Kobelco SK70SR, SK70SR-1E, SK70SR-1ES Workshop Repair & Service Manual

Catalog:

Model:

Complete digital workshop manual contains service, maintenance, and troubleshooting information for the Kobelco SK70SR, SK70SR-1E, SK70SR-1ES Hydraulic Excavator. Diagnostic and repair procedures are covered in great detail to repair, maintain, rebuild, refurbish or restore your hydraulic excavator like a professional mechanic in local service/repair workshop. This cost-effective quality manual is 100% complete and intact as should be without any missing pages. It is the same factory shop manual used by dealers that guaranteed to be fully functional to save your precious time.

This manual for Kobelco SK70SR, SK70SR-1E, SK70SR-1ES Hydraulic Excavator is divided into different sections. Each section covers a specific component or system and, in addition to the standard service procedures, includes disassembling, inspecting, and assembling instructions. A table of contents is placed at the beginning of each section. Pages are easily found by category, and each page is expandable for great detail. It is in the cross-platform PDF document format so that it works like a charm on all kinds of devices. You do not need to be skilled with a computer to use the manual.

“SK70SR (S5YT0001E).pdf”

Kobelco SK70SR Hydraulic Excavator Shop Manual; 912 pages

“SK70SR-1E (S5YT0002E).pdf”

Kobelco SK70SR-1E Hydraulic Excavator Shop Manual; 966 pages

“SK70SR-1E(S) (S5YT0003E01).pdf”

Kobelco SK70SR-1E, SK70SR-1ES Hydraulic Excavator Shop Manual; 1,054 pages

EXCERPT:

INDEX

1 SPECIFICATIONS SECTION

2 MAINTENANCE SECTION

3 SYSTEM SECTION

4 DISASSEMBLY SECTION

5 TROUBLESHOOTING

6 ENGINE SECTION

7 PROCEDURE OF INSTALLING OPTIONS SECTION

...

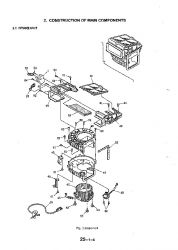

24. COMPONENTS SYSTEM

24.1.3.2 FUNCTION

1. Reducing valve

(1) Neutral (Fig. 24-21)

Spool (301) is pushed up by spring (335} (for return) via spring seat (311) and washer (215) and is located in the neutral position as shown in the cross-sectional view. Therefore, since the output port connects only with port T by the spool select function, the pressures at output ports 1, 2 are equal to that of port T.

(2) The control of the remote control valve is tilted from its neutral (Fig. 24-22)

If cam (420) is rotated clockwise in the cross-sectional view, push rod (214) on port 1 is pushed down. This moves the spool down via washer 1, spring seat (for secondary pressure setting), spring (324 ), washer 2 (217), and washer 3 (313) and connects port P with port 1. The oil supplied by the pilot pump runs to port 1 and generates pressure.

If the control lever (or pedal) is inclined and when the pressure at port 1 rises to a level equivalent to the action of the spring that sets the secondary pressure, the hydraulic pressure acting on the spool balances the spring action, thereby keeping the output pressure at port 1 constant. The spool at port 2 is held neutral ; the oil returning from the control valve is discharged via port T.

On some specifications, the push rod comes in direct contact with the top of the spool in the neighborhood of the maximum angle of the control. This pushes in the spool forcibly which connects port P with the output port and makes the pressures at both ports equal.

2. Damping mechanism of the control

(1) Neutral

The push rod is pushed up by springs (336) via piston (224) (damping) and is located as shown in the cross-sectional view.

(2) The control is inclined from its neutral position : [Refer to the functional explanation (1) of damping]

If the cam is turned clockwise in the cross-sectional view, the push rod on the port 1 side is pushed down which brings the piston down.

On that occasion, the oil in the damping piston chamber is discharged through the orifice. The pressure then generated creates a damping force.

In the meantime, the push rod on the port 2 side moves up by the damping spring via the piston.

On that occasion, the oil in the tank chamber is sucked into the damping piston chamber through the ball checks (3 places) that consists of bushing (223) and ball (225). The oil outside of the piston chamber gets out of the path to port T, from the top end of the casing.