Komatsu Bulldozer D135A Repair Service Manuals

Catalog:

Model:

Complete service repair manual for Komatsu Bulldozer D135A-2, with technical information to maintain, diagnose, repair, and service like professional mechanics.

Komatsu Bulldozer D135A workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

SEBM015A0206 - Bulldozer D135A-2 Shop Manual (SN10301&up).pdf

SEAM015A0201 - Bulldozer D135A-2 Operation & Maintenance Manual.pdf

PRODUCT DETAILS:

Total Pages: 479 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

TABLE OF CONTENTS

10 STRUCTURE AND FUNCTION

20 TESTING AND ADJUSTING

30 DISASSEMBLY AND ASSEMBLY

40 MAINTENANCE STANDARD

SEAM015A0201 - Bulldozer D135A-2 Operation & Maintenance Manual.....2

COVER.....2

FOREWORD.....3

BREAKING IN YOUR NEW MACHINE.....4

CONTENTS.....5

GENERAL LOCATIONS AND SPECIFICATIONS.....6

INSTRUMENTS AND CONTROLS .....8

CHECK BEFORE STARTING.....38

OPERATING YOUR MACHINE.....44

COLD WEATHER OPERATION.....64

METHOD FOR RELEASING WHEN ASSIST BRAKE HAS BEEN APPLIED.....69

OPERATING RIPPER.....73

BULLDOZER'S WORK.....77

TIPS FOR LONGER UNDERCARRIAGE LIFE.....79

ADJUSTMENT OF WORK EQUIPMENT.....81

HOW TO REVERSE THE REVERSIBLE FAN.....85

SELECTION OF RIPPER POINT.....87

PERIODIC MAINTENANCE.....88

PERIODICAL REPLACEMENT OF SAFETY.....89

MAINTENANCE TABLE.....92

OIL FILLER AND LEVEL GAUGE POSITIONS.....96

EVERY 250 HOURS SERVICE.....98

EVERY 500 HOURS SERVICE.....108

EVERY 1000 HOURS SERVICE.....112

EVERY 2000 HOURS SERVICE.....118

EVERY 4000 HOURS SERVICE.....121

WHEN REQUIRED.....122

ADJUSTMENT.....134

TROUBLE SHOOTING GUIDE.....142

SERVICE METER.....146

MACHINE AND ENGINE SERIAL NUMBERS.....148

FUEL,COOLANT AND LUBRICANTS.....150

SAFETY AND OPERATION.....152

CONTENTS.....153

SAFETY HINTS.....154

PRECAUTIONS FOR MAINTENANCE.....168

CAR STEREO.....174

AIR CONDITIONER.....177

LOCKING CAP.....185

HANDLING OF BATTERY.....187

STORAGE.....190

COOLANT AND LUBRICANTS.....191

SEBM015A0206 - Bulldozer D135A-2 Shop Manual (SN10301&up).....193

COVER.....193

CONTENTS.....194

10 STRUCTURE AND FUNCTION.....215

GENERAL.....216

POWER TRAIN HYDRAULIC SYSTEM.....218

POWER TRAIN HYDRAULIC CIRCUIT DIAGRAM.....219

TORQUE CONVERTER.....220

TORQFLOW TRANSMISSION.....224

TRANSMISSION CONTROL.....230

TORQFLOW HYDRAULIC PIPING.....231

TORQFLOW HYDRAULIC SYSTEM.....232

TORQFLOW HYDRAULIC CIRCUIT DIAGRAM.....233

TRANSMISSION CONTROL VALVE.....234

TRANSMISSION LUBRICATION RELIEF VALVE.....239

TRANSMISSION PUMP.....240

TRANSMISSION AND STEERING OIL STRAINER.....241

TRANSMISSION OIL FILTER.....242

BEVEL GEAR SHAFT AND STEERING CLUTCH.....243

STEERING CONTROL.....245

STEERING AND BRAKE PIPING.....246

STEERING AND BRAKE HYDRAULIC SYSTEM.....247

STEERING AND BRAKE HYDRAULIC CIRCUIT DIAGRAM.....248

STEERING PUMP.....249

STEERING MAIN RELIEF VALVE.....250

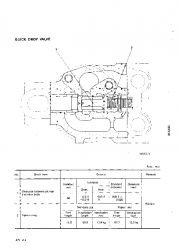

STEERING AND BRAKE CONTROL VALVE.....251

STEERING BRAKE.....255

SPRING ASSIST BRAKE SYSTEM.....259

FINAL DRIVE.....263

PTO (POWER TAKE OFF).....264

TRACK FRAME.....265

IDLER CUSHION.....266

IDLER.....267

TRACK ROLLER AND CARRIER ROLLER.....268

TRACK (LUBRICATED TRACK LINK).....269

TRACK (DRY TYPE TRACK LINK).....270

SUSPENSION.....271

HYDRAULIC PIPING.....272

HYDRAULIC CONTROL.....274

HYDRAULIC SYSTEM (WITHOUT RIPPER).....276

HYDRAULIC CIRCUIT DIAGRAM (WITHOUT RIPPER).....277

HYDRAULIC SYSTEM (WITH RIPPER).....278

HYDRAULIC CIRCUIT DIAGRAM (WITH RIPPER).....279

HYDRAULIC TANK (WITHOUT RIPPER).....280

HYDRAULIC TANK (WITH RIPPER).....281

HYDRAULIC PUMP.....282

BLADE CONTROL VALVE.....283

MAIN RELIEF VALVE (WITHOUT RIPPER).....290

RIPPER CONTROL VALVE.....291

HYDRAULIC LEVER OPERATION.....296

HYDRAULIC CYLINDER.....300

CYLINDER STAY.....304

STRAIGHT TILTDOZER.....305

VARIABLE MULTIPLE SHANK RIPPER.....307

ELECTRICAL CIRCUIT DIAGRAM.....309

EVMS (ELECTRONIC VEHICLE MONITORING SYSTEM).....311

AIR CONDITIONER.....317

20 TESTING AND ADJUSTING.....319

TABLE OF STANDARD VALUES FOR ENGINE.....320

TABLE OF STANDARD VALUES FOR CHASSIS.....321

TABLE OF ELECTRICAL JUDGEMENT STANDARD VALUE.....326

TESTING AND ADJUSTING.....328

TESTING AND ADJUSTING TOOL LIST.....329

ADJUSTING VALVE CLEARANCE.....330

MEASURING COMPRESSION PRESSURE.....331

TESTING AND ADJUSTING FUEL INJECTION TIMING.....332

MEASURING TORQUE CONVERTER STALL SPEED.....333

BLEEDING AIR FROM FUEL SYSTEM.....334

BLEEDING AIR FROM HYDRAULIC CYLINDER.....334

MEASURING OIL PRESSURE.....335

ADJUSTING FUEL CONTROL LINKAGE.....337

ADJUSTING GEAR SHIFT LEVER LINKAGE.....339

ADJUSTING STEERING CLUTCH LINKAGE.....341

ADJUSTING BRAKE PEDAL TRAVEL.....342

ADJUSTING BRAKE PEDAL LINKAGE.....343

ADJUSTING BRAKE CONTROL LINKAGE.....345

ADJUSTING RIPPER CONTROL LINKAGE.....346

ADJUSTING CLEARANCE OF IDLER.....347

H-MODE TROUBLESHOOTING.....349

PREPARATION FOR TROUBLESHOOTING.....350

METHOD OF READING TROUBLESHOOTING TABLE.....352

PREVENTING RECURRENCE OF THE SAME TROUBLE.....354

TROUBLESHOOTING.....355

H-1 TORQUE CONVERTER TEMPERATURE TOO HIGH.....355

H-2 MACHINE DOES NOT MOVE.....356

H-3 MACHINE LACKS POWER OR SPEED.....358

H-4 EXCESSIVE TIME LAG WHEN STARTING MACHINE OR SHIFTING GEAR.....359

H-5 MACHINE MOVES WHEN ENGINE IS STARTED.....360

H-6 EXCESSIVE SHOCK WHEN STARTING MACHINE OR SHIFTING GEAR.....360

H-7 MACHINE TRAVELS IN ONE DIRECTION ONLY (FORWARD OR REVERSE).....360

H-8 STEERING CLUTCH DOES NOT DISENGAGE.....361

H-9 STEERING CLUTCH SLIPS.....362

H-10 STEERING BRAKE DOES NOT WORK.....363

H-11 BLADE LIFT LACKS POWER AND SPEED.....364

H-12 BLADE DOES NOT LIFT.....365

H-13 THE FRONT OF MACHINE CANNOT BE RAISED OFF GROUND BY THE BLADE.....366

H-14 HYDRAULIC DRIFT OF LIFT CYLINDER IS LARGE.....367

H-15 BLADE MOVES UNSTEADILY WHEN LEVELING THE GROUND (CONTROL LEVER IN "HOLD").....368

H-16 BLADE LOWERS UNDER THE FOLLOWING CONDITIONS.....368

H-17 TRAVEL OF THE PISTON RODS IN THE RIGHT AND LEFT LIFT CYLINDERS IS DIFFERENT(APPLICABLE TO STRAIGHT -TILT DOZER ONLY).....368

H-18 BLADE TILTING FORCE IS LACK, BLADE TILTING SPEED IS SLOW, THE MACHINE CANNOT BE RAISED OFF GROUND BY BLADE TILTING FORCE.....369

H-19 TILT CYLINDER DOES NOT MOVE OFF (TILTING IS IMPOSSIBLE).....370

H-20 HYDRAULIC DRIFT OF TILT CYLINDER IS LARGE.....371

H-21 HYDRAULIC DRIFT OF RIPPER CYLINDER IS LARGE.....372

H-22 OPERATING FORCE IS HEAVY.....373

M-MODE TROUBLESHOOTING.....374

POSITION OF CONNECTORS FOR TROUBLESHOOTING.....375

CONNECTOR TYPE AND MOUNTING POSITION.....376

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS.....377

PROCEDURE FOR TROUBLESHOOTING.....381

CHECKS BEFORE TROUBLESHOOTING.....382

METHOD OF USING TROUBLESHOOTING CHART.....383

TABLE OF FAILURE MODES AND CAUSES (MACHINE MONITOR SYSTEM).....385

M-1 NO MONITOR PANEL DISPLAY IS GIVEN WHEN STARTING SWITCH IS TURNED ON.....386

M-2 WHEN STARTING SWITCH IS TURNED ON, ALL LAMPS ON MONITOR PANEL STAY LIGHTED AND DO NOT GO OUT.....386

M-3 WHEN STARTING SWITCH IS ON (ENGINE STOPPED), CHECK ITEMS FLASH. (CHECK ITEM LEVELS ARE AT SPECIFIED LEVEL).....387

M-4 NO PREHEATING IS BEING CARRIED OUT, BUT PREHEATING DISPLAY LIGHTS UP.....388

M-5 WHEN STARTING SWITCH IS TURNED ON AND ENGINE IS STARTED, CHECK ITEMS FLASH.....389

M-6 WHEN STARTING SWITCH IS TURNED ON (ENGINE STOPPED) CAUTION ITEMS FLASH.....390

M-7 WHEN STARTING SWITCH IS TURNED ON (ENGINE STOPPED), CAUTION ITEMS FLASH. (WHEN THERE IS AN ABNORMALITY IN THE ENGINE OR IN THE CHECK ITEMS.).....391

M-8 WHEN STARTING SWITCH IS TURNED ON (ENGINE STOPPED), BUZZER DOES NOT SOUND FOR ONE SECOND.....394

a) CAUTION ITEM IS FLASHING BUT BUZZER DOES NOT SOUND.....394

b) THERE IS NO ABNORMALITY IN MONITOR DISPLAY,BUT BUZZER SOUNDS.....394

M-9 WHEN STARTING SWITCH IS TURNED ON (ENGINE STOPPED), LAMPS DO NOT LIGHT UP FOR 2 SECONDS.....395

a) CAUTION ITEM IS FLASHING,BUT WARNING LAMPS DOES NOT FLASH.....395

b) THERE IS NO ABNORMALITY IN MONITOR DISPLAY,BUT LAMPS LIGHT UP.....395

M-10 PANEL LIGHTING OF MONITOR PANEL DOES NOT LIGHT UP.....396

M-11 SERVICE METER DOES NOT MOVE AFTER ENGINE IS STARTED.....397

M-12 WATER TEMPERATURE GAUGE SHOWS ABNORMALLY LOW TEMPERATURE.....398

M-13 WATER TEMPERATURE GAUGE GIVES NO DISPLAY.....398

M-14 TORQUE CONVERTER OIL TEMPERATURE GAUGE SHOWS ABNORMALLY LOW TEMPERATURE.....399

M-15 TORQUE CONVERTER OIL TEMPERATURE GAUGE GIVES NO DISPLAY.....399

M-16 FUEL GAUGE ALWAYS DISPLAYS TANK FULL.....400

M-17 FUEL GAUGE GIVES NO DISPLAY.....400

30 DISASSEMBLY AND ASSEMBLY.....401

METHOD OF USING MANUAL.....403

PRECAUTIONS WHEN CARRYING OUT OPERATION.....404

SPECIAL TOOL LIST.....406

WEIGHT TABLE.....411

TABLE OF TIGHTENING TORQUE AND STANDARD VALUE.....413

TABLE OF OIL AND COOLANT QUANTITIES.....426

PRECAUTIONS WHEN HANDLING PIPING DURING DISASSEMBLY.....427

STARTING MOTOR.....429

REMOVAL.....429

INSTALLATION.....429

ALTERNATOR.....429

REMOVAL.....429

INSTALLATION.....429

AIR COMPRESSOR.....429

REMOVAL.....429

INSTALLATION.....429

NOZZLE HOLDER.....431

REMOVAL.....431

INSTALLATION.....431

FUEL INJECTION PUMP.....431

REMOVAL.....431

INSTALLATION.....431

ENGINE OIL COOLER.....433

REMOVAL.....433

INSTALLATION.....433

THERMOSTAT.....433

REMOVAL.....433

INSTALLATION.....433

WATER PUMP.....433

REMOVAL.....433

INSTALLATION.....433

TURBOCHARGER.....433

REMOVAL.....433

INSTALLATION.....433

CYLINDER HEAD.....435

REMOVAL.....435

INSTALLATION.....439

RADIATOR GUARD.....441

REMOVAL.....441

INSTALLATION.....441

RADIATOR.....443

REMOVAL.....443

INSTALLATION.....443

PTO.....443

REMOVAL.....443

INSTALLATION.....443

DISASSEMBLY.....445

ASSEMBLY.....447

FUEL TANK.....449

REMOVAL.....449

INSTALLATION.....449

ENGINE.....451

REMOVAL.....451

INSTALLATION.....455

TORQUE CONVERTER.....457

REMOVAL.....457

INSTALLATION.....457

DISASSEMBLY.....459

ASSEMBLY.....465

TORQUE CONVERTER RELIEF VALVE.....471

REMOVAL.....471

INSTALLATION.....471

DISASSEMBLY.....471

ASSEMBLY.....471

TORQUE CONVERTER REGULATOR VALVE.....471

REMOVAL.....471

INSTALLATION.....471

DISASSEMBLY.....471

ASSEMBLY.....471

TRANSMISSION.....473

REMOVAL.....473

INSTALLATION.....473

DISASSEMBLY.....475

ASSEMBLY.....487

TRANSMISSION CONTROL VALVE.....501

REMOVAL.....501

INSTALLATION.....501

DISASSEMBLY.....503

ASSEMBLY.....505

TRANSMISSION LUBRICATION VALVE.....507

REMOVAL.....507

INSTALLATION.....507

DISASSEMBLY.....507

ASSEMBLY.....507

BEVEL GEAR AND SHAFT.....509

DISASSEMBLY.....509

ASSEMBLY.....511

STEERING CLUTCH.....517

REMOVAL.....517

INSTALLATION.....517

DISASSEMBLY.....519

ASSEMBLY.....519

STEERING RELIEF VALVE.....521

REMOVAL.....521

INSTALLATION.....521

DISASSEMBLY.....521

ASSEMBLY.....521

BRAKE BOOSTER.....523

DISASSEMBLY.....523

ASSEMBLY.....523

STEERING AND BRAKE VALVE.....523

REMOVAL.....523

INSTALLATION.....523

DISASSEMBLY.....525

ASSEMBLY.....525

TRANSMISSION PUMP.....527

REMOVAL.....527

INSTALLATION.....527

STEERING PUMP.....527

REMOVAL.....527

INSTALLATION.....527

ASSIST BRAKE CYLINDER.....527

REMOVAL.....527

INSTALLATION.....527

DISASSEMBLY.....529

ASSEMBLY.....531

NO.1 PINION.....535

DISASSEMBLY.....535

ASSEMBLY.....537

FINAL DRIVE.....539

DISASSEMBLY.....539

ASSEMBLY.....543

TRACK FRAME.....549

REMOVAL.....549

INSTALLATION.....549

RECOIL SPRING.....551

REMOVAL.....551

INSTALLATION.....551

DISASSEMBLY.....553

ASSEMBLY.....553

IDLER.....555

REMOVAL.....555

INSTALLATION.....555

TRACK ROLLER.....555

REMOVAL.....555

INSTALLATION.....555

CARRIER ROLLER.....557

REMOVAL.....557

INSTALLATION.....557

TRACK SHOE.....557

REMOVAL.....557

INSTALLATION.....557

OVERALL DISASSEMBLY.....559

OVERALL ASSEMBLY.....564

PRESS-FITTING JIG DIMENSION TABLE FOR LINK PRESS.....580

FIELD DISASSEMBLY OF ONE LINK.....581

FIELD ASSEMBLY OF ONE LINK.....583

DISASSEMBLY OF MASTER LINK.....585

ASSEMBLY OF MASTER LINK.....587

HYDRAULIC PUMP.....590

REMOVAL.....590

INSTALLATION.....590

BLADE CONTROL VALVE.....590

REMOVAL.....590

INSTALLATION.....590

DISASSEMBLY.....592

ASSEMBLY.....594

RIPPER CONTROL VALVE.....596

REMOVAL.....596

INSTALLATION.....596

DISASSEMBLY.....596

ASSEMBLY.....596

BLADE RELIEF VALVE.....598

DISASSEMBLY.....598

ASSEMBLY.....598

RIPPER RELIEF VALVE.....598

DISASSEMBLY.....598

ASSEMBLY.....598

BLADE LIFT CYLINDER.....600

REMOVAL.....600

INSTALLATION.....600

BLADE TILT CYLINDER.....600

REMOVAL.....600

INSTALLATION.....600

RIPPER LIFT CYLINDER.....602

REMOVAL.....602

INSTALLATION.....602

RIPPER TILT CYLINDER.....602

REMOVAL.....602

INSTALLATION.....602

HYDRAULIC CYLINDER.....604

DISASSEMBLY.....604

ASSEMBLY.....608

BLADE.....612

REMOVAL.....612

INSTALLATION.....612

DISASSEMBLY.....614

ASSEMBLY.....614

MULTIPLE SHANK RIPPER.....616

DISASSEMBLY.....616

ASSEMBLY.....616

CAB.....618

REMOVAL.....618

INSTALLATION.....618

TURNING OVER ROPS CAB.....620

REMOVAL.....620

INSTALLATION.....622

40 MAINTENANCE STANDARD.....624

TORQUE CONVERTER.....625

TORQFLOW TRANSMISSION.....627

TRANSMISSION CONTROL VALVE.....629

TRANSMISSION LUBRICATION VALVE.....631

TRANSMISSION PUMP.....632

BEVEL GEAR SHAFT.....633

STEERING CLUTCH.....635

STEERING PUMP.....637

STEERING MAIN RELIEF VALVE.....638

STEERING AND BRAKE CONTROL VALVE.....639

STEERING BRAKE .....641

ASSIST BRAKE CYLINDER.....643

ASSIST BRAKE AUTOMATIC DRAIN VALVE.....644

FINAL DRIVE.....645

TRACK FRAME.....647

RECOIL SPRING.....648

IDLER.....649

TRACK ROLLER.....651

CARRIER ROLLER.....653

TRACK.....654

SUSPENSION.....658

HYDRAULIC PUMP.....659

BLADE CONTROL VALVE.....660

RIPPER CONTROL VALVE.....662

HYDRAULIC CYLINDER.....664

CYLINDER STAY.....667

STRAIGHT TILTDOZER.....668

VARIABLE MULTI-SHANK RIPPER.....670

Komatsu Bulldozer D135A Repair Service Manuals