Case 85XT/90XT/95XT Skid Steers Workshop Repair & Service Manual

Catalog:

Model:

Complete digital official shop manual contains service, maintenance, and troubleshooting information for the Case 85XT, 90XT, 95XT Skid Steers. Diagnostic and repair procedures are covered in great detail to repair, maintain, rebuild, refurbish or restore your Skid Steers like a professional mechanic in local service/repair workshop. This cost-effective quality manual is 100% complete and intact as should be without any missing pages. It is the same factory shop manual used by dealers that guaranteed to be fully functional to save your precious time.

This manual for Case 85XT, 90XT, 95XT Skid Steers is divided into different sections. Each section covers a specific component or system and, in addition to the standard service procedures, includes disassembling, inspecting, and assembling instructions. A table of contents is placed at the beginning of each section. Pages are easily found by category, and each page is expandable for great detail. It is in the cross-platform PDF document format so that it works like a charm on all kinds of devices. You do not need to be skilled with a computer to use the manual.

1,436 pages, bookmarked, Searchable, Printable, high quality PDF

7-52254 - 85XT, 90XT, 95XT Skid Steers Service Manual.pdf

MODELS Covered

Case 85xt

Case 90xt

Case 95xt

SECTIONS covered

General

Section Index – General

Standard Torque Specifications

Fluids and Lubricants

Metric Conversion Chart

Loctite Product Chart

Engines

Section Index – Engines

Engine and Radiator Removal and Installation

Aftercooler

Cylinder Head and Valve Train

Cylinder Block

Lubrication System

Cooling System

Turbocharger

Turbocharger Failure Analysis

Fuel System

Section Index – Fuel System

Fuel System and Filters

Fuel Injectors

Bosch Model VE Fuel Injection Pump

Electrical

Section Index – Electrical

Electrical “How It Works’

Electrical “How It Works’

(85XT Machines With Pl.N. JAF0352234 And After)

90XT Machines With Pl.N. JAF0320050 And After)

(95XT Machines With Pl.N. JAF0311357 And After)

Removal and Installation of Electrical Components

Electrical Specifications and Troubleshooting

Electrical Specifications. Troubleshooting, and Schematics

Battery

Starter and Starter Solenoid

Alternator

Power Train

Section Index – Power Train

Hydrostatic How It Works

Removal and Installation of Power Train Components

Removal and Installation of Power Train Components

(85XT Machines With Pl.N. JAF0352234 Ana After)

(90XT Machines With Pl.N. JAF0320050 And After)

(95XT Machines With Pl.N. JAF0311357 And After)

Hydrostatic Troubleshooting

Drive Coupling

Piston Pumps – Tandem Pump (M51)

Drive Motors – 90XT and 95XT

Drive Motors – 85XT

Gear Box

Sprockets. Chains, and Axle Assemblies

Solenoid Valve for Two Speed Drive Motor

Accumulator for Charge Circuit

Accumulator for Charge Circuit

(90XT Machines With Pl.N. JAF0298607 And After)

(95XT Machines With Pl.N. JAF0299000 And After)

Wheels and Tires

Brakes

Section Index – Brakes

How It Works

Brake – 85XT (Machines Before PIN JAF0273132)

Brake – 85XT (Machines With PIN JAF0273132 And After)

Brake – 90XT and 95XT

Brake Pump

Hydraulics

Section Index – Hydraulics

“How It Works’

Hydraulic System ‘How It Works”

(85XT Machines With P.I.N. JAF0352234 And After)

(90XT Machines With P.I.N. JAF0320050 And After)

(95XT Machines With P.I.N. JAF0311357 And After)

Hydraulic System Troubleshooting

Hydraulic System Troubleshooting

(85XT Machines With P.I.N. JAF0352234 And After)

(90XT Machines With P.I.N. JAF0320050 And After)

(95XT Machines With P.I.N. JAF0311357 And After)

Cleaning the Hydraulic System and Hydrostatic System

Removal and Installation of Hydraulic Components

Removal and Installation of Hydraulic Components

(85XT Machines With P.I.N. JAF0352234 And After)

(90XT Machines With P.I.N. JAF0320050 And After)

(95XT Machines With P.I.N. JAF0311357 And After)

Gear (Equipment) Pump

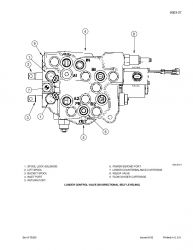

Loader Control Valve

Loader Control Valve (2 Spool Valve)

(85XT Machines With P.I.N. JAF0352234 And After)

90XT Machines With P.I.N. JAF0320050 And After)

(95XT Machines With P.I.N. JAF0311357 And After)

Loader Control Valve (Bi-Directional Self Leveling Valve)

(85XT Machines With P.I.N. JAF0352234 And After)

(95XT Machines With P.I.N. JAF0311357 And After)

Cylinders

Optional High Pressure High Flow Pump (Piston Pump)

Optional Low Pressure High Flow Pump (Gear Pump)

Control Valve for Low Pressure High Flow System

Self-Leveling Valve

Solenoid Valve for Hydraulic Coupler System

D125 Backhoe Control Valve – North American Only

Accumulator for Ride Control

Flat Faced Couplers

Solenoid Valve for High Pressure High Flow System (Piston Pump)

Mounted Equipment

Section Index – Mounted Equipment

Pedals and Levers

Loader

Attachment Coupler

ROPS Canopy. Seat. Seat Belts, and Operators Compartment

Heater

Backhoe (D125 Backhoe)

Trencher

Steel Track

Rubber Track

Air Conditioning Troubleshooting – Fof Systems With R134A Refrigerant

Air Conditioner System Gauges and Testing – For Systems With R134A Refrigerant

Air Conditioner System Service – For Systems With R134A Refrigerant

Refrigerant Recovery. Compressor Removal and System Evacuation and Recharging

Air Conditioner Component Service – Fof Systems With R134A Refrigerant

Hydraulic and Electrical Schematic Foldout

SECTIONS covered

Description

Fluids and Lubricants

Electrical “How It Works”

Electrical Specifications and Troubleshooting

Hydrostatic System How It Works and Troubleshooting

“How It Works”

Hydraulic System Troubleshooting

Pedals and Levers

Hydraulic and Electrical Schematic Foldout

EXCERPT:

HYDRAULIC COMPONENTS

Components Defined

Reservoir - Located in the left rear of chassis.

Pressurized to 34.5 kpa (5 psi), with a -3.5 kpa (- 0.5 psi) vacuum breaker. A 100 mesh suction screen is located near the bottom of the reservoir to supply filtered oil to the hydraulic gear pump.

Hydraulic gear pump - Supplies flow to charge the hydrostatic tandem pump assembly and operate the hydraulic system.

Constant pressure priority valve - Integrated with the hydraulic gear pump to provide priority oil

flow to charge the hydrostatic tandem pump assembly, with remaining flow supplying the hydraulic system.

Loader control valve - Is a three spool valve controlling the loader, bucket and auxiliary circuits.

The main relief valve is also par t of the valve assembly.

Bucket cylinders - Used to control the movement of the bucket with cushioning employed at the rod end of the cylinder.

Loader lift cylinders - Used to raise and lower the loader frame with cushioning employed at the base end of the cylinder.

Auxiliary disconnects -Located on the left loader frame for the purpose of auxiliary hydraulic power to attachments.

Return filter - Provides 2 Micron filtration for return oil from the hydraulic system.

Charge filter - Filters charge oil prior to entering the hydrostatic tandem pump assembly. Provides 2 Micron filtration.

Oil cooler - Cools hydraulic system return oil and hydrostatic drains.

Self Leveling Valve - Used to maintain a level bucket position as the loader frame is raised.

Reservoir

The hydraulic system begins at the reservoir located in the left rear frame. The reservoir has a capacity of 66.2 litres (17.5 U.S. gallons) and is pressurized to 34.5 kPa (5 psi) . Pressure is controlled by the relief in the reservoir cap. A vacuum breaker is also employed in the cap to open at -3.5 kPa, (-0.5 psi) allowing air to enter the reservoir. A 100 mesh strainer is located in the outlet port of the reservoir to assure that contamination larger than 150 Microns does not enter the inlet of the hydraulic gear pump. The strainer can be removed for cleaning.

Hydraulic Pump/Priority Valve

A Sauer/Sundstrand gear pump, supplies oil for the hydraulic and hydrostatic systems. Pump flow enters an integral priority flow divider, sending priority flow 18.0 litres/min. (4.8 gpm) to the charge port, supplying charge oil to the closed-loop of the hydrostatic system. Remaining pump flow is diverted to the equipment port for use in the hydraulic system, for loader, bucket, auxiliary and power beyond circuits. Return oil from the hydraulic system passes through the filter and cooler before returning to the reservoir.

The hydraulic pump is mounted to and driven by hydrostatic tandem pump. The hydrostatic tandem pump is directly coupled to the engine and driven from the flywheel end.

Case 85XT/90XT/95XT Skid Steers Workshop Repair & Service Manual