Doosan DL300 Wheel Loader Factory Service & Shop Manual

Catalog:

Model:

Complete workshop repair service manual with electrical wiring diagrams for Doosan DL300 Wheel Loader. It's the same service manual used by dealers that guaranteed to be fully functional and intact without any missing page.

This Doosan DL300 Wheel Loader service & repair manual (including maintenance, overhaul, disassembling & assembling, adjustment, tune-up, operation, inspecting, diagnostic & troubleshooting…) is divided into different sections. Each section covers a specific component or system with detailed illustrations. A table of contents is placed at the beginning of each section. Pages are easily found by category, and each page is expandable for great detail. The printer-ready PDF documents work like a charm on all kinds of devices.

“K1010636E.pdf”

Doosan DL300 Wheel Loader Shop Manual

K1010636E; Serial Number 5001 and Up; 766 pages

TABLE OF CONTENTS

Safety

Wheel Loader Safety ......................... SP000095

Specifications

Specification for DL300...................... SP000104

General Maintenance

General Maintenance Procedures.............. SP000097

Standard Torques.......... SP000098

Drive Train

Transmission and Torque Converter ............. SP000118

Transmission Error Codes (ZF) ............... SP000100

Front Axle (ZF-MT-L 3095) ................... SP000199

Rear Axle (ZF-MT-L 3085).................... SP000217

Drive Shaft .............. SP000218

Brake

Service Brake ......... SP000219

Brake Supply Valve ....... SP000220

Parking Brake ......... SP000221

Brake Pedal Valve ......... SP000222

Accumulator............ SP000223

Steering

Steering ............... SP000224

Cushion Valve......... SP000328

Emergency Steering ...... SP000225

Frame

Articulation Center ......... SP000231

Counterweight......... SP000130

Tank

Oil Tank ............... SP000226

Fuel Tank............. SP000227

Hydraulics

Main Control Valve ........ SP000233

Load Isolation System ....................... SP000228

Cooling System....... SP000229

Pilot System............ SP000230

Hydraulic Schematic (DL300) ............... SP000234

Electrical System

Air Conditioner ........ SP000172

Electrical System ........... SP000268

Electrical Schematic (DL300) ............... SP000272

…

EXCERPT:

Drive Axle

The drive axle consists of differential, final reduction gear assembly, wet type hydraulic disk brake unit, and axle shafts to which wheels are attached.

The power from drive unit is transmitted through the drive shafts to front and rear drive axles. The power is then transmitted to differential where it is divided into right and left axle shafts to final reduction gear assembly on each shaft end, thus driving the wheels.

The wet type hydraulic disk brake unit is installed in front of final reduction gear assembly and serves as a service brake.

Axle Mount

The front axle is bolted directly to front frame.

The rear axle is supported by the trunnion method in which axle supports are installed across the rear axle and bolted to rear frame. Consequently, the rear axle is cradled up and down around the center line of differential according to ground condition the loader travels. The trunnion mounted drive axle helps improve operator comfort because loaders with a trunnion mounted drive axle jolt less than those with the conventional cradle supported drive axle, when they travel on bad ground conditions.

…

CENDL3000001..2

DL300 Electrical Wiring Diagram..3

K1010630E - DL300 Operation and Maintenance Manual..4

Presentation..10

Presentation..10

Intended Use..11

Engine..11

Electrical System..11

Power Transmission..11

Brake System..12

Parking Brake..12

Steering System..12

Cabin..12

FOPS and ROPS..12

Hydraulic System..12

Equipment..12

CE Marking, EMC Directive..13

CE Marking..13

The EU EMC Directive..13

Communication Equipment Installation..14

Protection Against Electromagnetic Interference..14

Product Plates..15

01-omK1010630E-48.pdf..0

Safety..16

To the Operator of a DOOSAN Daewoo Wheel Loader..16

Learn Signal Words Used With Safety Alert Symbol..17

General Safety Essentials..19

Accessory Applications..19

Location of Safety Labels..19

1. Warnings for Operation, Inspection and Maintenance (41902545A, 19000092)..21

2. Warnings for Cooling Fan (21903315, 19000557)..21

3. Warnings When Opening Engine Hood (21903315, 19000095)..22

4. Warnings for Using Wheel Block (41902547A, 19000207)..22

5. Warnings for Handling Accumulator (19000703, 19000099)..23

Accumulator..23

6. Keep Out of Steering Turn Area (41901992A, 19000120)..24

7. Warnings for High Temperature Hydraulic Oil (19000691, 19000097)..24

8. Warnings for High Temperature Coolant (19000692, 19000097)..25

9. Warnings for Battery Maintenance (19000537, 19000100)..25

10. Warnings for Performing Maintenance On Front Attachment (41902546A, 19000105)..26

11. Warnings to Use Safety Lock (41901993, 19000121)..26

12. Warning Tag (19000695, 19000098)..27

Unauthorized Modifications..28

General Hazard Information..28

Safety Rules..28

Safety Features..28

Inside Operator's Compartment..29

Clothing and Personal Protective Items..30

Breathing Masks, Ear Protection May Be Required..30

Vibration Level Information..30

Recommendations for Limiting Vibrations..30

Asbestos Dust Hazard Prevention..31

Mounting and Dismounting..32

Fuel, Oil and Hydraulic Fluid Fire Hazards..32

Precautions When Handling Fluids at High Temperature..33

Injury from Work Equipment..33

Fire Extinguisher and First Aid Kit..34

Protection from Falling or Flying Objects..34

Install Additional Safety Equipment If Conditions Require..35

Maintain Standard Safety Equipment in Good Condition..35

Attachment Precautions..35

Accumulator..36

Engine Ventilation..36

Before Starting Engine..37

Work Site Precautions..37

Checks Before Starting Engine..38

Engine Starting..38

Before Operating Machine..39

Machine Operation..41

Operate While Seated at Operator's Station Only..41

Seat Belts Must Be Used at All Times..41

Movement Alarms..41

Travel Precautions..42

Sloping Terrain Requires Caution..42

Avoid High Voltage Cables..43

Before Starting to Dig, Contact Authorities..43

Be Aware of Height Obstacles..43

Use Care on Loose Support..44

Use Solid Support Blocking..44

Digging Beneath Overhangs..44

Digging Beneath Wheel Loader..44

Stay Alert for People Moving Through Work Area..44

Be Aware of and Conform to Local Regulations..45

Never Use Ether Starting Aids..45

Observe General Safety Rules..45

Take Time to Provide Good Visibility..46

Keep "Pinch Point" Areas Clear Use Caution in Reverse..46

Operate Carefully on Snow and Ice, In Very Cold Temperatures..47

Parking Machine..47

Shutdown Control Functions..48

Never Let Anyone Ride on Attachment..48

Maintenance..49

Use Warning Tag During Service..49

Clean Before Inspection or Maintenance..49

Proper Tools..50

Use of Lighting..50

Fire Prevention and Explosion Prevention..50

Burn Prevention..51

Welding Repairs..51

Precautions for Removal, Installation, and Storage of Attachments..52

Precautions When Working on Machine..52

Lock Inspection Covers..53

Crushing Prevention and Cutting Prevention..53

Do Not Run Engine If Repairs or Work Are Being Performed Alone..53

Always Use Adequate Equipment Supports and Blocking..53

Do Not Work on Hot Engines or Hot Cooling or Hydraulic Systems..54

Hydraulic Cylinder Seals Require Periodic Replacement..54

Highpressure Hydraulic Lines Can Store a Great Deal of Energy..54

Cool Down Is Required Before Radiator or Reservoir Checks..54

Precautions with Highpressure Line, Tubes and Hoses..55

Obtain Immediate Medical Attention if Pressurized Oil Pierces Skin...56

Use Correct Replacement Fasteners Tightened to Proper Torque..56

Safety Critical Parts Must Be Replaced Periodically..56

Dispose of All Petroleum Based Oils and Fluids Properly..57

Check Tire Pressure and Condition..57

Decreasing Risk of Injuries or Death From Boom and Bucket..58

Battery..60

Battery Hazard Prevention..60

Disconnect Batteries Before Electrical Service or Electrical Welding..61

Use Low Heat Portable Lighting..61

Boost Starting or Charging Engine Batteries..61

Towing..62

Precautions When Towing..62

Shipping and Transportation..63

Obey State and Local OvertheRoad Regulations..63

02-omK1010630E-64.pdf..0

OP000036..64

Operating Controls..64

1. “Component Locations” on page 22..64

2. “Operator's Area” on page 24..64

3. “Steering Console and Pedals” on page 25..64

4. “Gauges” on page 216..64

5. “Gauges” on page 216..64

6. “Right Side Switch Panel” on page 226..64

7. “Various Cabin Locations” on page 241..64

8. “Heater and Air Conditioner Operation” on page 245..64

9. “Stereo / CD Player (Optional)” on page 250..64

10. “Seat Adjustment (Standard)” on page 252..64

11. “Seat Adjustment (Option)” on page 254..64

12. “Seat Belt” on page 256..64

13. “Door Side Latch” on page 257..64

14. “Fuse Box/Relay/Engine Emergency Stop Switch” on page 259..64

Component Locations..65

Figure 1..65

1..66

Bucket Teeth..66

2..66

Bucket..66

3..66

Air Conditioner Condenser..66

4..66

Rear Wheel Cover..66

5..66

Battery Box..66

6..66

Rear Light..66

7..66

Counterweight..66

8..66

Fan Motor..66

9..66

Towing Pin..66

10..66

Muffler Tail Pipe..66

11..66

Oil Tank..66

12..66

Tilt Lever..66

13..66

Front Wheel Cover..66

14..66

Bucket Cylinder..66

15..66

Headlight Support..66

16..66

Ladder..66

17..66

Work Light..66

18..66

Operator's Cabin..66

19..66

Air Cleaner..66

20..66

Engine Air Intake Precleaner..66

21..66

Engine..66

22..66

Muffler..66

23..66

CAC Cooler..66

24..66

Radiator..66

25..66

Grille..66

26..66

Fan..66

27..66

Fuel Tank..66

28..66

Engine Oil Fill Cap..66

29..66

Engine Oil Filter..66

30..66

Engine Oil Level Dipstick..66

31..66

32..66

Rear Axle..66

33..66

Drive Shaft (Rear)..66

34..66

Transmission..66

35..66

Transmission Oil Filter..66

36..66

Drive Shaft (Center)..66

37..66

Center Pin..66

38..66

Steering Wheel Cylinder..66

39..66

Boom Cylinder..66

40..66

Drive Shaft (Front)..66

41..66

Parking Brake..66

42..66

Front Axle..66

43..66

Loader Arm..66

44..66

Link..66

Operator's Area..67

Figure 2..67

Steering Console and Pedals..68

Figure 3..68

Figure 4..69

1. Starter Switch..69

A threeposition starter switch is used to start or shut down engine for equipment operation...69

O. Turning the switch to this position turns the engine "OFF" along with its electrical system. In this position the engine is "OFF" but the interior cabin light and fuel tank transfer pump (if equipped) are functional...69

I. Turning the switch to this position turns the engine electrical system "ON." When the switch is first turned "ON" the six indicator/warning lights across the top of the instrument panel, will light for approximately two seconds. The batter...69

NOTE: Preheat Indicator Light The operation of the preheat cycle depends on coolant temperature. When the engine coolant is cold enough, the preheat indicator light will remain "ON" until the engine preheat cycle is completed. The preheat cyc...69

. Moving switch to this position will crank engine. When engine starts, release key and allow it to return to the "I" (ON) position. Do not operate the starter switch for more than fifteen seconds at a time. This will help prevent damage to starter...69

Figure 5..70

2. Horn Button (Two Places)..70

Pressing the button at the end of the combination switch (Figure 5) or the left button at the tip of the pilot control valve lever (joystick) (Left) of the two levers (Figure 6), the horn will sound...70

NOTE: Starter switch must be "ON."..70

Figure 6..70

Figure 7..70

Figure 8..71

3. Combination Switch..71

A. Left Side Directional Switch Pushing lever forward, activates left outside directional lights and directional indicator light on instrument panel...71

B. Right Side Directional Switch Pulling lever back, activates right outside directional lights and directional indicator light on instrument panel...71

NOTE: When turn is completed the lever automatically returns to the "NEUTRAL" position. Should it not, it can be manually returned by hand...71

NOTE: Turn signals will function with starter switch in "OFF" position...71

C. Window Washer Switch When the outside area of the lever is pressed, it activates the washer pump and sprays fluid on the windshield. (Only while being pressed.)..71

NOTE: Do not operate the windshield washer without any fluid. If operate without any fluid, the washer motor may be damaged. Check level in washer tank, and add fluid as required...71

NOTE: Using soapy water or synthetic detergent instead of window cleaning fluid, may damage the wiper blade or painted surfaces. Use standard window cleaning fluid: SSK703..71

D. Horn Button The center button on end of lever activates horn. (Only while being pressed.)..71

E. Wiper Switch Activates wipers when outside area of lever is rotated...71

J: Intermittent Mode wipes every five seconds...71

0: Stop (Off)...71

I: Normal Speed Mode...71

II: High Speed Mode...71

Figure 9..71

F. Push Down Locks into position and light turns "ON" the high beams...71

G. Neutral Position Normal low beams...71

H. Pull Up Momentarily turns "ON" both the low beams and high beams. (Returns to "NEUTRAL" position when released.)..71

NOTE: High and low beams will only function with the headlight switch in the "||" position...71

Figure 10..72

4. Accelerator Pedal..72

Controls the travel speed of loader and working speed of load handling system...72

Figure 11..73

5. Steering Wheel Adjustment Lever..73

Control lever (1, Figure 11) is used allow wheel to be moved to the most convenient position for the operator...73

Adjusting Steering Wheel Tilt..73

Pull lever (1, Figure 12) upward and move wheel (2, Figure 12) to desired position. Push lever down (Tilt angle is 21°)...73

Adjusting Steering Wheel Telescopic..73

Pull lever (1, Figure 12) upward and move wheel (2, Figure 12) to desired position. Push lever down (telescopic stroke is 80 mm)..73

Figure 12..73

Figure 13..73

6. Brake Pedal (Right and Left Pedals)..73

Pressing brake pedal will apply the brakes to the loader. The brake pedal modes can be switched from "INCHING" to "NO INCHING" or vice versa, by using the transmission cutoff switch (See page 335)...73

Figure 14..74

7. Steering Wheel..74

Rotating steering wheel controls position of front wheels and this determines direction of machine travel...74

Figure 15..74

8. Kickdown Switch (Two places)..74

When transmission is in 2nd gear, pressing this switch will shift transmission into 1st gear. This will allow the driver to perform a quick digging movement...74

NOTE: Kickdown is "RELEASED" when transmission is placed in "NEUTRAL" position or the switch is pressed again...74

Kickdown function range:..74

. Automatic: 2nd, 3rd, 4th...74

. Manual: 2nd...74

Figure 16..74

A second kickdown switch (Figure 16) is on the right button in the tip of the pilot control valve lever (joystick) (Right one of two levers)...74

Figure 17..74

Figure 18..75

9. Transmission Lever..75

Rotating the switch shifts transmission between 1st, 2nd, 3rd or 4th gears...75

NOTE: There is a transmission display, on the dash, that indicates, gears, direction of travel, error codes and kickdown activation. (See page 316)..75

Figure 19..75

A transmission neutral lever lock is in base of transmission lever. This neutral lever lock prevents the transmission lever from being moved out of "NEUTRAL."..75

N "NEUTRAL LOCK" position. Prevents lever from being moved out of "NEUTRAL."..75

D "DRIVE" position. Allows lever to be moved from "NEUTRAL" to "FORWARD and REVERSE."..75

Figure 20..76

10. Front Instrument Panel..76

See “Front Instrument Panel” on page 315...76

Figure 21..76

11. Hour Meter..76

A LCD Meter that records total time. When engine is running, the hourglass icon blinks every four seconds. This shows that the hour meter is working...76

Figure 22..77

12. Automatic Shift Mode Switch..77

. 14; Auto 14 mode (Working mode)..77

1) Turn the gear selector control to gear position 4..77

2) Set the shift mode selector to "Auto 1°Í4..77

3) Selector the directional gear and accelerate the machine...77

4) Up and downshifts are made automatically between 1st 2nd 3rd 4th gears forward and between 2nd 3rd 4th in reverse...77

5) It is unnecessary to use kickdown function for 1st gear...77

. Auto 24 mode (Travel mode)..77

1) 13 is same as Auto 14..77

2) Up and downshifts are made automatically between 2nd 3rd 4th gears forward and between 2nd 3rd 4th in reverse...77

3) Kickdown switch must be used for shifting to 1st gear...77

. Manual mode..77

After starting gear shifting is done manually...77

Figure 23..77

13. Hazard Warning Light Switch..77

This warning light is used when the equipment is stopped due to a malfunction or when an emergency occurs. When this switch is pressed the directional indicator lights in front and back of the machine light up and flash, warning others in the...77

O. In this position, this switch turns "OFF" hazard warning lights...77

I. In this position, this switch turns "ON" all turn signals and they flash simultaneously...77

NOTE: Hazard warning lights will function with starter switch in "OFF" position...77

Front Instrument Panel..78

Figure 24..78

Gauges..79

1..79

Fuel Gauge..79

2..79

Speedometer..79

3..79

Hour Meter..79

4..79

Tachometer..79

5..79

Engine Coolant Temperature Gauge..79

6..79

Transmission Oil Temperature Gauge..79

7..79

Transmission Display..79

Warning and Indicator Lights..79

8..79

Preheat Indicator Light..79

9..79

Air Cleaner Clogged Warning Light..79

10..79

Battery Warning Light..79

11..79

Left Turn and Hazard Warning Light..79

12..79

High Beam Indicator Light..79

13..79

Right Turn and Hazard Warning Light..79

14..79

Work Light Indicator Light..79

15..79

Brake Fluid Pressure Warning Light..79

16..79

F/R (Forward/Reverse) Selector Indicator Light..79

17..79

Parking Brake Indicator Light..79

18..79

Emergency Steering Indicator Light (Option)..79

19..79

Engine Warning Light..79

20..79

Not Used..79

21..79

Not Used..79

22..79

Mirror Heating Indicator Light..79

23..79

Reverse Fan Indicator Light..79

24..79

Electric Steering Select Indicator Light (Option)..79

Figure 25..80

1. Fuel Gauge..80

This gauge displays amount of fuel in tank. "F" means the tank is "full"; "E" means the tank is "empty." If the pointer comes close to the "E" (red zone), add fuel as soon as possible. When the pointer comes close to the "E" (red zone), appro...80

Figure 26..80

2. Speedometer..80

This meter displays speed at which vehicle is traveling...80

Figure 27..80

3. Hour Meter..80

A LCD meter that records total time. When engine is running, the hourglass icon blinks every four seconds. This shows that the hour meter is working...80

Figure 28..81

4. Tachometer..81

This meter displays engine speed in revolutions per minute...81

Figure 29..81

5. Engine Coolant Temperature Gauge..81

This gauge displays temperature of engine coolant...81

Figure 30..81

6. Transmission Oil Temperature Gauge..81

This gauge displays temperature of oil in transmission converter and transmission circuit...81

7. Transmission Display..82

Figure 31..82

A transmission display is in the gauge panel on the dash. The LCD indicates, gears, direction of travel, error codes, and activated kickdown...82

Figure 32..82

Figure 32, shows the transmission display in detail...82

A. Indicates travel direction and gear selection. See Figure 33 for more detailed information...82

B. Indicates normal operation and error codes...82

NOTE: Most codes are only two digits...82

C. Indicates that error codes have occurred and are stored...82

D. Indicates that operation must be stopped immediately to prevent damage to transmission and hazardous operating condition...82

Figure 33..82

The gear range indicator bars will indicate which gear is selected by displaying the corresponding number of bars. The forward and reverse indicator bars will be "OFF" when the transmission is in "MANUAL MODE."..82

When transmission is in "AUTOMATIC MODE," all the gear range indicator bars and both travel direction indicators will be "ON."..82

Figure 34..83

8. Preheat Indicator Light..83

This indicator light will turn "ON," when the engine preheat function is operating. Do not start engine as long as this light is "ON."..83

Figure 35..83

9. Air Cleaner Clogged Warning Light..83

This warning light will turn "ON," when dirt has built up in the air filter and is beginning to restrict flow of air. Clean or replace air filter before continuing to operate machine. To turn indicator light "OFF," turn starter switch "OFF" a...83

Figure 36..83

10. Battery Warning Light..83

When starter switch is first turned to "ON" position, this red warning light should turn "ON." When engine is running this red light should turn "OFF." If light remains "ON" when engine is running, alternator is defective...83

Figure 37..84

11. Left Turn and Hazard Warning Light..84

This light blinks when left turn signal is turned "ON." Both lights blink when warning lights are turned "ON."..84

NOTE: If left and right turn indicators blink together, or if they blink faster than normal, a light bulb is not operating or flasher solenoid is damaged...84

Figure 38..84

12. High Beam Indicator Light..84

This indicator light will turn "ON," when the headlights are turned to "HIGH BEAM."..84

Figure 39..84

13. Right Turn and Hazard Warning Light..84

This light blinks when right turn signal is turned "ON." Both lights blink when warning lights are turned "ON."..84

NOTE: If left and right turn indicators blink together, or if they blink faster than normal, a light bulb is not operating or flasher solenoid is damaged...84

Figure 40..85

14. Work Light Indicator Light..85

This indicator light will turn "ON," when the front and/or rear work lights are activated...85

Figure 41..85

15. Brake Fluid Pressure Warning Light..85

This warning light will turn "ON," when pressure drops in brake fluid circuit. When light turns "ON," an alarm also sounds...85

Figure 42..85

16. F/R (Forward/Reverse) Selector Indicator Light (Option)..85

This indicator light will turn "ON," when the 2nd gear function is selected...85

NOTE: See “F/R (Forward/Reverse) Travel Control System (Option)” on page 318 for further information...85

Figure 43..86

17. Parking Brake Indicator Light..86

This indicator light will turn "ON," when the parking brake is "APPLIED." If vehicle is moved while parking brake is applied, a warning alarm will sound...86

Figure 44..86

18. Emergency Steering Indicator Light (Option)..86

This indicator light will turn "ON," when the emergency steering system is activated due to a hydraulic failure. Immediately stop any operation, stop machine, "APPLY" parking brake, and shut down engine...86

NOTE: The light will also turn "ON" when the system is being tested...86

Figure 45..87

19. Engine Warning Light..87

If a defect is present in the engine system, and it is recognized by the ECU and cause a malfunction in operation, it can be displayed with the engine warning light to indicate a warning to the operator. If this Light turns "ON" or "blinking,...87

. Light turned "ON": nonfatal system error..87

. Light is "BLINKING": fatal system error..87

NOTE: The engine warning light flashes out the two digit fault code in the diagnostic mode...87

Figure 46..87

20. Not Used..87

21. Not Used..87

Figure 47..87

22. Mirror Heater Indicator Light..87

This indicator light will turn "ON," when the mirror heater is operated...87

Figure 48..88

23. Cooling Fan Reverse Rotation Indicator Light..88

This indicator light will turn "ON," when the cooling fan rotates in the reverse direction...88

Figure 49..88

24. Electric Steering Select Indicator Light..88

This indicator light will turn "ON," when the electric steering system is selected...88

Right Side Switch Panel..89

Figure 50..89

Figure 51..90

1. Pilot Control Valve Lever (Two Lever) (Option)..90

Move left control lever forward (2, Figure 51) to dump bucket, or rearward (4, Figure 51) to roll back bucket...90

Move right control lever forward (3, Figure 51) to lower boom or rearward (5, Figure 51) to raise boom...90

Float (right lever in full forward detent position (1, Figure 51)): This position allows oil flow in and out both ends of cylinders so the bucket can follow the contour of the ground. Manually release lever from the position...90

ReturntoDig (left lever in full rearward detent position (6, Figure 51)):Bucket will return to set dig position...90

Boom Height Kickout right lever in full rearward detent position (7, Figure 51)): Lever will remain in this position until boom is at a preset height, then will return to neutral automatically...90

Figure 52..90

A. Kickdown Switch (Two Places)..90

(See page 311)..90

Figure 53..90

B. Horn Switch (Two Places) / Log Fork Switch (Option)..90

. Horn switch function...90

. Log fork switch function...90

When the log forks control lever is pushed forward or pulled back while this switch is pressed, the log forks are allowed to open or closed. (See page 328)..90

Figure 54..91

1A. Pilot Control Valve Lever (Joystick) (Option)..91

If loader is equipped with log forks this lever controls boom, bucket and log forks...91

Used to position bucket and boom. This lever is capable of raising or lowering boom, and crowding or dumping bucket. When machine is being traveled, the lever (joystick) can be "LOCKED" out, to prevent any movement of bucket or boom. To "LOCK...91

Pilot control valve lever (joystick) operating pattern and description of operation...91

Figure 55..91

HL. Hold lever in Lower Mode..91

L. Lower..91

HC. Hold lever in Bucket Crowd..91

C. Bucket Crowd..91

N. Neutral..91

D. Bucket Dump..91

R. Raise..91

HR. Hold lever in Raise Mode..91

A. When the log forks control lever (6, Figure 54) is pushed forward the log forks are allowed to open...91

B. When the log forks control lever (6, Figure 54) is pulled back the log forks are allowed to close...91

This lever is capable of forward travel and reverse travel (2nd gear function)...91

1. Neutral Switch..91

When this switch is pressed, 2nd gear function will be operated, and then 2nd gear indicator light turns "ON."..91

When 2nd gear function is operated, this switch is pressed, and then machine is neutral...91

2. Forward Switch..92

When this switch is pressed at forward traveling while "KD" (5, Figure 54) switch is pressed, machine can travel forward. When machine is travelled, it can convert forward and reverse travel without pressing "KD" (5, Figure 54) switch...92

3. Reverse Switch..92

When this switch is pressed at reverse traveling while "KD" (5, Figure 54) switch is pressed, machine can travel reverse. When machine is travelled, it can convert forward and reverse travel without pressing "KD" (5, Figure 54) switch...92

4. Horn Switch..92

(See page 330)..92

5. Kickdown Switch..92

(See page 329)..92

NOTE: Operating condition of 2nd gear function...92

. Start a engine...92

. Transmission lever is neutral...92

. Parking brake switch is off (release)...92

NOTE: Release condition of 2nd gear function...92

. When the transmission lever will be push forward or pull reverse...92

. When the parking brake switch turns "ON."..92

. When the starter switch turns "OFF."..92

Figure 56..92

2. Kickdown Switch (TWO PLACES)..92

Kickdown Switch Function When transmission is in 2nd gear, pressing this switch (Figure 57) will shift transmission into 1st gear. This will allow the driver to perform a quick digging movement...92

Kickdown function range:..92

. Automatic: 2nd, 3rd, 4th...92

. Manual: 2nd...92

NOTE: Kickdown is "RELEASED" when transmission is placed in "NEUTRAL" position or the switch is pressed again...92

Figure 57..93

A second kickdown switch (Figure 56) is on the end of the transmission lever...93

Figure 58..93

3. Horn Button (Two Places)..93

Pressing the lowest button at the tip of the left pilot control valve lever (joystick) (Figure 58) or the button at the end of the combination switch (Figure 59) will sound the horn...93

NOTE: Starter switch must be "ON."..93

Figure 59..93

Figure 60..94

4. Cigar Lighter..94

Push the lighter all the way into the socket and release your hand. After pushing it in, it will be ejected when it is heated. If it does not eject after a short time, pull it out and have it serviced...94

Figure 61..94

5. Economic Mode Switch..94

This economic mode switch allows the operator to switch between 100% throttle torque and droop curve and about an 80% derated torque curve and droop. In the economy mode, fuel consumption is clearly reduced by utilising a reduced-power charac...94

O. In this position torque switch is set to the "off" position, and 100% torque is permitted for hard digging or driving up sleep inclines...94

I. In this position torque switch is turn "ON", which limits engine torque to 80% of maximum...94

6. Not Used..94

Figure 62..95

7. Headlight Switch..95

O. In this position, this switch turns "OFF" clearance, tail, instrument panel, switch and headlights...95

NOTE: If the switch is not in this position with the engine not running, the pilot buzzer will sound to warn the operator that the batteries are being discharged...95

I. In this position, this switch turns "ON" clearance, tail, instrument panel and switch lights...95

Figure 63..95

8. Front Work Light Switch..95

O. In this position, this switch turns "OFF" work lights mounted on the front top of cabin...95

I. In this position, this switch turns "ON" work lights mounted on the front top of cabin...95

Figure 64..96

9. Rear Work Light Switch..96

O. In this position, this switch turns "OFF" work lights mounted on the rear top of cabin and the sides of radiator...96

I. In this position, this switch turns "ON" work lights mounted on the sides of radiator...96

II. In this position, this switch turns "ON" work lights mounted on the rear top of cabin and the top of the sides of radiator...96

Figure 65..96

10. Rear Wiper Switch..96

O. In this position, this switch turns "OFF" windshield wiper mounted on rear windshield of operator's cabin...96

I. In this position, windshield washer fluid sprays onto the rear windshield while running the rear wiper. When released, the switch returns to the "O" (OFF) position...96

II. In this position, this switch turns "ON" windshield wiper mounted on rear windshield of operator's cabin...96

Figure 66..97

11. Pilot Cutoff Switch..97

O. In this position the operator cannot operate the pilot control valve lever (joystick)...97

I. In this position the operator can fully control the movement of the pilot control valve lever (joystick)...97

Figure 67..97

12. Parking Brake switch..97

O. In this position, the parking brake is "RELEASED" and the indicator light on the front instrument panel turns "OFF."..97

I. In this position, the parking brake is "APPLIED" and the indicator light on the front instrument panel comes "ON." This brake can also be used as an emergency brake...97

Figure 68..97

Figure 69..98

13. Transmission Cutoff Switch..98

This switch changes the mode of the brake pedal from "INCHING" to "NO INCHING."..98

O. In this position, the "NO INCHING" mode is selected...98

In the "NO INCHING" mode, the power transmission line is still connected when the brake pedal is pressed, thus, making it easier to start off on an incline. This mode is also suitable for traveling, because both dynamic engine braking and the...98

I. In this position, the "INCHING" mode is selected...98

In this mode, the transmission is put in "NEUTRAL" by pressing the left brake pedal. This mode is suitable for a load handling operation. When the accelerator pedal is pressed in this setting, more power is concentrated on the load handling s...98

NOTE: 1) Transmission "CUTOFF" function dose not operate at 3rd and 4th gear for protection of transmission...98

2) Despite transmission "CUTOFF" switch, the right brake pedal has braking function only...98

Figure 70..98

14. Mirror Heating Switch..98

This switch is used to operate a heater installed in the mirror. Press the switch and the mirror heater will remove frost and ice from mirror...98

O. "OFF" position...98

I. "ON" position...98

Figure 71..99

15. Reverse Fan Switch..99

This switch causes the radiator cooling fan to rotate in the reverse direction. The function of reversing the direction of the radiator cooling fan is effective in cleaning the radiator...99

O. "OFF" position...99

I. "ON" position...99

Activate the switch for reverse rotation in the following order;..99

A. Turn the starter switch "O" (OFF) °Ê "I" (ON) and then turn the of the cooling fan reverse rotation switch "O" (OFF) °Ê "I" (ON) and start the engine...99

B. For reverse operation, the cooling fan reverse rotation indicator light turns "ON" the same time...99

C. To return to forward rotation, shut down engine, change the position of the reverse switch "ON" °Ê "OFF," and start the engine again...99

Figure 72..99

16. Engine Diagnostic Switch..99

If the engine warning light turns "ON" or "blinks," when the engine is running, it means a fault code has been recorded. When this occurs, the engine diagnostic switch allows the operator to view the fault codes. The active fault code is star...99

17. Not Used..100

Figure 73..100

18. Boom Float Switch (Option)..100

Boom float allows the bucket to follow the contour of the ground/working surface. When pressing this switch and setting work lever to float position, the lever is locked (detent) and boom is lowered. When boom is matched to setting position, ...100

O. In this position, this switch turns "OFF" boom float...100

I. In this position, this switch turns "ON" boom float...100

Figure 74..100

19. Load Isolation System (LIS) Switch (Option)..100

This switch enables the boom cylinder to absorb shock loading of the machine during traveling and working. It improves dynamic stability, machine life, and comfortability. It is most effective when traveling with load in the bucket...100

O. In this position, the LIS turned "OFF."..100

I. In this position, the LIS turned "ON" at all travel speeds...100

II. In this position, the LIS will "AUTOMATICALLY TURN ON" if the forward travel speed exceed 6 km/h (3.7 MPH) or reverse travel speed exceed 4 km/h (2.5 MPH). LIS will automatically turn "OFF" if the forward speed is less than 4 km/h (2.5 MP...100

Figure 75..100

20. Seat Heater Switch (Option)..100

This switch is used to operate the seat heater. When the switch is pressed, the seat heater starts to heat seat...100

O. In this position, this switch turns "OFF" seat heater...100

I. In this position, this switch turns "ON" seat heater...100

Figure 76..101

21. Fuel Heater Switch (Option)..101

This switch is used to operate the fuel heater. When the switch is pressed, the fuel heater starts to heat fuel. If the fuel temperature is 5°C and higher, the fuel heater does not operate, even if switch in "I " (ON) position..101

O. In this position, this switch turns "OFF" fuel heater...101

I. In this position, this switch turns "ON" fuel heater...101

Figure 77..101

22. Emergency Steering Test Switch and Automatic Test (option)..101

Emergency Steering Test Switch..101

This switch is used to test whether the emergency steering system is properly functioning...101

The system must be tested during the startup procedure to ensure that the system is properly functioning...101

Test emergency steering system using the following procedure:..101

A. Turn starter switch to "I" (ON) position...101

NOTE: Do not start engine...101

B. Press emergency steering test switch and turn steering wheel at the same time. If system is functioning properly the unit should steer. The emergency steering indicator light should turn "ON."..101

NOTE: If unit does not steer, do not operate unit until problem is corrected...101

C. Release switch. Switch will automatically return to "O" (OFF) position...101

Automatic Test..101

This is a system check that tests the hydraulic oil pressure in the emergency steering system lines. With starter switch turn to "I" (ON) position, an emergency warning light on the front gauge panel will turn "ON" for about three seconds...101

Figure 78..102

23. Rotating Beacon Light Switch (Option)..102

O. In this position, this switch turns "OFF" rotating beacon light...102

I. In this position, this switch turns "ON" rotating beacon light...102

Figure 79..102

24. Power Socket for 12 Volt..102

This is a power socket for only 12V DC devices...102

This socket can be used for charging a cellular phone or powering a small 12V DC electrical device...102

Open the cap when using it...102

NOTE: This socket is designed for small electrical capacity devices. Do not use this socket for large electrical capacity devices. Thus, damage can be avoided...102

Figure 80..102

25. F/R (Forward/Reverse) Selector Switch..102

O. In this position, the F/R control switch is "OFF"..102

I. In this position, the F/R control switch is activated. When released the switch returns to the "O" (OFF) position, but the system is still activated. When this switch is depressed again, F/R control switch is "OFF"..102

NOTE: 1) When activating system, the transmission lever and F/R control switch must be in "NEUTRAL."..102

2) If the transmission lever is actuated (moved), the gearshift functions of the F/R control switch are deactivated, and forward/reverse travel is again controlled by the transmission lever...102

Figure 81..103

26. F/R (Forward/Reverse) Control Switch..103

To be able to use the forward/reverse function, the F/R selector switch must first be depressed. When the switch is activated, the F/R selector indicator light will be turned "ON" in the instrument panel...103

O. In this position, the machine is in "NEUTRAL"..103

I. In this position, the machine travels "FORWARD"..103

II. In this position, the machine travels "REVERSE"..103

NOTE: If the transmission lever is moved out of "NEUTRAL" while operating the F/R control switch, the transmission lever will override the switch. The F/R control switch system will require, that the F/R selector switch to be pressed again, w...103

27. Cup Holder..103

Place to put beverages...103

Various Cabin Locations..104

Figure 82..104

Figure 83..105

1. Cabin Light..105

Located in the middle of front cabin, it illuminates the cabin for night work. Light turns on when the switch is in the "ON" or "O" position but off in the "OFF" position. Cabin light may be turned "ON" and "OFF" irrespective of the position ...105

Figure 84..105

2. Stereo / CD Player (Option)..105

For operation of stereo see “Stereo / CD Player (Optional)” on page 250...105

Figure 85..105

3. Heater and Air Conditioner Control Panel..105

For operation of heater and air conditioner see “Heater and Air Conditioner Operation” on page 245...105

Figure 86..106

4. Speakers..106

Emits sound generated by stereo...106

Figure 87..106

5. Storage Compartments..106

There are two storage compartments (1 and 2, Figure 87) located both sides behind of the operator's seat. Keep the operation manual and other documents in this compartment...106

6. Windshield Washer Tank..106

Contains windshield washer fluid. It is located behind the operator's seat. (3, Figure 87)..106

Figure 88..106

7. Electrical Box..106

Contains relays and electric components. It is located on left side of cabin...106

Figure 89..107

8. Fuse Box..107

The fuse box is on the upper side of electric box. For a detailed explanation of fuses see “Fuse Box/Relay/Engine Emergency Stop Switch” on page 259...107

Heater and Air Conditioner Operation..108

Location of Controls and Vents..108

Figure 90..108

Operation Panel..109

Figure 91..109

Figure 92..109

1. Fan and Air Conditioner Switch..109

A. "OFF" Switch Turns "OFF" the heater and air conditioner unit...109

B. "A/C" Switch Turns "ON" the air conditioner when one of the blower switches is activated...109

Figure 93..110

2. Blower Fan Switches..110

These switches are used to control the speed of the blower fan...110

A. "LO" Switch Used for low blower speed...110

B. "MID" Switch Used for intermediate blower speed...110

C. "HI" Switch Used for high blower speed...110

NOTE: If you do not select a blower speed the heater and air conditioner will not work...110

Figure 94..110

3. Temperature Control Switch..110

The temperature control consists of 24 stages. An LED is turned "ON" for every three stages. Whenever pushing it, it changes in stages. Pushing it continuously, it changes continuously...110

A. "COOL" Switch Lowers the temperature...110

B. "WARM" Switch Raises the temperature...110

LED COLOR STATUS..110

Green LED Air conditioner. Full green, maximum operation of air conditioner...110

Red LED Heater. Full red, maximum operation of heater...110

Figure 95..110

4. Selector Switch for Wind Direction..110

A. Used to direct air flow to upper portion of operator's cabin...110

Figure 96..111

B. Used to direct air flow to lower portion of operator's cabin...111

Figure 97..111

C. Used to direct air flow for defrosting front window of operator's cabin...111

Figure 98..111

5. Ventilation Selector Switch..111

A. "A" Switch Draws fresh air into operator's compartment...111

B. "B" Switch Recirculates air within the operator's compartment. Used to rapidly reduce condensation on windows...111

Memory Function of Used Mode..112

Additional Operating Instruction..112

NOTE: The blower switch must be on "LO" speed...112

NOTE: The filter must be cleaned out every 500 hours and replaced with a new one every 1,000 hours...112

NOTE: In the event that the unit is being operated in a dusty environment, the cleaning and replacement must be performed more frequently...112

Stereo / CD Player (Optional)..113

Stereo..113

Figure 99..113

CD Player (Optional)..114

Figure 100..114

Seat Adjustment (Standard)..115

Figure 101..115

Figure 102..115

1. Adjusting Seat Forward/Backward Lever..115

Holding lever (3, Figure 102), raise it, while pushing or pulling seat to desired position. Release lever once desired position is reached. Adjustment range is 160 mm (6.3 in)...115

2 and 3. Adjusting Seat's Angle and Height Lever..115

Pulling left lever (3, Figure 102) up allows rear part of seat to be moved up or down. Pulling lever (2) up allows front part of seat to be moved up or down. Adjust seat according to operator's size and work conditions. Adjustment range is 60...115

4. Weight Adjustment Knob..115

Turning knob (4, Figure 102) to right makes suspension harder. Turning knob to left makes suspension softer. Adjust according to operator's weight by checking weight indicator dial. Adjustment range is from 50 120 kg (110 265 lb)...115

5. Backrest Adjustment Lever..115

Pulling up right lever (5, Figure 102) allows seat backrest to be moved forward or backward...115

Figure 103..116

6. Angle Adjustment of Armrest..116

Adjustment angle of left and right armrest (6, Figure 103) is done by turning a dial in bottom of armrest. When you adjust angle, manually raise armrest before turning dial...116

7. Headrest..116

Headrest (7, Figure 103) can be adjusted forward/ backward and up/down. Move it by holding both sides...116

Recommendations for Limiting Vibrations..116

1. Select the right machine, equipment and attachments for a particular application...116

2. Replace any damaged seat by a DOOSAN genuine part. Keep the seat maintained and adjusted...116

. Adjust the seat and suspension for the weight and size of the operator...116

. Inspect and maintain the suspension and adjustment mechanisms of the seat regularly...116

3. Check that the machine is properly maintained...116

. Tire pressure, brakes, steering, linkages, etc...116

4. Steer, brake, accelerate, shift gears, move the attachments and load the attachments smoothly...116

5. Adjust the machine speed and travel path to reduce the vibration level...116

. Slow down if it is necessary when passing rough terrain...116

. Drive around obstacles and excessive rough terrain conditions...116

6. Keep the terrain on work sites where the machine is working and traveling in good condition...116

. Remove any large rocks or obstacles...116

. Fill any ditches and holes...116

. Provide machines for and schedule time to maintain the terrain conditions...116

7. Travel over longer distance (e.g. on public roads) at adjusted (medium) speed...116

. Always adjust the speed for preventing bouncing...116

Seat Adjustment (Option)..117

Figure 104..117

Figure 105..117

1. Adjusting Seat Forward/Backward Lever..117

Holding lever (1, Figure 104), raise it, while pushing or pulling seat to desired position. Release lever once desired position is reached. Adjustment range is 152 mm (6 in)...117

2. Seat Height and Firmness / Adjustment Knob..117

To raise seat or increase firmness in ride, turn key to "ON" and push in on height/firmness adjustment knob (5, Figure 105)...117

To lower seat height or decrease firmness in ride, pull out on height/firmness adjustment knob (5, Figure 105). Adjustment range is 76 mm (3 in)...117

3. Backrest Adjustment Lever..117

Lift backrest tilt adjustment lever (2, Figure 104) and allow cushion to angle forward or lean backward into desired position and release handle...117

4. Lumbar Control Knob..117

Rotate lumbar control knob (4, Figure 104) to increase or decrease support to lower back...117

5. Angle Adjustment of Armrest..118

Rotate armrest tilt knob (3, Figure 104) to tilt to desired armrest position...118

6. Adjustment of Upper Backrest (6, Figure 104)..118

To upper it, hold up with both hands at the corners on the bottom of upper backrest. To lower it, press with both hands at the corners on the top of upper backrest. Adjustment range is 125 mm (4.9 in)...118

Seat Belt..119

Figure 106..119

Seat Belt Locking and Unlocking..119

Figure 107..119

Door Side Latch..120

Figure 108..120

1. Door side latches (1. LH, Figure 108) and (2. RH, Figure 109) are used to secured the doors (RH, LH) to the side of the cabin when they are opened...120

NOTE: Keep the door closed and locked when machine is not in use...120

Figure 109..120

Figure 110..120

2. The RH side door, which is emergency exit from the cabin, can be opened in two positions...120

Position 1. (ventilation position)..120

. Open the window and secured it with the lock bar. (A, Figure 110)..120

Position 2. (full opened position)..120

. Open the window and push it to backward..120

Figure 111..121

3. To release doors from both sides of the cabin. Pull the handles (Figure 111) in the direction of arrows. The handles are located on both sides of the operator's seat...121

Arm Rest..121

Figure 112..121

Fuse Box/Relay/Engine Emergency Stop Switch..122

Figure 113..122

Fuse Boxes..122

Figure 114..122

Figure 115..124

Relays..124

Figure 116..124

Figure 117..124

Circuit Breaker..124

Figure 118..125

Fusible Link..125

Figure 119..125

Figure 120..126

Engine Emergency Stop Switch..126

O. In this position, the engine emergency stop system is "OFF"..126

I. In this position, "Emergency Stop" is selected the engine will shut down..126

NOTE: When released, the switch will return to "O" (OFF) position..126

Figure 121..126

04-omK1010630E-86.pdf..0

Inspection, Maintenance and Adjustment..152

Basic Preventive Maintenance..152

Safety When Servicing..155

Preventive Maintenance..163

Table of Recommended Lubricants..165

Axle Oils DL400, DL300, DL250..167

Fluid Capacities..170

Lubrication and Service Chart..171

Maintenance Intervals..175

10 Hour / Daily Service..177

50 Hour / Weekly Service..187

250 Hour / Monthly Service..194

500 Hour / 3 Month Service..199

1,000 Hour / 6 Month Service..205

1,500 Hour / 9 Month Service..211

2,000 Hour / Yearly Service..214

12,000 Hour / Six Year Service..219

Severe Conditions Maintenance..220

Bolt Torque Chart..221

Electrical System..222

Engine Cooling System..224

Handling of Accumulator..226

Hydraulic Pressure Checks..227

Long Term Storage..232

Parking Brake Adjustment..233

Tires..235

05-omK1010630E-2.pdf..0

Transportation..238

Loading and Unloading..238

Summary of Safety Precautions for Lifting..239

06-omK1010630E-8.pdf..0

Troubleshooting..240

Engine..240

Hydraulic System..242

Travel System..244

General..244

Steering..245

Braking..246

Electrical System..246

07-omK1010630E-8.pdf..0

OP000041..248

Specification..248

General Specifications..248

Working Range and Dimensions..250

Figure 1..250

Working Capacities..252

Bucket Capacity..252

Tipping Load..252

Material Weight..252

Approximate Weight of Workload Materials..252

08-인덱스1-4.pdf..0

Index..256

K1010636E - DL300 Shop Manual..260

Table of Contents..262

Safety..0

Wheel Loader Safety SP000095..264

Safety Precautions..268

Applicable Models..268

To the Operator of a DOOSAN Wheel Loader..269

Learn the Signal Words Used with the Safety Alert Symbol..271

General Safety Essentials..273

Accessory Applications..273

Location of Safety Labels..273

Unauthorized Modifications..273

General Hazard Information..274

Safety Rules..274

Safety Features..274

Inside Operator's Compartment..275

Clothing and Personal Protective Items..276

Breathing Masks, Ear Protection May Be Required..277

Vibration Level Information..277

Asbestos Dust Hazard Prevention..277

Mounting and Dismounting..278

Fuel, Oil and Hydraulic Fluid Fire Hazards..278

Precautions When Handling Fluids at High Temperature..278

Injury from Work Equipment..279

Fire Extinguisher and First Aid Kit..279

Protection from Falling or Flying Objects..280

Install Additional Safety Equipment If Conditions Require..280

Maintain Standard Safety Equipment in Good Condition..281

Attachment Precautions..282

Accumulator..282

Engine Ventilation..282

Before Starting Engine..283

Work Site Precautions..283

Checks Before Starting Engine..285

Engine Starting..285

Before Operating Machine..287

Machine Operation..288

Operate While Seated at Operator's Station ONLY..288

Seat Belts Should Be Used at All Times..288

Movement Alarms..288

Travel Precautions..289

Sloping Terrain Requires Caution..289

Avoid High Voltage Cables..290

Before Starting to Dig, Contact Authorities..290

Be Aware of Height Obstacles..290

Use Care on Loose Support..290

Use Solid Support Blocking..291

Digging Beneath Overhangs..291

Digging Beneath Wheel Loader..291

Stay Alert for People Moving Through Work Area..291

Be Aware of and Conform to Local Regulations..291

Never Use Ether Starting Aids..292

Observe General Safety Rules..292

Take Time to Provide Good Visibility..292

Keep "Pinch Point" Areas Clear Use Caution in Reverse..293

Operate Carefully on Snow and Ice and in Very Cold Temperatures..293

Parking Machine..293

Shutdown Control Functions..294

Never Let Anyone Ride on Attachment..294

Maintenance..295

Use Warning Tag During Service..295

Clean Before Inspection or Maintenance..295

Proper Tools..296

Use of Lighting..296

Fire Prevention and Explosion Prevention..296

Burn Prevention..297

Welding Repairs..298

Precautions for Removal, Installation, and Storage of Attachments..298

Precautions When Working on Machine..299

Lock Inspection Covers..299

Crushing Prevention and Cutting Prevention..299

Do Not Run Engine If Repairs or Work Are Being Performed Alone..300

Always Use Adequate Equipment Supports and Blocking..300

Do Not Work on Hot Engines or Hot Cooling or Hydraulic Systems..300

Hydraulic Cylinder Seals Require Periodic Replacement..300

Highpressure Hydraulic Lines Can Store a Great Deal of Energy..300

Precautions with Highpressure Line, Tubes and Hoses..301

Obtain Immediate Medical Attention if Pressurized Oil Pierces Skin...302

Use Correct Replacement Fasteners Tightened to Proper Torque..302

Safety Critical Parts Must Be Replaced Periodically..302

Dispose of All Petroleum Based Oils and Fluids Properly..302

Check Tire Pressure and Condition..303

Battery..304

Battery Hazard Prevention..304

Disconnect Batteries Before Electrical Service or Electrical Welding..304

Use Low Heat Portable Lighting..305

Boost Starting or Charging Engine Batteries..305

Towing..306

Precautions When Towing..306

Shipping and Transportation..307

Obey State and Local OvertheRoad Regulations..307

Summary of Safety Precautions for Lifting..307

Specifications..0

Specification for DL300 SP000104..308

Safety Precautions..312

Applicable Models..268

Component Locations..313

General Specifications..316

Engine Performance Curves..317

Working Range and Dimensions..319

Working Capacities..322

Bucket Capacity..322

Tipping Load..322

Material Weight..322

Approximate Weight of Workload Materials..322

General Maintenance..0

General Maintenance Procedures SP000097..326

Safety Precautions..330

Applicable Models..268

Welding Precautions and Guidelines..331

Hydraulic System General Precautions..332

Maintenance Service and Repair Procedure..334

General Precautions..334

Hydraulic System Cleanliness and Oil Leaks..335

Maintenance Precautions for Hydraulic System Service..335

Oil Leakage Precautions..336

Cleaning and Inspection..337

General Guidelines..337

Bearing inspection..338

Normal Bearing..339

Bent Cage..339

Galling..340

Abrasive Step Wear..340

Etching..341

Misalignment..341

Indentations..341

Fatigue Spalling..342

Brinelling..342

Cage Wear..342

Abrasive Roller Wear..343

Cracked Inner Race..343

Smears..343

Frettage..344

Heat Discoloration..344

Stain Discoloration..344

Standard Torques SP000098..346

Safety Precautions..350

Applicable Models..268

Torque Values for Standard Metric Fasteners..331

Torque Values for Standard U.S. Fasteners..352

Type 8 Phosphate Coated Hardware..354

Torque Values for Hose Clamps..355

Torque Values for Split Flanges..356

Torque Wrench Extension Tools..357

Torque Multiplication..357

Other Uses for Torque Wrench Extension Tools..358

Tightening Torque Specifications (Metric)..358

I. "Loctite" Fastener Adhesives..360

II. "Loctite" Pipe Thread Sealant..360

III. "Loctite" gasket/flange sealer..360

IV. "Loctite" retaining compounds..361

V. "Loctite" Adhesives..361

Drive Train..0

Transmission and Torque Converter SP000118..362

Transmission and Torque Converter..367

Applicable Models..367

General..368

Transmission and Torque Converter..370

Powershift Transmission..371

Transmission Control..371

Schedule of Measuring Points and Connection 4 WG210..373

Oil Circuit Diagram 4WG210 Forward 1st Speed..375

Transmission Electrical Components..377

TCU (Transmission Control Unit)..379

Transmission Control Valve..379

Transmission Oil Temperature Sensor..379

Engine Pickup Sensor..380

Central Gear Pickup Sensor..380

Turbine Pickup Sensor..380

Output Speed Sensor..381

Shift Lever Switch (DW3)..381

Forward, Reverse Switch Lever (Optional)..382

Finger Tip Work Lever..383

2-Lever (Optional)..383

3-Lever (Optional)..383

Switch Circuit..384

Auto Selector Switch..384

Display..385

Transmission Faults Codes..386

Fault Display..386

CAN Message..386

Description of Fault Codes..386

Abbreviations..387

Definition of Operation Modes..387

Normal..387

Substitute Clutch Control..387

Limphome..387

Transmission Shut Down..388

TCU Shut Down..388

Table of Fault Codes..388

Measurement of Resistance at Actuator/ sensors and Cable..388

Actuator..388

Cable..389

Transmission Electrical Circuits..390

T/M Controller Circuit..390

Traveling Circuits..391

Neutral..392

Forward First Gear..393

Forward Second Gear..394

Forward Third Gear..395

Forward Fourth Gear..396

Reverse First Gear..397

Reverse Second Gear..398

Reverse Third Gear..399

Downshift..400

Overview..400

Kickdown: Forward Second Gear to Forward First Gear (Auto Selector Switch "O" Manual Mode)..401

Downshift (Auto Selector Switch "Second Gear" Auto Mode)..402

Downshift (Auto Selector Switch "Third Gear" Auto Mode)..404

Transmission Cutoff..405

LIS (Load Isolation System) Option..406

Aeb Starter..408

Introduction..408

Procedure to Start AEB..409

Display During AEB-mode..409

Installation View (S/N 1001 thru 2000)..411

Inner Section..411

Front View..412

Front View with Disk Brake..413

Side View..413

Side View with Disk Brake..415

Rear View..416

Rear View with Disk Brake..417

Installation View (S/N 2001 thru 3000, 3001 and Up)..418

Inner Section..418

Front View..419

Front View with Disk Brake..420

Side View..421

Side View with Disk Brake..422

Rear View..423

Rear View with Disk Brake..424

Special Tools..425

Gearshift System..425

Engine Connection..428

Pressure Oil Pump..429

Gearbox Housing..430

Input..432

Coupling..433

Output..439

Power Takeoff..440

Hydraulic Control Unit (HSG94)..441

Disassembly..443

Reassembly..446

Transmission Disassembly..452

Hydraulic Control Unit (HSG94) and Duct plate..452

Engine Connection Converter..453

Hydraulic Pump..455

Converter Back Pressure Valve..456

Remove Output, Input and Clutches..457

Disassemble Clutch KV and KR..461

Disassemble Clutch K1, K2 and K3..465

Disassemble Clutch K4..467

Disassemble Drive Shaft..469

Transmission Reassembly..470

Install Oil Tube..470

Reassemble Clutch KV and KR..472

Reassemble Clutch K1, K2 and K3..477

Reassemble Clutch K4..483

Preassemble Drive Shaft..489

Preassemble and Install Output..490

Install Preassembled Drive Shaft and Clutches..491

Install Pump Shaft (Power Takeoff)..495

Install Output Flanges..496

Converter Back Pressure Valve..497

Oil Feed Housing Transmission Pump..498

Engine Connection Converter..500

Converter Safety Valve..502

Mount Duct Plate and Hydraulic Control Unit..503

Install Plugs and Oil Level Tube..504

Speed Sensor and Inductive Transmitters..505

Transmission Error Codes (ZF) SP000100..506

Safety Precautions..350

Applicable Models..268

Introduction..511

Abbreviations..511

Display..512

Description of Fault Codes..512

Display During Operation..513

Display During AEB-Mode..515

Definition of Operating Modes..517

Normal..517

Substitute Clutch Control..517

Limphome..517

Transmission shut Down..517

TCU Shut Down..518

Table of Fault Codes..519

Table of Fault Codes ERGOControl..555

Measurement of Resistance at Actuator/ sensors and Cable..558

Actuator..302

Cable..302

Front Axle (ZF-MT-L 3095) SP000199..560

Safety Precautions..312

Applicable Models..268

General Description..566

Outline..566

Drive Axle..566

Axle Mount..566

Differential..314

Differential Operation..569

Limited Slip Differential Cross Section..314

Lubrication Instructions..571

Oil Drain..572

Oil Filling..572

Check..572

Oil Change Intervals..572

Oil Level Check..572

Bleeders..572

Brake..572

Brake Bleeding at Vehicle..482

Make Wear Measurement on Multidisk Brake..573

Wear measurement Multidisk brake..573

Inscriptions On Model Identification Plate..574

Torque Limits for Screws..484

Torque Limits for Screws (In Nm) According to ZF Standards 148..484

Examples of Gear Tooth Contact Patterns for the Gleason Geartooth System..576

Special Tool..579

List of Special Tools for Disassembly and Reassembly..579

ZF Multitrac Rigid Axle MTL 3095..588

Disassembly of Output and Brake..588

Reassembly of Output and Brake..597

Disassembly of Differential Carrier and Brake Tubes..610

Disassembly of Differential Carrier..610

Disassembly of Limited Slip Differential..614

Disassembly of Drive Pinion..615

Disassembly of Brake Tubes..617

Reassembly of Brake Tubes and Differential Carrier..618

Reassembly of Oil Pipes..618

Reassembly of Differential Carrier..621

Determine Shim Thickness for Tooth Contact Pattern..621

Install Drive Pinion..622

Reassemble of Limited Slip Differential..626

Determine Disk Clearance 0.2 0.8 mm..628

Adjustment of Backlash and Bearing Preload..631

Parking Brake..634

Functional Characteristics and Maintenance Instructions for Springloaded Sliding Caliper Brakes..634

1. Functional Characteristics of Springloaded Sliding Caliper Brakes..634

2. Mounting and Basic Setting Regulations..635

3. Adjusting Regulations..636

4. Emergency Release of Parking Brake..636

5. Maintenance and Repair Work..637

Maintenance and Exchange of Brake Pads..637

Changing the Seal..638

6. General..639

Rear Axle (ZF-MT-L 3085) SP000217..640

Safety Precautions..312

Applicable Models..268

General Description..646

Outline..646

Drive Axle..646

Axle Mount..646

Differential (Standard)..649

Differential Operation..649

Limited Slip Differential Cross Section..650

Lubrication Instructions..651

Oil Drain..652

Oil Filling..652

Check..652

Oil Change Intervals..652

Oil Level Check..652

Bleeders..652

Brake..652

Brake Bleeding at Vehicle..652

Make Wear Measurement on Multidisk Brake..653

Wear Measurement of Multidisk Brake..653

Inscriptions on Model Identification Plate..654

Torque Limits for Screws..655

Torque Limits for Screws (In Nm) According to ZF Standards 148..655

Examples of Gear Tooth Contact Patterns for the Gleason Geartooth System..656

Special Tool..659

List of Special Tools for Disassembly and Reassembly..659

ZF Multitrac Rigid Axle MTL 3085..669

Disassembly of Output and Brake..669

Reassembly of Output and Brake..678

Disassembly of Differential Carrier and Brake Tubes..691

Disassembly of Differential Carrier..691

Disassembly of Limited Slip Differential..694

Disassembly of Drive Pinion..696

Disassembly of Brake Tubes..698

Reassembly of Brake Tubes and Differential Carrier..700

Reassembly of Brake Tubes..700

Reassembly of Differential Carrier..702

Determine Shim Thickness for Tooth Contact Pattern..702

Install Drive Pinion..704

Reassemble of Limited Slip Differential..707

Determine Disk Clearance 0.2 0.8 mm..709

Adjustment of Backlash and Bearing Preload..713

Drive Shaft SP000218..716

Safety Precautions..350

Applicable Models..268

Drive Shaft Weight..331

Drive Shaft Coupling Dimension..721

Drive Shaft, Tightening Torque..721

Brake..0

Service Brake SP000219..722

Safety Precautions..350

Applicable Models..268

General Description..721

Service Brake System..526

Brake Supply Valve SP000220..732

Safety Precautions..350

Applicable Models..268

Brake, Pilot & Fan Motor Supply Valve..526

Specifications..739

Parking Brake SP000221..740

Safety Precautions..350

Applicable Models..268

General Description..538

Functional Characteristics and Maintenance Instructions for Spring Loaded Sliding Caliper Brakes..747

1. Functional Characteristics of Spring Loaded Sliding Caliper Brakes..554

2. Mounting and Basic Setting Regulations..750

3. Adjusting Regulations..282

4. Emergency Release of Parking Brake..751

5. Maintenance and Repair Work..283

Maintenance and Exchange of Brake Pads..283

Changing the Seal..286

6. General..555

Brake Pedal Valve SP000222..756

Safety Precautions..350

Applicable Models..268

General Description..721

Theory of Operation..727

Specification..763

Accumulator SP000223..764

Safety Precautions..350

Applicable Models..268

General Description..769

Specifications..771

Steering..0

Steering SP000224..772

Safety Precautions..312

Applicable Models..268

General Description..777

Power Steering System..777

EHPS Valve..779

Parts List..781

Description of operation of EHPS with integrated priority valve..782

Steering Spool at Neutral Position..783

Steering Spool Operated..324

1. Turning Left..785

2. Turning Right..324

Pressure Reducing Valves..787

Pilot Relief Valve..788

Steering Unit..789

Function..789

Exploded View of a Steering Unit..790

Function..791

Picture of Components in the EHPS..579

Cushion Valve SP000328..794

Safety Precautions..350

Applicable Models..268

Cushion Valve..771

Cushion Valve Operation..536

Function..512

Working Principle..512

Specifications..799

Parts List..512

Emergency Steering SP000225..802

Safety Precautions..350

Applicable Models..268

General Description..771

Emergency Steering Function Test..275

Emergency Steering Automatic Test..297

Pump & DC Motor..811

Frame..0

Articulation Center SP000231..812

Safety Precautions..350

Applicable Models..268

General Description..817

Maintenance Standard..291

Counterweight SP000130..820

Safety Precautions..350

Applicable Models..268

Specifications..546

Counterweight..546

Tank..0

Oil Tank SP000226..826

Safety Precautions..350

Applicable Models..268

General Description..831

Parts List..831

Specifications..373

Fuel Tank SP000227..834

Safety Precautions..350

Applicable Models..268

General Description..831

Parts List..831

Specifications..832

Fuel Sender Setting..840

Hydraulics..0

Main Control Valve SP000233..842

Safety Precautions..846

Applicable Models..268

Parts List..847

Disassembly..849

Order of Replacement..849

Cleaning and Inspection (Wear Limits and Tolerances)..851

Reassembly..852

Reassembly Order..853

Valve Maintenance..855

Main Relief Valve..855

Disassembly..528

Cleaning and Inspection..855

Reassembly..856

Overload Relief Valve..857

Disassembly..857

Cleaning and Inspection..857

Reassembly..858

Anticavatation Valve..858

Disassembly..858

Cleaning and Inspection..859

Reassembly..859

Valve Adjustment..528

Main Relief Valve Adjustment..860

Overload Relief Valve Adjustment..860

Installation..861

Operation..861

Load Isolation System SP000228..862

Safety Precautions..350

Applicable Models..268

General Description..546

Over View..868

Hydraulic Circuit..551

Function..269

Maintenance and Service work..870

LIS Valve-RSM2..276

Specification..871

Characteristic Curve..871

Parts List..279

Accumulator..279

Specification..873

Parts List..811

Cooling System SP000229..874

Safety Precautions..350

Applicable Models..268

General..546

Cooling System..547

Circuit..269

Specifications..819

Checking Hydraulic Function..883

Maximum Fan Speed, Checking..274

Fan Motor..277

Cooling Fan : Bi-directional motor with speed control..278

Cooling Fan Maximum Speed..283

Proportional Pressure Relief Cartridge..283

Function..283

Proportional inverse pressure relief valve..284

Screw-in cartridge..285

Efficiency..887

Parts List..888

Solenoid Operated Spool Valve..291

Check Valve..291

Cooling Fan : Bi-directional Motor..556

Pilot System SP000230..892

Safety Precautions..350

Applicable Models..268

Overview..546

Function..898

Block Diagram..280

Finger-tip 3 Lever + 3 Spool Control Valve..282

Finger-tip 2 Lever + 2 Spool Control Valve..285

FNR Lever + 3 Spool Control Valve..286

FNR Lever + 2 Spool Control Valve..288

Finger-tip Joystick..283

Specification..556

Parts List..902

Walvoil FNR Joystick..903

Specification..807

Parts List..904

Hydraulic SchematicSP00234..906

Electrical System..0

Air Conditioner SP000172..916

Safety Precautions..350

Applicable Models..268

General Description..552

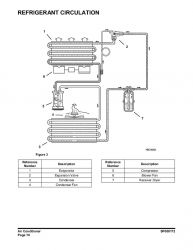

Refrigerant Circulation..273

Control Specifications..279

Temperature Level Control and Display..282

Air Discharge According to Path Selection..307

Face + Rear..491

Defroster + Rear..903

Airconditioning System Circuit Diagram..369

Refrigerant System Repairs..873

Refrigerant Safe Handling Procedures..882

Repair and Replacement Procedure..873

Leakage Check..372

Refrigerant Charging..373

Inspecting System for Leakage..515

Electrical SystemSP000268..948

Electrical Schematic (DL300)..1016

Safety Precautions..312

Applicable Models..1020

General Description..1022

DL300..1023