Case 621B, 721B Loaders Workshop Repair & Service Manual

Catalog:

Model:

Complete official workshop manual contains service, maintenance, and troubleshooting information for the Case 621B, 721B Loaders. Diagnostic and repair procedures are covered in great detail to repair, maintain, rebuild, refurbish or restore your Case 621B, 721B Loaders like a professional mechanic in local service/repair workshop. This cost-effective quality manual is 100% complete and intact as should be without any missing pages. It is the same factory shop manual used by dealers that guaranteed to be fully functional to save your precious time.

This manual for Case 621B, 721B Loaders is divided into different sections. Each section covers a specific component or system and, in addition to the standard service procedures, includes disassembling, inspecting, and assembling instructions. A table of contents is placed at the beginning of each section. Pages are easily found by category, and each page is expandable for great detail. It is in the cross-platform PDF document format so that it works like a charm on all kinds of devices. You do not need to be skilled with a computer to use the manual.

1,860 pages, bookmarked, Searchable, Printable, high quality PDF

621B, 721B Loaders Service Manual.pdf

621 B 6T-590; 721 B 6T-830

MODELS Covered

Case 621B 721B loader

621B 6T-590 Engine

721B 6T-830 Engine

SECTIONS covered

General

Loctite Product Chart

Standard Torque Specifications

Fluids and Lubricants

Engines

Engine Removal and Installation and Radiator Removal and Installation – 621B

Engine Removal and Installation and Radiator Removal and Installation – 721B

Stall Tests

621B 6T-590 Engine

Specification Details

Cylinder Head and Valve Train

Cylinder Block – Crankshaft, Pistons, Rods, Sleeves, Camshaft,

Bearings, Seals, and Flywheel

Lubrication System

Cooling System

Turbocharger

721B 6T-830 Engine

Specification Details

Cylinder Head and Valve Train

Cylinder Block – Crankshaft, Pistons, Rods, Sleeves, Camshaft,

Bearings, Seals, and Flywheel

Lubrication System

Cooling System

Turbocharger

Turbocharger Failure Analysis

Fuel System

621B 6T-590 Engine

Fuel System and Filters

Fuel Injection Pump and Drive Gear

Fuel Injectors

721B 6T-830 Engine

Fuel System and Filters

Fuel Injection Pump and Drive Gear

Fuel Injectors

Description

Electrical

Removal and Installation of Starter and Alternator

Electrical Schematics, Troubleshooting and

Using Booster Batteries to Start the Engine

Electrical Schematics and Troubleshooting – Units with Auto Shift Transmission

Starter and Starter Solenoid – Nippondenso – 621B

Starter and Starter Solenoid – Nippondenso – 721B

Batteries

Instrument Cluster and Gauges

65 Ampere Alternator – Bosch

Steering

Removal and Installation of Steering Components

Steering Specifications and Troubleshooting

Steering Control Valve

Flow Control Valve

Steering Cylinder

Center Pivot

Auxiliary Steering Motor and Pump

Power Train

Removal and Installation of Power Train Components

Transmission Specifications, Schematic, and Troubleshooting – Units Without Auto

Shift Transmission

Transmission Specifications, Schematic, and Troubleshooting – Units With Auto Shift

Transmission

Transmission Repair – 621B (4WG150)

Transmission Repair – 721B (4WG180)

Front and Rear Axle Repair

Drive Shaft, Center Bearing and Universal Joints

Wheels and Tires

Transmission Control Valve – Units Without Auto Shift Transmission

Transmission Control Valve – Units With Auto Shift Transmission

Brakes

Removal and installation of Brake Components

Hydraulic Brake Troubleshooting

Brake Pump

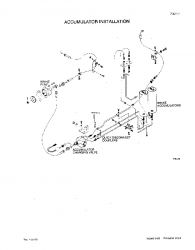

Brake Accumulators

Brake Actuator Valve

Brake Accumulator Valve

Parking Brake

NOTE: For parking brake and brake pedal adjustments, see Section 9009.

Hydraulics

Removal and Installation of Hydraulic Components

Hydraulic Specifications, Schematics. Troubleshooting and Pressure Checks

Cleaning the Hydraulic System

Hydraulic Pump

Loader Control Valve

Cylinders

Coupler Lock Valve • XT Loader

Remote Control Valves

Pressure Reductng’Sequence Valve

Chassis

Air Conditioning Troubleshooting and System Checks

Air Conditioning Troubleshooting and System Checks – For Systems with HFC-134a

Refrigerant

Air Conditioner System Service • Refrigerant Recovery,

System Evacuation and Recharging

Air Conditioner System Service • Refrigerant Recovery, System Evacuation and

Recharging for Systems with HFC-134a Refrigerant

Removal and Installation of Air Conditioning Components

Removal and Installation of Air Conditioning Components – For Systems with

HFC-134a Refrigerant

Air Conditioning Compressor and Clutch

Air Conditioning Compressor and Clutch – For Systems with HFC-134a Refrigerant

Loader

ROPS Cab and ROPS Canopy

Seat and Seat Belts

Suspension Seat

Pedals and Levers

Cab Window Replacement

EXCERPT:

STEP 80

Measure the cylinder sleeve bore for taper as follows:

1. Measure the bore parallel to the crankshaft at the top end of the ring travel zone.

2. Measure the bore in the same position at the bottom end of the ring travel zone.

3. Measure the bore at right angles to the crankshaft at the top end of the ring travel zone.

4. Measure the bore in the same position at the bottom end of the travel zone.

Compare the results of the measurements (1) and (3) with (2) and (4), to find out if the bore has taper. To measure use a inside micrometer, bore gauge or taper gauge. If the taper is more than 0.04 mm, the cylinder sleeve must be replaced.

STEP 81

Measure the cylinder sleeve bores for out-of-round as follows:

1. Measure the bore parallel to the crankshaft at the top end of the ring travel.

2. Measure the bore in the same position at the bottom end of the ring travel.

3. Measure the bore at right angles to the crankshaft at the top end of the ring travel.

4. Measure the bore in the same position at the bottom end of the ring travel.

Compare the measurements (1) and (3) to find the outof-round wear at the top end of the bore.

Compare the measurements (2) and (4) to find the outof-round wear at the bottom of the bore.

If out-of-round is more than 0.04 mm, the cylinder sleeve must be replaced.

Removing the Cylinder Sleeves

IMPORTANT: Cover the crankshaft journals with a clean cloth. Foreign material from the cylinder sleeve or the cylinder block will cause damage to the crankshaft.

STEP 82

Install a sleeve puller to remove the cylinder sleeve. Position the puller in the sleeve. Make sure that the jaws of the puller do not contact the four block lugs. Tighten the lock bar against the cylinder sleeve.

IMPORTANT: Make sure that the jaws of the sleeve puller do not contact the block lugs.

STEP 83

Carefully turn the bearing nut until the cylinder sleeve is loose from the cylinder block.

STEP 84

Remove the cylinder sleeve from the cylinder block.

Remove the a-ring from the cylinder sleeve.

...

Case 621B, 721B Loaders Workshop Repair & Service Manual