Case 580L, 580 Super L, 590L, 590 Super L Factory Service & Shop Manual

Catalog:

Model:

Complete workshop repair service manual with Electrical Wiring Diagrams for Case 580L, 580 Super L, 590L, 590 Super L Loader Backhoe. It's the same service manual used by dealers that guaranteed to be fully functional and intact without any missing page.

This Case 580L, 580 Super L, 590L, 590 Super L Loader Backhoe service repair manual (including maintenance, overhaul, disassembling & assembling, adjustment, tune-up, operation, inspecting, diagnostic & troubleshooting…) is divided into different sections. Each section covers a specific component or system with detailed illustrations. A table of contents is placed at the beginning of each section. Pages are easily found by category, and each page is expandable for great detail. The printer-ready PDF documents work like a charm on all kinds of devices.

1,702+1,468 pages, bookmarked, Searchable, Printable, high quality PDF

7-10402 - "L" Series 2 Loader Backhoe Family (570LXT, 580L, 580 Super L, 590L, 590 Super L) Service Manual.pdf

7-48854 - "L" Series Loader Backhoe Family (580L, 580 Super L, 590L, 590 Super L) Service Manual.pdf

Case Factory Manuals. Digital PDF format with all its advantages, just like the original paper manual. Step by step Instructions, illustrations, diagrams.

PDF Manual:

Instant download: You will receive a link for download on your email immediately after payment.

Compatible with PC, MAC/ Tablet / Smartphone

Searchable PDF

Bookmarks

Printable: pages or entire manual

Zoomable: detailed exploded diagrams, picture

Models

Case 570LXT Series 2 Loader Landscaper

Contents

Service Repair Manual

General

Section Index – General

Standard Torque Specifications

Fluids and Lubricants

Loctite Product Chart

Engines

Section Index – Engine

Engine and Radiator Removal and Installation

Stall Tests

For Engine Repair, See the Engine Service Manual

Fuel System

For Fuel System Repair, See the Engine Service Manual

Electrical

Section Index – Electrical

Removal and Installation of Electrical Components

Electrical Specifications and Troubleshooting

Batteries

Starter Motor – Denso

Instrument Cluster

Alternator

Steering

Section Index – Steering

Removal and Installation of Steering Components

Steering Specifications, Pressure Checks and Troubleshooting

Steering Control Valve

Steering Cylinders

Front Axle – Two Wheel Drive

Front Axle – Four Wheel Drive

Power Train

Section Index – Power Train

Removal and Installation of Power Train Components

Standard Transmission Specifications, Pressure Checks and Troubleshooting

Wheels and Tires

Rear Axle and Planetaries – 570LXT

Standard (Carraro) Transmission

Brakes

Section Index – Brakes

Removal and Installation of Brake Components

Master Cylinder

Hydraulics

Section Index – Hydraulics

Removal and Installation of Hydraulic Components

Hydraulic Specifications, Troubleshooting, and Pressure Checks

Cleaning the Hydraulic System

Hydraulic Pump – 570LXT

Loader Control Valve

Cylinders

Three Point Hitch Control Valve

Auxiliary Control Valve

Accumulator for Machines with Optional Ride Control

Solenoid Valve for Machines with Optional Ride Control

Mounted Equipment

Section Index – Mounted Equipment

Pedals and Levers

Air Conditioning Troubleshooting For Systems With R-134a Refrigerant

Air Conditioning System Gauges and Testing For Systems With R-134a Refrigerant

Air Conditioning System Service For Systems With R-134a Refrigerant

Air Conditioning Components Service For Systems With R-134a Refrigerant

Loader

ROPS Cab and Canopy

Seat Belts

Air Suspension Seat (Sears)

Suspension Seat (Milsco)

Hydraulic Schematic Foldout (570LXT)

Operator’s Manual

To The Owner

After Delivery Check

Right, Left, Front And Rear Of Machine

Identification Numbers

Machine Components

Safety/Decals/Hand Signals

Safety Features

Safety Rules

Before Operation

Machine Operation

Parking The Machine

Burn Prevention

Fire Or Explosion Prevention

Maintenance

Wheel And Tire Maintenance

Roll-Over Protection Structure

Cast Ductile Iron

Safety Decals

Hand Signals

Instruments And Controls

Instrument Cluster

Transmission Controls

Foot Pedals

Front Console Controls

Left Side Instrument Console Controls

Loader Controls

Three-Point Hitch Control

Standard Seat

Standard Suspension Seat

Seatbelts

Cab Climate Control Panel (If Equipped)

Cab And Canopy Options

Storage And Convenience Options

Table Of Contents

Operating Instructions

Run-In Period Of A New Machine

Engine Operation

Engine Starting Aids

Machine Operation

Towing A Disabled Machine

Operating In Cold Weather

Operating In Hot Weather

Loader Operation

Loader Hydraulic Coupler (Optional)

Three Point Hitch Operation

Vandal Lockup Kits

Wheels/Tires

Lubrication / Maintenance Charts

General Safety Before You Service

Engine Hourmeter

Support Strut For Loader Lift Arms

Fluids And Lubricants

Lubrication/Maintenance Chart

Systemgard Lubrication Analysis Program

Environment

Lubrication/Filters/Fluids

Opening The Engine Hood

Loader Grease Fittings

Machine Grease Fittings

Three Point Hitch Grease Fittings

Fluid Levels

Engine Oil Recommendations

Engine Service Specifications

Air Filter System

Engine Cooling System

Diesel Fuel System

Hydraulic System

Transmission

Rear Axle

Front Four Wheel Drive Axle

Cab Air Filter

Maintenance And Adjustments

Loader Return-To-Dig Adjustment

Ether Starting Aid

Fan Drive Belt Replacement

Plastic And Resin Parts

Spark Arrester Muffler (If Equipped)

Ride Control Accumulator

Cab Air Conditioning

Roll-Over Protective Structure

Fire Extinguisher

Electrical System

Batteries

Lamp Replacement

Instrument Cluster

Fuses

Accessory Outlets (If Equipped)

Machine Storage

Removal From Storage

Specifications

Engine Data (Naturally Aspirated)

Engine Data (Turbocharged)

Bolt Torques

Main Relief Valve Pressures

Travel Speeds

Operating Weights

Loader Buckets

Basic Machine Dimensions

Loader Operating Data And Dimensions

Three Point Hitch Lift Capacities

Index

After Delivery Check

EXCERPT:

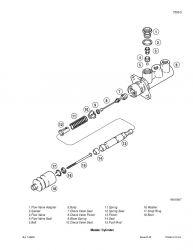

MASTER CYLINDER

Removal

STEP 1

Park the machine on a level surface. Raise the loader and lock the support strut to hold the loader.

STEP 2

Apply the parking brake.

STEP 3

Open the hood.

STEP 4

Loosen the clamp for the exhaust pipe at the muffler.

Remove the exhaust pipe from the muffler.

STEP 5

Remove the tie strap (1 ). Disconnect the electrical connectors (2) for the air restriction indicator. Loosen

the clamp (3) on the air cleaner hose. Disconnect the hose from the air cleaner.

STEP 6

Remove the cap screws and flat washers that fasten the cover to the uprights. Remove the cover and air cleaner as an assembly.

STEP 7

Remove the bolts, flat washers, and insulator curtain that covers the master cylinders.

NOTE: See the illustration on page 6 for the following steps.

STEP 8

Remove any dirt from the master cylinder (1) and the area around the master cylinder (1).

…

Case 580L, 580 Super L, 590L, 590 Super L Factory Service & Shop Manual