Komatsu Hydraulic Excavators PC88MR Repair Service Manuals

Catalog:

Model:

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavators PC88MR, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Hydraulic Excavators PC88MR workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

CEBM007301 - Hydraulic Excavator PC88MR-8 Shop Manual.pdf

SEN04329-11 - Hydraulic Excavator PC88MR-8 Shop Manual.pdf

SEN06467-02 - Hydraulic Excavator PC88MR-10 Shop Manual.pdf

TEN00287-06 - Hydraulic Excavator PC88MR-8 Operation & Maintenance Manual.pdf

TEN00468-01 - Hydraulic Excavator PC88MR-8 Operation & Maintenance Manual.pdf

WEAM009700 - Hydraulic Excavator PC80MR-3 Operation & Maintenance Manual.pdf

CEAM021202 - Hydraulic Excavator PC88MR-8 Operation & Maintenance Manual.pdf

Total Pages: 4,973 pages

File Format: PDF

Language: English

EEAM004900 - Hydraulic Excavator PC95-1 Operation & Maintenance Manual....2

CONTENTS....11

FOREWORD....4

SAFETY INFORMATION....5

INTRODUCTION....7

PERMITTED USES....7

MAIN FEATURES....7

RUNNING IN THE MACHINE....7

LOCATION OF MACHINE COMPONENT IDENTIFICATION PLATES....9

SERIAL NUMBERS AND ADDRESS OF DEALER....10

SAFETY AND ACCIDENT PREVENTION....17

1. SAFETY MEASURES ....18

1.1 GENERAL PRECAUTIONS ....18

1.2 SAFETY DEVICES ....18

1.3 PERSONAL PROTECTIVE CLOTHING AND EQUIPMENT ....18

1.4 UNAUTHORISED MODIFICATIONS ....19

1.5 LEAVING THE DRIVING SEAT ....19

1.6 ENTERING AND LEAVING THE MACHINE ....20

1.7 PREVENTION OF FUEL AND OIL FIRES ....20

1.8 PREVENTION OF BURNS AND SCALDING ....21

1.9 PREVENTION OF ASBESTOS DUST CONTAMINATION ....22

1.10 PREVENTION OF INJURY BY WORK EQUIPMENT ....22

1.11 FIRE EXTINGUISHERS AND FIRST AID KIT ....23

1.12 PRECAUTIONS REGARDING THE CAB FRAME ....23

1.13 PRECAUTIONS REGARDING EQUIPMENT ....23

PRECAUTIONS....24

2. PRECAUTIONS TO BE TAKEN BEFORE STARTING THE ENGINE ....25

2.1 ON-SITE SAFETY ....25

2.2 FIRE PREVENTION ....25

2.3 PRECAUTIONS REGARDING THE CAB ....26

2.4 VENTILATION OF ENCLOSED AREAS ....26

2.5 CLEANING WINDOWS, MIRRORS AND HEADLIGHTS - CHECKING WIPER BLADES, LAMPS ....26

3. PRECAUTIONS TO BE TAKEN WHILE WORKING ....27

3.1 STARTING THE ENGINE ....27

3.2 CHECKS PRIOR TO REVERSING ....27

3.3 MOVING THE MACHINE ....28

3.4 WORKING ON SLOPES ....29

3.5 PREVENTION OF ELECTROCUTION ....30

3.6 VISIBILITY ....31

3.7 WORKING ON FROZEN OR SNOW-COVERED GROUND ....31

3.8 PREVENTION OF DAMAGE BY THE EQUIPMENT ....31

3.9 WORKING ON LOOSE OR PLOUGHED SOIL ....31

3.10 PARKING THE MACHINE ....32

4. TRANSPORTING THE MACHINE ON ANOTHER VEHICLE ....33

4.1 LOADING AND UNLOADING ....33

4.2 THE ROUTE ....33

5. THE BATTERY ....34

5.1 SAFETY PRECAUTIONS FOR WORK ON BATTERIES ....34

5.2 STARTING THE ENGINE WITH JUMP LEADS ....34

6. PRECAUTIONS FOR EMERGENCY RECOVERY ....35

7. PRECAUTIONS TO BE TAKEN DURING MAINTENANCE ....36

7.1 WARNING NOTICES ....36

7.2 TOOLS ....36

7.3 PERSONAL PRECAUTIONS ....36

7.4 EQUIPMENT ....37

7.5 KEEPING THE MACHINE CLEAN ....37

7.6 RUNNING THE ENGINE DURING MAINTENANCE ....37

7.7 RULES FOR REFUELLING AND ADDING OIL ....38

7.8 LEVEL OF COOLANT IN THE RADIATOR ....38

7.9 USING LAMPS ....39

7.10 BATTERY AND ALTERNATOR PRECAUTIONS ....39

7.11 PRECAUTIONS REGARDING HIGH PRESSURE HOSES ....40

7.12 PRECAUTIONS TO BE TAKEN WHEN WORKING ON HIGH PRESSURE SYSTEMS ....40

7.13 PRECAUTIONS FOR MAINTENANCE WORK INVOLVING HIGH TEMPERATURES AND PRESSURES ....40

7.14 THE RADIATOR COOLING FAN AND FAN BELT ....41

8. SAFETY AND NOISE ABATEMENT NOTICES ....42

8.1 LOCATION OF SAFETY NOTICES ....42

8.2 LOCATION OF NOISE ABATEMENT NOTICES ....43

TECHNICAL SPECIFICATIONS ....44

OVERALL DIMENSIONS WITH MONOBLOCK BOOM....45

OVERALL DIMENSIONS WITH ARTICULATED BOOM....45

TECHNICAL SPECIFICATIONS....46

THE MACHINE AND ITS OPERATIONS....47

9. SAFETY DEVICES ....48

9.1 EQUIPMENT SAFETY DEVICES ....48

10. GENERAL VIEWS ....49

10.1 GENERAL VIEW (MONOBLOCK BOOM) ....49

10.2 GENERAL VIEW (ARTICULATED BOOM) ....50

10.3 GENERAL VIEW OF INSIDE OF CAB ....51

11. INSTRUMENTS AND CONTROLS ....52

11.1 INSTRUMENTS, WARNING LIGHTS, AND PUSH-BUTTONS ....52

11.1.1 INSTRUMENTS....53

11.1.2 WARNING LIGHTS AND INDICATORS....53

11.1.3 PUSH-BUTTONS AND SWITCHES....54

11.2 LOCATION OF MACHINE CONTROLS ....57

11.2.1 MACHINE CONTROLS....58

1 - ARTICULATED BOOM CONTROL PEDAL....58

2 - 3 TRANSLATION AND STEERING LEVER....58

4 - BOOM ROTATION PEDAL....59

5 - 6 EQUIPMENT CONTROL LEVERS....60

7 - BLADE CONTROL LEVER....62

8 - ACCELERATOR LEVER....62

9 - SWING LOCK LEVER....62

10 - EQUIPMENT CONTROL LOCK....63

11 - SPEED CONTROL PEDAL....64

12 - WORKING BRAKE....64

12. FUSES AND RELAYS ....65

12.1 FUSES ....65

12.2 RELAYS....67

13. THE CAB AND DRIVING POSITION ....68

13.1 THE CAB ....68

13.2 VENTILATION AND HEATING ....71

13.3 THE DRIVING SEAT ....72

13.4 THE SAFETY BELT ....73

14. OPERATING THE MACHINE ....74

14.1 CHECKS PRIOR TO STARTING THE ENGINE ....74

14.1.1 VISUAL CHECKS....74

14.1.2 DAILY CHECKS....74

14.1.3 OPERATING CHECKS....75

14.2 STARTING THE ENGINE ....76

14.2.1 STARTING A WARM ENGINE AND STARTING IN WARM WEATHER....76

14.2.2 STARTING A COLD ENGINE AND STARTING IN COLD WEATHER....77

14.3 WARMING UP THE ENGINE....77

14.4 WARMING UP THE HYDRAULIC FLUID ....78

14.5 MOVING THE MACHlNE ....78

14.5.1 STEERING AND DIRECTION CHANGING....79

14.5.2 NEGOTIATING SLOPES....81

14.5.3 MAXIMUM DEPTH OF WATER....82

15. PARKING THE MACHINE ....83

15.1 PARKING ON LEVEL GROUND ....83

15.2 PARKING ON A SLOPE ....84

16. STOPPING THE ENGINE ....85

17. TRANSPORTING THE MACHINE ON ANOTHER VEHICLE ....86

17.1 LOADING AND UNLOADING ....86

17.2 THE ROUTE ....87

18. COLD WEATHER PRECAUTIONS ....88

18.1 FUEL AND LUBRICANTS ....88

18.2 COOLANT ....88

18.3 THE BATTERY ....89

18.4 OTHER PRECAUTIONS ....89

18.5 PRECAUTIONS AT THE END OF A WORKING DAY ....89

19. WARM WEATHER PRECAUTIONS ....90

20. USING THE WORK EQUIPMENT ....91

20.1 ORGANISATION OF THE WORK AREA ....91

20.2 POSITIONING THE BUCKET ACCORDING TO THE JOB ....91

20.3 POSITIONING THE MACHINE FOR DIGGING ....92

20.4 DIGGING METHOD ....93

20.5 CHANGING THE WORK EQUIPMENT ....95

20.5.1 CHANGING THE BUCKET....95

21. FAULT FINDING ....96

21.1 RUNNING OUT OF FUEL ....96

21.2 IF THE BATTERY IS FLAT....96

21.2.1 USING JUMP LEADS TO START THE ENGINE....97

21.3 OTHER FAULTS....99

21.3.1 ELECTRICAL SYSTEM....99

21.3.2 ENGINE....100

21.3.3 HYDRAULIC SYSTEM....101

MAINTENANCE....102

22. MAINTENANCE GUIDE ....103

23. MAINTENANCE NOTES ....105

23.1 ENGINE MAINTENANCE NOTES ....105

23.1.1 ENGINE OIL....105

23.1.2 COOLING WATER....106

23.1.3 FUEL....106

23.2 HYDRAULIC SYSTEM MAINTENANCE NOTES ....107

23.3 ELECTRICAL SYSTEM MAINTENANCE NOTES ....107

23.4 NOTES ON LUBRICATION ....108

23.5 PARTS SUBJECT TO RAPID WEAR AND REQUIRING REGULAR REPLACEMENT ....108

24. FUEL, COOLANT, AND LUBRICANTS ....109

25. NUT AND BOLT TIGHTENING TORQUES ....111

25.1 STANDARD TIGHTENING TORQUES ....111

25.2 SPECIAL TIGHTENING TORQUES ....111

26. SCHEDULED MAINTENANCE ....112

26.1 PRE-STARTING CHECKS ....116

26.1.a VARIOUS CHECKS....116

26.1.b CHECKING THE COOLANT LEVEL....116

26.1.c CHECKING THE FUEL LEVEL....117

26.1.d CHECKING THE ENGINE OIL LEVEL....117

26.1.e CHECKING THE LEVEL OF THE HYDRAULIC FLUID....118

26.1.f CHECKING THE ELECTRICAL SYSTEM....119

26.1.g DRAINING THE FUEL LINE WATER TRAP....119

26.2 AFTER THE FIRST 50 HOURS ....120

26.3 EVERY 50 HOURS ....120

26.3.a GREASING THE SWIVEL JOINT....120

26.3.b CLEANING THE ENGINE AIR FILTER DUST TRAP....120

26.4 EVERY 100 HOURS ....121

26.4.a GREASING THE ARTICULATIONS....121

26.4.b CLEANING THE MAIN AIR FILTER ELEMENT....125

26.5 AFTER THE FIRST 250 HOURS ....126

26.6 EVERY 250 HOURS ....126

26.6.a ADJUSTING FAN BELT TENSION....126

26.6.b CHECKING THE ELECTROLYTE LEVEL IN THE BATTERY....127

26.6.c CHECKING THE OIL LEVEL IN THE FINAL DRIVES....128

26.6.d CHECKING THE OIL LEVEL IN THE SWING MOTOR....129

26.6.e CHANGING THE HYDRAULIC SYSTEM FILTER ELEMENT....129

26.6.f CHANGING THE SERVOCONTROL FILTER ELEMENT....131

26.6.g CHANGING THE ENGINE OIL....131

26.6.h CHANGING THE ENGINE OIL FILTER....132

26.7 EVERY 500 HOURS ....133

26.7.a CHANGING THE MAIN AIR FILTER ELEMENT....133

26.7.b DRAINING THE FUEL TANK....133

26.7.c CLEANING THE OUTSIDE OF THE RADIATOR....134

26.7.d CHANGING THE FUEL FILTER AND CLEANING THE FUEL PUMP’S GAUZE FILTER....134

26.7.e CHECKING THE GREASE LEVEL IN THE FIFTH WHEEL PINION GEAR....136

26.7.f GREASING THE FIFTH WHEEL....136

26.8 EVERY 1000 HOURS ....137

26.8.a CHANGING THE AIR FILTER BACKUP ELEMENT....137

26.9 EVERY 2000 HOURS ....138

26.9.a CHANGING THE HYDRAULIC FLUID....138

26.9.b CHANGING THE FINAL DRIVES OIL....139

26.9.c CHANGING THE SWING MOTOR OIL....140

26.9.d CHANGING THE GREASE IN THE FIFTH WHEEL PINION GEAR....141

26.9.e CHANGING THE COOLANT....142

26.9.f CHECKING ENGINE VALVE CLEARANCE....142

26.9.g CHECKING THE ALTERNATOR AND STARTER MOTOR....142

26.10 OCCASIONAL MAINTENANCE....143

26.10.a WASHING OUT THE COOLING SYSTEM....143

26.10.b ADJUSTING TRACK TENSION....144

26.10.c CHECKING THE SECURITY OF THE TRACK SHOES....146

27. EXTENDED PERIODS OF DISUSE ....147

27.1 PREPARING TO LAY UP THE MACHINE ....147

27.2 PREPARING THE MACHINE FOR USE....147

FGAMPC9510 - Hydraulic Excavator PC95-1 Operation & Maintenance Manual....149

CONTENTS ....162

FOREWORD....150

SAFETY INFORMATION ....152

INTRODUCTION ....154

PERMITTED USES ....154

MAIN FEATURES ....154

RUNNING IN THE MACHINE ....154

SUMMARY OF PICTOGRAMS ....156

LOCATION OF MACHINE COMPONENT IDENTIFICATION PLATES ....159

SERIAL NUMBERS AND ADDRESS OF DEALER ....160

POSITION AND CONTENTS OF <<CE>> PLATE ....161

SAFETY AND ACCIDENT PREVENTION....169

1. SAFETY MEASURES ....170

1.1 GENERAL PRECAUTIONS ....170

1.2 SAFETY DEVICES ....170

1.3 PERSONAL PROTECTIVE CLOTHING AND EQUIPMENT ....170

1.4 UNAUTHORISED MODIFICATIONS ....171

1.5 LEAVING THE DRIVING SEAT ....171

1.6 ENTERING AND LEAVING THE MACHINE ....172

1.7 PREVENTION OF FUEL AND OIL FIRES ....172

1.8 PREVENTION OF BURNS AND SCALDING ....173

1.9 PREVENTION OF ASBESTOS DUST CONTAMINATION ....174

1.10 PREVENTION OF INJURY BY WORK EQUIPMENT ....174

1.11 FIRE EXTINGUISHERS AND FIRST AID KIT ....175

1.12 PRECAUTIONS REGARDING THE CAB FRAME ....175

1.13 PRECAUTIONS REGARDING EQUIPMENT ....175

PRECAUTIONS....176

2. PRECAUTIONS TO BE TAKEN BEFORE STARTING THE ENGINE ....177

2.1 ON-SITE SAFETY ....177

2.2 FIRE PREVENTION ....177

2.3 PRECAUTIONS REGARDING THE CAB ....178

2.4 VENTILATION OF ENCLOSED AREAS ....178

2.5 CLEANING WINDOWS, MIRRORS AND HEADLIGHTS - CHECKING WIPER BLADES, LAMPS ....178

3. PRECAUTIONS TO BE TAKEN WHILE WORKING ....179

3.1 STARTING THE ENGINE ....179

3.2 CHECKS PRIOR TO REVERSING ....179

3.3 MOVING THE MACHINE ....180

3.4 WORKING ON SLOPES ....181

3.5 PREVENTION OF ELECTROCUTION ....182

3.6 VISIBILITY ....183

3.7 WORKING ON FROZEN OR SNOW-COVERED GROUND ....183

3.8 PREVENTION OF DAMAGE BY THE EQUIPMENT ....183

3.9 WORKING ON LOOSE OR PLOUGHED SOIL ....183

3.10 PARKING THE MACHINE ....184

4. TRANSPORTING THE MACHINE ON ANOTHER VEHICLE ....185

4.1 LOADING AND UNLOADING ....185

4.2 THE ROUTE ....185

5. THE BATTERY ....186

5.1 SAFETY PRECAUTIONS FOR WORK ON BATTERIES ....186

5.2 STARTING THE ENGINE WITH JUMP LEADS ....186

6. PRECAUTIONS FOR EMERGENCY RECOVERY ....187

7. PRECAUTIONS TO BE TAKEN DURING MAINTENANCE ....188

7.1 WARNING NOTICES ....188

7.2 TOOLS ....188

7.3 PERSONAL PRECAUTIONS ....189

7.4 EQUIPMENT ....189

7.5 KEEPING THE MACHINE CLEAN ....189

7.6 RUNNING THE ENGINE DURING MAINTENANCE ....190

7.7 RULES FOR REFUELLING AND ADDING OIL ....190

7.8 LEVEL OF COOLANT IN THE RADIATOR ....191

7.9 USING LAMPS ....191

7.10 BATTERY AND ALTERNATOR PRECAUTIONS ....191

7.11 PRECAUTIONS REGARDING HIGH PRESSURE HOSES ....192

7.12 PRECAUTIONS TO BE TAKEN WHEN WORKING ON HIGH PRESSURE SYSTEMS ....192

7.13 PRECAUTIONS FOR MAINTENANCE WORK INVOLVING HIGH TEMPERATURES AND PRESSURES ....193

7.14 THE RADIATOR COOLING FAN AND FAN BELT ....193

8. SAFETY AND NOISE ABATEMENT NOTICES ....194

8.1 LOCATION OF SAFETY NOTICES ....194

8.2 LOCATION OF NOISE ABATEMENT NOTICES ....195

9. VIBRATIONS TO WHICH THE USER IS SUBJECTED....195

TECHNICAL SPECIFICATIONS....196

10. TECHNICAL SPECIFICATIONS ....197

10.1 OVERALL DIMENSIONS ....197

10.2 TECHNICAL SPECIFICATIONS ....198

10.3 LIFTING CAPACITY ....198

10.3.1 LIFTING CAPACITY WITH MONOBLOCK BOOM....199

10.3.2 LIFTING CAPACITY WITH ARTICULATED BOOM ....200

THE MACHINE AND ITS OPERATIONS....201

11. SAFETY DEVICES ....202

11.1 EQUIPMENT SAFETY DEVICES ....202

12. GENERAL VIEWS ....203

12.1 GENERAL VIEW (MONOBLOCK BOOM) ....203

12.2 GENERAL VIEW (ARTICULATED BOOM) ....204

12.3 GENERAL VIEW OF INSIDE OF CAB ....205

13. INSTRUMENTS AND CONTROLS ....206

13.1 INSTRUMENTS, WARNING LIGHTS, AND PUSH-BUTTONS ....206

13.1.1 INSTRUMENTS ....208

13.1.2 WARNING LIGHTS AND INDICATORS ....208

13.1.3 PUSH-BUTTONS AND SWITCHES ....209

13.1.4 ELECTRICAL ACCESSORIES ....211

13.2 LOCATION OF MACHINE CONTROLS ....213

13.2.1 MACHINE CONTROLS ....214

1 - ARTICULATED BOOM CONTROL PEDAL ....214

2 - 3 TRANSLATION AND STEERING LEVER ....214

4 - BOOM ROTATION PEDAL ....215

5 - 6 EQUIPMENT CONTROL LEVERS ....216

7 - BLADE CONTROL LEVER ....218

8 - ACCELERATOR LEVER ....218

9 - SWING LOCK LEVER ....219

10 - EQUIPMENT CONTROL LOCK ....220

11 - SPEED CONTROL PEDAL ....220

12 - WORKING BRAKE ....221

14. FUSES AND RELAYS ....222

14.1 FUSES ....222

14.2 RELAYS ....224

15. THE CAB AND DRIVING POSITION ....225

15.1 THE CAB ....225

15.2 VENTILATION AND HEATING ....228

15.3 THE DRIVING SEAT ....229

15.4 THE SAFETY BELT ....230

15.5 EMERGENCY EXIT ....231

15.6 FIRE EXTINGUISHERS ....231

15.7 FIRST AID KIT ....232

15.8 TECHNICAL DOCUMENTATION ....232

16. OPERATING THE MACHINE ....233

16.1 CHECKS PRIOR TO STARTING THE ENGINE ....233

16.1.1 VISUAL CHECKS ....233

16.1.2 DAILY CHECKS ....233

16.1.3 OPERATING CHECKS ....234

16.2 STARTING THE ENGINE ....235

16.2.1 STARTING A WARM ENGINE AND STARTING IN WARM WEATHER ....235

16.2.2 STARTING A COLD ENGINE AND STARTING IN COLD WEATHER ....236

16.3 WARMING UP THE ENGINE ....236

16.4 WARMING UP THE HYDRAULIC FLUID ....237

16.5 MOVING THE MACHINE ....237

16.5.1 STEERING AND DIRECTION CHANGING ....238

16.5.2 NEGOTIATING SLOPES ....240

16.5.3 MAXIMUM DEPTH OF WATER ....241

17. PARKING THE MACHINE ....242

17.1 PARKING ON LEVEL GROUND ....242

17.2 PARKING ON A SLOPE ....243

18. STOPPING THE ENGINE ....244

19. TRANSPORTING THE MACHINE ON ANOTHER VEHICLE....244

19.1 LOADING AND UNLOADING ....244

19.2 THE ROUTE ....246

20. COLD WEATHER PRECAUTIONS ....247

20.1 FUEL AND LUBRICANTS ....247

20.2 COOLANT ....247

20.3 THE BATTERY ....248

20.4 OTHER PRECAUTIONS ....248

20.5 PRECAUTIONS AT THE END OF A WORKING DAY ....248

21. WARM WEATHER PRECAUTIONS ....249

22. USING THE WORK EQUIPMENT ....250

22.1 ORGANISATION OF THE WORK AREA ....250

22.2 POSITIONING THE BUCKET ACCORDING TO THE JOB ....250

22.3 POSITIONING THE MACHINE FOR DIGGING ....251

22.4 DIGGING METHOD ....252

22.5 CHANGING THE WORK EQUIPMENT ....254

22.5.1 CHANGING THE BUCKET ....254

23. FAULT FINDING ....255

23.1 RUNNING OUT OF FUEL ....255

23.2 IF THE BATTERY IS FLAT ....255

23.2.1 USING JUMP LEADS TO START THE ENGINE ....256

23.3 OTHER FAULTS....258

23.3.1 ELECTRICAL SYSTEM....258

23.3.2 ENGINE ....259

23.3.3 HYDRAULIC SYSTEM ....260

MAINTENANCE....261

24. MAINTENANCE GUIDE ....262

25. MAINTENANCE NOTES ....264

25.1 ENGINE MAINTENANCE NOTES ....264

25.1.1 ENGINE OIL ....264

25.1.2 COOLING WATER ....265

25.1.3 FUEL ....265

25.2 HYDRAULIC SYSTEM MAINTENANCE NOTES ....266

25.3 ELECTRICAL SYSTEM MAINTENANCE NOTES ....266

25.4 NOTES ON LUBRICATION ....267

25.5 PARTS SUBJECT TO RAPID WEAR AND REQUIRING REGULAR REPLACEMENT ....267

26. FUEL, COOLANT, AND LUBRICANTS ....268

27. NUT AND BOLT TIGHTENING TORQUES ....270

27.1 STANDARD TIGHTENING TORQUES ....270

27.2 SPECIAL TIGHTENING TORQUES ....270

28. LUBRICATION ....271

28.1 LUBRICATION CHART ....271

29. SCHEDULED MAINTENANCE....272

29.1 PRE-STARTING CHECKS ....275

29.1.a VARIOUS CHECKS ....275

29.1.b CHECKING THE COOLANT LEVEL ....275

29.1.c CHECKING THE FUEL LEVEL ....276

29.1.d CHECKING THE ENGINE OIL LEVEL ....276

29.1.e CHECKING THE LEVEL OF THE HYDRAULIC FLUID....277

29.1.f CHECKING THE ELECTRICAL SYSTEM ....278

29.1.g DRAINING THE FUEL LINE WATER TRAP ....278

29.2 AFTER THE FIRST 50 HOURS ....279

29.3 EVERY 50 HOURS....279

29.3.a GREASING THE SWIVEL JOINT....279

29.3.b CLEANING THE ENGINE AIR FILTER DUST TRAP....279

29.4 EVERY 100 HOURS....280

29.4.a GREASING THE ARTICULATIONS....280

29.4.b CLEANING....283

29.4.c GREASING THE FIFTH WHEEL....284

29.4.d LUBRICATION OF THE OVERLOAD DEVICE CAM....284

29.5 AFTER THE FIRST 250 HOURS....284

29.6 EVERY 250 HOURS....285

29.6.a ADJUSTING FAN BELT TENSION....285

29.6.b CHECKING THE ELECTROLYTE LEVEL IN THE BATTERY....285

29.6.c CHECKING THE OIL LEVEL IN THE F....286

29.6.d CHECKING THE OIL LEVEL IN THE SWING....287

29.6.e CHANGING THE HYDRAULIC SYSTEM FILTER ELEMENT....287

29.6.f CHANGING THE SERVOCONTROL FILTER ELEMENT....288

29.6.g CHANGING THE ENGINE OIL....289

29.6.h CHANGING THE ENGINE OIL FILTER....290

29.7 EVERY 500 HOURS....291

29.7.a CHANGING THE MAIN AIR FILTER ELEMENT....291

29.7.b DRAINING THE FUEL TANK....291

29.7.c CLEANING THE OUTSIDE OF THE RADIATOR....292

29.7.d CHANGING THE FUEL FILTER AND CLEANING THE FUEL PUMP’S GAUZE FILTER....292

29.7.e CHECKING THE GREASE LEVEL IN THE FIFTH WHEEL PINION GEAR....294

29.8 EVERY 1000 HOURS....295

29.8.a CHANGING THE AIR FILTER BACKUP ELEMENT....295

29.9 EVERY 2000 HOURS....296

29.9.a CHANGING THE HYDRAULIC FLUID....296

29.9.b CHANGING THE FINAL DRIVES OIL....298

29.9.c CHANGING THE SWING MOTOR OIL....298

29.9.d CHANGING THE GREASE IN THE FIFTH WHEEL PINION GEAR....300

29.9.e CHANGING THE COOLANT....301

29.9.f CHECKING ENGINE VALVE CLEARANCE....302

29.9.g CHECKING THE ALTERNATOR AND STARTER MOTOR....302

29.10 OCCASIONAL MAINTENANCE....303

29.10.a WASHING OUT THE COOLING SYSTEM....303

29.10.b ADJUSTING TRACK TENSION....304

29.10.c CHECKING THE SECURITY OF THE TRACK SHOES....306

30. EXTENDED PERIODS OF DISUSE ....307

30.1 PREPARING TO LAY UP THE MACHINE ....307

30.2 PREPARING THE MACHINE FOR USE ....308

AUTHORISED OPTIONAL EQUIPMENT....309

31. AUTHORISED OPTIONAL EQUIPMENT ....310

31.1 OPTIONAL EQUIPMENT CHARACTERISTICS....310

32. DEMOLITION HAMMER ....311

32.1 DESCRIPTION AND OPERATION ....311

32.2 FITTING AND REMOVING THE DEMOLITION HAMMER ....311

32.2.1 FITTING THE DEMOLITION HAMMER ....311

32.2.2 REMOVING THE DEMOLITION HAMMER ....314

33. CLAMSHELL BUCKET....315

33.1 DESCRIPTION AND OPERATION....315

33.2 FITTING THE CLAMSHELL BUCKET ....316

WEAMPC9501 - Hydraulic Excavator PC95-1 Operation & Maintenance Manual....320

FOREWORD....322

SAFETY INFORMATION....324

INTRODUCTION....326

PERMITTED USES....326

MAIN FEATURES....326

RUNNING IN THE MACHINE....326

SUMMARY OF PICTOGRAMS....328

LOCATION OF MACHINE COMPONENT IDENTIFICATION PLATES....331

SERIAL NUMBERS AND ADDRESS OF DEALER....332

POSITION AND CONTENTS OF <<CE>> PLATE....333

CONTENTS....334

SAFETY AND ACCIDENT PREVENTION....342

1. SAFETY MEASURES....343

1.1 GENERAL PRECAUTIONS....343

1.2 SAFETY DEVICES....343

1.3 PERSONAL PROTECTIVE CLOTHING AND EQUIPMENT....343

1.4 UNAUTHORISED MODIFICATIONS....344

1.5 LEAVING THE DRIVING SEAT....344

1.6 ENTERING AND LEAVING THE MACHINE....345

1.7 PREVENTION OF FUEL AND OIL FIRES....345

1.8 PREVENTION OF BURNS AND SCALDING....346

1.9 PREVENTION OF ASBESTOS DUST CONTAMINATION....347

1.10 PREVENTION OF INJURY BY WORK EQUIPMENT....347

1.11 FIRE EXTINGUISHERS AND FIRST AID KIT....348

1.12 PRECAUTIONS REGARDING THE CAB FRAME....348

1.13 PRECAUTIONS REGARDING EQUIPMENT....348

PRECAUTIONS....350

2. PRECAUTIONS TO BE TAKEN BEFORE STARTING THE ENGINE....351

2.1 ON-SITE SAFETY....351

2.2 FIRE PREVENTION....351

2.3 PRECAUTIONS REGARDING THE CAB....352

2.4 VENTILATION OF ENCLOSED AREAS....352

2.5 CLEANING WINDOWS, MIRRORS AND HEADLIGHTS - CHECKING WIPER BLADES, LAMPS....352

3. PRECAUTIONS TO BE TAKEN WHILE WORKING....353

3.1 STARTING THE ENGINE....353

3.2 CHECKS PRIOR TO REVERSING....353

3.3 MOVING THE MACHINE....354

3.4 WORKING ON SLOPES....355

3.5 PREVENTION OF ELECTROCUTION....356

3.6 VISIBILITY....357

3.7 WORKING ON FROZEN OR SNOW-COVERED GROUND....357

3.8 PREVENTION OF DAMAGE BY THE EQUIPMENT....357

3.9 WORKING ON LOOSE OR PLOUGHED SOIL....357

3.10 PARKING THE MACHINE....358

4. TRANSPORTING THE MACHINE ON ANOTHER VEHICLE....359

4.1 LOADING AND UNLOADING....359

4.2 THE ROUTE....359

5. THE BATTERY....360

5.1 SAFETY PRECAUTIONS FOR WORK ON BATTERIES....360

5.2 STARTING THE ENGINE WITH JUMP LEADS....360

6. PRECAUTIONS FOR EMERGENCY RECOVERY....361

7. PRECAUTIONS TO BE TAKEN DURING MAINTENANCE....362

7.1 WARNING NOTICES....362

7.2 TOOLS....362

7.3 PERSONAL PRECAUTIONS....363

7.4 EQUIPMENT....363

7.5 KEEPING THE MACHINE CLEAN....363

7.6 RUNNING THE ENGINE DURING MAINTENANCE....364

7.7 RULES FOR REFUELLING AND ADDING OIL....364

7.8 LEVEL OF COOLANT IN THE RADIATOR....365

7.9 USING LAMPS....365

7.10 BATTERY AND ALTERNATOR PRECAUTIONS....365

7.11 PRECAUTIONS REGARDING HIGH PRESSURE HOSES....366

7.12 PRECAUTIONS TO BE TAKEN WHEN WORKING ON HIGH PRESSURE SYSTEMS....366

7.13 PRECAUTIONS FOR MAINTENANCE WORK INVOLVING HIGH TEMPERATURES AND PRESSURES....367

7.14 THE RADIATOR COOLING FAN AND FAN BELT....367

8. SAFETY AND NOISE ABATEMENT NOTICES....368

8.1 LOCATION OF SAFETY NOTICES....368

8.2 LOCATION OF NOISE ABATEMENT NOTICES....369

9. VIBRATIONS TO WHICH THE USER IS SUBJECTED....369

TECHNICAL SPECIFICATIONS....370

10.TECHNICAL SPECIFICATIONS....371

10.1 OVERALL DIMENSIONS....371

10.2 TECHNICAL SPECIFICATIONS....372

10.3 LIFTING CAPACITY....372

10.3.1 LIFTING CAPACITY TABLE....373

10.3.2 LIFTING CAPACITY WITH MONOBLOCK BOOM....375

10.3.3 LIFTING CAPACITY WITH ARTICULATED BOOM....376

THE MACHINE AND ITS OPERATIONS....378

11. SAFETY DEVICES....379

11.1 EQUIPMENT SAFETY DEVICES....379

12. GENERAL VIEWS....380

12.1 GENERAL VIEW (MONOBLOCK BOOM)....380

12.2 GENERAL VIEW (ARTICULATED BOOM)....381

12.3 GENERAL VIEW OF INSIDE OF CAB....382

13. INSTRUMENTS AND CONTROLS....383

13.1 INSTRUMENTS, WARNING LIGHTS, AND PUSH-BUTTONS....383

13.1.1 INSTRUMENTS....385

13.1.2 WARNING LIGHTS AND INDICATORS....385

13.1.3 PUSH-BUTTONS AND SWITCHES....386

13.1.4 ELECTRICAL ACCESSORIES....389

13.2 LOCATION OF MACHINE CONTROLS....390

13.2.1 MACHINE CONTROLS....391

1 - ARTICULATED BOOM CONTROL PEDAL....391

2 - 3 TRANSLATION AND STEERING LEVER....391

4 - BOOM ROTATION PEDAL....392

5 - 6 EQUIPMENT CONTROL LEVERS....393

7 - BLADE CONTROL LEVER....395

8 - ACCELERATOR LEVER....395

9 - SWING LOCK LEVER....396

10 - EQUIPMENT CONTROL LOCK....397

11 - WORKING BRAKE....398

14. FUSES AND RELAYS....399

14.1 FUSES....399

14.2 RELAYS....401

15. THE CAB AND DRIVING POSITION....402

15.1 THE CAB....402

15.2 VENTILATION AND HEATING....405

15.3 THE DRIVING SEAT....406

15.4 THE SAFETY BELT....407

15.5 EMERGENCY EXIT....408

15.6 FIRE EXTINGUISHERS....408

15.7 FIRST AID KIT....409

15.8 TECHNICAL DOCUMENTATION....409

16. OPERATING THE MACHINE....410

16.1 CHECKS PRIOR TO STARTING THE ENGINE....410

16.1.1 VISUAL CHECKS....410

16.1.2 DAILY CHECKS....410

16.1.3 OPERATING CHECKS....411

16.2 STARTING THE ENGINE....412

16.2.1 STARTING A WARM ENGINE AND STARTING IN WARM WEATHER....412

16.2.2 STARTING A COLD ENGINE AND STARTING IN COLD WEATHER....413

16.3 WARMING UP THE ENGINE....413

16.4 WARMING UP THE HYDRAULIC FLUID....414

16.5 MOVING THE MACHINE....414

16.5.1 STEERING AND DIRECTION CHANGING....415

16.5.2 NEGOTIATING SLOPES....417

16.5.3 MAXIMUM DEPTH OF WATER....418

17. PARKING THE MACHINE....419

17.1 PARKING ON LEVEL GROUND....419

17.2 PARKING ON A SLOPE....420

18. STOPPING THE ENGINE....421

19. TRANSPORTING THE MACHINE ON ANOTHER VEHICLE....421

19.1 LOADING AND UNLOADING....421

19.2 THE ROUTE....423

20. COLD WEATHER PRECAUTIONS....424

20.1 FUEL AND LUBRICANTS....424

20.2 COOLANT....424

20.3 THE BATTERY....425

20.4 OTHER PRECAUTIONS....425

20.5 PRECAUTIONS AT THE END OF A WORKING DAY....425

21. WARM WEATHER PRECAUTIONS....426

22. USING THE WORK EQUIPMENT....427

22.1 ORGANISATION OF THE WORK AREA....427

22.2 POSITIONING THE BUCKET ACCORDING TO THE JOB....427

22.3 POSITIONING THE MACHINE FOR DIGGING....428

22.4 DIGGING METHOD....429

22.5 CHANGING THE WORK EQUIPMENT....431

22.5.1 CHANGING THE BUCKET....431

23. FAULT FINDING....432

23.1 RUNNING OUT OF FUEL....432

23.2 IF THE BATTERY IS FLAT....432

23.2.1 USING JUMP LEADS TO START THE ENGINE....433

23.3 OTHER FAULTS....435

23.3.1 ELECTRICAL SYSTEM....435

23.3.2 ENGINE....436

23.3.3 HYDRAULIC SYSTEM....437

MAINTENANCE....438

24. MAINTENANCE GUIDE....439

25. MAINTENANCE NOTES....441

25.1 ENGINE MAINTENANCE NOTES....441

25.1.1 ENGINE OIL....441

25.1.2 COOLING WATER....442

25.1.3 FUEL....442

25.2 HYDRAULIC SYSTEM MAINTENANCE NOTES....443

25.3 ELECTRICAL SYSTEM MAINTENANCE NOTES....443

25.4 NOTES ON LUBRICATION....444

25.5 PARTS SUBJECT TO RAPID WEAR AND REQUIRING REGULAR REPLACEMENT....444

26. FUEL, COOLANT, AND LUBRICANTS....445

27. NUT AND BOLT TIGHTENING TORQUES....447

27.1 STANDARD TIGHTENING TORQUES....447

27.2 SPECIAL TIGHTENING TORQUES....447

28. LUBRICATION....448

28.1 LUBRICATION CHART....448

29. SCHEDULED MAINTENANCE....449

29.1 PRE-STARTING CHECKS....452

29.1.a VARIOUS CHECKS....452

29.1.b CHECKING THE COOLANT LEVEL....452

29.1.c CHECKING THE FUEL LEVEL....453

29.1.d CHECKING THE ENGINE OIL LEVEL....453

29.1.e CHECKING THE LEVEL OF THE HYDRAULIC FLUID....454

29.1.f CHECKING THE ELECTRICAL SYSTEM....455

29.1.g DRAINING THE FUEL LINE WATER TRAP....455

29.2 AFTER THE FIRST 50 HOURS....456

29.3 EVERY 50 HOURS....456

29.3.a GREASING THE SWIVEL JOINT....456

29.3.b CLEANING THE ENGINE AIR FILTER DUST TRAP....456

29.4 EVERY 100 HOURS....457

29.4.a GREASING THE ARTICULATIONS....457

29.4.b CLEANING THE MAIN AIR FILTER ELEMENT....460

29.4.c GREASING THE FIFTH WHEEL....461

29.4.d LUBRICATION OF THE OVERLOAD DEVICE CAM....461

29.5 AFTER THE FIRST 250 HOURS....461

29.6 EVERY 250 HOURS....462

29.6.a ADJUSTING FAN BELT TENSION....462

29.6.b CHECKING THE ELECTROLYTE LEVEL IN THE BATTERY....462

29.6.c CHECKING THE OIL LEVEL IN THE FINAL DRIVES....463

29.6.d CHECKING THE OIL LEVEL IN THE SWING MOTOR....464

29.6.e CHANGING THE HYDRAULIC SYSTEM FILTER ELEMENT....464

29.6.f CHANGING THE SERVOCONTROL FILTER ELEMENT....465

29.6.g CHANGING THE ENGINE OIL....466

29.6.h CHANGING THE ENGINE OIL FILTER....467

29.7 EVERY 500 HOURS....468

29.7.a CHANGING THE MAIN AIR FILTER ELEMENT....468

29.7.b DRAINING THE FUEL TANK....468

29.7.c CLEANING THE OUTSIDE OF THE RADIATOR....469

29.7.d CHANGING THE FUEL FILTER AND CLEANING THE FUEL PUMP’S GAUZE FILTER....469

29.7.e CHECKING THE GREASE LEVEL IN THE FIFTH WHEEL PINION GEAR....471

29.8 EVERY 1000 HOURS....472

29.8.a CHANGING THE AIR FILTER BACKUP ELEMENT....472

29.9 EVERY 2000 HOURS....473

29.9.a CHANGING THE HYDRAULIC FLUID....473

29.9.b CHANGING THE FINAL DRIVES OIL....475

29.9.c CHANGING THE SWING MOTOR OIL....475

29.9.d CHANGING THE GREASE IN THE FIFTH WHEEL PINION GEAR....477

29.9.e CHANGING THE COOLANT....478

29.9.f CHECKING ENGINE VALVE CLEARANCE....479

29.9.g CHECKING THE ALTERNATOR AND STARTER MOTOR....479

29.10 OCCASIONAL MAINTENANCE....480

29.10.a WASHING OUT THE COOLING SYSTEM....480

29.10.b ADJUSTING TRACK TENSION....481

29.10.c CHECKING THE SECURITY OF THE TRACK SHOES....483

30. EXTENDED PERIODS OF DISUSE....484

30.1 PREPARING TO LAY UP THE MACHINE....484

30.2 PREPARING THE MACHINE FOR USE....485

AUTHORISED OPTIONAL EQUIPMENT....486

31. AUTHORISED OPTIONAL EQUIPMENT....487

31.1 OPTIONAL EQUIPMENT CHARACTERISTICS....487

32. DEMOLITION HAMMER....488

32.1 DESCRIPTION AND OPERATION....488

32.2 FITTING AND REMOVING THE DEMOLITION HAMMER....488

32.2.1 FITTING THE DEMOLITION HAMMER....488

32.2.2 REMOVING THE DEMOLITION HAMMER....491

33. CLAMSHELL BUCKET....492

33.1 DESCRIPTION AND OPERATION....492

33.2 FITTING THE CLAMSHELL BUCKET....493

WEBMPC9500 - Hydraulic Excavator PC95-1 Shop Manual....496

COVER PAGE....496

CONTENTS....498

10 STRUCTURE AND FUNCTION....511

P.T.O...512

POWER TRAIN....513

FINAL DRIVE - SPROCKET....514

TRACK FRAME....515

IDLER AND RECOIL SPRING....516

CARRIER ROLLER....517

TRACK ROLLER....517

TRACK SHOE....518

SWING CIRCLE....519

SWING MACHINERY....520

CHECK VALVE AND OIL COOLER SAFETY BY-PASS....521

HYDRAULIC CIRCUIT DIAGRAM....522

MAIN HYDRAULIC PUMP....523

PUMP DRIVE....524

SUMMATION HORSEPOWER CONTROL....525

3 CIRCUIT CONTROL VALVE....528

MODE-SYSTEM....530

AUXILIARY PUMP....531

CONTROL VALVE (Ports)....532

CONTROL VALVE (Valve)....534

SWING MOTOR....535

SWING MOTOR RELIEF VALVE....536

CENTER SWIVEL JOINT....537

TRAVEL MOTOR....538

TRAVEL ACCELERATION VALVE....539

SERVOCONTROL FEED UNIT....540

SWING MOTOR BRAKING CIRCUIT SELECTOR VALVE....542

ACCUMULATOR....543

R.H. PPC VALVE....544

L.H. PPC VALVE....545

TRAVEL PPC VALVE....546

2nd BOOM PPC VALVE....547

BOOM SWING PPC VALVE....548

BLADE PPC VALVE....549

BLADE SAFETY VALVE....550

SOLENOID VALVES....551

ELECTRICAL CIRCUIT DIAGRAM (Engine Line)....553

ELECTRICAL CIRCUIT DIAGRAM (Solenoid Valve)....555

ELECTRICAL CIRCUIT DIAGRAM (Light Line)....557

20 TESTING AND ADJUSTMENTS....559

NORMAL OR STANDARD TECHNICAL DATA....560

EQUIPMENT FOR TESTING, ADJUSTING, AND IDENTIFYING FAULTS....577

MEASURING THE ENGINE SPEED....579

VALVE CLEARANCE ADJUSTMENT....580

MEASUREMENT OF COMPRESSION PRESSURE....581

CHECKING AND TIGHTENING THE FAN-BELT....582

ADJUSTING THE STROKE OF THE ACCELERATOR LEVER....583

ADJUSTING PPC VALVES CLEARANCE....584

ADJUSTING THE SAFETY MICROSWITCH....586

CENTRING THE STROKE OF THE BLADE CONTROL LEVER....586

MEASURING THE SWING CIRCLE AXIAL CLEARANCE....587

TESTING AND ADJUSTING TRACK-SHOE TENSION....588

BLEEDING AIR - RELEASING RESIDUAL PRESSURE....589

Bleeding air from pumps P1 and P2....589

Bleeding air from the PPC valves circuit....589

Bleeding air from the cylinders....590

Releasing residual pressure from the circuits....590

CHECKING AND REGULATING PRESSURE IN THE HYDRAULIC CIRCUITS....591

CHECKING THE INTERVENTION POINT OF THE SUMMATION HORSEPOWER CONTROL....597

CHECKING THE INITIAL HORSEPOWER CONTROL POINT FOR THE 3-CIRCUIT CONTROL VALVE....598

CHECKING AND ADJUSTING PRESSURES IN THE SERVOCONTROL SUPPLY UNITS....599

ADJUSTING THE MAIN SAFETY VALVE OF PUMP P4....600

MEASURING PUMP DELIVERY....601

MEASURING TRAVEL DEVIATION....602

ADJUSTING THE MAXIMUM SPEED OF THE TRAVEL MOTORS....603

CHECKING THE CORRECT FUNCTIONING OF THE TRAVEL ACCELERATION VALVE....605

TESTING FOR INTERNAL OIL LEAKAGE IN THE TRAVEL MOTORS....606

ADJUSTING BOOM AND ARM SAFETY VALVES....607

ADJUSTING 2nd BOOM SAFETY VALVES....608

MEASURING THE INITIAL INTERVENTION POINT OF THE OVERLOAD SENSOR....609

ADJUSTING THE VALVE THAT CONTROLS THE CLOSING SPEED OF THE 2nd BOOM....610

MEASUREMENT OF INTERNAL OIL LEAKAGES IN THE SWING MOTOR....611

CHECKING FOR LEAKAGES INSIDE THE SWIVEL JOINT....612

ANALYSIS OF THE CAUSES OF HYDRAULIC DRIFTS....614

1. Boom test....614

2. Arm test....614

3. Testing the functionality of the boom and arm safety valve....615

4. 2nd boom test....616

5. Testing the functionality of the 2nd boom safety valves....617

6. Bucket test....617

7. Boom swing test....618

8. Blade test....618

9. Swing motor test....619

10. Testing the travel motors....620

TROUBLESHOOTING....623

PROCEDURES TO FOLLOW WHILE TROUBLESHOOTING....624

RULES TO BE OBSERVED WHEN WORKING ON HYDRAULIC CIRCUITS OR EQUIPMENT....625

TABLE OF FAILURE MODES AND CAUSES TESTS TO BE CARRIED OUT BEFORE TROUBLESHOOTING....627

EXCESSIVE TRAVEL DEVIATION....628

THE MACHINE DEVIATES EXCESSIVELY AT THE COMMENCEMENT OF TRAVEL....632

WORK EQUIPMENT, REVOLVING FRAME SWING AND TRAVEL ARE SLOW OR WITHOUT POWER....633

WORK EQUIPMENT, REVOLVING FRAME SWING AND TRAVEL MECHANISMS FUNCTION INTERMITTENTLY....634

THE REVOLVING FRAME SWING SPEED IS SLOW IN BOTH DIRECTIONS....635

THE REVOLVING FRAME SWING SPEED IS SLOW IN ONE DIRECTION, AND DOES NOT BRAKE PROPERLY ON THAT SIDE....636

DIFFICULTIES WITH RAISING OR LOWERING THE BOOM....637

EXCESSIVE RESPONSE TIME FOR THE BOOM, ARM AND BUCKET....638

BOOM SLOW TO RISE - ARM SLOW TO CLOSE....640

THE SERVOCONTROL SUPPLY GROUP DOES NOT FUNCTION OR THE PRESSURE IS UNSTABLE ....641

THE CONTROL LEVERS MOVE, BUT EQUIPMENT MOVEMENTS ARE INCOMPLETE OR HAVE NO EFFECT....642

SPEEDS DO NOT CHANGE IF THE WORKING MODE SELECTOR IS POSITIONED ON E....644

ABNORMAL NOISES IN THE PUMPS....644

ENGINE LOSES POWER OR STALLS DURING WORK....645

30 DISASSEMBLY AND ASSEMBLY....646

HOW TO READ THE MANUAL....648

PRECAUTIONS TO BE TAKEN WHEN WORKING....649

SPECIAL TOOLS....650

STARTER MOTOR....652

REMOVAL AND INSTALLATION....652

ALTERNATOR....653

REMOVAL AND INSTALLATION....653

NOZZLE HOLDER....654

REMOVAL AND INSTALLATION....654

AIR FILTER GROUP....655

REMOVAL AND INSTALLATION....655

MUFFLER....656

REMOVAL....656

INSTALLATION....657

ENGINE HOOD....658

REMOVAL AND INSTALLATION....658

FIXED HOOD....659

REMOVAL....659

INSTALLATION....660

SEAT....661

REMOVAL AND INSTALLATION....661

CABIN....662

REMOVAL AND INSTALLATION....662

COUNTERWEIGHT....663

REMOVAL AND INSTALLATION....663

RADIATOR....664

REMOVAL AND INSTALLATION....664

HYDRAULIC OIL COOLER....665

REMOVAL AND INSTALLATION....665

HEATING FAN....666

REMOVAL....666

INSTALLATION....667

FUEL TANK....668

REMOVAL AND INSTALLATION....668

HYDRAULIC OIL TANK....669

REMOVAL AND INSTALLATION....669

ENGINE-PUMP GROUP....670

REMOVAL....670

INSTALLATION....672

PUMP GROUP....673

REMOVAL AND INSTALLATION....673

HYDRAULIC PUMP....674

DISASSEMBLY....674

ASSEMBLY....681

GEAR-PUMP....687

REMOVAL AND INSTALLATION....687

DISASSEMBLY....688

ASSEMBLY....691

ENGINE-PUMP COUPLING JOINT....696

REMOVAL AND INSTALLATION....696

SWIVEL JOINT....697

REMOVAL AND INSTALLATION....697

SWING MOTOR....698

REMOVAL AND INSTALLATION....698

SWING MACHINERY....699

REMOVAL AND INSTALLATION....699

DISASSEMBLY....700

ASSEMBLY....708

REVOLVING FRAME....719

REMOVAL....719

INSTALLATION....720

SWING CIRCLE....721

REMOVAL AND INSTALLATION....721

TRAVEL MOTOR....722

REMOVAL AND INSTALLATION....722

TRACK SHOES....723

REMOVAL AND INSTALLATION....723

SPROCKET....724

REMOVAL AND INSTALLATION....724

FINAL DRIVE....725

REMOVAL AND INSTALLATION....725

DISASSEMBLY....726

ASSEMBLY....732

IDLER AND RECOIL SPRING....742

REMOVAL AND INSTALLATION....742

IDLER....743

DISASSEMBLY AND ASSEMBLY....743

RECOIL SPRING AND CYLINDER....744

DISASSEMBLY AND ASSEMBLY....744

TRACK ROLLER....745

REMOVAL AND INSTALLATION....745

CARRIER ROLLER....746

REMOVAL AND INSTALLATION....746

R.H. PPC VALVE (BOOM - BUCKET)....747

REMOVAL AND INSTALLATION....747

L.H. PPC VALVE (ARM-SWING)....748

REMOVAL AND INSTALLATION....748

BLADE PPC VALVE....749

REMOVAL AND INSTALLATION....749

PPC VALVE (For travel, boom swing, 2-piece boom)....750

REMOVAL AND INSTALLATION....750

SERVOCONTROL FEED UNIT....751

REMOVAL AND INSTALLATION....751

CONTROL VALVE....752

REMOVAL AND INSTALLATION....752

BOOM CYLINDER....753

REMOVAL AND INSTALLATION....753

BOOM CYLINDER (For 2-piece boom)....754

REMOVAL....754

INSTALLATION....755

2-PIECE BOOM CYLINDER....756

REMOVAL....756

INSTALLATION....757

ARM CYLINDER....758

REMOVAL AND INSTALLATION....758

BUCKET CYLINDER....759

REMOVAL AND INSTALLATION....759

BOOM SWING CYLINDER....760

REMOVAL AND INSTALLATION....760

BLADE CYLINDER....761

REMOVAL AND INSTALLATION....761

WORK EQUIPMENT CYLINDERS....762

DISASSEMBLY....762

ASSEMBLY....763

OVERLOAD SENSOR....767

REMOVAL AND INSTALLATION....767

WORK EQUIPMENT (For the boom)....768

REMOVAL AND INSTALLATION....768

WORK EQUIPMENT (2-piece boom version)....769

REMOVAL....769

INSTALLATION....770

BUCKET....771

REMOVAL AND INSTALLATION....771

ARM....772

REMOVAL....772

INSTALLATION....774

2-PIECE BOOM....775

REMOVAL....775

INSTALLATION....776

BOOM....777

REMOVAL AND INSTALLATION....777

BOOM (2-piece boom version)....778

REMOVAL....778

INSTALLATION....779

SWING BRACKET....780

REMOVAL AND INSTALLATION....780

BLADE....781

REMOVAL AND INSTALLATION....781

40 MAINTENANCE STANDARD....782

P.T.O...783

TRAVEL MACHINERY....784

SPROCKET....785

TRACK FRAME AND RECOIL SPRING....786

IDLER....787

CARRIER ROLLER....788

TRACK ROLLER....789

TRACK SHOE....790

SWING CIRCLE....791

SWING MACHINERY....792

CHECK VALVE AND OIL COOLER SAFETY BY-PASS....793

PUMP DRIVE....794

SUMMATION HORSEPOWER CONTROL - MODE SYSTEM....795

AUXILIARY PUMP....796

CONTROL VALVE....797

SWING MOTOR RELIEF VALVE....798

TRAVEL MOTOR....799

SERVOCONTROL FEED UNIT....800

L.H. AND R.H. PPC VALVE....801

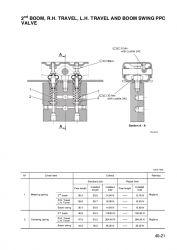

2nd BOOM, R.H. TRAVEL, L.H. TRAVEL AND BOOM SWING PPC VALVE....802

BLADE PPC VALVE....803

BLADE SAFETY VALVE....804

CYLINDERS....805

WORK EQUIPMENT (1 - piece boom)....807

WORK EQUIPMENT (2 - piece boom)....809

Komatsu Hydraulic Excavators PC88MR Repair Service Manuals