Case & New Holland 445/M2, 445T/M2, 668T/M2 Engine Factory Service & Shop Manual

Catalog:

Model:

Complete workshop repair service manual for Case New Holland 445/M2, 445T/M2, 668T/M2 Engine. It's the same service manual used by dealers that guaranteed to be fully functional and intact without any missing page.

This 445/M2, 445T/M2, 668T/M2 Engine. service repair manual (including maintenance, overhaul, disassembling & assembling, adjustment, tune-up, operation, inspecting, diagnostic & troubleshooting…) is divided into different sections. Each section covers a specific component or system with detailed illustrations. A table of contents is placed at the beginning of each section. Pages are easily found by category, and each page is expandable for great detail. The printer-ready PDF documents work like a charm on all kinds of devices.

“6-74500NA.pdf”

CASE Engines 445/M2, 445T/M2 and 668T/M2 Service Manual

Bur 6-74500NA; Part Number: 6-74500; 180 pages; December 2003

(430, 440 and 440CT Skid Steers)

“6-49731NA.pdf”

New Holland 445/M2, 445T/M2, 668T/M2 Engine Service Manual

180 pages; Issued 02-2003 (Revised 12-2003)

Revision History

First Edition 02-2003 445/M2, 445T/M2, 668T/M2 6-49730 NA

First Revision 12-2003 445/M2, 445T/M2, 668T/M2 6-49731 NA

EXCERPT:

CONTENT OF SECTIONS

General information - 1

Feed - 2

Duty - Industrial applications

Mechanical injection Engines - 3

Overhaul and technical specifications - 4

Equipment - 5

Installation guidelines

Safety instructions - Appendix

PREFACE TO USER'S GUIDELINE MANUAL

Section 1 describes the engine illustrating its features and working in general.

Section 2 describes the type of fuel feed.

Section 3 relates to the specific duty and is divided in four separate parts.

1. Mechanical part, related to the engine overhaul, limited to those components with different characteristics based on the relating specific duty.

2. Electrical part, concerning wiring harness, electrical and electron1c equipment with different characteristics based on the relating specific duty.

3. Maintenance planning and specific overhaul.

4. Troubleshooting part dedicated to the operators who, being entitled to provide technical assistance, shall have simple and direct instructions to identify the cause of the major inconveniences.

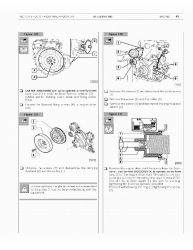

Sections 4 and 5 illustrate the overhaul operations of the engine overhaul on stand and the necessary equipment to execute such operations.

Installation general prescriptions are reported within the appendix.

Such prescriptions shall be strictly followed by the operators in-charge of installation to avoid incorrect working as well as serious failures which may reduce performance and life of the engine.

Furthermore, the appendix reports general safety prescriptions to be followed by all operators whether being in-charge of installation or maintenance, in order to avoid serious Injury.

…

Checks not included in maintenance planning-daily checks

It is a good habit to execute, before engine start, a series of simple checks that might represent a valid warranty to avoid inconveniences, even serious, during engine running. Such checks are usually up to the operators and to the vehicle’s drivers.

- Level controls and checks of any eventual leakage from the fuel, cooling and lubricating circuits

- Notify the maintenance if any inconvenience is detected of if any filling is necessary

After engine start and while engine is running, proceed with the following checks and controls

- Check presence of any eventual leakage from the fuel, cooling and cooling and lubricating circuits

- Verify absence of noise or unusual rattle during engine working

- Verify, using the vehicle devices, the prescribed pressure temperature and other parameters

- Visual check of fumes (color of exhaust emissions)

- Visual check of cooling liquid level, in the expansion tank

…