuel injection timing specification....801

Checking fuel injection timing....802

Adjusting fuel injection timing....805

Fuel injectors....806

Removal of fuel injectors....806

Testing of fuel injectors....809

Disassembly and inspection of fuel injectors....810

Adjusting fuel injector pressure....812

Reassembly of fuel injectors....812

Installation of the fuel injectors....813

Testing and adjusting, Part 4....816

Before you begin servicing....818

Introduction....821

Cooling system diagram....821

Engine coolant pump components....822

Engine coolant system check....823

Engine coolant pump....823

Removal of engine coolant pump....823

Disassembly of engine coolant pump....825

Cleaning and inspection....825

Reassembly of engine coolant pump....826

Installation of engine coolant pump....827

Testing and adjusting, Part 5....830

Before you begin servicing....832

Introduction....834

Oil pump service information....834

Lubrication system diagram....837

Checking engine oil pressure....838

Trochoid oil pump....838

3D82AE to 4D88E oil pump components....838

Disassembly of oil pump....839

Cleaning and inspection....840

Reassembly of oil pump....841

Trochoid oil pump....842

3D82AE-B, 3D88E-B, 3D88E-U, 4D88E-B, 4D88E-U, S3D84E-Z, S4D84E-Z Oil pump components....842

Disassembly of oil pump....843

Cleaning and inspection....843

Reassembly of oil pump....845

Trochoid oil pump....846

4D94LE/98E oil pump components....846

Disassembly of oil pump....846

Cleaning and inspection....847

Reassembly of oil pump....848

Testing and adjusting, Part 6....850

Before you begin servicing....852

Introduction....854

Specifications....854

Turbocharger service information....854

Troubleshooting....855

Excessive exhaust smoke....855

Generates white smoke....856

Sudden oil decrease....856

Decrease in output....856

Poor (slow) response (starting) of turbocharger....856

Abnormal sound or vibration....856

Turbocharger components....857

Turbocharger component functions....859

Theory of operation....860

Compressor side sealing mechanism....860

Waste gate modulation....860

Washing procedure....861

Periodic inspection....862

Visual inspection....862

Inspection of rotor rotation....862

Inspection of rotor play....862

Removal of turbocharger....862

Checking rotor play....863

Waste gate valve test....863

Waste gate actuator leak test....864

Installation of turbocharger....864

Testing and adjusting, Part 7....866

Before you begin servicing....868

Introduction....870

Starter motor information....870

3D82AE to 4D88E - Standard and optional....870

4D94LE to S4D98E - Standard and optional....871

Starter motor specifications....872

Starter motor troubleshooting....873

Starter motor components....874

Starter motor....875

Removal of starter motor....875

Disassembly of starter motor....875

Cleaning and inspection....877

Reassembly of starter motor....882

Check pinion projection length....883

No-load test....884

Installation of starter motor....885

Testing and adjusting, Part 8....888

Before you begin servicing....890

Introduction....893

Dynamo and alternator information....893

3D82AE to S4D98E - Standard and optional dynamos....893

3D82AE to S4D98E - Standard and optional alternators....893

Alternator specifications....894

Dynamo specifications....894

Alternator troubleshooting....895

Alternator components....896

Alternator wiring diagram....897

Alternator standard output....898

Alternator....899

Removal of alternator....899

Disassembly of alternator....899

Reassembly of alternator....901

Installation of alternator....903

Dynamo component location....904

Dynamo wiring diagram....905

Operation of dynamo....905

Dynamo standard output....906

Testing of dynamo....907

Testing stator coil continuity....907

Testing stator coil short-to-ground....907

Testing dynamo regulated output....907

Dynamo....907

Removal of dynamo....907

Disassembly of dynamo....908

Reassembly of dynamo....908

Installation of dynamo....909

40 Troubleshooting....912

Troubleshooting of mechanical system....912

Special service tools....914

Troubleshooting by measuring compression pressure....916

Compression pressure measurement method....916

Quick reference table for troubleshooting....919

Failure Diagnostic List....920

Komatsu 68E, 74E, 78E, 82E, 84E, 88E, 94E, 98E Series Diesel Engine Repair Service Manuals