Case 327B, 330B Articulated Dump Trucks Factory Service & Shop Manual

Catalog:

Model:

Complete workshop repair service manual with electrical wiring diagrams for Case 327B, 330B Articulated Dump Trucks . It's the same service manual used by dealers that guaranteed to be fully functional and intact without any missing page.

This Case 327B, 330B Articulated Dump Trucks service & repair manual (including maintenance, overhaul, disassembling & assembling, adjustment, tune-up, operation, inspecting, diagnostic & troubleshooting…) is divided into different sections. Each section covers a specific component or system with detailed illustrations. A table of contents is placed at the beginning of each section. Pages are easily found by category, and each page is expandable for great detail. The printer-ready PDF documents work like a charm on all kinds of devices.

“87573455 NA.pdf”

Case 327B, 330B Articulated Dump Trucks Service Manual; 1214 pages

Issued 11-2006

“84187913.pdf”

Case 327B, 330B Articulated Dump Trucks Service Manual; 1278 pages

Print No. 84187913

First Edition English 09/09 From serial no. ZCNAD30TP8P457003

“84150684 NA.pdf”

Case 327B, 330B Tier 3 Simplemux Articulated Truck Service Manual; 1397 pages

ASN HHD03(27)(30)BN_PG56092~ HHD03(27)(30)BN_PG56076~ 84150684 NA

Issued 01June 08

EXCERPT:

327B-330B

SECTION 5 AUTOMATIC TRANSMISSION

CLEANING, INSPECTING AND CHECKING

Cleaning components

All components must be clean to allow an effective inspection. During assembly, do not let dust and foreign bodies inside the trans- mission. Even the smallest particles can damage accurately mated components. Use petroleum based solvents for cleaning only, with the exception of benzene and derivatives. Solvents such as trichlorethylene, benzol, acetone and all aromatic products may damage polyacrylic rubber seals.

Accurately clean all removed parts. Follow the precautions below:

* Accurately clean the guards, inside and out, to allow checking and to prevent dirt from penetrating inside;

* use only solvent to clean the clutch plates. Clean all other metal transmission components perfectly with solvent or steam. Do not use caustic soda based solutions for steam cleaning;

* dry all components with compressed air, except for the bearings. Apply grease to steam cleaned components immediately after drying;

* clean oil pipes by passing a piece of soft wire in both direction and washing with solvent. Dry the pipes with compressed air;

…

84150684 NA...2

Table of Contents...5

General...11

Engines...157

Electrical...325

Steering...509

Power Train...603

Brakes...1129

Hydraulics...1213

Mounted Equipment...1229

84187913...1399

Table of Contents...1404

INTRODUCTION...1401

SECTION 1 - GENERAL...1408

SECTION 2A - TECHNICAL DATA...1442

SECTION 2B - TECHNICAL DATA...1486

SECTION 3 - FAILURE CODES...1530

SECTION 4 - ENGINE...1594

SECTION 5 - AUTOMATIC TRANSMISSION...1748

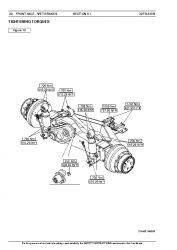

SECTION 6.1 - FRONT AXLE - DISC BRAKES...1868

SECTION 6.2 - INTERMEDIATE AXLE - DISC BRAKES...1938

SECTION 6.3 - REAR AXLE...2080

SECTION 7 - DRIVELINE...2132

SECTION 8 - SUSPENSIONS...2152

SECTION 9 - WHEELS AND TIRES...2190

SECTION - 10 HYDRAULIC SYSTEM...2204

SECTION 11 - ELECTRICAL SYSTEM...2334

SECTION 12 - PNEUMATIC SYSTEM...2508

SECTION 13 - GREASING SYSTEM...2574

SECTION 14 - AIR CONDITIONING SYSTEM...2594

SECTION 15 - CAB...2624

SECTION 16 - CHASSIS...2650

87573455 NA...2677

Table of Contents...2683

Conditions of Use and Safety Instrutions...2687

Technical Data...2725

Failure Codes...2797

Engine...2845

Automatic Transmission...3009

Front Axle - Dry Disc Brakes...3131

Intermediate Axle - Dry Disc Brakes...3271

Rear Axle - Dry Disc Brakes...3413

Driveline...3527

Suspensions...3547

Wheels and Tires...3579

Hydraulic System...3593

Steering and Dumping System...3601

Emergency Steering System...3653

Braking System...3661

Electrical System...3687

Pneumatic System...3791

Greasing System...3813

Air-Conditioning System...3825

Cab and Covers...3841

Chassis...3867