Doosan DL250 Wheel Loader Factory Service & Shop Manual

Catalog:

Model:

Complete workshop repair service manual with electrical wiring diagrams for Doosan DL250 Wheel Loader. It's the same service manual used by dealers that guaranteed to be fully functional and intact without any missing page.

This Doosan DL250 Wheel Loader service & repair manual (including maintenance, overhaul, disassembling & assembling, adjustment, tune-up, operation, inspecting, diagnostic & troubleshooting…) is divided into different sections. Each section covers a specific component or system with detailed illustrations. A table of contents is placed at the beginning of each section. Pages are easily found by category, and each page is expandable for great detail. The printer-ready PDF documents work like a charm on all kinds of devices.

“K1023773E.pdf”

Doosan DL250 Wheel Loader Shop Manual

K1023773E; Serial Number 5001 and Up; 800 pages

TABLE OF CONTENTS

Safety

Wheel Loader Safety..................... SP000865

Specifications

Specification for DL250.................... SP000866

General Maintenance

General Maintenance Procedures ..................... SP000097

Standard Torques .................... SP000813

Drive Train

Transmission and Torque Converter.................... SP000867

Transmission Error Codes (ZF)...................... SP001056

Front Axle (ZF-MT-L 3085)............................. SP000868

Rear Axle (ZF-MT-L 3075) ............................. SP000869

Drive Shaft ................... SP000870

Brake

Service Brake........................... SP000871

Brake Supply Valve.................... SP000872

Parking Brake .......................... SP000873

Brake Pedal Valve................... SP000874

Accumulator.............................. SP000875

Steering

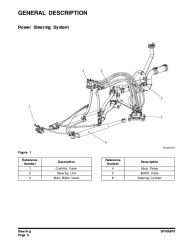

Steering ..................... SP000876

Cushion Valve.......................... SP000328

Emergency Steering ................... SP000877

Frame

Articulation Center ................... SP000878

Counterweight........................... SP000130

Tank

Oil Tank..................... SP000879

Fuel Tank..................... SP000880

Hydraulics

Cylinders.................... SP001027

Main Pump................... SP001035

Main Control Valve..................... SP000881

Load Isolation System................... SP000882

Cooling System........................ SP000883

Pilot System............................. SP000884

Hydraulic Schematic DL250............................ SP000886

Electrical System

Air Conditioner ......................... SP001211

Electrical System ..................... SP000924

Electrical Schematic DL200/ DL250..................... SP000925

…

EXCERPT:

Accumulators are solidly constructed to resist the high operating pressures of the fluids they contain. There are only three main moving parts: a valve assembly at the top allows adding or expelling gas from the compressible, precharged upper chamber; a valve assembly at the bottom of the accumulator for passing hydraulic fluid in and out, and an elastic diaphragm to separate the two chambers.

The flexible diaphragm changes shape to conform to the changing pressures and volumes of the two fluids in the upper and lower chambers.

There are six possible positions the diaphragm can be in and they are as follows:

1. With no gas charge in the upper chamber 0 bar (0 psi, empty) and no oil in the bottom 0 bar (0 psi, dry) the elastic diaphragm hangs loosely.

…