John Deere 750C and 850C Crawler Dozer Operator's Manual (OMT165719)

Catalog:

Model:

Complete Operator's Manuals for John Deere 750C and 850C Crawler Dozer. It's the same service manual used by dealers that guaranteed to be fully functional and intact without any missing page.

This John Deere 750C and 850C Crawler Dozer Operator's Manual is divided into different sections. Each section covers a specific component or system with detailed illustrations. A table of contents is placed at the beginning of each section. Pages are easily found by category, and each page is expandable for great detail. The printer-ready PDF documents work like a charm on all kinds of devices.

OMT165719 (K8 English) - John Deere 750C and 850C Crawler Dozer Operator's Manual.pdf

OMT165719 - John Deere 750C and 850C Crawler Dozer Operator's Manual.pdf

omt165720 - Bouteurs chenillés 750C et 850C.pdf

omt165721 - Bulldozer sobre orugas 750C y 850C.pdf

Category: Operator's Manual

Language: English Spanish French

Published on 2019/11/07

TABLE OF CONTENTS

Section 05: Safety...17

750C and 850C Crawler Dozer...19

Recognize Safety Information...20

Understand Signal Words...21

Follow Safety Instructions...22

Avoid Unauthorized Machine Modifications...23

Avoid Injury from Rollover Accidents ---- Wear Your Seat Belt ---- Do Not Attempt to Jump Clear of Tipping Machine--Serious or Fatal Crushing Injuries Will Result ---- Machine Will Tip Over Faster Than You Can Jump Free...24

Avoid Injury from Backover Accidents ---- Before Moving Machine, Be Sure All Persons Are Clear of Area ---- Always Be Alert for Bystanders Moving into the Work Area. Use Horn or Other Signal to Warn Bystanders Before Moving Machine ---- When Using a Signal Person, Keep Person in View at All Times, Be Sure Signal Person Is Clear Before Backing Up...25

Avoid Injury from Rollaway Accidents ---- To Prevent Rollaway, Always Make Sure Machine Is Properly Secured Before Leaving Operator's Seat ---- Death or Serious Injury May Result If You Attempt to Mount or Stop a Moving Machine...26

Avoid Injury from: ---- Loading Machine on a Trailer, Fastening Machine to Trailer, Unloading Machine from Trailer ---- Always Use Caution When Loading and Unloading Machines on a Trailer ---- Always Know and Follow the Recommended Procedures for the Machine Because All Machines Are Not Loaded, Fastened and Unloaded the Same Way. ---- Always Keep Bystanders Clear of the Area...27

Inspect Machine...29

Use Handholds and Steps...30

Prevent Machine Runaway...31

Avoid Worksite Hazards...32

Use Seat Belt Properly...34

Maintain Seat Belt...116

Secondary Exits...36

Operating on Slopes...165

Park Machine Safely...38

Keep Riders Off Machine...39

Handle Fuel Safely—Avoid Fires...40

Handle Fluids Safely—Avoid Fires...41

Prepare for Emergencies...42

Handle Starting Fluid Safely...43

Clean Trash from Machine...44

Protect Against Flying Debris...45

Wear Protective Clothing...46

Protect Against Noise...47

Warn Others of Service Work...48

Handle Chemical Products Safely...49

Keep ROPS Installed Properly...50

Practice Safe Maintenance...51

Stay Clear of Moving Parts...53

Support Machine Properly...54

Decommissioning — Proper Recycling and Disposal of Fluids and Components...55

Remove Paint Before Welding or Heating...56

Avoid High-Pressure Fluids...57

Avoid Heating Near Pressurized Fluid Lines...58

Prevent Battery Explosions...306

Clean the Machine Regularly...60

Service Cooling System Safely...61

Store Attachments Safely...62

Travel Safely...63

Section 06: Safety Signs...64

Safety Sign...72

Safety Sign...72

Safety Sign...72

Safety Sign...72

Safety Sign...72

Safety Sign...72

Safety Sign...72

Section 10: Operator's Station...73

Display Monitor Gauges and Indicators...75

Monitor Display Window...77

Select Button Operation...78

Engine Coolant Temperature Gauge...80

Fuel Level Gauge...81

Engine Oil Pressure Gauge...82

STOP-Engine Indicator and Alarm...83

Service Required Indicator...84

Engine Alternator Voltage Indicator...85

Engine Air Filter Restriction Indicator...86

Transmission Oil Temperature Hot Indicator...87

Transmission Oil Filter Restriction Indicator...88

Hydraulic Oil Filter Restriction Indicator...89

Return FNR to Neutral Indicator...90

Check Service Code Indicator...91

Ether Injection Indicator...92

Fasten Seat Belt Indicator...93

Transmission Oil Pressure Gauge...94

Battery Disconnect Switch...95

Blade Control Lever...96

Park Lock Levers...97

Engine Speed Lever—All Machines...98

Transmission Speed Lever—Lever Steer Machines...99

FNR Lever—Lever Steer Machine...100

FNR Lever—Pedal Steer Machine...101

Pedals—Lever Steer Machine...103

Pedals—Pedal Steer Machine...104

Work Lights—If Equipped...105

Air Conditioner and Heat...106

Dome and Swivel Light...107

Mirror...108

Door Latch...109

Windows...110

Cab Windows...111

Windshield Wiper and Washer Controls—Cab...112

Grease Gun—If Equipped...113

Operator's Manual Holder...114

Adjusting Seat...115

Seat Belt...116

Section 15: Break-In...117

Observe Engine Operation Closely...118

After the First 10 Hours...119

Between the First 50 to 100 Hours...120

Section 20: Pre-Start Inspection...121

Inspect Machine Daily Before Starting...122

Section 25: Operating the Engine...409

Check Instruments Before Starting...125

Starting the Engine...409

Starting Fluid—Cold Weather Start Aid...129

Using Booster Batteries—24-Volt System...131

Using Coolant Heater—If Equipped...133

Check Instruments After Starting...134

Warm-Up Engine...409

Engine Cold Weather Warm-Up...299

Stalled Engine...409

Stopping the Engine—Normal Shutdown...138

Section 30: Driving the Machine...141

Driving the Machine...141

Operating Suggestions...142

Extend Undercarriage Life...143

Operating Park Lock Levers...145

Driving the Machine—Pedal Steer Machine...146

Driving the Machine—Lever Steer Machine...149

Travel Speed...151

Operating Brake Pedal...152

Stopping the Machine...153

Parking the Machine...154

Lock All Compartments...452

Section 35: Operating the Machine...157

Blade Operation Tips...158

Blade Control Lever—Operation...159

Determining Blade Pitch...161

Changing Blade Pitch...162

Avoid Track Damage...451

Changing Blade Angle—Mechanical Angle...164

Operating on Slopes...165

Operating in Rough Terrain...166

Operating in Water and Mud...167

Side-by-Side Dozing...168

Slot Dozing...169

Tilt Dozer Ditching...170

Backfilling...171

Leveling a Stockpile...172

Moving Boulders...173

Bench Cut...175

Brush Removal...176

Tree Removal...177

Stump Removal...179

Section 40: Transporting...181

Loading Machine on a Trailer...182

Towing...184

Section 45: Fuels and Lubricants...187

Diesel Fuel...188

Storing Fuel...189

Fuel Tank...190

Low Sulfur Diesel Fuel Conditioner...191

Do Not Use Galvanized Containers...192

Diesel Engine Oil...193

Transmission, Hydraulic, and Hand Pump Reservoir Oil...194

Inner and Outer Final Drive Oil...195

Track Rollers, Front Idler, Carrier Roller and Track Frame Outer Pivot Oil...196

Grease...197

Lubricant Storage...198

Alternative and Synthetic Lubricants...199

Mixing of Lubricants...200

Section 50: Periodic Maintenance...201

Install Do Not Operate Tag...202

Service Your Machine at Specified Intervals...203

Check Hour Meter Regularly...204

Use Correct Fuels and Lubricants...205

Prepare Machine for Maintenance...206

Maintenance and Repair Record Keeping System...479

Oilscan Plus Oilscan Plus is a registered trademark of Deere & Company , Coolscan Plus Coolscan Plus is a registered trademark of Deere & Company and 3-Way Coolant Test Kit...201

Maintenance and Repair Record Keeping System...479

Section 55: Maintenance—As Required...214

Check and Adjust Alternator Belt Tension—750C (S.N. —831315)...215

Check and Adjust Fan Belt Tension—750C (S.N. —831315)...216

Check and Adjust Compressor Belt Tension—If Equipped—750C (S.N. —831315)...217

Check Track Sag...218

Adjust Track Sag...220

Check Air Restriction Indicator...223

Section 60: Maintenance—Every 10 Hours or Daily...224

Check Coolant Level...225

Check Engine Oil Level—750C (S.N. —831315)...227

Check Engine Oil Level—750C (S.N. 831316— ) and 850C...229

Check Hydraulic Oil Level...231

Check Transmission Oil Level...233

Lubricate Dozer Linkage...235

Lubricate All-Hydraulic Blade...236

Section 65: Maintenance—Every 50 Hours...238

Lubricate Left and Right Track Frame Pivot...239

Lubricate Lift Cylinder Pivots...240

Lubricate Track Adjust Cylinder...241

Section 75: Maintenance—Every 250 Hours...242

Change Engine Oil and Filter Elements...243

Check Inner and Outer Final Drive Housings Oil Level...247

Check Radiator Coolant Level...249

Section 80: Maintenance—Every 500 Hours...250

Check Coolant Conditioner...251

Change Primary Fuel Filter—750C (S.N. —831315)...253

Change Secondary Fuel Filter—750C (S.N. —831315)...255

Change Primary Fuel Filter—750C (S.N. 831316— )...256

Change Secondary Fuel Filter—750C (S.N. 831316— )...258

Change Primary Fuel Filter—850C...259

Change Secondary Fuel Filter—850C...261

Check Battery Electrolyte Level and Terminals...263

Check Air Intake Hose...266

Section 85: Maintenance—Every 1000 Hours...267

Check Left and Right Track Frame Pivot Oil Level...268

Change Final Drive Oil...269

Clean Engine Crankcase Vent Tube...271

Remove and Inspect Air Filter Elements...272

Measure and Adjust Engine Valve Clearances—750C (S.N. —831315)...276

Section 86: Maintenance—Every 2000 Hours...278

Change Hydraulic Oil and Filter...279

Change Hydrostatic Transmission Oil and Filter...281

Measure and Adjust Engine Valve Clearances—750C (S.N. 831316— )...283

Measure and Adjust Engine Valve Clearances—850C...285

Check Engine Speeds...287

Section 90: Maintenance...288

Servicing the Cooling System...290

Test the Coolant Freeze-Protection Level...291

Checking Coolant Hoses...292

Draining the Cooling System...293

Diesel Engine Coolant (engine with wet sleeve cylinder liners)...296

Filling the Cooling System...298

Engine Cold Weather Warm-Up...299

Do Not Adjust Injection Pump...300

Do Not Service Injection Nozzles...301

Drain Fuel Filter Sediment—850C...302

Fuel Drain and Shut-Off Valve...303

Clean Dusty Primary Element...304

Clean Dust Unloader Valve...305

Prevent Battery Explosions...306

Prevent Acid Burns...307

Service Batteries Carefully...309

Check Electrolyte Specific Gravity...310

Using Battery Charger...311

Precautions for Alternator and Regulator...312

Using Booster Battery...313

Replacing Batteries...314

Removing Batteries...315

Fuse Specifications...316

Fuse (Blade-Type) Color Codes...318

Adding 12-Volt Accessories...319

Remove and Install Halogen Bulb...320

Checking Neutral Start System...321

Change Reverse Warning Alarm Volume...322

Track Sag General Information...323

Checking Idlers and Rollers for Oil Leakage...325

Checking Idler and Track Roller Oil Level...326

Checking Carrier Roller Oil Level...328

Checking Idler Horizontal Movement...329

Checking Idler Vertical Movement...330

Cab or ROPS Tilting Procedure...331

Check and Adjust Front Crossbar-to-Crossbar Support and Main Frame Clearances...336

Adjusting Engine Speed Control Lever...338

Welding Procedure...339

Cleaning Cab Air Filter...340

Cleaning Cab Air Filter—Interior...341

Checking Fire Extinguisher—If Equipped...342

Checking Air Conditioner Refrigerant Level—If Equipped...343

Service Control Valves, Cylinders, Pumps and Motors...344

Engine Speed Adjustment—750C (S.N. 831316— ) and 850C (S.N. —822867)...345

Hardware Torque Specifications...347

Checking Track Shoe Cap Screw Torque...348

Checking Track Shoe Cap Screw Torque—Master Link...349

Metric Bolt and Screw Torque Values...350

Additional Metric Cap Screw Torque Values...352

Service Metric Series Four Bolt Flange Fitting...354

Unified Inch Bolt and Screw Torque Values...356

Checking Oil Lines and Fittings...358

Service Recommendations for O-Ring Boss Fittings...359

Service Recommendations For Flat Face O-Ring Seal Fittings...361

Service Recommendations For Inch Series Four Bolt Flange Fittings...363

Section 95: Operational Checkout...366

Operational Checkout...366

Section 100: Troubleshooting...407

Using Troubleshooting Charts...408

Engine...409

Electrical System...420

Hydraulic System...428

Hydrostatic Transmission...432

Brake System...434

Air Conditioning...435

Transmission Controller Service Codes...436

Engine Controller Service Codes—850C (S.N. 822868— )...443

Section 105: Storage...448

Prepare Machine for Storage...449

Avoid Track Damage...451

Lock All Compartments...452

Monthly Storage Procedure...453

Section 110: Machine Numbers...455

Record Product Identification Number (PIN)...456

Record Engine Serial Number...457

Record Winch Serial Number—If Equipped...458

Record C-Frame or Pushbeam Serial Number...459

Record Transmission Serial Numbers...460

Section 115: Specifications...461

750C Specifications...462

750C General Specifications...464

750C Dimensions...466

750C WT Dimensions...468

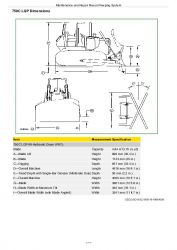

750C LGP Dimensions...469

850C Specifications...470

850C General Specifications...472

850C Dimensions...474

850C WT Dimensions...476

850C LGP Dimensions...477

Section CLIS: Checklists...478

Maintenance and Repair Record Keeping System...479

John Deere 750C and 850C Crawler Dozer Operator's Manual (OMT165719)