Toyota Van 1982-1991 Workshop Repair & Service Manual

Catalog:

Model:

Complete digital official shop manual contains service, maintenance, and troubleshooting information for the Toyota Van 1982-1991. Diagnostic and repair procedures are covered in great detail to repair, maintain, rebuild, refurbish or restore your Van like a professional mechanic in local service/repair workshop. This cost-effective quality manual is 100% complete and intact as should be without any missing pages. It is the same factory shop manual used by dealers that guaranteed to be fully functional to save your precious time.

This manual for Toyota Van 1982-1991 is divided into different sections. Each section covers a specific component or system and, in addition to the standard service procedures, includes disassembling, inspecting, and assembling instructions. A table of contents is placed at the beginning of each section. Pages are easily found by category, and each page is expandable for great detail. It is in the cross-platform PDF document format so that it works like a charm on all kinds of devices. You do not need to be skilled with a computer to use the manual.

Toyota Van (VR22-29-31-32 Series) Service Manual.pdf

MAKE: Toyota

YEAR: 1982 1983 1984 1985 1986 1987 1988 1989 1990 1991

Model: Van (YR 22, 29, 31, 32 Series) (a.k.a. TownAce van, MasterAce Surf van, Model F, Toyota Tarago, Space Cruiser, Daihatsu Delta Wide)

1,017 pages, bookmarked, Searchable, Printable, high quality PDF

EXCERPT:

1987 TOYOTA VAN

REPAIR MANUAL

INTRODUCTION

MAINTENANCE

ENGINE MECHANICAL

EMISSION CONTROL SYSTEMS

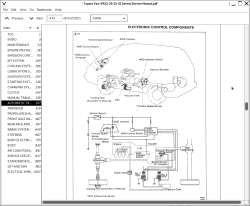

EFI SYSTEM

COOLING SYSTEM

LUBRICATION SYSTEM

IGNITION SYSTEM

STARTING SYSTEM

CHARGING SYSTEM

CLUTCH

MANUAL TRANSMISSION

AUTOMATIC TRANSMISSION

TRANSFER

PROPELLER SHAFT

FRONT AXLE AND SUSPENSION

REAR AXLE AND SUSPENSION

BRAKE SYSTEM

STEERING

BODY ELECTRICAL SYSTEM ]

BODY

AIR CONDITIONING SYSTEM

SERVICE SPECIFICATIONS

STANDARD BOLT TORQUE SPECIFICATIONS

SSTAND SSM

AUTOMATIC TRANSMISSION

HYDRAULIC CIRCUIT

ELECTRICAL WIRING DIAGRAM

...

ENGINE MECHANICAL - Cylinder Head

PREPARATION FOR REMOVAL (See page EM-9)

1. DISCONNECT CABLE FROM NEGATIVE TERMINAL OF BATTERY

2. REMOVE RIGHT SEAT

3. REMOVE ENGINE SERVICE HOLE COVER

4. DRAIN COOLANT

Open the radiator and engine drain cocks, and allow coolant to drain into a clean container.

5. DRAIN ENGINE OIL

6. [w/ PS]

REMOVE POWER STEERING PUMP (See page SR-29)

7. REMOVE EXHAUST PIPE AND BRACKET

8. DISCONNECT ACCELERATOR CABLE WITH BRACKET FROM THROTTLE BODY

9. REMOVE AIR CLEANER PIPE AND HOSES

10. DISCONNECT WATER TEMPERATURE SENDER GAUGE CONNECTOR FROM CYLINDER HEAD

11. DISCONNECT EFI CONNECTORS

(a) Water thermo sensor connector

(b) Cold start injector time switch connector

(c) Cold start injector connector

(d) Air valve connector

(e) Throttle position sensor connector

(f) [2WD M/T] Oxygen sensor connector

(g) [w/ A/C]

Water temperature switch connector

12. DISCONNECT HOSES

(a) Radiator inlet hose

(b) Radiator breather hose

(c) Reserve tank hose

(d) Heater outlet hose

(e) PCV hoses

(f) Water by-pass hoses

13. DISCONNECT VACUUM HOSES

(a) Brake booster vacuum hose

(b) Charcoal canister hose

(c) Label and disconnect emission control hoses

14. REMOVE THROTTLE BODY

Remove the throttle body from the air intake chamber.

15. REMOVE EGR VALVE

(a) Remove the two nuts from the air intake chamber.

(b) Remove the union nut from exhaust manifold and EGR valve.

16. DISCONNECT PIPE AND HOSES

(a) Cold start injector pipe

(b) Water by-pass hoses

(c) Pressure regulator hose

17. REMOVE AIR INTAKE CHAMBER

(a) Remove the air intake chamber brackets.

NOTE: Use a 1 2 mm socket wrench to remove the rear chamber bracket.

(b) Remove the air intake chamber with the air valve.

NOTE: Use 1 0 mm and 1 2 mm socket wrenches to remove the air intake chamber with the air valve.

18. DISCONNECT INJECTOR CONNECTOR

(a) Remove the wire clamp bolt.

(b) Disconnect the injector connectors from the injectors.

19. REMOVE PARTS

(a) Exhaust manifold bracket

(b) Heater pipe bracket

(c) Fuel inlet pipe union bolt from fuel filter

(d) Fuel outlet hose

REMOVAL OF CYLINDER HEAD (See page EM-9)

1. REMOVE SPARK PLUGS AND TUBES

2. REMOVE CYLINDER HEAD COVER

Remove the cap nuts, seal washers, cylinder head cover and gasket.

3. REMOVE ROCKER ARM SHAFT ASSEMBLY

(a) Uniformly loosen and remove the three bolts and two nuts in several passes, in sequence shown.

(b) Remove the rocker shaft assembly.

4. REMOVE PUSH RODS

NOTE: Keep the push rods in correct order.

5. REMOVE CYLINDER HEAD

(a) Uniformly loosen and remove the thirteen head bolts in several passes, in the sequence shown.

CAUTION: Head warpage or cracking could result from bolts removing in incorrect order.

...