Komatsu Articulated Dump Truck HM300-2R Repair Service Manuals

Catalog:

Model:

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Articulated Dump Truck HM300-2R, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Articulated Dump Truck HM300-2R workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 2,023 pages

File Format: PDF

Language: English

SEN02269-06 - Articulated Dump Truck HM300-2R Shop Manual.pdf

GEN00091-00 - Articulated Dump Truck HM300-2R Field Assembly Instruction.pdf

PEN00193-09 - Articulated Dump Truck HM300-2R Operation & Maintenance Manual.pdf

PEN00470-11 - Articulated Dump Truck HM300-2R Operation & Maintenance Manual.pdf

MAIN SECTIONS

GEN00091-00 - Articulated Dump Truck HM300-2R Field Assembly Instruction...2

COVER...2

Contents...3

1 Drawings of removed units...5

2 Dimensions of removed units...5

3 Assembly procedure, necessary equipments, and schedule...6

4 Necessary tools and equipments...6

5 Assembly procedure No...7

0100 Positioning bare machine...7

0150 Installation of rear monitor...8

0200 Installing engine hood mirrors...9

0250 Installation of right and left mudguards...10

0300 Adjusting N2 gas of front and rear suspensions...11

Attached sheet: Mirror adjustment for reference...12

PEN00193-09 - Articulated Dump Truck HM300-2R Operation & Maintenance Manual...15

COVER...15

FOREWORD...16

BEFORE READING THIS MANUAL...17

SAFETY INFORMATION...18

INTENDED USE...19

USE OF MACHINE...19

DIRECTIONS OF MACHINE...19

VISIBILITY FROM OPERATOR'S SEAT...19

LOCATION OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR...20

PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE...20

ENGINE SERIAL NO. PLATE...20

SERVICE METER POSITION...21

TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR...21

CONTENTS...22

SAFETY...26

SAFETY...27

SAFETY LABELS...30

POSITION FOR ATTACHING SAFETY LABELS...31

SAFETY LABELS...32

GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE...38

PRECAUTIONS BEFORE STARTING OPERATION...38

PREPARATIONS FOR SAFE OPERATION...38

FIRE PREVENTION...40

PRECAUTIONS WHEN GETTING ON OR OFF MACHINE...41

DO NOT GET CAUGHT IN ARTICULATING PORTION AND DUMP BODY...43

PRECAUTIONS RELATED TO PROTECTIVE STRUCTURES...43

UNAUTHORIZED MODIFICATION...43

PRECAUTIONS RELATED TO ATTACHMENTS AND OPTIONS...44

PRECAUTIONS WHEN RUNNING ENGINE INSIDE BUILDING...44

PRECAUTIONS FOR OPERATION...45

PRECAUTIONS FOR JOBSITE...45

STARTING ENGINE...47

OPERATION...50

TRANSPORTATION...54

TOWING...55

PRECAUTIONS FOR MAINTENANCE...56

PRECAUTIONS BEFORE STARTING INSPECTION AND MAINTENANCE...56

PRECAUTIONS FOR INSPECTION AND MAINTENANCE...61

TIRES...66

OPERATION...68

GENERAL VIEW...69

GENERAL VIEW OF MACHINE...69

GENERAL VIEW OF CONTROLS AND GAUGES...70

EXPLANATION OF COMPONENTS...72

MACHINE MONITOR...72

OTHER FUNCTIONS OF MACHINE MONITOR...93

SWITCHES...97

CONTROL LEVERS AND PEDALS...107

BODY PIVOT PIN...112

ARTICULATE LOCK...112

LOCATION OF FIRE EXTINGUISHER...113

DUST INDICATOR...113

CIRCUIT BREAKER...113

FUSES...114

CAR RADIO...117

CAR STEREO...123

AIR CONDITIONER...131

OPERATION...136

CHECK BEFORE STARTING ENGINE...136

STARTING ENGINE...153

OPERATIONS, CHECKS AFTER STARTING ENGINE...155

STOPPING ENGINE...156

CHECKS AFTER STOPPING ENGINE...156

MOVING MACHINE OFF (FORWARD, REVERSE), STOPPING...157

SHIFTING GEAR...162

TRAVELING DOWNHILL...164

STEERING THE MACHINE...170

OPERATION USING DIFFERENTIAL LOCK...171

LOADING OPERATIONS...172

DUMP OPERATIONS...174

CAB TILT OPERATION...176

PRECAUTIONS FOR OPERATION...179

PARKING MACHINE...180

CHECKS AFTER COMPLETION OF WORK...181

LOCKING...181

HANDLING TIRES...182

DETERMINING AND MAINTAINING TRAVEL ROAD...183

DETERMINING TRAVEL ROAD...183

MAINTAINING TRAVEL ROAD...183

TRANSPORTATION...184

PRECAUTIONS WHEN TRANSPORTING...184

STEPS FOR TRANSPORTATION...184

METHOD OF SECURING MACHINE...185

METHOD OF LIFTING MACHINE...186

COLD WEATHER OPERATION...190

PRECAUTIONS FOR LOW TEMPERATURE...190

PRECAUTIONS AFTER COMPLETION OF WORK...191

AFTER COLD WEATHER...192

LONG-TERM STORAGE...193

BEFORE STORAGE...193

DURING STORAGE...193

AFTER STORAGE...193

PRECAUTIONS BEFORE TRAVELING AFTER LONG-TERM STORAGE...193

TROUBLESHOOTING...194

AFTER RUNNING OUT OF FUEL...194

IF TRANSMISSION HAS TROUBLE...194

METHOD OF LOWERING DUMP BODY IN EMERGENCY...194

METHOD OF TOWING MACHINE...195

IF BATTERY IS DISCHARGED...199

OTHER TROUBLE...203

MAINTENANCE...210

GUIDES TO MAINTENANCE...211

OUTLINE OF SERVICE...213

HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC...213

OUTLINE OF ELECTRIC SYSTEM...217

WEAR PARTS...218

WEAR PARTS LIST...218

RECOMMENDED FUEL, COOLANT, AND LUBRICANT...219

USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE...220

RECOMMENDED BRANDS, RECOMMENDED QUALITY FOR PRODUCTS OTHER THAN KOMATSU GENUINE OIL...221

STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS...222

TORQUE LIST...222

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS...224

SAFETY CRITICAL PARTS...225

MAINTENANCE SCHEDULE CHART...226

MAINTENANCE SCHEDULE CHART...226

SERVICE PROCEDURE...229

INITIAL 250 HOURS SERVICE (ONLY AFTER THE FIRST 250 HOURS)...229

WHEN REQUIRED...230

CHECK BEFORE STARTING...254

EVERY 50 HOURS SERVICE...255

EVERY 250 HOURS SERVICE...256

EVERY 500 HOURS SERVICE...267

EVERY 1000 HOURS SERVICE...274

EVERY 2000 HOURS SERVICE...284

EVERY 4000 HOURS SERVICE...291

EVERY 6000 HOURS SERVICE...294

EVERY 8000 HOURS SERVICE...295

SPECIFICATIONS...296

SPECIFICATIONS...297

ATTACHMENTS, OPTIONS...298

HANDLING AUTOMATIC RETARDER, ACCELERATOR CONTROL(ARAC)...299

EXPLANATION OF COMPONENTS...299

METHOD OF OPERATION...300

HANDLING PAYLOAD METER HM...301

FEATURES OF PAYLOAD METER HM...301

METHOD OF USING ACCURATELY...302

GENERAL LOCATIONS...304

CONTENT OF DISPLAY (CONTROLLER, EXTERNAL DISPLAY LAMPS)...307

EXTERNAL DISPLAY LAMPS...309

DETAILS OF DATA STORED IN MEMORY OF PAYLOAD METER...311

OPERATION OF SWITCHES...314

ABNORMALITY AND WARNING DISPLAY (ERROR CODE)...327

WHEN ERROR CODE F-09 IS DISPLAYED...328

PROCEDURE WHEN DOWNLOADING...329

OTHERS...332

USE OF REAR VIEW MONITOR...333

NAME AND FUNCTON OF EACH PART OF REAR VIEW MONITOR...333

SETTING OF REAR VIEW MONITOR...336

CAUTIONS WHEN USING REAR VIEW MONITOR...336

HANDLING DUMPING COUNTER...337

HANDLING BATTERY DISCONNECTOR SWITCH...338

HANDLING MACHINES EQUIPPED WITH KOMTRAX...340

BASIC PRECAUTIONS...340

INDEX...342

PEN00470-11 - Articulated Dump Truck HM300-2R Operation & Maintenance Manual...346

COVER...346

FOREWORD...347

BEFORE READING THIS MANUAL...348

SAFETY INFORMATION...349

INTENDED USE...350

USE OF MACHINE...350

DIRECTIONS OF MACHINE...350

VISIBILITY FROM OPERATOR'S SEAT...351

LOCATION OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR...352

PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE...352

ENGINE SERIAL NO. PLATE...352

SERVICE METER POSITION...353

TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR...353

CONTENTS...354

SAFETY...359

SAFETY...360

SAFETY LABELS...363

POSITION FOR ATTACHING SAFETY LABELS...364

SAFETY LABELS...365

GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE...372

PREPARATIONS FOR SAFE OPERATION...372

EPARATIONS FOR SAFE OPERATION...372

PRECAUTIONS WHEN GETTING ON OR OFF MACHINE...375

DO NOT GET CAUGHT IN ARTICULATING PORTION AND DUMP BODY...377

PRECAUTIONS RELATED TO PROTECTIVE STRUCTURES...377

UNAUTHORIZED MODIFICATION...377

PRECAUTIONS RELATED TO ATTACHMENTS AND OPTIONS...378

PRECAUTIONS WHEN RUNNING ENGINE INSIDE BUILDING...378

PRECAUTIONS FOR OPERATION...379

PRECAUTIONS FOR JOBSITE...379

STARTING ENGINE...381

OPERATION...384

TRANSPORTATION...388

TOWING...389

PRECAUTIONS FOR MAINTENANCE...390

PRECAUTIONS BEFORE STARTING INSPECTION AND MAINTENANCE...390

PRECAUTIONS FOR INSPECTION AND MAINTENANCE...395

TIRES...400

OPERATION...403

GENERAL VIEW...404

GENERAL VIEW OF MACHINE...404

GENERAL VIEW OF CONTROLS AND GAUGES...405

EXPLANATION OF COMPONENTS...407

MACHINE MONITOR...407

OTHER FUNCTIONS OF MACHINE MONITOR...428

SWITCHES...432

CONTROL LEVERS AND PEDALS...443

BODY PIVOT PIN...448

ARTICULATE LOCK...448

LOCATION OF FIRE EXTINGUISHER...449

DUST INDICATOR...449

CIRCUIT BREAKER...449

FUSES...450

CAR RADIO...453

CAR STEREO...459

AIR CONDITIONER...467

OPERATION...472

CHECK BEFORE STARTING ENGINE...472

STARTING ENGINE...490

OPERATIONS, CHECKS AFTER STARTING ENGINE...492

CANCELING DUMP BODY HOLD CONDITION...493

MOVING MACHINE OFF (FORWARD, REVERSE), STOPPING...494

SHIFTING GEAR...499

TRAVELING DOWNHILL...501

STEERING THE MACHINE...507

OPERATION USING DIFFERENTIAL LOCK...508

LOADING OPERATIONS...509

DUMP OPERATIONS...511

CAB TILT OPERATION...513

PRECAUTIONS FOR OPERATION...516

PARKING MACHINE...517

CHECKS AFTER COMPLETION OF WORK...518

LOCKING...518

HANDLING TIRES...519

DETERMINING AND MAINTAINING TRAVEL ROAD...520

DETERMINING TRAVEL ROAD...520

MAINTAINING TRAVEL ROAD...520

TRANSPORTATION...521

PRECAUTIONS WHEN TRANSPORTING...521

STEPS FOR TRANSPORTATION...521

METHOD OF SECURING MACHINE...522

METHOD OF LIFTING MACHINE...523

COLD WEATHER OPERATION...527

PRECAUTIONS FOR LOW TEMPERATURE...527

PRECAUTIONS AFTER COMPLETION OF WORK...528

AFTER COLD WEATHER...529

LONG-TERM STORAGE...530

BEFORE STORAGE...530

DURING STORAGE...530

AFTER STORAGE...530

PRECAUTIONS BEFORE TRAVELING AFTER LONG-TERM STORAGE...530

TROUBLESHOOTING...531

AFTER RUNNING OUT OF FUEL...531

IF TRANSMISSION HAS TROUBLE...532

METHOD OF LOWERING DUMP BODY IN EMERGENCY...532

METHOD OF TOWING MACHINE...533

IF BATTERY IS DISCHARGED...537

OTHER TROUBLE...541

MAINTENANCE...547

GUIDES TO MAINTENANCE...548

OUTLINE OF SERVICE...550

HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC...550

OUTLINE OF ELECTRIC SYSTEM...554

WEAR PARTS...555

WEAR PARTS LIST...555

RECOMMENDED FUEL, COOLANT, AND LUBRICANT...556

USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE...557

RECOMMENDED BRANDS, RECOMMENDED QUALITY FOR PRODUCTS OTHER THAN KOMATSU GENUINE OIL...559

STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS...560

TORQUE LIST...560

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS...562

SAFETY CRITICAL PARTS...563

MAINTENANCE SCHEDULE CHART...564

MAINTENANCE SCHEDULE CHART...564

SERVICE PROCEDURE...567

INITIAL 250 HOURS SERVICE (ONLY AFTER THE FIRST 250 HOURS)...567

WHEN REQUIRED...568

CHECK BEFORE STARTING...590

EVERY 50 HOURS SERVICE...591

EVERY 250 HOURS SERVICE...592

EVERY 500 HOURS SERVICE...603

EVERY 1000 HOURS SERVICE...610

EVERY 2000 HOURS SERVICE...628

EVERY 4000 HOURS SERVICE...635

EVERY 6000 HOURS SERVICE...638

EVERY 8000 HOURS SERVICE...639

SPECIFICATIONS...641

SPECIFICATIONS...642

ATTACHMENTS, OPTIONS...645

HANDLING AUTOMATIC RETARDER, ACCELERATOR CONTROL(ARAC)...646

EXPLANATION OF COMPONENTS...646

METHOD OF OPERATION...647

HANDLING PAYLOAD METER HM...648

FEATURES OF PAYLOAD METER HM...648

METHOD OF USING ACCURATELY...649

GENERAL LOCATIONS...651

CONTENT OF DISPLAY (CONTROLLER, EXTERNAL DISPLAY LAMPS)...654

EXTERNAL DISPLAY LAMPS...656

DETAILS OF DATA STORED IN MEMORY OF PAYLOAD METER...658

OPERATION OF SWITCHES...661

ABNORMALITY AND WARNING DISPLAY (ERROR CODE)...674

WHEN ERROR CODE F-09 IS DISPLAYED...675

PROCEDURE WHEN DOWNLOADING...676

OTHERS...679

USE OF REAR VIEW MONITOR...680

NAME AND FUNCTON OF EACH PART OF REAR VIEW MONITOR...680

SETTING OF REAR VIEW MONITOR...683

CAUTIONS WHEN USING REAR VIEW MONITOR...683

HANDLING DUMPING COUNTER...684

HANDLING BATTERY DISCONNECTOR SWITCH...685

HANDLING MACHINES EQUIPPED WITH KOMTRAX...687

BASIC PRECAUTIONS...687

INDEX...689

SEN02269-06 - Articulated Dump Truck HM300-2R Shop Manual...693

COVER...693

00 Index and foreword...0

Index...695

Composition of shop manual...696

Table of contents...698

Foreword and general information...709

Safety notice...710

How to read the shop manual...715

Explanation of terms for maintenance standard...717

Handling of electric equipment and hydraulic component...719

Handling of connectors newly used for engines...728

How to read electric wire code...731

Precautions when carrying out operation...734

Method of disassembling and connecting push-pull type coupler...737

Standard tightening torque table...740

Conversion table...744

01 Specification...0

Specification and technical data...751

Specification drawings...752

Specifications...753

Weight table...756

Fuel, coolant and lubricants...757

10 Structure, function and maintenance standard...0

Engine and cooling system...761

Radiator, oil cooler, aftercooler...762

Output shaft...763

Power train, Part 1...767

Power train skeleton...768

Torque converter and transmission hydraulic piping...770

Brake cooling oil control valve (BCV)...772

Power train pump...773

Torque converter...776

Transmission...782

Transmission control valve...810

ECMV...811

Main relief, torque converter relief valve...818

Power train, Part 2...821

Drive shaft...822

Axle...823

Differential...826

Limited slip differential...832

Final drive...836

Steering system...843

Steering column...844

Brake system...847

Brake piping...848

Brake valve...850

Accumulator charge valve...853

Accumulator...857

Slack adjuster...858

Brake...860

Proportional reducing valve...865

Brake system tank...866

Parking brake...868

Parking brake solenoid...872

Undercarriage and frame...875

Suspension...876

Suspension cylinder...882

Oscillation hitch...884

Hydraulic system...889

Steering, hoist oil pressure piping diagram...890

Dump body control...891

Hydraulic tank and filter...892

Flow amp valve...893

Steering valve...896

Steering cylinder...900

Hoist valve...902

EPC valve...908

Hoist cylinder...909

Hydraulic pump...910

Cab and its attachments...913

ROPS cab...914

Cab tilt...915

Air conditioner...916

Rear view monitor...924

Controller related...927

Electrical system, Part 1...929

Machine monitor system...930

Electrical system, Part 2...951

Automatic shift control system...952

Retarder control system...984

Auto emergency steering system...996

Dump control lever...997

Electrical system, Part 3...1003

Payload meter (Card type)...1004

Electrical system, Part 4...1037

Sensors, switches...1038

KOMTRAX terminal system (If equipped)...1046

20 Standard value table...0

Standard service value table...1049

Standard value table for engine...1050

Standard value table for chassis...1051

30 Testing and adjusting...0

Testing and adjusting, Part 1...1059

Tools for testing, adjusting, and troubleshooting...1061

Sketches of special tools...1066

Measuring engine speed...1067

Measuring intake air pressure (boost pressure)...1068

Measuring exhaust temperature...1069

Measuring exhaust gas color...1071

Adjusting valve clearance...1072

Measuring compression pressure...1074

Measuring blow-by pressure...1076

Measuring engine oil pressure...1077

Handling of fuel system devices...1078

Releasing residual pressure from fuel system...1078

Testing fuel pressure...1079

Testing fuel return and leak amount...1080

Bleeding air from fuel circuit...1083

Testing fuel circuit for leakage...1085

Testing and adjusting alternator belt tension...1086

Testing and adjusting air conditioner compressor belt tension...1086

Adjusting the body mount...1087

Testing and adjusting, Part 2...1089

Measuring torque converter stall speed...1091

Measuring power train oil pressure...1092

Adjusting transmission speed sensor...1100

Testing and adjusting brake oil pressure...1102

Testing of accumulator nitrogen gas pressure and procedure for charging accumulator with nitrogen gas...1106

Testing brake performance...1109

Bleeding air from brake circuit...1110

Measuring wear of wheel brake disc...1111

Measuring wear of parking brake pad...1112

Method for emergency release of parking brake...1114

Testing and adjusting steering circuit oil pressure...1115

Testing and adjusting suspension cylinder...1117

Method of tilting cab up...1121

Testing and adjusting dump circuit oil pressure...1123

Adjusting body positioner sensor...1126

Procedure for adjusting length of spring in body heating spherical joint...1127

Handling engine controller high voltage circuit...1127

Adjusting transmission controller...1128

Method for emergency escape at electrical system failure...1129

Testing and adjusting, Part 3...1135

Setting and adjusting various equipments...1136

Special function of machine monitor (EMMS)...1147

How to start operation of KOMTRAX terminal...1181

Lamp display of KOMTRAX terminal...1184

Pm Clinic check sheet...1187

40 Troubleshooting...0

Failure code table and fuse locations...1191

Failure code table...1192

Before troubleshooting by failure codes...1199

General information on troubleshooting...1203

Points to remember when troubleshooting...1204

Sequence of events in troubleshooting...1205

Checks before troubleshooting...1206

Classification and procedures for troubleshooting...1207

Information in troubleshooting table...1208

Connection table for connector pin numbers...1210

T-branch box and T- branch adapter table...1246

Troubleshooting by failure code (Display of code), Part 1...1251

Failure code [1500L0] (Dual engagement)...1253

Failure code [15B0NX] (Transmission oil filter: Clogged)...1254

Failure code [15F0KM] (R → F shifting abuse 1: Operational error or incorrect setting)...1256

Failure code [15F0MB] (R → F shifting abuse 2: Functional deterioration)...1256

Failure code [15F7KM] (forward clutch disc abuse)...1257

Failure code [15G0MW] (R clutch: Slipping)...1258

Failure code [15G7KM] (reverse clutch disc abuse)...1260

Failure code [15H0MW] (Hi clutch: Slipping)...1261

Failure code [15J0MW] (Lo clutch: Slipping)...1264

Failure code [15K0MW] (1st clutch: Slipping)...1266

Failure code [15L0MW] (2nd clutch: Slipping)...1268

Failure code [15M0MW] (3rd clutch: Slipping)...1270

Failure code [15SBL1] (R clutch solenoid: Fill signal is ON when command current is OFF.)...1272

Failure code [15SBMA] (R clutch solenoid: Malfunction)...1276

Failure code [15SCL1] (Hi clutch solenoid: Fill signal is ON when command current is OFF.)...1278

Failure code [15SCMA] (Hi clutch solenoid: Malfunction)...1282

Failure code [15SDL1] (Lo clutch solenoid: Fill signal is ON when command current is OFF.)...1284

Failure code [15SDMA] (Lo clutch solenoid: Malfunction)...1286

Failure code [15SEL1] (1st clutch solenoid: Fill signal is ON when command current is OFF)...1290

Failure code [15SEMA] (1st clutch solenoid: Malfunction)...1294

Failure code [15SFL1] (2nd clutch solenoid: Fill signal is ON when command current is OFF.)...1296

Failure code [15SFMA] (2nd clutch solenoid: Malfunction)...1300

Failure code [15SGL1] (3rd clutch solenoid: Fill signal is ON when command current is OFF.)...1302

Failure code [15SGMA] (3rd clutch solenoid: Malfunction)...1306

Failure code [15SJMA] (Lockup clutch solenoid: Malfunction)...1308

Failure code [15SKMA] (Inter-axle differential lockup pressure control valve: Malfunction)...1310

Failure code [2F00KM] (Parking brake: Error in operation or setting)...1312

Failure code [2G42ZG] (Front accumulator: Oil pressure too low)...1314

Failure code [2G43ZG] (Rear accumulator: Oil pressure too low)...1314

Troubleshooting by failure code (Display of code), Part 2...1317

Failure code [989A00] (Engine over run prevention command signal: Operating)...1319

Failure code [989D00] (Rear section tipping over alarm: Alarm is activated.)...1319

Failure code [AA10NX] (Air cleaner element: Clogged)...1320

Failure code [AB00MA] (Alternator: Malfunction)...1322

Failure code [B@BAZK] (Engine oil : Level too low)...1323

Failure code [B@BCNS] (Eng overheat)...1324

Failure code [B@BCZK] (Radiator coolant: Level too low)...1325

Failure code [B@BFZK] (Fuel level: Level too low)...1326

Failure code [B@C6NS] (Front brake oil: Overheat)...1327

Failure code [B@C8NS] (Center brake oil: Overheat)...1327

Failure code [B@CENS] (Torque converter: Overheat)...1328

Failure code [B@HAZK] (Hydraulic tank oil: Level too low)...1329

Failure code [B@JANS] (Steering oil: Overheat)...1330

Failure code [CA111] (Abnormality in engine controller)...1331

Failure code [CA115] (Abnormal engine Ne and Bkup sensors)...1332

Failure code [CA122] (Charge pressure sensor too high)...1334

Failure code [CA123] (Charge pressure sensor too low)...1336

Failure code [CA131] (Throttle sensor tool high)...1338

Failure code [CA132] (Throttle sensor tool low)...1340

Failure code [CA135] (Oil pressure sensor too high)...1342

Failure code [CA141] (Oil pressure sensor too low)...1344

Failure code [CA144] (Coolant temperature sensor too high)...1346

Failure code [CA145] (Coolant temperature sensor too low)...1348

Failure code [CA153] (Charge temperature sensor too high)...1350

Failure code [CA154] (Charge temperature sensor too low)...1352

Failure code [CA187] (Sensor power source 2 too low)...1352

Failure code [CA221] (Atmospheric sensor too high)...1354

Failure code [CA222] (Atmospheric sensor too low)...1356

Failure code [CA227] (Sensor power source 2 too high)...1358

Failure code [CA234] (Engine over speed)...1360

Failure code [CA238] (Abnormal power source for Ne speed sensor)...1362

Failure code [CA263] (Fuel temperature sensor too high)...1364

Failure code [CA265] (Fuel temperature sensor too low)...1366

Failure code [CA271] (PCV1 short circuit)...1367

Failure code [CA272] (PCV1 disconnection)...1368

Failure code [CA273] (PCV2 short circuit)...1369

Failure code [CA274] (PCV2 disconnection)...1370

Failure code [CA322] (Injector No. 1 system disconnection or short circuit)...1372

Failure code [CA323] (Injector No. 5 system disconnection or short circuit)...1374

Failure code [CA324] (Injector No. 3 system disconnection or short circuit)...1376

Failure code [CA325] (Injector No. 6 system disconnection or short circuit)...1378

Failure code [CA331] (Injector No. 2 system disconnection or short circuit)...1380

Failure code [CA332] (Injector No. 4 system disconnection or short circuit)...1382

Troubleshooting by failure code (Display of code), Part 3...1385

Failure code [CA342] (Abnormal engine controller data consistency)...1387

Failure code [CA351] (Abnormal injector drive circuit)...1388

Failure code [CA352] (Sensor power source 1 too low)...1389

Failure code [CA386] (Sensor power source 1 too high)...1390

Failure code [CA431] Idle validation switch error...1392

Failure code [CA432] (Abnormal process with idle validation switch)...1396

Failure code [CA441] (Power source voltage too low)...1397

Failure code [CA442] (Power source voltage too high)...1397

Failure code [CA449] (Common rail pressure too high 2)...1398

Failure code [CA451] (Common rail pressure sensor too high)...1400

Failure code [CA452] (Common rail pressure sensor too low)...1402

Failure code [CA553] (Common rail pressure too high 1)...1402

Failure code [CA554] (In-range error of common rail pressure sensor)...1403

Failure code [CA559] (Loss of pressure feed from supply pump 1)...1404

Failure code [CA689] (Abnormal engine Ne speed sensor)...1408

Failure code [CA731] (Abnormal engine Bkup speed sensor phase)...1410

Failure code [CA757] (Loss of all engine controller data)...1410

Failure code [CA778] (Abnormal engine Bkup speed sensor)...1412

Failure code [CA1633] (Abnormal KOMNET)...1414

Failure code [CA2185] (Throttle sensor power source too high)...1416

Failure code [CA2186] (Throttle sensor power source too low)...1418

Failure code [CA2249] (Loss of pressure feed from supply pump 2)...1418

Failure code [CA2555] (Disconnection in intake air heater relay)...1419

Failure code [CA2556] (Intake air heater relay short circuit)...1420

Failure code [DAF9KM] (Machine monitor connector: Error in operation or setting)...1422

Failure code [DAFRKR] (Abnormal CAN communication (machine monitor): Abnormal communication)...1424

Failure code [DAQ0KK] (Transmission controller: Power source voltage too low)...1426

Failure code [DAQ0KT] (Transmission nonvolatile memory: Abnormality in controller)...1428

Failure code [DAQ2KK] (Transmission controller solenoid power source: Voltage too low)...1429

Failure code [DAQRKR] (COMMUNICATION LOST: Defective communication)...1430

Failure code [DAQRMA] (Transmission controller option setting: Malfunction)...1432

Failure code [DB10KT] (Retarder controller nonvolatile memory: Abnormality in controller)...1432

Failure code [DB12KK] (Retarder controller solenoid power source: Power source voltage too low)...1433

Failure code [DB13KK] (Retarder controller battery direct power source: Power source voltage too low)...1434

Failure code [DB19KQ] (Retarder controller model select signal: Inconsistent model selection signal)...1435

Failure code [DB1QMA] (Retarder controller option setting: Malfunction)...1435

Failure code [DB1RKR] (CAN communication (retarder controller): Communication disabled)...1436

Failure code [DB2RKR] (CAN communication (engine controller): Communication disabled)...1438

Failure code [DDTHKA] (Fill switch for Hi clutch: Disconnection)...1440

Failure code [DDTJKA] (Fill switch for Lo clutch: Disconnection)...1442

Failure code [DDTKKA] (Fill switch for 1st clutch: Disconnection)...1444

Failure code [DDTLKA] (Fill switch for 2nd clutch: Disconnection)...1445

Failure code [DDTMKA] (Fill switch for 3rd clutch: Disconnection)...1446

Failure code [DDTNKA] (Fill switch for R clutch: Disconnection)...1447

Failure code [DF10KA] (Gear shift lever: Disconnection)...1448

Failure code [DF10KB] (Gear shift lever: Short circuit)...1451

Troubleshooting by failure code (Display of code), Part 4...1455

Failure code [DGF1KX] (Transmission oil temperature sensor: Input signal out of range)...1458

Failure code [DGR3KZ] (Center brake oil temperature sensor: Disconnection or short circuit)...1460

Failure code [DGR3L8] (Center brake oil temperature sensor: Inconsistent analog signals)...1462

Failure code [DGR4KZ] (Front brake oil temperature sensor: Disconnection or short circuit)...1464

Failure code [DGR4L8] (Front brake oil temperature sensor: Inconsistent analog signals)...1466

Failure code [DGR6KX] (Steering oil temperature sensor: Input signal out of range)...1468

Failure code [DGT1KX] (Torque converter oil temperature sensor: Input signal out of range)...1470

Failure code [DHT5KX] (Torque converter oil pressure sensor: Input signal out of range)...1472

Failure code [DHT5L6] (Torque converter oil pressure sensor: Inconsistent signals during a travel and stop)...1474

Failure code [DHU2KX] (Front accumulator oil pressure sensor: Input signal out of range)...1476

Failure code [DHU3KX] (Rear accumulator oil pressure sensor: Input signal out of range)...1478

Failure code [DJF1KA] (Fuel level sensor: Disconnection)...1480

Failure code [DK51L5] (Retarder lever potentiometer: Potentiometer signal is inconsistent with switch signal)...1482

Failure code [DK52KX] (Dump lever potentiometer failure 1: Input signal out of range)...1484

Failure code [DK53L8] (Dump lever potentiometer failure 2: Inconsistent analog signal)...1486

Failure code [DK54KX] (Body positioner sensor: Input signal out of range)...1488

Failure code [DKH0KX] (Inclination sensor: Inclination out of range)...1490

Failure code [DLF1KA] (Transmission input shaft speed sensor: Disconnection)...1492

Failure code [DLF1LC] (Transmission input shaft speed sensor: Inconsistent rotation speed signal)...1493

Failure code [DLF2KA] (Transmission intermediate shaft speed sensor: Disconnection)...1494

Failure code [DLF2LC] (Transmission intermediate shaft speed sensor: Inconsistent speed signal)...1495

Failure code [DLF4KA] (Differential speed sensor: Disconnection)...1496

Failure code [DLT3KA] (Transmission output shaft speed sensor: Disconnection)...1497

Failure code [DV00KB] (Alarm buzzer output: Short circuit)...1498

Failure code [DW72KZ] (Kick-out solenoid output system: Disconnection or short circuit)...1500

Failure code [DW73KZ] (Hoist selector valve output system: Disconnection or short circuit)...1502

Failure code [DW78KZ] (Rear brake BCV command output system: Disconnection or short circuit)...1504

Failure code [DW79KZ] (Front brake BCV command output system: Disconnection or short circuit)...1506

Failure code [DX11K4] Trouble in rear wheel proportional solenoid pressure reducing valve 1...1508

Failure code [DX11KA] (Rear brake proportional pressure reducing solenoid valve output circuit: Disconnection)...1510

Failure code [DX11KB] (Rear brake proportional pressure reducing solenoid valve: Short circuit)...1511

Failure code [DX11KY] (Rear brake proportional pressure reducing solenoid valve: Short circuit to power source line)...1512

Failure code [DX11MA] (Rear brake proportional pressure reducing solenoid valve: Malfunction)...1514

Failure code [DX12K4] (Front brake proportional pressure reducing solenoid valve: Out of control)...1516

Failure code [DX12KA] (Front brake proportional pressure reducing solenoid valve output circuit: Disconnection)...1518

Failure code [DX12KB] (Front brake proportional pressure reducing solenoid valve: Short circuit)...1519

Troubleshooting by failure code (Display of code), Part 5...1521

Failure code [DX12KY] (Front brake proportional pressure reducing solenoid valve: Short circuit to power source line)...1523

Failure code [DX12MA] (Front brake proportional pressure reducing solenoid valve: Malfunction)...1524

Failure code [DX13KA] (Hoist EPC valve output circuit: Disconnection)...1526

Failure code [DX13KB] (Hoist EPC valve output circuit: Short circuit)...1527

Failure code [DX13KY] (Hoist EPC valve output circuit: Short circuit in power source line)...1528

Failure code [DXH0KA] (Inter-axle differential lock pressure control valve: Disconnection)...1529

Failure code [DXH0KB] (Inter-axle differential lock pressure control valve: Short circuit)...1530

Failure code [DXH0KY] (Inter-axle differential lockup pressure control valve: Short circuit to power source line)...1531

Failure code [DXH1KA] (Lockup clutch solenoid output circuit: Disconnection)...1532

Failure code [DXH1KB] (Lockup clutch solenoid output circuit: Short circuit)...1533

Failure code [DXH1KY] (Lockup clutch solenoid output circuit: Short circuit to power source line)...1534

Failure code [DXH2KA] (Hi clutch solenoid output circuit: Disconnection)...1536

Failure code [DXH2KB] (Hi clutch solenoid output circuit: Short circuit)...1538

Failure code [DXH2KY] (Hi clutch solenoid output circuit: Short circuit to power source line)...1540

Failure code [DXH3KA] (Lo clutch solenoid output circuit: Disconnection)...1544

Failure code [DXH3KB] (Lo clutch solenoid output circuit: Short circuit)...1546

Failure code [DXH3KY] (Lo clutch solenoid output circuit: Short circuit in power source line)...1548

Failure code [DXH4KA] (1st clutch solenoid output circuit: Disconnection)...1552

Failure code [DXH4KB] (1st clutch solenoid output circuit: Short circuit)...1554

Failure code [DXH4KY] (1st clutch solenoid output circuit: Short circuit to power source line)...1556

Failure code [DXH5KA] (2nd clutch solenoid output circuit: Disconnection)...1560

Failure code [DXH5KB] (2nd clutch solenoid output circuit: Short circuit)...1562

Failure code [DXH5KY] (2nd clutch solenoid output circuit: Short circuit in power source line)...1564

Failure code [DXH6KA] (3rd clutch solenoid output circuit: Disconnection)...1568

Failure code [DXH6KB] (3rd clutch solenoid output circuit: Short circuit)...1570

Failure code [DXH6KY] (3rd clutch solenoid output circuit: Short circuit to power source line)...1572

Failure code [DXH7KA] (R clutch solenoid output circuit: Disconnection)...1576

Failure code [DXH7KB] (R clutch solenoid output circuit: Short circuit)...1578

Failure code [DXH7KY] (R clutch solenoid output circuit: Short circuit to power source line)...1580

Troubleshooting of electrical system (E-mode)...1585

Before troubleshooting of electrical system...1587

Contents of troubleshooting table...1590

E-1 Engine does not start...1591

E-2 Automatic preheating does not operate...1594

E-3 Machine monitor does not display all, when starting switch is turned ON...1598

E-4 Machine monitor does not operate when starting switch is OFF...1600

E-5 Alarm buzzer does not sound...1602

E-6 Gauges of machine monitor, caution lamps or character display section do not display properly...1603

E-7 Selection of display in character display section cannot be changed...1604

E-8 Power mode selecting function does not operate properly...1608

E-9 AISS function does not operate properly...1609

E-10 Seat belt caution lamp does not display properly...1610

E-11 Turn signal lamp or turning lamp (hazard lamp) does not work properly...1611

E-12 Night illumination (lighting) does not work properly...1614

E-13 Emergency steering does not operate...1621

E-14 Dump lever does not operate normally...1626

E-15 KOMTRAX system does not operate normally...1628

E-16 Electric priming pump does not operate or does not stop automatically...1632

E-17 Air conditioner does not operate normally...1634

Troubleshooting of hydraulic and mechanical system (H-mode)...1641

Contents of troubleshooting table...1643

H-1 Machine does not start...1644

H-2 Machine does not travel smoothly (machine jerks)...1646

H-3 Lockup cannot be cancelled...1646

H-4 Excessive shock when starting or shifting...1647

H-5 Transmission does not shift up...1648

H-6 Machine lacks power or speed when traveling...1649

H-7 Time lag is excessive when starting or shifting gear...1651

H-8 Torque converter oil temperature is high...1652

H-9 Torque converter oil pressure is low...1653

H-10 Front brake is ineffective...1654

H-11 Center brake is ineffective...1655

H-12 Steering wheel is heavy...1656

H-13 Steering wheel does not work...1657

H-14 Steering wheel vibrates...1658

H-15 Dump body lifting speed is slow...1659

H-16 Dump body does not work...1660

H-17 Excessive hydraulic drift of dump body...1661

Troubleshooting of engine (S-mode)...1663

How to use a troubleshooting chart...1665

S-1 Engine is hard to start...1668

S-2 Engine does not start...1669

S-3 Engine does not pick up smoothly...1672

S-4 Engine stops during operations...1673

S-5 Engine does not rotate smoothly...1674

S-6 Engine lacks output (or lacks power)...1675

S-7 Exhaust gas color is black (incomplete combustion)...1676

S-8 Oil consumption is excessive (or exhaust gas color is blue)...1677

S-9 Oil gets contaminated prematurely...1678

S-10 Fuel consumption is excessive...1679

S-11 Oil is in coolant (or coolant spurts back or coolant level goes down)...1680

S-12 Oil pressure drops...1681

S-13 Oil level rises (coolant or fuel mixes)...1682

S-14 Coolant temperature rises too high (overheat)...1683

S-15 Abnormal noise comes out...1684

S-16 Vibration is excessive...1685

S-17 Air cannot be bled from fuel circuit...1686

50 Disassembly and assembly...0

General information on disassembly and assembly...1689

How to read this manual...1690

Coating materials list...1692

Special tool list...1695

Sketches of special tools...1700

Engine and cooling system (SAA6D125E-5)...1715

Removal and installation of fuel supply pump assembly...1716

Removal and installation of fuel injector assembly...1721

Removal and installation of cylinder head assembly...1726

Removal and installation of engine front seal...1738

Removal and installation of engine rear seal...1740

Removal and installation of engine assembly...1744

Removal and installation of radiator assembly...1752

Removal and installation of cooling assembly...1754

Removal and installation of output shaft assembly...1757

Disassembly and assembly of output shaft assembly...1762

Power train, Part 1...1767

Removal and installation of transmission and front differential assembly...1768

Disconnection and connection of front differential assembly and transmission assembly...1774

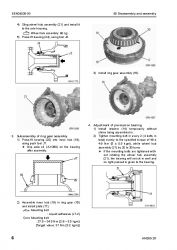

Disassembly and assembly of front differential assembly...1776

Disassembly and assembly of torque converter assembly...1791

Power train, Part 2...1799

Disassembly and assembly of transmission assembly...1800

Power train, Part 3...1843

Removal and installation of center differential assembly...1844

Disassembly and assembly of center differential assembly...1848

Removal and installation of rear differential assembly...1865

Disassembly and assembly of rear differential assembly...1867

Power train, Part 4...1883

Removal and installation of front final drive and brake assembly...1884

Disassembly and assembly of front final drive and brake assembly...1887

Removal and installation of center final drive and brake assembly...1897

Disassembly and assembly of center final drive and brake assembly...1899

Power train, Part 5...1909

Disassembly and assembly of rear final drive assembly...1910

Removal and installation of center axle assembly...1917

Removal and installation of rear axle assembly...1920

Undercarriage and frame...1923

Removal and installation of front suspension cylinder assembly...1924

Removal and installation of rear suspension cylinder assembly...1926

Removal and installation of equalizer bar...1927

Removal and installation of hitch frame assembly...1929

Disassembly and assembly of hitch frame assembly...1939

Hydraulic system...1947

Removal and installation of flow amp valve...1948

Removal and installation of hoist valve assembly...1950

Disassembly and assembly of steering cylinder assembly...1953

Disassembly and assembly of hoist cylinder assembly...1957

Body...1963

Removal and installation of body assembly...1964

Cab and its attachments...1967

Removal and installation of operator’s cab...1968

Removal and installation of operator’s cab glass (Stuck glass)...1973

Disassembly and assembly of operator’s seat assembly (If equipped)...1980

Electrical system...1991

Removal and installation of air conditioner unit assembly...1992

Removal and installation of engine controller...1997

Removal and installation of retarder controller...1999

Removal and installation of transmission controller assembly...2001

90 Diagrams and drawings...0

Hydraulic diagrams and drawings...2003

Power train hydraulic circuit diagram...2005

Steering and hoist hydraulic circuit diagram...2006

Brake hydraulic circuit diagram...2008

Brake cooling hydraulic circuit diagram...2009

Electrical diagrams and drawings...2011

Electrical circuit diagram for inside cab (1/4)...2013

Electrical circuit diagram for inside cab (2/4)...2014

Electrical circuit diagram for inside cab (3/4)...2015

Electrical circuit diagram for inside cab (4/4)...2016

Electrical circuit diagram for outside cab (1/3)...2017

Electrical circuit diagram for outside cab (2/3)...2018

Electrical circuit diagram for outside cab (3/3)...2019

Electrical circuit diagram for payload meter...2020

Connectors table and arrangement drawing...2021

Komatsu Articulated Dump Truck HM300-2R Repair Service Manuals