John Deere 3029 Diesel Engine - Level 23 ECU Component Technical Manual (CTM120619)

Catalog:

Model:

Complete Component Technical Manual with Electrical Wiring Diagrams for John Deere 3029 Diesel Engine - Level 23 ECU, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

John Deere 3029 Diesel Engine - Level 23 ECU Component Technical Manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

ctm120619 English - 3029 Diesel Engine — Level 23 ECU - (Worldwide Edition) Component Technical Manual.pdf

ctm120628 French - Moteur diesel 3029—Contrôleur ECU niveau 23 -: (Édition mondiale)

ctm120629 German - Dieselmotor 3029 — ECU (Level 23) -: (Weltweite Ausgabe)

ctm120663 Spanish - Motor diésel 3029 — ECU Nivel 23 -: (Edición mundial)

ctm120639 Italian - Motore diesel 3029 – ECU livello 23 -: (Edizione universale)

ctm120654 Portuguese - 3029 Motor a Diesel — Nível 23 ECU -: (Edição Mundial)

PRODUCT DETAILS:

Total Pages: 3,577 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

TABLE OF CONTENTS

Section 01: General Information................62

Group 000: Safety................62

Understand Signal Words................66

Recognize Safety Information................67

Replace Safety Signs................68

Follow Safety Instructions................69

California Proposition 65 Warning................70

Exhaust Filter Cleaning................71

Avoid Hot Exhaust................72

Work In Ventilated Area................73

Decommissioning — Proper Recycling and Disposal of Fluids and Components................74

Prevent Machine Runaway................75

Practice Safe Maintenance................76

Work in Clean Area................78

Wear Protective Clothing................79

Service Machines Safely................80

Use Proper Tools................81

Construct Dealer-Made Tools Safely................82

Support Machine Properly................83

Use Proper Lifting Equipment................84

Protect Against Noise................85

Illuminate Work Area Safely................86

Install All Guards................87

Stay Clear of Rotating Drivelines................88

Protect Against High Pressure Spray................89

Service Cooling System Safely................90

Remove Paint Before Welding or Heating................91

Precautions for Welding................92

Wait Before Opening High-Pressure Fuel System................94

Avoid High-Pressure Fluids................95

Avoid Heating Near Pressurized Fluid Lines................96

Avoid Static Electricity Risk When Refueling................97

Handle Fluids Safely—Avoid Fires................99

Prepare for Emergencies................100

Handling Batteries Safely................101

Prevent Acid Burns................103

Prevent Battery Explosions................105

Live With Safety................106

Group 001: Engine Identification Information................63

Engine Serial Number Plate Information................109

OEM Engine Option Code Label................111

Emissions Control System Certification Label................113

Information Relative to Emissions Regulations................114

Group 002: Fuels, Lubricants, and Coolants................63

Diesel Fuel................117

Supplemental Diesel Fuel Additives................119

Lubricity of Diesel Fuel................120

Handling and Storing Diesel Fuel................121

Biodiesel Fuel................122

Testing Diesel Fuel................124

Fuel Filters................125

Minimizing the Effect of Cold Weather on Diesel Engines................126

John Deere Break-In Plus™ Engine Oil — Interim Tier 4, Final Tier 4, Stage IIIB, Stage IV, and Stage V................128

Diesel Engine Oil — Interim Tier 4, Final Tier 4, Stage IIIB, Stage IV, and Stage V................129

Diesel Engine Oil and Filter Service Intervals — Interim Tier 4, Final Tier 4, Stage IIIB, Stage IV, and Stage V— OEM Applications................131

Oilscan™ and CoolScan™................133

Diesel Engine Oil and Filter Service Intervals................134

Mixing of Lubricants................135

Alternative and Synthetic Lubricants................136

Lubricant Storage................137

Oil Filters................138

Diesel Engine Coolant (engine with wet sleeve cylinder liners)................139

Water Quality for Mixing with Coolant Concentrate................141

Operating in Warm Temperature Climates................142

Testing Coolant Freeze Point................143

Disposing of Coolant................145

Section 02: Repair and Adjustments................146

Group 010: Engine Rebuild................146

Check Air Intake System................158

Check and Service Cooling System................159

Check Crankcase Vent System................160

Check Electrical System................161

Check Exhaust System................163

Clean Engine................164

Disconnect Turbocharger Oil Supply Line................165

Engine Assembly Sequence................166

Engine Break-In Guidelines................168

Engine Disassembly Sequence................171

Engine Overhaul Guidelines................173

Engine Repair Stand................174

General Tune-Up Recommendations................175

Install Lift Straps................176

Lifting Procedure................178

Safety Precautions................180

Sealant Application Guidelines................181

Group 020: Cylinder Head and Valves................146

Crankcase Pressure Relief Valve — Inspection and Installation................185

Cylinder Block Top Deck — Cleaning and Inspection................187

Cylinder Head — Cleaning and Inspection................188

Cylinder Head — Flatness Check................189

Cylinder Head — Installation................190

Cylinder Head — Removal................195

Cylinder Head — Thickness Measurement................197

Cylinder Head Gasket — Inspection................199

Fuel Injector Heat Shield — Installation................201

Fuel Injector Heat Shield — Removal................202

Fuel Injector Sleeves — Installation................203

Fuel Injector Sleeves — Removal................205

Fuel Supply Pump Push Rod — Installation................214

Fuel Supply Pump Push Rod — Measurement................210

Fuel Supply Pump Push Rod — Removal................216

Push Rod — Cleaning and Inspection................213

Push Rod — Installation................214

Push Rod — Removal................216

Rocker Arm Cover — Inspection................217

Rocker Arm Cover — Installation................218

Rocker Arm Cover — Removal................220

Rocker Arm Shaft Assembly — Assemble................222

Rocker Arm Shaft and Components — Inspection................225

Rocker Arm Shaft Assembly — Installation................227

Rocker Arm Shaft Assembly — Removal................229

Rocker Arm Shaft Assembly — Tear Down................231

Valve Assembly — Installation................233

Valve Assembly — Removal................235

Valve — Cleaning and Inspection................237

Valve — Clearance Adjustment................238

Valve — Grinding................242

Valve — Measurement................243

Valve — Recess Measurement................245

Valve Guide — Cleaning................247

Valve Guide — Knurling................248

Valve Guide — Measurement................249

Valve Rotator and Valve Keepers — Inspection................251

Valve Seat — Cleaning and Inspection................252

Valve Seat — Grinding and Measurement................253

Valve Seat Inserts — Installation................255

Valve Seat Inserts — Removal................256

Valve Spring — Inspection and Measurement................259

Group 030: Cylinder Block, Liners, Pistons and Rods Repair and Adjustment................147

Connecting Rod — Center-to-Center Bore Measurement................262

Connecting Rod — General Information................263

Connecting Rod and Cap — Inspection................265

Connecting Rod Bearing — Inspection and Measurement................267

Connecting Rod Bearing — Inspection and Measurement (Rod and Crankshaft in Engine)................269

Connecting Rod Cap Screw — Torque Procedure................271

Connecting Rod Pin Bore — Cleaning and Inspection................273

Connecting Rod Piston Pin Bushing — Installation................274

Connecting Rod Piston Pin Bushing — Removal................276

Cylinder Block — Cleaning and Inspection................277

Cylinder Block Components — Measurement................281

Cylinder Block O-ring — Installation................283

Cylinder Block, Piston, and Rod — Troubleshooting Guide................285

Cylinder Liner — Cleaning................287

Cylinder Liner — Installation................288

Cylinder Liner — Removal................291

Cylinder Liner — Standout Measurement................293

Cylinder Liner — Visual Inspection................297

Cylinder Liner Flange — Measurement................299

Cylinder Liner O-ring Bore — Cleaning................301

Cylinder Liner Packing — Installation................302

Piston — Cleaning................304

Piston — Visual Inspection................305

Piston and Connecting Rod Assembly — Assemble................306

Piston and Connecting Rod Assembly — Installation................308

Piston and Connecting Rod Assembly — Removal................312

Piston and Connecting Rod Assembly — Tear Down................315

Piston Spray Jet — Cleaning and Inspection................316

Piston Spray Jet — Installation................318

Piston Spray Jet — Removal................320

Piston Height — Measurement................322

Piston Pin and Bore — Inspection................323

Piston Pin and Connecting Rod Bushing — Inspection................325

Piston Protrusion — Measurement................327

Piston Rings — Installation................329

Piston Skirt — Measurement................331

Piston to Liner — Clearance Check................332

Group 040: Crankshaft, Main Bearings and Flywheel Repair and Adjustment................149

Auxiliary Drive Pulley — Installation................335

Auxiliary Drive Pulley — Removal................336

Crankshaft — End Play Check................337

Crankshaft — Grinding Specifications................339

Crankshaft — Inspection................340

Crankshaft — Installation................341

Crankshaft — Removal................346

Crankshaft Main Bearing Cap — Installation................348

Crankshaft Main Bearing Cap — Removal................353

Crankshaft Front Oil Seal — Installation................354

Crankshaft Front Oil Seal — Removal................355

Crankshaft Gear — Installation................356

Crankshaft Gear — Removal................358

Crankshaft Grinding — Guidelines................360

Crankshaft Journals and Bearing Assembly — Measurement................362

Crankshaft Main Bearing Cap — Line Bore Specifications................364

Crankshaft Main Bearing Cap — Oil Clearance Check................366

Crankshaft Rear Oil Seal — Installation................367

Crankshaft Rear Oil Seal — Removal................370

Crankshaft Thrust Bearing — Inspection................374

Crankshaft Timing Wheel — Installation................377

Crankshaft Timing Wheel — Removal................379

Crankshaft Pulley — Installation................380

Crankshaft Pulley — Removal................381

Flywheel — Inspection................383

Flywheel — Installation................384

Flywheel — Removal................386

Flywheel Face — Flatness Check................388

Flywheel Housing — Installation................389

Flywheel Housing — Removal................394

Flywheel Pilot Bearing Bore — Concentricity Check................396

Flywheel Ring Gear — Installation................397

Flywheel Ring Gear — Removal................398

Open Crankcase Ventilation System — Inspection................399

Open Crankcase Ventilation System — Installation................400

Open Crankcase Ventilation System — Removal................403

Group 050: Camshaft and Timing Gear Train Repair and Adjustment................150

Camshaft — Installation................407

Camshaft — Measure End Play................409

Camshaft — Removal................410

Camshaft — Visual Inspection................412

Camshaft and Upper Idler Gear — Timing................413

Camshaft Bushing — Replacement................415

Camshaft Follower — Inspection and Measurement................418

Camshaft Follower — Installation................419

Camshaft Follower — Removal................421

Camshaft Gear — Inspection................422

Camshaft Gear — Installation................423

Camshaft Gear — Removal................424

Camshaft Gear-Driven Auxiliary Drive Cover — Installation................425

Camshaft Gear-Driven Auxiliary Drive Cover — Removal................426

Camshaft Journals — Measurement................427

Camshaft Lobes — Height Measurement................429

Camshaft Thrust Plate — Measure Clearance and Thickness................431

Front Plate — Installation................432

Front Plate — Removal................434

Idler Gears — Measure End Play................436

Lower Idler Gear — Check and Replace Components................437

Lower Idler Gear — Installation................439

Lower Idler Gear — Removal................441

Timing Gear Cover — Installation................442

Timing Gear Cover — Removal................444

Timing Gears — Check Backlash................446

Upper Idler Gear — Check and Replace Components................448

Upper Idler Gear — Installation................451

Upper Idler Gear — Removal................452

Group 060: Lubrication System Repair and Adjustment................151

Dipstick Tube and Dipstick — Installation................458

Dipstick Tube and Dipstick — Removal................463

Oil Cooler Assembly — Installation................466

Oil Cooler Assembly — Removal and Inspection................469

Oil Fill Adapter — Installation................472

Oil Fill Adapter — Removal................473

Oil Filter Header — Installation................474

Oil Filter Header — Removal................476

Oil Pan — Installation................478

Oil Pan — Removal................480

Oil Pick-Up Tube — Installation................481

Oil Pick-Up Tube — Removal................482

Oil Pressure Regulating Valve — Installation................483

Oil Pressure Regulating Valve — Removal................485

Oil Pressure Regulating Valve Seat — Replacement................486

Oil Pump and Tube — Installation................488

Oil Pump and Tube — Removal................491

Group 070: Cooling System Repair and Adjustment................151

Belt Tension — Check................494

By-Pass Tube — Installation................496

By-Pass Tube — Removal................498

Coolant Heater — Servicing................499

Coolant Pump — Visual Inspection................501

Coolant Pump — Assemble................502

Coolant Pump — Tear Down................506

Coolant Pump — Installation................509

Coolant Pump — Removal................512

Cooling System — Air Bleeding................513

Cooling System — Deaeration................515

Fan (Fixed Speed Fan) — Installation................517

Fan (Fixed Speed Fan) — Removal................518

Oil Cooler Coolant Tubes — Installation................519

Oil Cooler Coolant Tubes — Removal................521

Thermostat and Housing — Installation................523

Thermostat and Housing — Removal................525

Group 080: Air Intake and Exhaust System Repair and Adjustment................152

Air Heater or Spacer — Installation................528

Air Heater or Spacer — Removal................530

Charge Air Cooler Outlet Elbow — Installation................532

Charge Air Cooler Outlet Elbow — Removal................533

Exhaust Manifold — Installation................534

Exhaust Manifold — Removal................536

Exhaust Throttle — Installation................537

Exhaust Throttle — Removal................539

Exhaust Throttle Bracket — Installation................541

Exhaust Throttle Bracket — Removal................542

Exhaust Throttle Coolant Return Line — Installation................543

Exhaust Throttle Coolant Return Line — Removal................545

Exhaust Throttle Coolant Supply Line — Installation................547

Exhaust Throttle Coolant Supply Line — Removal................549

Extending Turbocharger Life................551

Intake Manifold — Installation................554

Intake Manifold — Removal................556

Low Profile Turbocharger — Installation................557

Low Profile Turbocharger — Removal................559

Low Profile Turbocharger Exhaust Manifold — Installation................561

Low Profile Turbocharger Exhaust Manifold — Removal................564

Turbocharger — Break-In................566

Turbocharger — Failure Analysis................567

Turbocharger — Inspection................570

Turbocharger — Recommendations for Use................576

Wastegate Turbocharger Inlet Hose — Installation................577

Wastegate Turbocharger Inlet Hose — Removal................578

Wastegate Turbocharger — Installation................579

Wastegate Turbocharger — Removal................581

Wastegate Turbocharger Oil Drain Line — Installation................583

Wastegate Turbocharger Oil Drain Line — Removal................585

Wastegate Turbocharger Oil Supply Line — Installation................586

Wastegate Turbocharger Oil Supply Line — Removal................588

Group 090: Electronic Fuel System Repair and Adjustment................153

Electronic Injectors — Cleaning (In Engine)................591

Electronic Injectors — Installation................593

Electronic Injectors — Removal................597

Fuel Leak-Off Line — Installation................600

Fuel Leak-Off Line — Removal................603

Fuel System — Relieve Pressure................605

High-Pressure Common-Rail (HPCR) — Installation................606

High-Pressure Common-Rail (HPCR) — Removal................607

High-Pressure Common-Rail (HPCR) Heat Shield — Installation................608

High-Pressure Common-Rail (HPCR) Heat Shield — Removal................609

High-Pressure Fuel Pump — Disassembling and Reassembling................610

High-Pressure Fuel Pump — Installation................612

High-Pressure Fuel Pump — Removal................615

High-Pressure Fuel Lines — Installation................617

High-Pressure Fuel Lines — Removal................619

Injector Wiring Harness — Installation................710

Injector Wiring Harness — Removal................722

Low-Pressure Fuel Lines — Installation................625

Low-Pressure Fuel Lines — Removal................627

Low-Pressure Fuel Pump — Installation................629

Low-Pressure Fuel Pump — Removal................631

Pressure Limiter — Installation................633

Pressure Limiter — Removal................635

Fuel Filter Header — Installation................636

Fuel Filter Header — Removal................637

Primary Fuel Filter Element — Replace................638

Suction Control Valve — Installation................640

Suction Control Valve — Removal................642

Group 100: OEM Starting and Charging Systems Repair and Adjustment................154

Alternator — Installation................646

Alternator — Removal................648

Alternator — Lower Bracket — Installation................649

Alternator — Lower Bracket — Removal................651

Alternator — Upper Bracket — Installation................653

Alternator — Upper Bracket — Removal................654

Starter Motor — Installation................655

Starter Motor — Removal................657

Group 110: Electrical Engine Control Repair and Adjustment................154

Camshaft Position Sensor — Installation................660

Camshaft Position Sensor — Removal................662

Cold Start Aid Relay — Installation................663

Cold Start Aid Relay — Removal................667

Compressor Inlet Temperature Sensor — Installation................670

Compressor Inlet Temperature Sensor — Removal................671

Crankshaft Position Sensor — Installation................672

Crankshaft Position Sensor — Removal................674

Crankshaft Position Sensor and Harness Cover — Installation................676

Crankshaft Position Sensor and Harness Cover — Removal................677

DPF Differential Pressure Sensor — Installation................678

DPF Differential Pressure Sensor — Removal................681

Engine Control Unit (ECU) — Installation................683

Engine Control Unit (ECU) — Maintenance................685

Engine Control Unit (ECU) — Removal................686

Engine Coolant Temperature Sensor — Installation................687

Engine Coolant Temperature Sensor — Removal................689

Engine Oil Pressure Sensor — Installation................690

Engine Oil Pressure Sensor — Removal................691

Exhaust Filter Temperature Module — Installation................692

Exhaust Filter Temperature Module — Removal................694

Exhaust Manifold Pressure Sensor — Installation................695

Exhaust Manifold Pressure Sensor — Removal................698

Fuel Rail Pressure Sensor — Installation................700

Fuel Rail Pressure Sensor — Removal................703

Fuel Temperature Sensor — Installation................704

Fuel Temperature Sensor — Removal................705

Manifold Air Pressure (MAP) Sensor — Installation................706

Manifold Air Pressure (MAP) Sensor — Removal................707

Manifold Air Temperature (MAT) Sensor — Installation................708

Manifold Air Temperature (MAT) Sensor — Removal................709

Wiring Harness — Installation................710

Wiring Harness — Removal................722

Wiring Harness — Routing................733

Group 112: Connector Repair and Adjustment................735

Connector Repair and Adjustment................735

Installation of Repair Wire Assembly (RWA)................736

Repair AMP® Seal 16 - Type “A” Connectors................745

Repair AMP® Seal 16 - Type “B” Connectors................747

Repair AMP® Seal 16 - Type “C” Connectors................750

Repair Bosch Connectors................752

Repair DEUTSCH Connectors................754

Repair Metri-Pack™ Connectors................758

Repair WEATHER PACK® Connectors................760

Using High-Pressure Washing................761

Group 115: Aftertreatment Devices Repair and Adjustment................155

Diesel Particulate Filter Maintenance and Service................763

Diesel Oxidation Catalyst (DOC) — Cleaning................764

DPF Differential Pressure Sensor Manifold Fittings — Installation................767

DPF Differential Pressure Sensor Manifold Fittings — Removal................768

Exhaust Filter — Assemble................769

Exhaust Filter — Diesel Particulate Filter Ash Handling and Disposal................771

Exhaust Filter — Handling................772

Exhaust Filter — Tear Down and Inspection................774

Exhaust Filter — Cleaning................780

Exhaust Filter — Disposal................781

Exhaust Filter, Brackets, and Piping — Installation................782

Exhaust Filter, Brackets, and Piping — Removal................783

Section 03: Theory of Operation................784

Group 120: Base Engine Operation................784

Engine Sectional View Component Location Diagrams................789

General Engine Operation................791

General Engine Operation — Continued................793

Head Gasket Joint Construction and Operation................794

Group 123: Cooling System................784

Cooling System Component Location Diagrams................798

Cooling System Operation................800

Group 126: Lubrication System................784

Lubrication System Component Location Diagrams................803

Lubrication System Operation................805

Group 130: Electronic Fuel System................784

Electronic Fuel System Component Location Diagram 1................807

Electronic Fuel System Component Location Diagram 2................808

Electronic Fuel System Component Location Diagram 3................809

Electronic Injector (EI) Operation................810

High-Pressure Common-Rail (HPCR) Operation................815

High-Pressure Fuel Pump Operation................816

High-Pressure Fuel System Operation................817

Low-Pressure Fuel Pump Operation................818

Low-Pressure Fuel System Operation................819

Primary Fuel Filter Operation................822

Group 135: Air Intake and Exhaust System................784

Air Intake and Exhaust System Component Location Diagram 1................824

Air Intake and Exhaust System Component Location Diagram 2................825

Air Intake and Exhaust System Operation................826

Cold Start Aid Operation................828

Exhaust Throttle Operation................829

Wastegate Turbocharger Operation................830

Group 137: Aftertreatment System................784

Aftertreatment Component Location Diagram................832

Aftertreatment System Operation................833

Exhaust Filter Operation................834

Group 140: Electronic Control System................785

Analog Throttle................839

B5100 — Fuel Rail Pressure Sensor................840

B5101 — Engine Oil Pressure Sensor................842

B5102 — Exhaust Manifold Pressure Sensor................844

B5104 — Manifold Air Pressure (MAP) Sensor................846

B5109 — DPF Differential Pressure Sensor................848

B5204 — Exhaust Filter Temperature Module................849

B5206 — Manifold Air Temperature (MAT) Sensor................851

B5208 — Engine Coolant Temperature Sensor................853

B5209 — Fuel Temperature Sensor................855

B5214 — Intake Air Temperature (MAT) Sensor................857

B5301 — Crankshaft Position Sensor................859

B5302 — Camshaft Position Sensor................861

Barometric Air Pressure Sensor................863

Combination Throttle................864

Controller Area Network (CAN)................866

Cruise Control Operation................867

Digital Throttle................868

Electrical Component Location Diagram 1................870

Electrical Component Location Diagram 2................871

Electrical Component Location Diagram 3................872

Electrical Component Location Diagram 4................873

Electrical Component Location Diagram 5................874

Engine Control Unit (ECU) System Operation................875

Engine Control Unit (ECU) Temperature Sensor................878

Engine Derate and Shutdown Protection................879

Governor Droop Mode Selection................881

Measuring Pressure................882

Measuring Speed................883

Measuring Temperature................884

Pilot Injection Operation................885

Sensor Supply #1................886

Sensor Supply #2................887

Sensor Supply #3................888

Sensor Supply #4................889

Sensor Supply #5................890

Sensor Supply #6................891

Sensor Supply #7................892

Sensor Supply #8................893

Sensor Supply #9................894

Throttle Adjustments................895

Throttle Offset................896

Throttle Self-Calibration................897

Torque Speed Control (TSC)................898

Y5021 — Fuel Injector Harness................899

Y5002 — Suction Control Valve................901

Y5402 — Exhaust Throttle Actuator................903

Section 04: Diagnostics................905

Group 150: Observable Diagnostics and Tests................905

Abnormal Engine Noise................905

Coolant in Oil or Oil in Coolant................905

ECU Does Not Communicate with Powerview................905

ECU Does Not Communicate with Service ADVISOR................905

ECU Does Not Program with Service ADVISOR................905

Engine Coolant Temperature Below Normal................905

Engine Cranks and Will Not Start................905

Engine Does Not Develop Full Power................905

Engine Emits Excessive Black or Gray Exhaust Smoke................905

Engine Emits Excessive Blue Exhaust Smoke................905

Engine Emits Excessive White Exhaust Smoke................905

Engine Misfires or Runs Irregularly................905

Engine Will Not Crank................905

Excessive Fuel Consumption................905

Excessive Oil Carryover................905

Excessive Oil Consumption................905

Fuel in Coolant................905

Fuel in Oil................905

Group 155: Checks, Tests, and Procedures................905

Aftertreatment Verification Procedure................1102

Air in Fuel Check................1014

CAN Message Not Received................1016

CAN Message Received Error................1018

CAN Message Received Is Incorrect................1020

Carbon Removal Procedure................1023

Charge Air Cooler Test................1025

Cooling System Pressure Test................1027

Crankcase Pressure (Blow-By) Test................1030

Engine Cranking Speed Check................1036

Engine Oil Pressure Check................1038

Exhaust Condition Check................1039

Fuel Rail Cap and Plug Procedure................1050

Fuel Return Line (Leak off) Restriction Check................1052

Fuel Supply Quality Check................1053

Fuel System Bleeding................1055

High-Pressure Fuel System Check................1058

Low-Pressure Fuel System Check................1077

Mechanical Compression Test................1083

Primary CAN Diagnostic Procedure................1084

Problem Not Found Procedure................1091

Short to Voltage Procedure................1093

Terminal Test................1095

Thermostat — Testing................1099

Turbocharger Oil Seal Leak Check................1101

Verification Procedure................1102

Wastegate Turbocharger — Testing................1104

Wiggle Test................1105

Group 160: Diagnostic Instructions and Information................906

Clear Aftertreatment Latched DTC — Test Instructions................1107

Communication Error Test Instructions................1108

Connecting to Service ADVISOR................1109

Control Unit Information and Overview Test................1111

Cylinder Cutout Test Instructions................1113

Cylinder Electronic Compression Test Instructions................1116

Cylinder Misfire Test Instructions................1121

Data Points Used in Service ADVISOR................1123

Diagnostic Gauge — Active DTC Viewing Instructions................1135

Diagnostic Gauge — Data Parameters Viewing Instructions................1137

Diagnostic Gauge — Exhaust Filter Service Recovery Instructions................1140

Diagnostic Gauge — Stored DTC Clearing Instructions................1150

Diagnostic Gauge — Stored DTC Viewing Instructions................1154

Diagnostic Gauge — Stored DTC Viewing Instructions................1154

Diagnostic Test Box — Using................1156

Diagnostic Trouble Code Designations................1165

Digital Multimeter — Using................1169

DOC Calibration — Instructions................1171

DPF Calibration — Instructions................1172

Electrical Circuit Concepts................1173

Electrical Noise — Possible Causes................1179

Electronic Injector — Calibration Information................1180

Engine Control Unit (ECU) — Level Identification................1182

Engine Control Unit (ECU) — Donating this Engine’s ECU to be Used Elsewhere................1183

Engine Control Unit (ECU) — Replacing Current ECU with Another ECU................1187

Engine Control Unit (ECU) — Replacing Current ECU with Another ECU — Cannot Communicate with Current ECU................1189

Engine Control Unit (ECU) — Reprogramming Current ECU................1191

Engine Control Unit (ECU) — Reprogramming Instructions................1192

Engine Hours — Updating Instructions................1194

Engine Overspeed Verification Test................1196

ESM Operator Action Information Decoder — Instructions................1197

Exhaust Temperature Management Test Instructions................1198

Exhaust Throttle — Learn Value Reset Instructions................1199

Harness Diagnostic Mode Test................1200

Interactive Tests and Calibration Results — Printing, Exporting, or Saving Instructions................1202

Internal Data Monitor — Instructions................1203

Keep Electronic Control Unit Connectors Clean................1208

Load Profile Information Test — Instructions................1209

Lost ECU Data Reset Test................1211

Regeneration Abort Source Identification Test — Instructions................1212

Regeneration Failure — Possible Causes................1213

Service Regeneration Instructions................1215

Servicing Electronic Control Units................1217

Snapshot Instructions................1218

Software and Hardware Verification................1220

Trim Options Information................1223

View Non-Clearable DTCs — Test Instructions................1225

Welding Near Electronic Control Units................1226

Group 161: DTC SPN - 000001—000199................908

000028.03 - Digital Throttle Signal Out of Range High................908

000028.04 - Digital Throttle Signal Out of Range Low................908

000028.14 - Digital Throttle Inhibited................908

000029.03 - Secondary Analog Throttle Signal Out of Range High................908

000029.04 - Secondary Analog Throttle Signal Out of Range Low................908

000029.14 - Secondary Analog Throttle Inhibited................908

000091.03 - Primary Analog Throttle Signal Out of Range High................908

000091.04 - Primary Analog Throttle Signal Out of Range Low................908

000091.09 - Primary Analog Throttle Signal Erratic................908

000091.14 - Primary Analog Throttle Inhibited................908

000100.01 - Engine Oil Pressure Signal Extremely Low................908

000100.02 - Engine Oil Pressure is not Zero with Engine Stopped................908

000100.03 - Engine Oil Pressure Signal Out of Range High................908

000100.04 - Engine Oil Pressure Signal Out of Range Low................908

000100.18 - Engine Oil Pressure Signal Moderately Low................908

000102.00 - Manifold Air Pressure Signal Extremely High................908

000102.03 - Manifold Air Pressure Signal Out of Range High................908

000102.04 - Manifold Air Pressure Signal Out of Range Low................908

000102.07 - Manifold Air Pressure Signal In Range Invalid................908

000102.16 - Manifold Air Pressure Signal Moderately High................908

000105.00 - Manifold Air Temperature Signal Extremely High................908

000105.03 - Manifold Air Temperature Signal Out of Range High................908

000105.04 - Manifold Air Temperature Signal Out of Range Low................908

000105.15 - Manifold Air Temperature Signal Slightly High................908

000105.16 - Manifold Air Temperature Signal Moderately High................908

000108.02 - Barometric Pressure Signal Invalid................908

000108.07 - Barometric Pressure Signal Mismatch................908

000110.00 - Engine Coolant Temperature Signal Extremely High................908

000110.03 - Engine Coolant Temperature Signal Out of Range High................908

000110.04 - Engine Coolant Temperature Signal Out of Range Low................908

000110.15 - Engine Coolant Temperature Signal Slightly High................908

000110.16 - Engine Coolant Temperature Signal Moderately High................908

000110.17 - Engine Coolant Temperature Signal Slightly Low................909

000137.00 - Auxiliary Gauge Pressure Reading Extremely High................909

000137.01 - Auxiliary Gauge Pressure Reading Extremely Low................909

000157.01 - Fuel Rail Pressure Signal Extremely Low................909

000157.03 - Fuel Rail Pressure Signal Out of Range High................909

000157.04 - Fuel Rail Pressure Signal Out of Range Low................909

000157.16 - Fuel Rail Pressure Signal Moderately High................909

000157.17 - Fuel Rail Pressure Signal Slightly Low................909

000157.18 - Fuel Rail Pressure Signal Moderately Low................909

000158.12 - ECU Power Down Error................909

000160.02 - Primary Shaft Speed Invalid................909

000168.01 - Unswitched Battery Voltage Extremely Low................909

000168.16 - Unswitched Battery Voltage Moderately High................909

000168.18 - Unswitched Battery Voltage Moderately Low................909

000174.00 - Fuel Temperature Signal Extremely High................909

000174.03 - Fuel Temperature Signal Out Of Range High................909

000174.04 - Fuel Temperature Signal Out Of Range Low................909

000174.16 - Fuel Temperature Signal Moderately High................909

000189.31 - Engine Speed Derate Condition Exists................909

000190.00 - Engine Speed Extremely High................909

000190.16 - Engine Speed Moderately High................909

Group 162: DTC SPN - 000200—000699................909

000237.02 - VIN Security Data Invalid................909

000237.13 - VIN Option Code Security Data Conflict................909

000237.31 - VIN Security Data Missing................909

000443.00 - Auxiliary Gauge Pressure #2 Reading Extremely High................909

000443.01 - Auxiliary Gauge Pressure #2 Reading Extremely Low................909

000611.03 - Injector Drive Shorted to Voltage Source................909

000611.04 - Injector Drive Shorted to Ground................909

000629.11 - ECU Binary Input Error................909

000629.12 - ECU EEPROM Error................909

000629.13 - ECU Boot Block Error................909

000636.02 - Camshaft Position Signal Invalid................909

000636.05 - Camshaft Position Circuit Has High Resistance................910

000636.06 - Camshaft Position Circuit Has Low Resistance................910

000636.08 - Camshaft Position Signal Missing................910

000636.10 - Camshaft Position Signal Rate of Change Abnormal................910

000637.02 - Crankshaft Position Signal Invalid................910

000637.05 - Crankshaft Position Circuit Has High Resistance................910

000637.06 - Crankshaft Position Circuit Has Low Resistance................910

000637.07 - Crankshaft Position and Camshaft Position Signals Out of Sync................910

000637.08 - Crankshaft Position Signal Missing................910

000637.10 - Crankshaft Position Signal Rate of Change Abnormal................910

000640.11 - External Engine Protection Activated................910

000640.31 - External Derate Activated................910

000651.02 - Injector #1 Part Number Data Invalid................910

000651.05 - Injector #1 Circuit Has High Resistance................910

000651.06 - Injector #1 Circuit Has Low Resistance................910

000651.13 - Injector #1 Calibration Fault................910

000651.18 - Injector #1 Not Responding................910

000652.02 - Injector #2 Part Number Data Invalid................910

000652.05 - Injector #2 Circuit Has High Resistance................910

000652.06 - Injector #2 Circuit Has Low Resistance................910

000652.13 - Injector #2 Calibration Fault................910

000652.18 - Injector #2 Not Responding................910

000653.02 - Injector #3 Part Number Data Invalid................910

000653.05 - Injector #3 Circuit Has High Resistance................910

000653.06 - Injector #3 Circuit Has Low Resistance................910

000653.13 - Injector #3 Calibration Fault................910

000653.18 - Injector #3 Not Responding................910

000676.05 - Cold Start Aid Drive Circuit Has High Resistance................910

000676.06 - Cold Start Aid Drive Circuit Has Low Resistance................910

000676.31 - Cold Start Aid Signal Received When Not Expected................910

000695.19 - Unapproved Engine Speed Request................910

Group 163: DTC SPN - 000700—001999................910

000876.05 - A/C System Drive Circuit Has High Resistance................910

000876.06 - A/C System Drive Circuit Has Low Resistance................911

000970.31 - External Shutdown Commanded................911

000971.31 - External Derate Commanded................911

000974.03 - Remote Analog Throttle Signal Out of Range High................911

000974.04 - Remote Analog Throttle Signal Out of Range Low................911

001069.31 - Calculated Tire Size Is Out Of Range................911

001110.31 - Engine Protection System Activated................911

001136.00 - ECU Temperature Signal Extremely High................911

001136.02 - ECU Temperature Signal Invalid................911

001136.16 - ECU Temperature Signal Moderately High................911

001172.03 - Intake Air Temperature Signal Out of Range High................911

001172.04 - Intake Air Temperature Signal Out of Range Low................911

001180.00 - Calculated Turbocharger Turbine Inlet Temperature Extremely High................911

001180.16 - Calculated Turbocharger Turbine Inlet Temperature Moderately High................911

001209.03 - Exhaust Manifold Pressure Signal Out of Range High................911

001209.04 - Exhaust Manifold Pressure Signal Out of Range Low................911

001209.07 - Exhaust Manifold Pressure Mismatch................911

001321.06 - Engine Starter Solenoid Lockout Relay Circuit Has Low Resistance................911

001321.09 - Engine Starter Solenoid Control Request Signal Missing................911

001321.16 - Engine Starter Engaged for Too Long................911

001321.31 - Engine Speed Zero with Starter Solenoid Energized................911

001347.01 - Suction Control Valve Sticking and Fuel Rail Pressure Extremely Low................911

001347.05 - Suction Control Valve Circuit Has High Resistance................911

001347.06 - Suction Control Valve Circuit Has Low Resistance................911

001347.16 - Suction Control Valve Sticking and Fuel Rail Pressure Moderately High................911

001347.18 - Suction Control Valve Sticking and Fuel Rail Pressure Slightly Low................911

001550.05 - Air Conditioner Compressor Current Low................911

001550.06 - Air Conditioner Compressor Current High................911

001569.31 - Engine Power Derate Condition Exists................911

Group 164: DTC SPN - 002000—002299................911

002002.09 - No CAN Message Received From Source Address 2................911

002002.14 - Incorrect CAN Message Received From Source Address 2................911

002002.19 - Communication Error with Source Address 2................911

002003.09 - No CAN Message Received From Source Address 3................912

002003.14 - Incorrect CAN Message Received From Source Address 3................912

002003.19 - Communication Error with Source Address 3................912

002004.09 - No CAN Message Received From Source Address 4................912

002004.14 - Incorrect CAN Message Received From Source Address 4................912

002004.19 - Communication Error with Source Address 4................912

002005.09 - No CAN Message Received From Source Address 5................912

002005.14 - Incorrect CAN Message Received From Source Address 5................912

002005.19 - Communication Error with Source Address 5................912

002006.09 - No CAN Message Received From Source Address 6................912

002006.14 - Incorrect CAN Message Received From Source Address 6................912

002006.19 - Communication Error with Source Address 6................912

002007.09 - No CAN Message Received From Source Address 7................912

002007.14 - Incorrect CAN Message Received From Source Address 7................912

002007.19 - Communication Error with Source Address 7................912

002008.09 - No CAN Message Received From Source Address 8................912

002008.14 - Incorrect CAN Message Received From Source Address 8................912

002008.19 - Communication Error with Source Address 8................912

002009.09 - No CAN Message Received From Source Address 9................912

002009.14 - Incorrect CAN Message Received From Source Address 9................912

002009.19 - Communication Error with Source Address 9................912

002010.09 - No CAN Message Received From Source Address 10................912

002010.14 - Incorrect CAN Message Received From Source Address 10................912

002010.19 - Communication Error with Source Address 10................912

002011.09 - No CAN Message Received From Source Address 11................912

002011.14 - Incorrect CAN Message Received From Source Address 11................912

002011.19 - Communication Error with Source Address 11................912

002012.09 - No CAN Message Received From Source Address 12................912

002012.14 - Incorrect CAN Message Received From Source Address 12................912

002012.19 - Communication Error with Source Address 12................912

002013.09 - No CAN Message Received From Source Address 13................912

002013.14 - Incorrect CAN Message Received From Source Address 13................912

002013.19 - Communication Error with Source Address 13................912

002014.09 - No CAN Message Received From Source Address 14................913

002014.14 - Incorrect CAN Message Received From Source Address 14................913

002014.19 - Communication Error with Source Address 14................913

002015.09 - No CAN Message Received From Source Address 15................913

002015.14 - Incorrect CAN Message Received From Source Address 15................913

002015.19 - Communication Error with Source Address 15................913

002016.09 - No CAN Message Received From Source Address 16................913

002016.14 - Incorrect CAN Message Received From Source Address 16................913

002016.19 - Communication Error with Source Address 16................913

002017.09 - No CAN Message Received From Source Address 17................913

002017.14 - Incorrect CAN Message Received From Source Address 17................913

002017.19 - Communication Error with Source Address 17................913

002018.09 - No CAN Message Received From Source Address 18................913

002018.14 - Incorrect CAN Message Received From Source Address 18................913

002018.19 - Communication Error with Source Address 18................913

002019.09 - No CAN Message Received From Source Address 19................913

002019.14 - Incorrect CAN Message Received From Source Address 19................913

002019.19 - Communication Error with Source Address 19................913

002020.09 - No CAN Message Received From Source Address 20................913

002020.14 - Incorrect CAN Message Received From Source Address 20................913

002020.19 - Communication Error with Source Address 20................913

002021.09 - No CAN Message Received From Source Address 21................913

002021.14 - Incorrect CAN Message Received From Source Address 21................913

002021.19 - Communication Error with Source Address 21................913

002022.09 - No CAN Message Received From Source Address 22................913

002022.14 - Incorrect CAN Message Received From Source Address 22................913

002022.19 - Communication Error with Source Address 22................913

002023.09 - No CAN Message Received From Source Address 23................913

002023.14 - Incorrect CAN Message Received From Source Address 23................913

002023.19 - Communication Error with Source Address 23................913

002024.09 - No CAN Message Received From Source Address 24................913

002024.14 - Incorrect CAN Message Received From Source Address 24................913

002024.19 - Communication Error with Source Address 24................913

002025.09 - No CAN Message Received From Source Address 25................914

Section 05: Tools and Other Materials................2987

Group 170: Special Tools................2875

DFRG9................2881

DFRG11................2883

75240................2885

D01003AA................2886

D01045AA................2887

D01168AA................2888

D01200AA................2889

D01218AA................2890

D01300AA................2891

D05012ST-A................2892

D05104ST................2893

D15001NU................2894

D17015BR................2895

D17024BR................2896

D17527CI................2897

J-35616-20................2898

JD248A................2899

JD254A................2900

JD262A................2901

JDE83................2902

JDE85................2903

JDE138................2904

JDE41296................2905

JDG22................2906

JDG23................2907

JDG360................2908

JDG361................2909

JDG362................2910

JDG363................2911

JDG364................2912

JDG410................2913

JDG451................2914

JDG529................2915

JDG536................2916

JDG675................2917

JDG676................2918

JDG678................2919

JDG680................2920

JDG698A................2921

JDG739B................2922

JDG777................2923

JDG782A................2924

JDG820................2925

JDG839................2926

JDG1145................2927

JDG1449................2928

JDG1571................2929

JDG1649A................2930

JDG1923A................2931

JDG10015................2932

JDG10205................2933

JDG10233................2934

JDG10243................2935

JDG10259................2936

JDG10261................2937

JDG10273................2938

JDG10446................2939

JDG10447................2940

JDG10452................2941

JDG10453................2942

JDG10456................2943

JDG10457................2944

JDG10460................2945

JDG10461................2946

JDG10464................2947

JDG10465................2948

JDG10466................2949

JDG10539A................2950

JDG10631................2951

JDG10824................2952

JDG11005................2953

JDG11019................2954

JDG11100A................2955

JDG11205................2956

JDG11233................2957

JDG11260................2958

JDG11263................2959

JDG11409................2961

JDG11413................2962

JDG11772................2963

JDG11790................2964

JDG11791................2965

JDG11864................2966

JT01682A................2967

JT03115................2968

JT03513C................2969

JT05470................2970

JT05480................2973

JT05697A................2974

JT05719................2975

JT05993................2976

JT07042................2977

JT07253................2978

JT07306................2979

JT30040B................2980

JT30041A................2981

JT30042................2982

KJD10164................2983

RE523854................2984

Group 180: Lubricants, Sealants, and Other Materials................2987

Other Materials................2987

Section 06: Specifications................2989

Group 200: Repair and General OEM Specifications................2989

Metric Bolt and Screw Torque Values................2992

Unified Inch Bolt and Screw Torque Values................2994

Group 210: Diagnostic Specifications................2989

2.9 L Engine Schematic 1................2998

2.9 L Engine Schematic 2................3000

2.9 L Wiring Diagram 1................3003

2.9 L Wiring Diagram 2................3005

2.9 L Wiring Diagram 3................3007

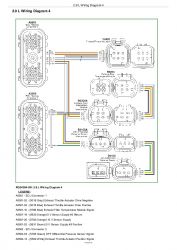

2.9 L Wiring Diagram 4................3009

2.9 L Wiring Diagram 5................3011

2.9 L Wiring Diagram 6................3013

2.9 L Wiring Diagram 7................3016

2.9 L Wiring Diagram 8................3018

2.9 L Wiring Diagram 9................3020

Engine Coolant Temperature and Fuel Temperature Sensor Characteristics................3022

Manifold Air Temperature Sensor Characteristics................3023

OEM Engines - Derate Specifications................3024

Connector and Wire Splice Location Diagrams................3028

John Deere 3029 Diesel Engine - Level 23 ECU Component Technical Manual (CTM120619)