John Deere PowerTech 13.5L OEM Diesel Engines Base Engine Repair Component Technical Manual (CTM415)

Catalog:

Model:

John Deere PowerTech™ 13.5L OEM Diesel Engines Base Engine Repair - (Worldwide Edition) Component Technical Manual (including maintenance, overhaul, disassembling & assembling, adjustment, tune-up, operation, inspecting, diagnosis & troubleshooting…) is divided into different sections. Each section covers a specific component or system with detailed illustrations. A table of contents is placed at the beginning of each section. Pages are easily found by category, and each page is expandable for great detail. The printer-ready PDF documents work like a charm on all kinds of devices.

This manual contains high quality images, circuit diagrams, instructions to help you to maintenance, troubleshoot, diagnose, and repair. This document is printable, without restrictions, contains searchable text, bookmarks, crosslinks for easy navigation.

CTM415 English - PowerTech™ 13.5L OEM Diesel Engines Base Engine Repair - (Worldwide Edition) Component Technical Manual (CTM).pdf

ctm418 German - PowerTech™ 13,5-l-OEM-Dieselmotoren Reparatur des Grundmotors -: (Weltweite Ausgabe).pdf

TABLE OF CONTENTS

Section 01: General Information................20

Group 000: Safety................20

Avoid Heating Near Pressurized Fluid Lines................24

Avoid High-Pressure Fluids................25

Avoid Hot Exhaust................26

Avoid Static Electricity Risk When Refueling................27

Construct Dealer-Made Tools Safely................29

Decommissioning — Proper Recycling and Disposal of Fluids and Components................30

Follow Safety Instructions................31

Handle Agricultural Chemicals Safely................32

Handle Fluids Safely—Avoid Fires................34

Handling Batteries Safely................35

Illuminate Work Area Safely................37

Install All Guards................38

Live With Safety................39

Park Machine Safely................40

Practice Safe Maintenance................41

Precautions for Welding................43

Prepare for Emergencies................45

Prevent Acid Burns................46

Prevent Battery Explosions................48

Prevent Machine Runaway................49

Protect Against High Pressure Spray................50

Protect Against Noise................51

Recognize Safety Information................52

Remove Paint Before Welding or Heating................53

Replace Safety Signs................54

Service Cooling System Safely................55

Service Machines Safely................56

Stay Clear of Rotating Drivelines................57

Support Machine Properly................58

Understand Signal Words................59

Use Proper Lifting Equipment................60

Use Proper Tools................61

Use Steps and Handholds Correctly................62

Wait Before Opening High-Pressure Fuel System................579

Wear Protective Clothing................64

Work in Clean Area................65

Work In Ventilated Area................66

Group 001: Engine Identification and Applications................21

Engine Model Designation................69

Engine Serial Number Plate Information................71

Engine Option Code Label................72

Group 002: Fuels, Lubricants and Coolant................21

Diesel Fuel................75

Diesel Fuel Additive Products................77

BioDiesel Fuel................78

Minimizing the Effect of Cold Weather on Diesel Engines................80

Handling and Storing Diesel Fuel................82

Lubricity of Diesel Fuel................83

Testing Diesel Fuel................84

Fuel Filters................85

Engine Oil and Filter Service Intervals................86

Diesel Engine Oil — Tier 3 and Stage III................87

Diesel Engine Break-In Oil — Non-Emissions Certified and Certified Tier 1, Tier 2, Tier 3, Stage I, Stage II, and Stage III................89

Oil Filters................91

Grease................92

Alternative and Synthetic Lubricants................93

Lubricant Storage................94

Mixing of Lubricants................95

Diesel Engine Coolant (engine with wet sleeve cylinder liners)................96

Supplemental Coolant Additives................98

Operating in Warm Temperature Climates................99

Additional Information About Diesel Engine Coolants and John Deere LIQUID COOLANT CONDITIONER................100

Diesel Engine Coolant................102

Testing Diesel Engine Coolant................103

Drain Intervals for Diesel Engine Coolant................104

Section 02: Repair and Adjustments................105

Group 010: Engine Rebuild Guide, Break-In and Tune-Up................105

Engine Overhaul Guidelines................113

Engine Repair Stand................114

Safety Precautions................115

Disconnect Turbocharger Oil Inlet Line................116

Install Adapter on Repair Stand................118

Engine Lifting Procedure................119

Mount Engine on Repair Stand................121

Clean Engine................123

6135 Engine Disassembly Sequence................105

Sealant Application Guidelines................127

6135 Engine Assembly Sequence................105

Engine Break-In Guidelines................132

Perform Engine Break-In................133

Check Crankcase Ventilation System................135

Check Air Intake System................136

Check Exhaust System................138

Check and Service Cooling System................139

Check Electrical System................140

Group 020: Cylinder Head and Valves................105

Remove and Install Rocker Arm Cover................144

Clean and Inspect Crankcase Ventilation Assembly................146

Replace Rocker Arm Cover Gasket................147

Check and Adjust Valve Assembly Clearances and Injector Preload................148

Remove Rocker Arm Assembly................157

Remove Cylinder Head................159

Diagnosing Head Gasket Joint Failures................163

Head Gasket Inspection and Repair Sequence................165

Disassemble and Inspect Rocker Arms and Shaft Assembly................167

Preliminary Cylinder Head and Valve Checks................169

Assemble Rocker Arms and Shaft Assembly................171

Check Valve Height in Relation to Head Surface (Valve Recess)................172

Remove Valve Assembly................173

Inspect and Measure Valve Springs................175

Inspect Valve Rotators................176

Clean, Inspect, and Measure Valves................177

Grind Valves................178

Clean and Inspect Cylinder Head................179

Check Cylinder Head Flatness................181

Measure Cylinder Head Thickness................182

Measure Valve Guide ID................183

Replace Valve Guides................184

Clean and Inspect Valve Seats................186

Valve Seat — Grinding................187

Remove Valve Seat Inserts................189

Measure Valve Seat Bore in Cylinder Head................190

Install Valve Seat Inserts................191

Install Valves................192

Replace Unit Injector Sleeve in Cylinder Head Using JDG981................732

Replace Unit Injector Sleeve in Cylinder Head Using JDG1184................742

Remove Unit Injector Sleeve Using JDG10014................746

Clean and Inspect Top Deck of Cylinder Block................213

Measure Cylinder Liner Standout (Height Above Block)................241

Install Cylinder Head................216

Torque-Turn Cylinder Head Cap Screws................218

Install Rocker Arm Assembly................221

Complete Final Assembly for Cylinder Head Installation................225

Group 030: Cylinder Block, Liners, Pistons, and Rods................106

Remove and Install Cylinder Block Front Plate................229

Preliminary Liner, Piston, and Rod Checks................232

Connecting Rods—General Information................234

Remove Piston Spray Jets................235

Remove Pistons and Connecting Rods................237

Measure Cylinder Liner Standout (Height Above Block)................241

Remove Cylinder Liners Using D01062AA or D01073AA Cylinder Liner Puller................243

Remove Cylinder Liners Using JDG1145 Cylinder Liner Service Set................245

Visually Inspect Cylinder Liners................248

Deglaze Cylinder Liners................251

Clean Cylinder Liners................252

Cylinder Liner Manufacturing Date Code Explanation................253

Disassemble Piston/Rod Assembly and Clean Piston................255

Check Piston Oil Control Ring Groove Wear................257

Inspect Piston Pin and Pin Bore in Piston................258

Determine Piston-to-Liner Clearance................260

Measure Liner Flange Thickness................262

Inspect and Measure Connecting Rod Bearings................263

Inspect Connecting Rod and Cap................265

Inspect Piston Pins and Rod Bushings................269

Complete Disassembly of Cylinder Block (If Required)................271

Inspect and Clean Cylinder Block................273

Cylinder Block — Inspect and Reclaim................275

Cylinder Block — Measurements................289

Install Cylinder Liner Shim................290

Install Cylinder Liner O-Rings and Packings................291

Install Cylinder Liners................293

Assemble Pistons and Connecting Rods................295

Install Pistons and Connecting Rods................297

Torque-Turn Connecting Rod Cap Screws................301

Check Engine Rotation for Excessive Tightness................303

Install Piston Spray Jets................304

Measure Piston Protrusion................306

Complete Final Assembly................383

Group 040: Crankshaft, Main Bearings, and Flywheel................107

Crankshaft Rubber Damper Torque Sequence................310

Inspect Crankshaft Vibration Damper................311

Check Crankshaft End Play................313

Remove Crankshaft Rubber Damper and Pulley................314

Remove Viscous Damper and Front Crankshaft Oil Seal................316

Remove Timing Gear Cover................319

Check Flywheel Housing Face Runout................321

Check Flywheel Face Flatness................323

Remove Flywheel................324

Inspect and Repair Flywheel................325

Replace Flywheel Ring Gear................326

Remove and Install Flywheel Housing................327

Install Flywheel................329

Remove Rear Crankshaft Oil Seal and Housing Assembly................332

Crankshaft Unitized Rear Oil Seal — Removal................335

Crankshaft Unitized Rear Oil Seal and Housing — Installation................337

Crankshaft and Main Bearing Failure Analysis................342

Remove Crankshaft Main Bearings................343

Check Main Bearing-to-Journal Oil Clearance................345

Remove Crankshaft................346

Inspect Crankshaft................348

Measure Assembled ID of Bearings and OD of Crankshaft Journals................350

Measure Assembled ID of Main Bearing Caps (Without Bearings)................351

Replace Crankshaft Drive Gear................352

Inspect Thrust Bearings................354

Thrust Bearing New Part Specifications................355

Install Main and Thrust Bearing Inserts in Block................356

Install Crankshaft................358

Install Crankshaft Rear Oil Seal Housing................362

Install Crankshaft Rear Oil Seal and Wear Sleeve Assembly................364

Install Timing Gear Cover................366

Install Crankshaft Rubber Damper and Front Oil Seal................372

Install Viscous Damper Assembly and Front Oil Seal................377

Complete Final Assembly................383

Group 050: Camshaft and Timing Gear Train................108

Camshaft Timing Pin................385

Check and Adjust Camshaft-to-Crankshaft Timing................386

Adjust Front Timing Gear Backlash Using JDG993................735

Adjust Front Timing Gear Backlash Without Using JDG993................735

Remove and Install Camshaft................399

Replace Fuel Supply Pump Drive Pin................406

Visually Inspect Camshaft and Roller Followers................407

Inspect and Measure Camshaft Bushing ID and Journal OD................408

Measure Camshaft Lobe Lift Height................409

Inspect Camshaft Position Sensor Lobe................410

Replace Camshaft Bushings................411

SAE “A” (Front) and SAE “B” (Rear) Auxiliary Drive Assembly................417

SAE B Rear Auxiliary Drive — Removal and Installation................419

Align SAE “A” Front Auxiliary Drive Adapter................421

Group 060: Lubrication System................109

Oil Filter and Oil Conditioning Housing Assembly................425

Remove Oil Filter and Valve Housing/Oil Cooler Cover and Valve Housing................427

Inspect and Replace Oil Filter Adapter................428

Remove, Inspect, and Install Oil Pressure Regulating Valve................429

Remove, Inspect, and Install Oil Cooler and Oil Filter Bypass Valves................430

Remove, Inspect, and Install Oil Pressure Relief Valve................432

Remove, Clean, and Inspect Engine Oil Cooler................433

Install Oil Cooler/Oil Filter Valve Housing Assembly or Oil Cooler Cover/Valve Housing Assembly................436

Remove Engine Oil Pump................439

Clean and Inspect Oil Pump and Drive Gear................441

Install Engine Oil Pump................442

Remove Engine Oil Pan................445

Remove and Install Oil Pickup Tube................446

Install Engine Oil Pan................447

Oil Dipstick Tube Assembly — Installation................451

Oil Dipstick Tube Assembly — Removal................454

Group 070: Cooling System................109

Replace Bearings in Fan Drive Assembly................459

Inspect and Check Belt Tensioner Spring Tension................463

Replace Belt Tensioner Assembly................465

Remove Coolant Pump................467

Clean and Inspect Coolant Pump Parts................469

Install Coolant Pump................471

Remove and Install Thermostat Cover and Thermostats................472

Test Thermostat Opening Temperature................474

Remove and Install Thermostat Housing and Coolant Tubes................476

Remove and Install Coolant Heater—if Equipped................478

Bleed Air from Coolant System................480

Group 080: Air Intake and Exhaust System................110

Extending Turbocharger Life................485

Remove and Install Variable Geometry Turbocharger Actuator................488

Remove and Install Actuator Linkage................490

Remove Turbocharger................494

Turbocharger — Failure Analysis................499

Turbocharger Seven-Step Inspection................502

Perform Radial Bearing Clearance Test................508

Turbocharger — Repair................510

Prelube Turbocharger................511

Install Turbocharger................512

Turbocharger Break-In................517

Recommendations for Turbocharger Use................518

Remove, Inspect, and Install EGR Cooler................519

Exhaust Manifold — Remove................535

Exhaust Manifold — Install................536

Remove, Inspect, and Install Intake Manifold................530

Remove, Inspect, and Install EGR Valve (Tier 3/Stage III A)................532

Group 081: Air Intake and Exhaust System — PowerTech™ E Engines................110

Exhaust Manifold — Remove................535

Exhaust Manifold — Install................536

Turbocharger — Remove................538

Turbocharger — Install................540

Air Intake Manifold — Remove................543

Air Intake Manifold — Install................544

Group 082: Air Intake and Exhaust System — Marine Engines................111

Air Intake Manifold (Marine) — Removal................552

Air Intake Manifold (Marine) — Installation................558

Exhaust Manifold (Marine) — Removal................565

Exhaust Manifold (Marine) — Installation................568

Turbocharger (Marine) — Removal................571

Turbocharger (Marine) — Installation................574

Group 090: Fuel System................579

Fuel System................579

Group 100: Starting and Charging Systems................111

Remove and Install Alternator (OEM Engines)................582

Remove and Install Starter Motor (OEM Engines)................584

Section 03: Theory of Operation................585

Group 120: Base Engine Operation — PowerTech Plus................585

General Engine Operation................611

Lubrication System Operation................614

Cooling System Operation................617

Fuel System Theory of Operation................620

Head Gasket Joint Construction and Operation................621

Intake and Exhaust System Operation................623

Exhaust Gas Recirculator (EGR) Exhaust Gas Recirculator (EGR) & Variable Geometry Turbocharger (VGT) Operation{pgNO}585 Variable Geometry Turbocharger (VGT) Operation................602

Turbocharger Operation................624

How the Turbocharger is Lubricated................626

Group 121: Base Engine Operation — PowerTech & PowerTech E................585

General Engine Operation................611

Lubrication System Operation................614

Cooling System Operation................617

Fuel System Theory of Operation................620

Head Gasket Joint Construction and Operation................621

Intake and Exhaust System Operation................623

Turbocharger Operation................624

How the Turbocharger is Lubricated................626

Section 04: Diagnostics................627

Group 150: Observable Diagnostics and Tests................627

About this Section of the Manual................629

13.5L - L1 - Excessive Oil Consumption................627

13.5L - L2 Engine Oil Pressure High................627

13.5L - L3 - Engine Oil Pressure Low................627

13.5L - L4 - Fuel in Oil................627

13.5L - L5 - Soot or Sludge in the Oil................627

13.5L - C1 - Engine Coolant Temperature Above Normal................627

13.5L - C2 - Engine Coolant Temperature Below Normal................627

13.5L Engines - C3 - Coolant in Oil or Oil in Coolant................627

13.5L Engines - C4 - Coolant Leaking from Weep Hole................627

Dynamometer Test................642

Check Cylinder Compression................643

Engine Oil Consumption................646

Check Engine Oil Pressure................647

Check for Excessive Engine Crankcase Pressure (Blow-By) (Base Pressure)................648

Check for Turbocharger Oil Seal Leak................659

Inspect Thermostat and Test Opening Temperature................660

Cooling System Pressure Test................662

Charge Air Cooler Test................665

Check for Head Gasket Failures................667

Check Intake Manifold Pressure (Turbo Boost)................670

Check Intake Manifold Pressure (Turbo Boost) — Fix Geometry Turbocharger................671

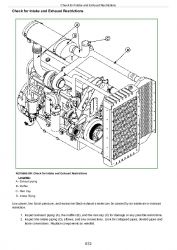

Check for Intake and Exhaust Restrictions................672

Check for Intake Air Leaks................674

Check for Exhaust Air Leaks................676

Check Camshaft-to-Crankshaft Timing................677

Check Crankshaft Position Sensor Depth................679

Check Engine Cranking Speed................681

EGR Cooler Test................682

Excessive Engine Vibration................683

Section 05: Tools and Other Materials................774

Group 170: Special Tools................687

75240................687

D01062AA................692

D01168AA................693

D01200AA................694

D01218AA................695

D01300AA................696

D05012ST-A................697

D05104ST................698

D05223ST................699

D01073AA................700

D17006BR................701

D17015BR................702

D17024BR................703

D17525CI................704

D17526CI................705

D17527CI................706

DFRG3................707

DFRG4................709

DFRG9................710

DFRG11................712

JDE41296................714

JDG164A................715

JDG451................716

JDG782A................717

JDG820................718

JDG839................719

JDG967................720

JDG968................721

JDG969A................722

JDG970B................723

JDG971................724

JDG972................725

JDG973................726

JDG974A................727

JDG975................728

JDG976................729

JDG977................730

JDG978................731

JDG981................732

JDG981-1................733

JDG982A................734

JDG993................735

JDG996................736

JDG1020................737

JDG1069................738

JDG1144................739

JDG1145................740

JDG1167................741

JDG1184................742

JDG1333................743

JDG1334................744

JDG1847................745

JDG10014................746

JDG10194................747

JDG10199................748

JDG10200................749

JDG10246A................750

JDG10249................751

JDG10357B................752

JDG10539A................753

JDG10668................754

JDG10996................755

JDG10997................756

JDG11008................757

JDG11056................758

JDG11084................759

JDG11334P3................760

JDG11373................761

JDG11374................762

JDG11544................763

JDG11831................764

JDG11860................765

JDG11864................766

JT01674A................767

JT05412................768

JT05697A................769

JT05993................770

JT07336................771

Group 180: Lubricants, Sealants, and Other Materials................774

Other Materials................774

Section 06: Specifications................776

Group 200: Repair and General OEM Specifications................776

General OEM Engine Specifications................778

Unified Inch Bolt and Screw Torque Values................779

Metric Bolt and Screw Torque Values................781

Engine Rebuild Guide, Break-In and Tune-Up (Group 010) Specifications................783

Cylinder Head and Valves (Group 020) Specifications................784

Cylinder Block, Liners, Pistons and Rods (Group 030) Specifications................787

Crankshaft, Main Bearings and Flywheel (Group 040) Specifications................790

Camshaft and Timing Gear Train (Group 050) Specifications................792

Lubrication System (Group 060) Specifications................793

Cooling System (Group 070) Specifications................795

Air Intake and Exhaust System (Group 080) Specifications — Variable Geometry Turbocharger................796

Air Intake and Exhaust System (Group 081) Specifications — Fixed Geometry Turbocharger................797

Starting and Charging Systems (Group 100) Specifications................798

Group 210: Diagnostic Specifications................776

Observable Diagnostics and Test Specifications................800

Dynamometer Test Specifications (OEM Engines)................801

Intake Manifold Pressure (Turbocharger Boost) Specifications................804

John Deere PowerTech 13.5L OEM Diesel Engines Base Engine Repair Component Technical Manual (CTM415)