Hyster S70-120XL (D004) Repair Service Manual

Catalog:

Model:

Complete service repair manual for Hyster S70-120XL (D004) Forklifts Trucks, with all the shop information to maintain, diagnose, repair, and rebuild like professional mechanics.

Hyster S70XL, S120XL (D004) workshop service & repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

897253 - Hyster S70-120XL (D004) Service Manual.pdf

Total Pages: 1,179 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

| Section | Part No. | SRM Number | Rev Date |

| FRAME | 897307 | 0100 SRM 0396 | 06/92 |

| GM V6-4.3L ENGINE (CARBURETED) | 599805 | 0600 SRM 0104 | 09/93 |

| PERKINS DIESEL ENGINE-1000 SERIES | 897341 | 0600 SRM 0412 | 08/97 |

| GM V6-4.3L ENGINE WITH FUEL INJECTION | 897800 | 0600 SRM 0590 | 11/03 |

| PERKINS DIESEL ENGINE-1000 SERIES (AR, YG, YH) | 1455747 | 0600 SRM 0705 | 11/01 |

| COOLING SYSTEM | 897934 | 0700 SRM 0626 | 11/01 |

| WEBER CARBURETOR WITH GOVERNOR | 897128 | 0900 SRM 0347 | 12/92 |

| LPG FUEL SYSTEM | 897129 | 0900 SRM 0348 | 09/01 |

| SINGLE-SPEED PS TRANSMISSION-REPAIR | 897308 | 1300 SRM 0397 | 02/04 |

| SINGLE-SPEED PS TRANS-DESCR / OPER | 897322 | 1300 SRM 0399 | 09/03 |

| DRIVE AXLE | 897323 | 1400 SRM 0400 | 02/97 |

| STEERING CONTROL UNIT | 910076 | 1600 SRM 0054 | 10/03 |

| STEERING CONTROL UNIT (ROSS HGF) | 910458 | 1600 SRM 0257 | 07/00 |

| STEERING AXLE | 897108 | 1600 SRM 0326 | 10/03 |

| BRAKE SYSTEM | 897120 | 1800 SRM 0338 | 07/00 |

| HYDRAULIC GEAR PUMPS | 910091 | 1900 SRM 0097 | 10/03 |

| HYDRAULIC SYSTEM | 897115 | 1900 SRM 0333 | 03/97 |

| HYDRAULIC PUMP DRIVE ASSEMBLY | 897121 | 1900 SRM 0339 | 10/03 |

| MAIN CONTROL VALVE | 899782 | 2000 SRM 0077 | 07/00 |

| TILT CYLINDERS | 910102 | 2100 SRM 0103 | 10/03 |

| ALTERNATOR | 899784 | 2200 SRM 0002 | 10/03 |

| STARTER | 910107 | 2200 SRM 0106 | 02/01 |

| HIGH ENERGY IGNITION SYSTEM | 899788 | 2200 SRM 0107 | 03/02 |

| INSTRUMENT PANEL INDICATORS / SENDERS | 910110 | 2200 SRM 0143 | 12/03 |

| MSTS-GM V6-4.3L (EARLY CONTROL MODULES) | 897412 | 2200 SRM 0463 | 04/93 |

| GM V6 ENGINE CONTROL-REPAIR (EARLY MODULES) | 897420 | 2200 SRM 0468 | 05/96 |

| GM V6 ENG CONTROL-DESC/OPER (EARLY MODULES) | 897435 | 2200 SRM 0473 | 03/94 |

| MSTS-GM V6-4.3L (LATER CONTROL MODULES) | 1473385 | 2200 SRM 0765 | 11/01 |

| GM V6 ENG CONTROL-DESC/OPER (LATER MODULES) | 1474823 | 2200 SRM 0781 | 01/00 |

| GM V6 ENGINE CONTROL-REPAIR (LATER MODULES) | 1474824 | 2200 SRM 0782 | 03/00 |

| LIFT CYLINDERS | 910119 | 4000 SRM 0135 | 10/03 |

| VISTA MASTS | 897122 | 4000 SRM 0340 | 09/02 |

| METRIC AND INCH (SAE) FASTENERS | 910442 | 8000 SRM 0231 | 03/03 |

| PERIODIC MAINTENANCE | 897304 | 8000 SRM 0393 | 12/03 |

| DIAGRAMS | 897305 | 8000 SRM 0394 | 02/88 |

| CAPACITIES and SPECIFICATIONS | 897306 | 8000 SRM 0395 | 03/88 |

| DIAGRAMS-GM ELECTRONIC ENGINE CONTROL | 897471 | 8000 SRM 0494 | 05/94 |

| PART NO. 897253 | |||

| Rev 02/04 | |||

Microprocessor Spark Timing System (MSTS)...3

Safety Precautions Maintenance and Repair...4

General...7

Description...8

What MSTS Does...8

How MSTS Begins Operation...8

Operation...9

Distributor...9

Ignition Coil...9

Ignition Module...9

When Engine Is Being Started...10

When Engine Is Running...11

Manifold Absolute Pressure (MAP) Sensor...12

Engine Coolant Temperature (ECT) Sensor...12

MSTS Module Corrections...13

Troubleshooting...14

General...14

Tools and Test Equipment...16

MSTS...17

Troubleshooting Procedure...17

Where to Start...17

Visual/Physical Inspection...17

Knowledge/Tools Required...17

Damage from Static Discharge (Static Electricity)...17

Troubleshooting Information...18

Malfunction Indicator Lamp (MIL)...18

Connecting CodeMate Tester...18

Reading Diagnostic Trouble Codes (DTC)...19

Clearing Diagnostic Trouble Codes (DTC's)...20

On-Board Diagnostic (OBD) System Check...20

Test Description...20

No Malfunction Indicator Lamp...22

Circuit Description...22

Test Description...22

No DTC-12, Malfunction Indicator Lamp ON...24

Circuit Description...24

Test Description...24

Starter Rotates Engine, Engine Does Not Run...25

Test Description...25

DTC-14 Engine Coolant Temperature (ECT) (Low Temperature Indicat...29

Circuit Description...29

Test Description...29

DTC-15 Engine Coolant Temperature Sensor (ECT) (High Temperature...31

Circuit Description...31

Test Description...31

DTC-34 Manifold Absolute Pressure (MAP) Sensor...33

Circuit Description...33

Test Description...33

DTC-41 Electronic Spark Timing (EST) Open Circuit...36

Circuit Description...36

Test Description...36

DTC-42 Electronic Spark Timing (EST) Grounded Circuit...38

Circuit Description...38

Test Description...38

DTC-51 MSTS Failure...40

Circuit Description...40

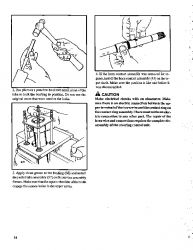

Distributor Repair...40

Remove...40

Disassemble...41

Inspect...41

Assemble...41

Install...42

Ignition Timing...42

Ignition Module Repair...43

Test For Fault...43

Replace...44

Sensing Coil Repair...44

Test For Fault...44

Replace...44

Ignition Coil Repair...45

Test For Fault...45

Remove...45

Install...45

MSTS Module Repair...46

Remove...46

Install...46

ECT Sensor Replacement...46

MAP Sensor Replacement...47

tables...3

Table 1. MSTS Module Connections...15

Table 2. Pressure Conversion Chart...16

Table 3. MSTS Diagnostic Codes...18

Steering Axle H6.00-7.00XL (H135-155XL, H135-155XL 2 ) (F006, G0...212

Remove...212

Install...213

Wheels and Hubs Repair (All Units)...213

Remove and Disassemble...213

Clean...213

Inspect...213

Assemble and Install...214

Spindles and Bearings Repair (All Units)...215

Remove...215

Clean...215

Assemble and Install...215

Tie Rods Repair (All Units)...216

Remove...216

Clean...216

Install...216

Steering Cylinder Repair...219

Remove and Disassemble...219

Clean and Inspect...219

Assemble and Install...219

Troubleshooting...220

hyster-897122-09-02-srm0340...273

toc...273

Vista ® Masts...273

Safety Precautions Maintenance and Repair...274

General...277

Description and Operation...277

Carriages...277

Two-Stage Mast With Limited Free-Lift...277

Two-Stage Mast With Full Free-Lift Mast...278

Three-Stage Mast With Full Free-Lift...279

Safety Procedures When Working Near Mast...281

Forks Replacement...283

Remove and Install...283

Hook Fork...283

Remove...283

Install...283

Pin Fork...284

Remove...284

Install...284

Carriage Repair...284

Remove...284

Sideshift Carriage Repair...286

Sideshift Carriage (Earlier Designs)...286

Disassemble...286

Assemble...287

Install...290

Sideshift Carriage (1993 and Later Design)...290

Remove...290

Repairs...290

Install...290

Weight of Mast Parts...293

Two-Stage Mast With Limited Free-Lift Repair...293

Remove...293

Disassemble...293

Clean and Inspect...295

Assemble...295

Install...297

Two-Stage Mast With Full Free-Lift Repair...297

Remove...297

Disassemble...297

Clean and Inspect...299

Assemble...299

Install...299

Three-Stage Mast With Full Free-Lift...300

Remove...300

Disassemble...300

Clean and Inspect...300

Assemble...300

Install...302

Mast Operation Check...304

Lift and Tilt System Leak Check...305

Lift System...305

Tilt System...305

Tilt Cylinder Stroke and Backward Tilt Angle Adjustment...306

Lift Chain Adjustments...306

Mast Adjustments...307

Carriage Adjustment...309

Troubleshooting...310

Fuel Filter Element, Replace...346

Diaphragm and Fuel Valve, Replace...346

Hoses Replacement...348

Vaporizer Repair...348

Remove...348

Disassemble...348

Clean...348

Inspect...348

Assemble...350

Install...354

Carburetor Repair...354

Remove...354

Disassemble...354

Clean...354

Assemble...354

Install...354

Governor Repair...356

Filter Unit Check...358

Vaporizer Check...358

Pressure Reducer Valve...358

Vapor Valve...358

Carburetor Adjustment...358

Idle Mixture...358

Idle Speed...358

Power Mixture...359

Throttle Linkage Adjustment...359

Troubleshooting...361

hyster-897304-12-03-srm0393...367

toc...367

Periodic Maintenance...367

Safety Precautions Maintenance and Repair...368

General...373

Serial Number Data...373

How to Move Disabled Lift Truck...373

How to Tow Lift Truck...373

How to Put Lift Truck on Blocks...374

How to Raise Drive Tires...374

How to Raise Steering Tires...374

Maintenance Schedule...375

Safety Procedures When Working Near Mast...386

Maintenance Procedures Every 8 Hours or Daily...388

How to Make Checks With Engine Stopped...388

Hydraulic System...388

Engine Oil...388

Drive Belts...388

Intake Manifold Rubber Cap...388

Cooling System...388

Air Filter...389

Fuel System...391

Primary Fuel Filter, Diesel Engine...391

Battery...391

Tires and Wheels...391

Forks...392

Adjust...392

Remove...392

Install...392

Forks, Mast, and Lift Chains, Inspect...394

Operator Restraint System...395

Safety Labels...396

How to Make Checks With Engine Running...397

Gauges, Lights, Horn, and Fuses...397

Oil Level, Powershift Transmission...398

Oil Level, Oil Clutch System, S6.00-7.00XL (S135-155XL)...398

Control Levers and Pedals...398

Lift System Operation...399

Inching/Brake Pedal...399

Service Brakes...399

Parking Brake...399

Steering System...400

Maintenance Procedures Every 250 Hours or 6 Weeks...400

Engine Oil and Filter, GM V-6...400

Mast, Lubrication...400

Lift Chains, Lubrication...401

Crankcase Breather, GM V-6 Engine...401

Drive Shafts, S6.00-7.00XL (S135-155XL)...401

Air Filter GM V-6 EPA Compliant Engine...401

Maintenance Procedures Every 350 Hours or 2 Months...402

Drive Belts...402

Perkins Diesel Engine...402

GM V-6 Engine, Early Models...402

GM V-6 Engine, Late Models...402

Forks, Wear and Damage Check...404

Lift Chains, Wear Check...405

Hydraulic Tank Breather, Clean and Check...405

Brake Fluid...405

Fuel System, Checks and Adjustments...405

Diesel Fuel System...405

LPG Carburetor...406

Gasoline Carburetor (Early Models)...406

Fuel Injection (Late Model GM V-6)...407

Steering Axle, Lubrication...407

Cooling System, Clean Debris from Radiator Core...407

Air Filter...407

Maintenance Procedures Every 500 Hours or 3 Months...408

Engine Oil and Filter, Perkins Diesel Engine...408

Crankcase Breather, Perkins Diesel Engine...408

PCV Valve, GM V-6...408

Maintenance Procedures Every 1000 Hours or 6 Months...408

Manifold Heat Valve, GM V-6...408

Crankcase Breather, GM V-6...408

Ignition System, GM V-6...408

Valve Clearance, Check and Adjust...409

Fuel Filter, Diesel Engine, Replace...409

Fuel System Air Removal, Perkins (1004.42 Diesel Engine)...409

Fuel Injection Pump With Vent Tube...409

Fuel Injection Pump With Vent Screw...410

Differential and Drive Axle, Oil Level Check...412

Differential S3.50-5.50XL (S70-120XL)...412

Differential and Drive Axle for Powershift Transmission S6.00-7...412

Differential, Speed Reducer, and Drive Axle for Manual Transmiss...412

Control Levers and Pedals, Lubrication...412

Cooling System GM V-6 EPA Compliant Engine...412

LPG Fuel Filter GM V-6 EPA Compliant Engine, Replace...413

Inspect Engine Electrical System, Connectors, and FCVS Connectio...413

Spark Plug Replacement...414

Remove...414

Install...414

Maintenance Procedures Every 2000 Hours or Yearly...415

Hydraulic System...415

Hydraulic Oil and Filter S3.50-5.50XL (S70-120XL), Replace...415

Hydraulic Oil and Filter S6.00-7.00XL (S135-155XL), Replace...415

Powershift Transmission (All Units), Oil Change and Oil Filter, ...415

Manual Transmission and Differential S6.00-7.00XL (S135-155XL), ...416

Oil Clutch System S6.00-7.00XL (S135-155XL), Oil and Filter Chan...416

Differential and Drive Axle for Powershift Transmission (All Uni...416

Cooling System...417

PCV Valve, GM V-6...417

Service Brakes...417

LPG Filter, Replace (Pre-2004)...417

Oxygen Sensor GM V-6 EPA Compliant Engine...418

Gasoline Fuel Filter, Replace...418

Air Filter Element, GM V-6 EPA Compliant Engine...418

Test LPG/GAS Regulator Pressure...418

Inspect Low Pressure Regulator (LPR) for Oil Buildup and Leaks...418

Check Throttle Shaft for Sticking...419

Inspect Exhaust Manifold and Piping for Leaks...419

Hood Latch Check...420

Lift Chain Adjustments...420

Fuel Injectors Repair...422

Lift and Tilt System Leak Check...422

Lift Cylinders, Leak Check...422

Tilt Cylinders, Leak Check...422

Welding Repairs...423

Overhead Guard Changes...423

Wheel and Tire Replacement...424

Solid Rubber Tire, Change...424

Wheels, Install...425

SIT Tire, Change for S3.50-5.50XL (D004), and S6.00-7.00XL (B024...425

Remove SIT Solid Tire From Wheel...426

Install SIT Solid Tire on Wheel...427

Adhesives and Sealants...428

Hydraulic Oil, Lubricant, and Coolant Specifications...428

tables...367

Table 1. Maintenance Schedule...375

Table 2. Hook-Type Carriage Chain Adjustment...421

Transmission Repair...471

Remove...471

Disassemble...472

Transmission, Disassemble...472

Input Shaft, Disassemble...473

Reverse Clutch, Disassemble...475

Output Shaft (Pinion) and Differential, Remove and Disassemble...478

Clean and Inspect...480

Assemble...480

Input Shaft, Assemble...481

Reverse Clutch, Assemble...489

Output Shaft (Pinion) and Differential, Assemble and Install...494

Transmission, Assemble...501

Control Valve, Install...504

Install...504

Control Valve Repair...505

Remove, Early Model S3.50-5.50XL (S70-120XL) Lift Trucks...505

Disassemble, Early Model S3.50-5.50XL (S70-120XL) Lift Trucks...505

Assemble, Early Model S3.50-5.50XL (S70-120XL) Lift Trucks...506

Install, Early Model S3.50-5.50XL (S70-120XL) Lift Trucks...506

Remove and Disassemble, Later Model S3.50-5.50XL (S70-120XL) Tru...506

Inspect, Later Model S3.50-5.50XL (S70-120XL) Trucks and S3.50-5...509

Assemble and Install, Later Model S3.50-5.50XL (S70-120XL) Truck...509

MONOTROL® Pedal Repair...511

Remove and Disassemble, S3.50-5.50XL (S70-120XL) Model Lift Truc...511

Assemble and Install, S3.50-5.50XL (S70-120XL) Model Lift Trucks...512

Remove and Disassemble, S3.50-5.50XM (S70-120XM) Model Lift Truc...514

Assemble and Install, S3.50-5.50XM (S70-120XM) Model Lift Trucks...514

Direction Control Lever Repair...516

Remove and Disassemble...516

Assemble and Install...516

Stall Test...517

Linkages Adjustment...518

Linkage for Inching/Brake Pedal, S3.50-5.50XL (S70-120XL) (D004)...518

Linkage for Direction Control Lever...520

Linkage for Inching/Brake Pedal, S3.50-5.50XM (S70-120XM) (E004,...520

Brake Shoe Adjustment...520

Inching/Brake Pedal Height Adjustment...520

Single Pedal Height Adjustment...520

Two Pedal Height Adjustment...520

Inching/Brake Linkage Adjustment...522

Oil Pressures Check...524

System Pressure Check Port...524

Torque Converter Check Port...524

Clutch Pressure Check Port...525

Inching Pressure...525

Solenoid Check Ports ( MONOTROL Control Only)...527

Lubrication Pressure Check Ports...527

System Pressure Check Port...527

Torque Converter Check Port...527

Reverse Clutch Pressure Check Port...527

Forward Clutch Pressure Check Port...527

Lubrication Pressure Check Port...527

Modulator Pressure Check Port...527

Troubleshooting...528

tables...467

Table 1. Ring and Pinion Tooth Contact Adjustment...499

Table 2. Stall Speed Specifications...517

Table 3. Transmission Oil Pressure Check, Early Model S3.50-5.50...525

Table 4. Transmission Oil Pressure Check, Later Model S3.50-5.50...526

hyster-897322-09-03-srm0399...535

toc...535

Single-Speed Powershift Transmission...535

Safety Precautions Maintenance and Repair...536

General...539

Mechanical Description...539

General...539

Torque Converter...539

Oil Pump...539

Shaft Assemblies...539

Input Shaft...539

Reverse Clutch Shaft...539

Countershaft...540

Ring Gear, Pinion, and Differential...540

Clutch Assemblies...541

Hydraulic Operation...542

Torque Converter...542

Shaft Assemblies...543

Control Valve...543

General...543

System Regulator...543

Clutch Pressure Regulator...543

Torque Converter Regulator...543

Inching Spool...543

Direction Spool, Manual Control...545

Direction Spool, MONOTROL Pedal...545

Modulation Spool...545

Accumulator...545

Drain Spool...545

MONOTROL Pedal...545

Control Valve...547

General...547

Regulator for Clutch Pressure...547

Inching Spool Assembly...547

Direction Spool...550

Direction Spool, Manual Control...551

Modulator Circuit...551

Regulator for Torque Convertor...551

Lubrication Circuit...551

Direction Control Lever...551

MONOTROL Pedal...552

Start Circuit, MONOTROL Pedal...552

Creep Speed Switch...553

Oil Flow Diagrams...553

Neutral...553

Valves, Repair...849

Valve Seats, Repair...850

Valve Springs...851

Rocker Arm Studs (Early Models)...851

Rocker Arm Studs (Late Models)...852

Assemble and Install...852

Cylinder Block Cleaning and Inspection...856

Piston Bore Preparation...856

Engine Mounts Installation...856

Lubrication System Repair...857

Oil Pump, Remove and Disassemble...857

Clean and Inspect...857

Oil Pump, Assemble and Install...857

Oil Sump, Install...858

Timing Cover, Timing Sprockets, Camshaft, and Valve Lifters...859

Timing Cover...859

Remove...859

Install...861

Timing Sprockets...861

Remove...861

Install...861

Camshaft...862

Remove...862

Inspect...862

Install...862

Balance Shaft...863

Remove...863

Install...864

Hydraulic Valve Lifters...864

Remove...864

Disassemble...865

Clean and Inspect...865

Assemble...865

Install...866

Crankshaft Repair...867

Remove...867

Inspect and Repair...867

How to Check Clearance Between Main Bearings and Their Journals...868

Install...869

Piston and Connecting Rod Assemblies Repair...870

Connecting Rod Bearings, Replace...870

Piston and Connecting Rod Assemblies, Remove...871

Disassemble...871

Piston, Clean and Inspect...872

Cylinder Bores, Inspect and Repair...872

Piston Rings...873

Assemble...874

Piston and Connecting Rod Assemblies, Install...874

Flywheel and Flywheel Housing Repair...875

Flywheel, Repair...875

Flywheel, Install...875

H3.50-5.00XL (H70-110XL), S3.50-5.50XL (S70-120XL), S6.00-7.00XL...875

H6.00-7.00XL (H135-155XL)...875

Flywheel Housing H3.50-5.00XL (H70-110XL), H3.50-5.50XM (H70-120...875

Engine Adapter H6.00-7.00XL (H135-155XL)...875

Coolant Pump Repair...876

Thermostat Replacement...876

Fan Mount Repair (Early Models)...876

Fan Mount Assembly Repair (Late Models)...876

Drive Belt Installation...878

Valve Clearance Adjustment (Early Models)...879

Valve Clearance Adjustment (New Models)...880

Compression Check...880

Engine Specifications...880

Engine Data...880

Cylinder Head...881

Hydraulic Valve Lifter...881

Camshaft...881

Pistons...881

Crankshaft...882

Connecting Rods...883

Balance Shaft...883

Cooling System...883

Lubrication System...883

Torque Specifications...884

Troubleshooting...885

tables...843

Table 1. Piston Rings Arrangement on Piston...874

hyster-897934-11-01-srm0626...891

toc...891

Cooling System...891

Safety Precautions Maintenance and Repair...892

General...895

Description...896

Radiator...896

Radiator Cap...896

Thermostat...896

Water Pump...897

Fan and Fan Shroud...897

Cooling System Checks...897

Radiator...897

Thermostat...897

Water Pump...898

Exhaust Leaks...898

Fan and Fan Shroud...898

Radiator Cleaning...898

Drain...898

Clean...898

Fill...899

Motorola Alternators...941

Diodes Check...942

Diode Bridge Check...942

Delco and Leece-Neville Alternators...942

Motorola Alternators...942

Rotor Field Winding Check...943

Stator Windings Check...944

Voltage Regulator Check...944

Troubleshooting...944

hyster-899788-03-02-srm0107...949

toc...949

High Energy Ignition (HEI) System...949

Safety Precautions Maintenance and Repair...950

Description...953

Distributor Repair...955

Remove...955

Disassemble...955

Assemble...960

Install, If Crankshaft WAS NOT Rotated when Distributor was Remo...961

Install, If Crankshaft WAS Rotated when Distributor was Removed...961

Ignition Coil Replacement...962

Some Four- and Six-Cylinder Models...962

Remove...962

Install...963

V8, Some Four- and Six-Cylinder Models...963

Remove...963

Install...964

Electronic Module Replacement...965

Remove...965

Install...965

Sensing Coil Replacement...966

Remove...966

Install...966

Spark Plugs Replacement...966

Remove...966

Install...967

Visual Check...967

High Voltage Wires Check...967

Ignition Coil Check...968

Coil in Distributor Cap Design...968

Separate Coil Design...968

Sensing Coil, Check...969

Electronic Module Check...969

Ignition Timing Adjustment...969

GM V8-366 (6-liter) Ignition System Check...971

GM V6-LPG (4.3 liter) GM V6-LPG (4.3 liter) Ignition Timing and ...971

Specifications...971

Troubleshooting...972

hyster-910076-10-03-srm0054...977

toc...977

Steering Control Unit...977

Safety Precautions Maintenance and Repair...978

General...981

Description...981

Operation...981

Steering Wheel and Column Assembly Repair...983

Steering Column Assembly Repair...983

Type A Steering Column Assembly...983

Remove and Disassemble...983

Assemble and Install...985

Type B Steering Column Assembly...987

Remove and Disassemble...987

Assemble and Install...987

Steering Control Unit...990

Disassemble...990

Clean...993

Assemble...994

System Air Removal...999

Troubleshooting...999

hyster-910091-10-03-srm0097...1003

toc...1003

Hydraulic Gear Pumps...1003

Safety Precautions Maintenance and Repair...1004

Description...1007

Operation...1008

Flow Control Valve...1008

Relief Valve...1009

Hydraulic Gear Pump Repair...1009

Remove...1009

Disassemble...1010

Clean...1010

Inspect...1011

Assemble...1014

Install...1016

Pump Output Check...1016

Method No. 1...1016

Method No. 2...1017

Hydraulic System Air Check...1018

Troubleshooting...1019

hyster-910102-10-03-srm0103...1025

toc...1025

Tilt Cylinders...1025

Safety Precautions Maintenance and Repair...1026

General...1029

Description...1029

Tilt Cylinder Repair...1029

Remove...1029

Disassemble...1029

Clean...1029

Assemble...1030

Tilt Cylinders With O-Ring or Single-Lip Seals...1030

Tilt Cylinders for XM and XMS Models...1031

Tilt Cylinders for H700-800A and Early Model H700-920B...1032

Install...1033

Tilt Cylinders Using Chevron Packing...1034

Install...1035

Tilt Cylinder Leak Check...1037

Tilt Cylinder Stroke and Mast Tilt Angle Adjustment...1038

Torque Specifications...1039

Piston Rod Nut...1039

Retainer...1040

Troubleshooting...1042

tables...1025

Table 1. Movement Rates (Maximum) for Tilt Cylinders...1038

hyster-910107-02-01-srm0106...1045

toc...1045

Starter...1045

Safety Precautions Maintenance and Repair...1046

General...1049

Description and Operation...1049

Starter Repair...1051

Remove...1051

Disassemble...1051

Clean...1052

Assemble...1052

Install...1053

General Checks and Adjustments...1053

Troubleshooting...1056

hyster-910110-12-03-srm0143...1061

toc...1061

Instrument Panel Indicators and Senders...1061

Safety Precautions Maintenance and Repair...1062

General...1065

Description...1066

Steering Column Gauges, Meters, and Indicators...1066

LED Display Panel...1066

Battery Discharge Indicators...1066

Brush Wear Indicators...1073

Motor Temperature Indicators...1073

LX Series Display Panel...1075

Hourmeter Functions...1075

Battery Indicator Function...1076

Status Code Function...1077

ZX Series Display Panels...1077

Display Panel...1077

Basic Display Panels...1077

Performance Display...1080

Brush Wear Indicators...1083

Adjustments - General...1084

Replacement - General Information...1084

Meter Replacement...1085

Sender Replacement...1086

Fuel Level Sender...1086

Pressure and Temperature Sender...1086

ITW Display Panel Replacement...1087

Remove...1087

Column Mount Display Panel (EV-100/200ZX Motor Controllers) Repl...1088

Remove...1088

Display Panel Assembly, Replace...1088

Indicator LEDs...1089

Battery Indicators...1089

Digital Display (Performance Display Panel Only)...1089

Status Code or Performance Level Switches and Indicator LEDs (Pe...1089

Basic Display Panel, Replace Parts...1089

Performance Display Panel, Replace Parts...1091

Dash Mount Display Panel (EV100/200ZX Motor Controllers) Replace...1092

Remove and Replace...1092

Specifications...1092

Meter Specifications...1092

Sender Specifications...1093

Troubleshooting...1093

Meter...1093

hyster-910119-10-03-srm0135...1097

toc...1097

Lift Cylinders...1097

Safety Precautions Maintenance and Repair...1098

Safety Procedures When Working Near Mast...1101

General...1105

Description...1105

Lowering Control Valve...1105

Cylinders (General)...1108

Cylinders (H520-620B, H700-800A)...1108

Retainer, Install...1108

Cylinders (H360-460B)...1110

Cylinders (Two-Speed)...1112

Lift Cylinder Repair...1114

Lift Cylinder Removal Without Removing Mast...1114

Standard Masts With Main Lift Cylinder Fastened to Crossmember o...1114

Standard and Full Free-Lift Masts With Lift Cylinder Fastened to...1114

Masts That Have Two Cylinders, Main Lift Cylinder and Free-Lift ...1114

Disassemble...1116

Assemble...1116

Lift Cylinder Installation in Mast...1118

Standard Masts With Main Lift Cylinder Fastened to Crossmember o...1118

Standard and Full Free-Lift Masts With Lift Cylinder Fastened to...1118

Chevron-Style Packing...1118

Chevron-Style Packing Installation on Piston...1119

Chevron-Style Packing Installation in Packing Gland...1121

Lift Cylinders for VISTA® Masts...1122

Description...1122

Lowering Control Valve...1122

Remove...1124

Disassemble...1125

Assemble...1126

Install...1127

Main Lift Cylinders...1127

Free-Lift Cylinder...1127

Lift System Leak Check...1128

Specifications...1129

Troubleshooting...1130

tables...1097

Table 1. Lift Trucks with Two-Speed Lift Cylinders...1113

Table 2. Cylinder Retainer Torque Specifications and Weight Guid...1129

hyster-910442-03-03-srm0231...1133

toc...1133

Metric and Inch (SAE) Fasteners...1133

Safety Precautions Maintenance and Repair...1134

General...1137

Threaded Fasteners...1137

Nomenclature, Threads...1137

Strength Identification...1138

Cotter (Split) Pins...1138

Fastener Torque Tables...1143

Conversion Table...1145

tables...1133

Table 1. Bolts and Screws...1139

Table 2. Studs and Nuts...1140

Table 3. Torque Nuts...1141

Table 4. Torque Nuts With Nylon Insert...1142

Table 5. Torque Values for Metric Fasteners*...1143

Table 6. Torque Values for Inch Fasteners*...1144

Hyster S70-120XL (D004) Repair Service Manual