John Deere 9950 Cotton Picker Diagnosis and Repair Service Manual (TM1349)

Catalog:

Model:

Complete All Inclusive Technical Manual with electrical wiring diagrams for John Deere 9950 Cotton Picker, with workshop information to maintain, diagnose, repair, and rebuild like professional mechanics (Diagnosis, Operation, Tests, Repair, Service, Troubleshooting).

John Deere 9950 Cotton Pickers workshop technical service manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

TM1349 English - John Deere 9950 Cotton Picker Technical Manual.pdf

omn200074 English - 9950 Cotton Picker (Issue F7) Operator's Manual.pdf

omn200242 English - 9950 Cotton Picker (Issue J8) Operator's Manual

PRODUCT DETAILS:

Total Pages: 1,126 pages

File Format: PDF (bookmarked, ToC, Searchable, Printable)

Language: English

This is a complete revision for TM-1349,

Binder and tabs from old manual 9950 Cotton Picker. may be saved and used with this manual.

New pages are dated (Mar-89). Listed below is a brief explanation of “WHAT” changed.

This manual was revised:

1. To show how to install the new lid parts required on 305 mm (12 in.) extensions.

2. To show replacement procedures and bleeding procedures for one filter fuel system.

3. To remove alternator repair information for both Motorola and Nippondenso.

Refer to CTM-11 for repair and diagnostic information.

4. To show new repair information on hydrostatic drive and transmission because of addition of operator presence system.

5. To show new removal/installation and repair procedure for final drive axle.

6. To remove repair, operation and test information on 22.6 cm (1.38 cu. in.) hydraulic pump.

Refer to CTM-7 for repair and diagnostic information.

7. To revise main control valve repair information because of addition of an orifice to port “F”’.

8. To revise basket lift cylinder repair information because of removal of an orifice plate from rear cylinder and revised orifice diameter in front cylinder.

9. To include repair information for new height sensing control valve.

10. To include repair information for new full length sleeved picker bars.

11. To revise the cotton fan repair information. The fan shaft has been revised. The inlet cap screw torque hasbeen increased, and rotor-to-inlet running clearance changed. The water pump drive sheave mounting to fan shaft has been revised.

12. To revise the operational checks to include the operator presence and by-pass system diagnostic procedures.

13. To provide test procedure for operator presence interlock module, adjustment procedure for picking unit engaged switch and a wiring diagram for the operator presence system.

14. To provide a new complete hydraulic and J.I.C. diagrams for machines above Serial No. 4001.

TABLE OF CONTENTS

SECTION 10—GENERAL

SECTION 20—ENGINE REPAIR

SECTION 30—FUEL AND AIR REPAIR

SECTION 40—ELECTRICAL REPAIR

SECTION 50—POWER TRAIN REPAIR

SECTION 60—STEERING/BRAKES REPAIR

SECTION 70—HYDRAULIC REPAIR

SECTION 80—AXLES AND WHEEL REPAIR

SECTION 90—OPERATOR STATION

SECTION 100—PICKING UNIT REPAIR

SECTION 110—PICKING UNIT LUBRICATION SYSTEM REPAIR

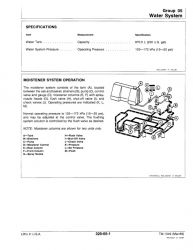

SECTION 120—WATER SYSTEM REPAIR

SECTION 130—AIR SYSTEM REPAIR

SECTION 140—BASKET UNLOADING AND METERING SYSTEM REPAIR

SECTION 199—SPECIAL TOOLS

SECTION 230—FUEL/AIR OPERATION AND TESTS

SECTION 240—ELECTRICAL OPERATION AND TESTS

SECTION 250—POWER TRAIN OPERATION AND TESTS

SECTION 260—STEERING/BRAKES OPERATION AND TESTS

SECTION 270—HYDRAULIC OPERATION AND TESTS

SECTION 290—OPERATOR STATION OPERATION AND TESTS

SECTION 300—PICKING UNIT OPERATION AND TESTS

SECTION 310—PICKING UNIT LUBRICATION SYSTEM OPERATION AND TESTS

SECTION 320—WATER SYSTEM OPERATION AND TESTS

SECTION 330—AIR SYSTEM OPERATION AND TESTS

SECTION 399—SPECIAL TOOLS

John Deere 9950 Cotton Picker Diagnosis and Repair Service Manual (TM1349)