John Deere 5045E, 5055E, 5065E and 5075E (FT4) Tractors (S.No. 748241— ) Repair Service Manual (TM902519)

Catalog:

Model:

Complete Repair Service Technical Manual for John Deere 5045E, 5055E, 5065E and 5075E (FT4) Tractors (S.No. 748241— ), with all the workshop information to maintain, repair, and rebuild like professional mechanics.

John Deere 5045E, 5055E, 5065E and 5075E (FT4) Tractors (S.No. 748241— ) workshop technical manual (repair) includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

TM902519 English - John Deere 5045E, 5055E, 5065E and 5075E (FT4) Tractors (S.No. 748241— ) Repair Technical Manual.pdf

tm902528 French - Manuel technique de remise en état, tracteurs 5045E, 5055E, 5065E et 5075E (FT4) (n de série 748241 —).pdf

PRODUCT DETAILS:

Total Pages: 904 pages

File Format: PDF (bookmarked, ToC, Searchable, Printable)

Language: English

TABLE OF CONTENTS

Section 10: General Information................18

Group 05: Safety................18

Recognize Safety Information................22

Understand Signal Words................23

Follow Safety Instructions................24

Handle Fluids Safely—Avoid Fires................25

Prevent Battery Explosions................26

Prepare for Emergencies................27

Prevent Acid Burns................28

Service Cooling System Safely................30

Avoid High-Pressure Fluids................31

Park Machine Safely................32

Support Machine Properly................33

Wear Protective Clothing................34

Work in Clean Area................35

Service Machines Safely................36

Work In Ventilated Area................37

Illuminate Work Area Safely................38

Replace Safety Signs................39

Use Proper Lifting Equipment................40

Service Tires Safely................41

Avoid Harmful Asbestos Dust................42

Avoid Heating Near Pressurized Fluid Lines................43

Remove Paint Before Welding or Heating................44

Use Proper Tools................45

Dispose of Waste Properly................46

Live With Safety................47

Group 10: General Specifications (9x3 TSS Transmission)................18

Machine Specifications................915

Repair Specifications................915

Ground Speed Estimates — Sync Shuttle Transmission................57

Service Recommendations for O-Ring Boss Fittings................80

Service Recommendations for Flat Face O-Ring Seal Fittings................82

Metric Bolt and Cap Screw Torque Values................84

Unified Inch Bolt and Cap Screw Torque Values................85

Glossary of Terms................87

Group 11: General Specifications (12x12 PR Transmission)................19

Machine Specifications................915

Repair Specifications................915

Ground Speed Estimates —PowrReverser Transmission................79

Service Recommendations for O-Ring Boss Fittings................80

Service Recommendations for Flat Face O-Ring Seal Fittings................82

Metric Bolt and Cap Screw Torque Values................84

Unified Inch Bolt and Cap Screw Torque Values................85

Glossary of Terms................87

Group 15: Fuel and Lubricants................19

Diesel Fuel................93

Handling and Storing Diesel Fuel................95

Lubricity of Diesel Fuel................96

Testing Diesel Fuel................97

Biodiesel Fuel................98

Do Not Use Galvanized Containers................100

Fill Fuel Tank................101

Diesel Engine Break-In Oil — Non-Emissions Certified and Certified Tier 1, Tier 2, Tier 3, Stage I, Stage II, and Stage III................103

Diesel Engine Oil — Interim Tier 4, Final Tier 4, Stage IIIB, Stage IV, and Stage V................105

Oil Filters................107

Diesel Engine Coolant (engine with wet sleeve cylinder liners)................108

Operating in Warm Temperature Climates................110

Water Quality for Mixing with Coolant Concentrate................111

Testing Coolant Freeze Point................112

Transmission and Hydraulic Oil................114

Additional Information About Diesel Engine Coolants and John Deere LIQUID COOLANT CONDITIONER................115

Use Correct Transmission/Hydraulic Filter Element................117

Gear Oil................118

Multipurpose Extreme Pressure (EP) Grease................119

Mixing of Lubricants................120

Alternative and Synthetic Lubricants................121

Lubricant Storage................122

Group 20: Serial Number Locations................20

Serial Numbers................124

Product Identification Number................125

Record Engine Serial Number................126

Fuel Injection Pump Serial Number................127

Alternator Serial Number Location................128

Power Steering Valve Serial Number Location................129

Starter Serial Number Location................130

Transaxle Serial Number Location (12x12 PR Transmission)................131

Record Front Axle (2-WD) Serial Number................132

Record Mechanical Front Wheel Drive (MFWD) Serial Number................133

Group 25: Features and Accessories................135

Features and Accessories................135

Standard Features................136

Factory Installed Optional Equipment................138

Field Installed Optional Kits and Accessories................139

Section 20: Engine Repair................140

Group 05: Engine................140

Service Equipment and Tools................913

Specifications................915

John Deere Engine Repair—Use CTM................144

Remove Engine — Cab................145

Remove Engine — OOS................154

Install Engine — Cab................162

Install Engine — OOS................170

Remove and Install Rocker Arm Cover................177

Group 30: Cooling System................140

Special or Essential Tools................910

Specifications................915

Torques for Hardware................181

Remove and Inspect Radiator (OOS)................182

Remove and Inspect Radiator (Cab)................188

Water Pump — Exploded View................194

Cooling System Repair—Use CTM................195

Section 30: Fuel, Air Intake and Exhaust Systems................196

Group 05: Fuel System................196

Special or Essential Tools................910

Injection Pump, Nozzle and Governor Repair—Use CTM................205

Remove, Inspect and Install Fuel Tank (OOS)................206

Remove, Inspect and Install Fuel Tank (Cab)................209

Remove, Inspect and Install Fuel Cooler................213

Group 10: Air Intake System................196

Remove, Inspect, and Install Air Cleaner Elements................218

Remove, Inspect and Install Air Cleaner Assembly................221

Check Air Inlet Pipe with Turbocharger................223

Remove and Install Turbocharger................224

Turbocharger Repair................226

Group 15: Exhaust System................196

Other Material................914

Specifications................915

Service Exhaust System................230

Section 40: Electrical Repair................238

Group 05: Battery, Starter and Alternator................238

Starter Repair—Use CTM................242

Remove and Install Battery (OOS)................243

Remove and Install Battery (CAB)................246

Remove and Install Starter................249

Replace Alternator/Regulator................250

Group 10: Electrical System Components................238

Essential or Recommended Tools................684

Other Material................914

Specifications................915

Servicing Electronic Control Units................255

Keep Electronic Control Unit Connectors Clean................256

Repair Engine Electrical System Components—Use CTM................257

Replace Air Filter Restriction Sensor................258

Replace Coolant Temperature Sensor................259

Replace Engine Speed Sensor................260

Replace Engine Oil Pressure Sensor................261

Replace Key Switch (OOS)................262

Replace Key Switch (CAB)................264

Replace Light Switch (OOS)................265

Replace Light Switch (CAB)................267

Replace Turn Signal Switch (OOS)................269

Remove and Replace Turn Signal Switch (Cab)................271

Replace Wiper Control Switch................272

Remove and Install Wiper Motor................273

Remove and Install Instrument Panel................789

Remove and Replace Forward, Neutral, Reverse Lever (If Equipped)................278

Remove and Install Acceleration Potentiometer (Shuttle Control) (If Equipped)................280

Replace Horn Switch (If Equipped)................281

Replace Starter Relay................282

Replace Hand Throttle Position Sensor................284

Replace Foot Throttle Position Sensor................286

Replace Rear PTO ON/OFF Switch (OOS)................291

Replace Electro-Hydraulic Control (EHC) Unit—Cab................292

Replace Electro-Hydraulic Control (EHC) Unit—OOS................294

Replace Engine Control Unit (ECU) (2.9 L)................296

Replace Enable Proportional Solenoid Valve—PR Transmission................298

Replace Transmission Reverse Solenoid Valve—PR Transmission................300

Replace Transmission Forward Solenoid Valve—PR Transmission................301

Replace Clutch Pedal Position Sensor (PR Transmission)................302

Remove and Install Rear PTO Switch (TSS Transmission)—OOS................305

Remove and Install Rear PTO Switch (TSS Transmission)—Cab................307

Replace Neutral Start Switch................309

Replace Seat Switch (OOS)................310

Replace Seat Switch (Cab)................312

Replace Fuel Level Sender (OOS)................313

Replace Fuel Level Sender (Cab)................314

Group 15: Wiring Harness................239

Service Equipment and Tools................913

Essential Tools................910

Remove Connector Body from Blade Terminals................319

Replace WEATHER PACK WEATHER PACK is a trademark of Packard Electric. Connector................239

Install WEATHER PACK WEATHER PACK is a trademark of Packard Electric. Contact................239

Repair (Pull Type) METRI-PACK™ Connectors................324

Repair (Push Type) METRI-PACK™ Connectors................326

Exploded View—CINCH Flexbox Connectors................329

CINCH™ Flexbox Connectors................330

Repair DEUTSCH™ Connectors................334

Replace Positive Battery Cable (OOS)................338

Replace Positive Battery Cable (CAB)................339

Replace Engine Power Cable................340

Replace Hood Wiring Harness (OOS and CAB)................342

Replace Beacon Lamp Wiring Harness (If Equipped)................344

Replace Front Console Wiring Harness—OOS (9x3 TSS Transmission)................345

Replace Front Console Wiring Harness—OOS (12x12 PowrReverser™ Transmission)................348

Replace Front Console Wiring Harness—Cab (9x3 TSS Transmission)................351

Replace Front Console Wiring Harness—Cab (12x12 PowrReverser™ Transmission)................353

Replace Right-Hand Console Wiring Harness—OOS (12x12 PowrReverser™ Transmission)................355

Replace Transmission Harness—Cab (12x12 PowrReverser™ Transmission)................356

Replace Engine Harness................359

Replace Cab Power Harness................360

Replace Rear Wiring Harness—OOS (9x3 TSS Transmission)................362

Replace Rear Wiring Harness—OOS (12x12 PowrReverser™ Transmission)................365

Replace Rear Wiring Harness—Cab (9x3 TSS Transmission)................368

Replace Rear Wiring Harness—Cab (12x12 PowrReverser™ Transmission)................372

Replace Roof Harness—Cab................376

Replace 7-Pin Connector Wiring Harness (CAB)................378

Replace 7-Pin Connector Wiring Harness (OOS)................379

Replace Exhaust Filter Harness................380

Replace Injector Harness................382

Section 50: Power Train Repair (12x12 PR Transmission)................383

Group 05: Clutch Housing................383

John Deere Transmission Repair — Use CTM................491

Specifications................915

Separate Engine from Clutch Housing (PR)................388

Install Engine to Clutch Housing (PR)................395

Remove, Inspect, and Repair Clutch Pedal and Linkage (PR IOOS)................402

Remove, Inspect, and Repair Clutch Pedal and Linkage (PR CAB)................404

Group 10: Clutch Assembly................383

Specifications................915

John Deere Transmission Repair — Use CTM................491

Group 15: Transmission................383

Other Material................914

Specifications................915

John Deere Transmission Repair — Use CTM................491

Inspect and Repair Gear and Range Shift Lever (OOS 12x12)................413

Inspect and Repair Gear and Range Shift Lever (CAB 12x12)................415

Group 21: Rear PTO................383

Other Material................914

Specifications................915

John Deere Transmission Repair — Use CTM................491

Group 26: Differential................383

Essential Tools................910

Service Equipment and Tools................913

Other Material................914

Specifications................915

Service Parts Kits................607

John Deere Transmission Repair — Use CTM................491

Group 30: Final Drives................383

Service Equipment and Tools................913

Other Material................914

Specifications................915

John Deere Transmission Repair — Use CTM................491

Group 35: Mechanical Front Wheel Drive................384

Mechanical Front Wheel Drive – If Equipped—Summary of References................509

Service Equipment and Tools................913

Essential Tools................910

Other Material................914

Specifications................915

MFWD Axle Repair — Use CTM................439

MFWD Dropbox Repair—Use CTM................440

Remove, Inspect and Install MFWD Drive Shaft(PR)................441

Remove and Install MFWD Axle Housing Assembly(PR)................442

Remove, Inspect and Install MFWD Axle Supports (Without Paddy Seal)(PR)................444

Section 51: Power Train Repair (9x3 TSS Transmission)................446

Group 05: Clutch Housing................446

John Deere Transmission Repair — Use CTM................491

Service Equipment and Tools................913

Other Material................914

Essential Tools................910

Specification................731

Separate Engine from Clutch Housing (TSS)................454

Install Engine to Clutch Housing (TSS)................461

Inspect and Repair Clutch Pedal and Linkage (TSS)................468

Inspect and Repair Clutch Pedal and Linkage (TSS- Cab)................470

Group 10: Clutch Assembly................446

Specification................731

John Deere Transmission Repair — Use CTM................491

Group 15: Transmission................446

Specifications................915

John Deere Transmission Repair — Use CTM................491

Inspect and Repair Gear and Range Shift Lever (OOS)................478

Inspect and Repair Gear and Range Shift Lever (CAB)................480

Group 21: Rear PTO................446

Other Material................914

Specifications................915

John Deere Transmission Repair — Use CTM................491

Remove, Inspect, and Install Rear PTO Lever and Linkage (CAB)................486

Remove, Inspect and Install Rear PTO Lever and Linkage — (OOS)................488

Group 26: Differential................446

John Deere Transmission Repair — Use CTM................491

Group 30: Final Drives................446

Service Equipment and Tools................913

Other Material................914

Specifications................915

Remove and Install Final Drive Assembly................496

Remove and Inspect Planetary Drive Assembly................498

Install Planetary Drive Assembly................501

Remove, Inspect, and Install Axle Shaft Assembly................504

Group 35: Mechanical Front Wheel Drive................447

Mechanical Front Wheel Drive – If Equipped—Summary of References................509

Service Equipment and Tools................913

Essential Tools................910

Other Material................914

Specifications................915

MFWD Axle Repair—Use CTM................514

Inspect and Repair MFWD Lever and Linkage................515

Disassemble and Repair MFWD Drop Gearbox................517

Remove and Install MFWD Drop Box................519

MFWD Drop Gearbox Cross Section................521

Assemble MFWD Drop Gearbox................523

Remove, Inspect and Install MFWD Drive Shaft................529

Remove and Install MFWD Axle Housing Assembly................530

Remove, Inspect and Install MFWD Axle Supports (Without Paddy Seal)................532

Section 60: Steering and Brake Repair................534

Group 05: Steering Repair................534

Other Material................914

Specifications................915

Service Parts Kits................607

Remove and Install Steering Wheel................539

Remove and Install Tilt/Telescoping Steering Column................541

Remove and Install Steering Column (9x3 TSS Transmission)................543

Remove and Install Steering Column and Valve................545

Disassemble and Inspect Steering Valve - Sauer Danfoss................548

Assemble Steering Valve - Sauer Danfoss................552

Remove and Install Steering Cylinder—2WD Axle................557

Disassemble, Inspect, and Assemble Steering Cylinder—2WD Axle................561

Remove, Inspect, and Install Tie Rod Assembly—2WD Axle................563

Remove and Install Steering Cylinder— MFWD Axle................566

Disassemble, Inspect, and Assemble Steering Cylinder—MFWD Axle................569

Remove, Inspect and Install Tie Rod Assembly—MFWD Axle................570

Inspect and Replace Steering Hydraulic Lines................573

Group 10: Brake Repair................534

Service Equipment and Tools................913

Other Material................914

Specifications................915

Remove and Install Brake Valve................581

Disassemble and Inspect Brake Pedals................583

Remove and Inspect Brakes................585

Install Brakes................587

Adjusting the Brake Pedals................590

Adjusting the Brake Switch................592

Bleeding Procedure................594

Adjust Brake Retractors................597

Inspect and Replace Brake Hydraulic Lines (Cab)................598

Inspect and Replace Brake Hydraulic Lines (OOS)................600

Section 70: Hydraulic Repair................602

Group 05: Hydraulic Pump and Filter................602

Essential Tools................910

Specifications................915

Service Parts Kits................607

Remove, Inspect, and Install Hydraulic Oil Pick-Up Screen................608

Remove and Install Hydraulic Pump................610

Remove Hydraulic Pump External Components................612

Disassemble and Inspect Hydraulic Pump................613

Assemble Hydraulic Pump................616

Install Hydraulic Pump External Components................618

Remove and Install Hydraulic Oil Filter/Manifold................620

Inspect and Replace Hydraulic Supply and Suction/Return Lines (TSS Transmission)................621

Inspect and Replace Hydraulic Supply and Suction/Return Lines (PR Transmission)................623

Group 15: JD Rockshaft................602

Other Material................914

Specifications................915

Inspect and Repair Rockshaft Control Lever Assembly................628

Inspect and Repair Rockshaft Control Linkage................634

Inspect and Repair Draft Sensing Support Assembly................638

Replace Main Relief Valve................641

Replace Rockshaft Surge Relief Valve................643

Replace Rockshaft Control Valve................645

Remove and Install Rockshaft Housing................649

Remove, Inspect, and Install Rockshaft Piston and Cylinder................652

Inspect and Repair SCV I Lever Linkage Assembly (OOS)................655

Inspect and Repair SCV I Lever Linkage Assembly (CAB)................656

Group 25: EATON Selective Control Valve (SCV)................602

Install Single Selective Control Valve (SCV)................662

Assemble Rear Quick Coupler................672

Remove, Inspect, and Install Selective Control Valve (SCV) Oil Liens................667

Install Second Selective Control Valve (SCV)................670

Assemble Rear Quick Coupler................672

Install Hydraulic Oil Lines................674

Remove, Inspect, and Install Selective Control Valve (SCV) Oil Lines CAB................678

Group 30: Mid Mount Selective Control Valve (SCV)................603

Essential or Recommended Tools................684

Other Material................914

Specifications................915

Service Parts Kit................687

Other Material................914

Specifications................915

Remove, Inspect and Install Joystick Assembly................690

Remove and Install Mid Mount Control Valve, and Oil Lines................700

Disassemble, Inspect and Assemble Dual Mid-Mount Selective Control Valve (SCV)................710

Remove and Install Mid Mount Control Valve................716

Remove, Inspect and Install Joystick and Cables—Mid Mount Valve................719

Disassemble, Inspect, and Assemble Joystick—Mid Mount Coupler................721

Disassemble, Inspect and Assemble Mid Mount Control Valve................723

Start-Up Procedure................727

Section 80: Miscellaneous Repair................729

Group 05: Front Axle................729

Specification................731

Remove and Install Front Axle—2WD................732

Remove and Install Front Axle — MFWD................735

Inspect and Replace Pivot Pin and Bushings—2WD Axle................739

Remove and Install Spindle Assembly—2WD................740

Inspect and Replace Spindle Shaft Bushings—2WD Axle................742

Group 10: Wheels................729

Specifications................915

Remove and Install Front or Rear Wheels................745

Inspect and Replace Front Wheel Bearings................746

Tighten Bolts—Rear Axle (M-20 Stud)................748

Tighten Nuts—Front Axle (MFWD)................749

Tighten Cap Screws—Front Axle (2WD)................750

Group 15: 3-Point Hitch................729

Specifications................915

Inspect and Repair Fixed Draft Links................753

Inspect and Repair Telescopic Draft Links (If Equipped)................754

Inspect and Repair Lift Link (If Equipped)................757

Inspect and Repair Lift Link (If Equipped)................757

Inspect and Repair Adjustable Lift Link (If Equipped)................761

Inspect and Repair Adjustable Lift Link (If Equipped)................761

Inspect and Repair Center Link................763

Group 25: Hood................729

Remove and Install Hood................767

Section 90: Operator Station Repair (OOS)................769

Group 05: Seat and Support................769

Remove and Install Seat and Support (OOS)................772

Disassemble, Inspect and Assemble Seat and Seat Switch................774

Group 06: Center Console................769

Remove and Install Cowl Cover (OOS)................778

Remove and Install Right-Side Control Console................780

Remove and Install Left-Side Control Console................785

Remove and Install Instrument Panel................789

Group 10: Roll-Gard™................769

Specifications................915

Remove and Install Roll-Gard™................793

ROPS Serial Number................797

Group 15: Operator Platform................769

Specifications................915

Remove Right-Side Platform and Step................800

Remove and Install Left-Side Platform and Handrail................807

Group 20: Fenders................769

Remove and Install Fenders................819

Group 25: Canopy (If Equipped)................769

Specifications................915

Remove and Install Canopy................828

Section 91: Operator Station Repair (Cab)................830

Group 05: Seat and Support................830

Remove and Install Seat and Support (Cab)................833

Group 10: Control Console................830

Specifications................915

Remove and Install Right-Side Control Console—Cab................836

Remove and Install Left-Side Control Console—Cab................840

Remove and Install Cowl Cover (Cab)................842

Remove and Install Front Control Console................843

Group 20: Cab Components................830

Essential Tools................910

Service Equipment and Tools................913

Other Material................914

Specifications................915

Remove, Inspect, and Install Cab Interior Recirculating Air Filters................850

Remove, Inspect, and Install Exterior Cab Intake Air Filter................852

Remove and Install Headliner................854

Remove and Install Left-Side Upholstery................857

Remove and Install Right-Side Upholstery................859

Remove and Install Windshield................861

Remove and Install Front Lower Windows................863

Remove and Install Rear Lower Window................865

Remove and Install Rear Upper Window................866

Remove and Install Side Windows................867

Remove and Install Cab Doors................869

Remove and Install Inner Roof for Air Conditioning Housing Repair................874

Remove Cab................885

Install Cab................897

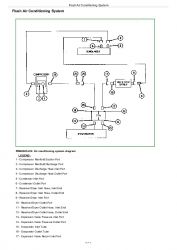

Group 30: Air Conditioning System................830

Essential Tools................910

Service Equipment and Tools................913

Other Material................914

Specifications................915

Adjust A/C Temperature Control Switch................916

Recover/Recycle Air Conditioning Refrigerant................918

Replace Air Conditioning Receiver/Dryer................919

Remove, Inspect, and Install Air Conditioning Condenser................921

Remove, Inspect, and Install Air Conditioning Compressor................925

Test Volumetric Efficiency of Compressor................927

Test Compressor Shaft Seal Leakage................929

Disassemble and Assemble Compressor Clutch................931

Disassemble, Inspect, and Assemble Compressor................933

Check Compressor Clutch Hub Clearance................937

Inspect Compressor Manifold................938

Remove Blower Motors................939

Remove Evaporator/Heater Core................940

Leak Test Evaporator/Heater Core................942

Install Evaporator/Heater Core................943

Service Expansion Valve................945

Expansion Valve Bench Test................946

Refrigerant Oil Information................948

Check Compressor Oil Charge................949

Determine Correct Refrigerant Oil Charge................950

Add Refrigerant Oil to System................952

System Information................953

Flush Air Conditioning System................954

Evacuate Air Conditioning System................959

Charge Air Conditioning System................960

Group 35: Heating System................831

Adjust Heater Temperature Control Cable................963

Replace Heater Temperature Control Cable................965

Remove Heater Control Valve................968

Leak Test Heater Control Valve................969

Install Heater Control Valve................970

John Deere 5045E, 5055E, 5065E and 5075E (FT4) Tractors (S.No. 748241— ) Repair Service Manual (TM902519)