Komatsu Hydraulic Excavator PC400LC-LK, PC400HD-LK Series Repair Service Manuals

Catalog:

Model:

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavator PC400LC-6LK, PC400HD-6LK, with all the technical information to maintain, diagnose, repair, and rebuild like professional mechanics.

Komatsu Hydraulic Excavator PC400LC-6LK, PC400HD-6LK avance workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

CEAM002901 - Hydraulic Excavator PC400LC-6LK, PC400HD-6LK avance Operation & Maintenance Manual.pdf

CEBM002502 - Hydraulic Excavator PC400LC-6LK, PC400HD-6LK avance Shop Manual.pdf

PRODUCT DETAILS:

Total Pages: 1,123 pages

File Format: PDF

Language: English

CEAM002901 - Hydraulic Excavator PC400LC-6LK, PC400HD-6LK avance Operation & Maintenance Manual....2

COVER....2

INTRODUCTION....8

FOREWORD....9

SAFETY INFORMATION....9

INTRODUCTION....10

INTENDED USE....10

FEATURES....10

BREAKING IN THE MACHINE....10

LOCATION OF PLATES, TABLE TO ENTER P.I.N. AND DISTRIBUTOR....11

P.I.N. PLATE LOCATION....11

ENGINE SERIAL NO. PLATE LOCATION....11

TABLE TO ENTER NUMBERS AND DISTRIBUTOR....11

TABLE OF CONTENTS....12

SAFETY....20

WARNING LABELS....21

GENERAL PRECAUTIONS....26

SAFETY RULES....26

SAFETY FEATURES....26

UNAUTHORIZED MODIFICATION....26

INSIDE OPERATOR’S COMPARTMENT....26

CLOTHING AND PERSONAL PROTECTIVE ITEMS....27

ALWAYS APPLY LOCK WHEN LEAVING OPERATOR’S SEAT....27

MOUNTING AND DISMOUNTING....27

INJURY FROM WORK EQUIPMENT....28

FIRE PREVENTION FOR FUEL AND OIL....28

PRECAUTIONS AT HIGH TEMPERATURES....28

ASBESTOS DUST HAZARD PREVENTION....29

FIRE EXTINGUISHER AND FIRST AID KIT....29

CAB GLASS....29

WINDOW WASHER FLUID....29

ESCAPE FROM FIRE....29

PROTECTION AGAINST FALLING OR FLYING OBJECTS....30

MACHINES WITH ACCUMULATOR....30

PRECAUTIONS FOR ATTACHMENTS....30

INDOOR VENTILATION....31

EMERGENCY EXIT FROM OPERATORS CAB....31

PRECAUTIONS DURING OPERATION....32

BEFORE STARTING ENGINE....32

SAFETY AT WORK SITE....32

FIRE PREVENTION....32

VENTILATION FOR ENCLOSED AREAS....32

IN OPERATOR’S CAB....33

PRECAUTIONS FOR MIRROR AND LIGHTS....33

WHEN STARTING ENGINE....33

OPERATING MACHINE....34

WHEN STARTING ENGINE....34

CHECK DIRECTION BEFORE STARTING MACHINE....34

CHECK THAT NO ONE IS IN AREA BEFORE SWINGING OR TRAVELING IN REVERSE....34

NEVER LET ANYONE RIDE ON ATTACHMENT....34

PRECAUTIONS WHEN TRAVELING....35

OPERATE CAREFULLY ON SNOW....35

TRAVELING ON SLOPES....36

PROHIBITED OPERATIONS....36

PRECAUTIONS FOR OPERATION....37

DO NOT GO CLOSE TO HIGH VOLTAGE CABLES....37

WORKING ON LOOSE GROUND....38

OPERATING ON SLOPES....38

PARKING THE MACHINE....38

PRECAUTIONS IN COLD WEATHER....39

TRANSPORTATION....40

LOADING AND UNLOADING....40

PRECAUTIONS WHEN LIFTING....40

SHIPPING....41

BATTERY....42

BATTERY HAZARD PREVENTION....42

STARTING WITH BOOSTER CABLES....42

CHARGING BATTERY....43

TOWING....44

PRECAUTIONS WHEN TOWING....44

BUCKET WITH HOOK....45

PROHIBITED OPERATIONS....45

PRECAUTIONS WHEN INSTALLING AND OPERATING BUCKET WITH HOOK....45

BEFORE CARRYING OUT MAINTENANCE....46

CONTACT WHEN THERE IS FAILURE....46

WARNING TAG....46

CLEAN BEFORE INSPECTION OR MAINTENANCE....46

NEAT CLEAN WORK PLACE....46

FOLLOW LEADER IN OPERATIONS WITH OTHER WORKERS....46

RADIATOR COOLANT LEVEL....47

DO NOT DISASSEMBLE RECOIL SPRING....47

PROPER TOOLS....47

STOP ENGINE PRIOR TO INSPECTION AND MAINTENANCE....47

SUPPORT FOR WORK EQUIPMENT....48

PERIODIC REPLACEMENT OF CRITICAL SAFETY PARTS....48

USE OF LIGHTING....48

FIRE PREVENTION....48

RULES TO FOLLOW WHEN ADDING FUEL OR OIL....49

PRECAUTIONS FOR MAINTENANCE....46

DURING MAINTENANCE....50

PERSONNEL....50

REMOVAL, INSTALLATION AND STORAGE OF ATTACHMENTS....50

WORK UNDER THE MACHINE....50

NOISE....50

WHEN WORKING ON MACHINE....50

LOCK INSPECTION COVERS....50

TWO WORKERS FOR MAINTENANCE WHEN ENGINE IS RUNNING....51

DO NOT DROP TOOLS OR PARTS INSIDE MACHINE....51

FLYING PIECES WITH HAMMER WORK....51

KEEP THE MACHINE CLEAN....51

WELDING REPAIRS....52

REMOVE BATTERY TERMINALS....52

ACTION WHEN ABNORMALITY IS FOUND DURING INSPECTION....52

RULES TO FOLLOW WHEN ADDING FUEL....52

WHEN ADJUSTING TRACK TENSION....53

HANDLING HIGH PRESSURE HOSES....53

WITH HIGH PRESSURE OIL....53

WHEN CARRYING OUT MAINTENANCE AT HIGH TEMPERATURE/PRESSURE....54

WASTE MATERIALS....54

CHECKS AFTER INSPECTION AND MAINTENANCE....54

MAINTENANCE FOR AIR CONDITIONER....54

OPERATION....55

GENERAL....56

GENERAL VIEW OF MACHINE....56

GENERAL VIEW OF OPERATORS COMPARTMENT....57

GENERAL VIEW OF MONITOR PANEL....58

EXPLANATION OF COMPONENTS....59

MACHINE MONITOR....59

MONITOR LIGHT GROUP....61

METER DISPLAY PORTION....63

SWITCHES....66

SWITCHES....69

CONTROL LEVERS AND PEDALS....74

ATTACHMENT CONTROLS....77

OPERATOR’S SEAT....79

SEAT ADJUSTMENT....79

SEAT BELT....81

FASTENING AND REMOVING....81

ADJUST THE BELT LENGTH....81

MONITOR PANEL....82

ADJUSTMENT ANGLE....82

ROOF VENT....82

WHEN OPENING....82

WHEN CLOSING....82

FRONT WINDOW....83

WHEN OPENING....83

WHEN CLOSING....84

FRONT BOTTOM WINDOW....85

DOOR LOCK....85

CAP, COVER WITH LOCK....86

METHOD OF OPENING AND CLOSING LOCK CAP....86

METHOD OF OPENING AND CLOSING COVER LOCK....86

OPERATOR EASE....87

HOT AND COOL BOX....87

STORAGE BOX....87

ASHTRAY....87

AIR CONDITIONER....88

GENERAL LOCATIONS ON CONTROL PANEL....88

PRECAUTIONS WHEN USING AIR CONDITIONER....90

CHECK, MAINTAIN AIR CONDITIONER....90

CAB HEATER....91

GENERAL LOCATION....91

HEATER FAN SWITCH....91

VENT SELECTOR SWITCH....92

DEFROSTER SELECTOR LEVER....92

PREPARATION FOR HEATER....93

AM/FM RADIO....94

EXPLANATION OF COMPONENTS....94

METHOD OF OPERATION....96

PRECAUTIONS WHEN USING....98

SPECIFICATIONS....98

ELECTRIC POWER TAKE OUT ADAPTER....98

FUSE....99

FUSIBLE LINK....100

CONTROLLERS....100

TOOL BOX....100

GREASE GUN HOLDER....100

HANDLING ACCUMULATOR....101

RELEASING PRESSURE ON MACHINE EQUIPPED WITH ACCUMULATOR....101

OPERATION....102

CHECK BEFORE STARTING ENGINE....102

WALK AROUND CHECK....102

CHECK BEFORE STARTING....104

ADJUSTMENT OF MIRRORS....107

ADJUST OPERATOR’S SEAT....107

ADJUST SEAT BELT....107

ADJUST ARM RESTS....107

ADJUST MONITOR PANEL....107

OPERATIONS AND CHECKS BEFORE STARTING ENGINE....108

STARTING ENGINE....110

NORMAL STARTING....110

STARTING IN COLD WEATHER....111

OPERATIONS AND CHECKS AFTER STARTING ENGINE....113

WHEN NORMAL....113

IN COLD AREAS (AUTOMATIC WARM UP OPERATION)....116

MOVING MACHINE....119

MOVING MACHINE FORWARD....119

MOVING MACHINE REARWARD....120

STEERING MACHINE....122

STEERING (CHANGING DIRECTION)....122

STOPPING MACHINE....124

SWINGING....125

OPERATION OF WORK EQUIPMENT....126

HANDLING ACTIVE MODE....127

HANDLING WORKING MODE....128

WORKING MODE....128

POWER MAX., SWIFT SLOW DOWN....128

PROHIBITIONS FOR OPERATION....130

PROHIBITED OPERATIONS USING SWING FORCE....130

PROHIBITED OPERATIONS USING TRAVEL FORCE....130

PRECAUTIONS WHEN OPERATING CYLINDERS TO END OF STROKE....130

PROHIBITED OPERATIONS USING DROPPING FORCE OF BUCKET....131

PROHIBITED OPERATIONS USING DROPPING FORCE OF MACHINE....131

DIGGING ROCKY GROUND....131

SUDDEN LEVER SHIFTING DURING HI SPEED TRAVEL PROHIBITED....131

PRECAUTIONS FOR OPERATION....132

PRECAUTIONS WHEN TRAVELING....132

PRECAUTIONS AT HI SPEED TRAVEL....132

PERMISSIBLE WATER DEPTH....132

PRECAUTIONS WHEN TRAVELING ON HILLS....133

BRAKING WHEN TRAVELING DOWNHILL....134

IF SHOES SLIP....134

IF ENGINE STOPS....134

PRECAUTIONS ON SLOPES....134

HOW TO ESCAPE FROM MUD....135

WHEN ONE SIDE IS STUCK....135

WHEN BOTH SIDES ARE STUCK....135

WORK POSSIBLE USING EXCAVATOR....136

BACKHOE WORK....136

SHOVEL WORK....136

DITCHING WORK....136

LOADING WORK....137

BUCKET REPLACEMENT OR INVERSION....138

REPLACEMENT....138

INVERSION....139

PARKING MACHINE....140

CHECK AFTER FINISHING WORK....142

STOPPING ENGINE....142

CHECK AFTER STOPPING ENGINE....142

LOCKING....143

TRANSPORTATION....144

TRANSPORTATION PROCEDURE....144

LOADING, UNLOADING WORK ON TRAILERS....144

LOADING....145

UNLOADING....146

SECURING MACHINE....148

REMOVAL, INSTALLATION OF MIRRORS....149

METHOD OF LIFTING MACHINE....149

TRACK FRAME GAUGE....151

REDUCING TRACK GAUGE....151

INCREASING TRACK GAUGE....151

COLD WEATHER OPERATION....152

PRECAUTIONS FOR LOW TEMPERATURE....152

FUEL AND LUBRICANTS....152

COOLANT....152

BATTERY....153

PRECAUTIONS AFTER COMPLETION OF WORK....154

AFTER COLD WEATHER....154

LONG TERM STORAGE....155

BEFORE STORAGE....155

DURING STORAGE....155

AFTER STORAGE....155

MACHINE START AFTER LONG TERM STORAGE....156

TROUBLESHOOTING....157

PHENOMENA THAT ARE NOT FAILURES....157

METHOD OF TOWING DISABLED MACHINE....157

USING MACHINE FOR LIGHT WEIGHT TOWING....157

PRECAUTIONS ON PARTICULAR JOB SITES....157

DISCHARGED BATTERY....158

REMOVING AND INSTALLING BATTERY....158

PRECAUTIONS FOR CHARGING BATTERY....158

STARTING ENGINE WITH BOOSTER CABLE....159

OTHER TROUBLE....161

ELECTRICAL SYSTEM....161

CHASSIS....162

ENGINE....163

ELECTRONIC CONTROL SYSTEM....164

MAINTENANCE....165

GUIDES TO MAINTENANCE....166

OUTLINES OF SERVICE....168

OUTLINE OF OIL, FUEL, COOLANT....168

OIL....168

FUEL....168

COOLANT....169

GREASE....169

STORING OIL AND FUEL....169

FILTERS....169

RELATING TO ELECTRICAL SYSTEM....169

OUTLINE OF HYDRAULIC SYSTEM....170

WEAR PARTS LIST....171

USE OF FUEL, COOLANT AND LUBRICANTS....172

PROPER SELECTION OF FUEL, COOLANT AND LUBRICANTS....172

ABBREVIATIONS....172

ENGINE OIL SPECIFICATIONS....173

NORMAL OPERATION....173

ARCTIC OPERATION....173

DAMPER CASE, SWING MACHINERY CASE, TRACK FRONT IDLERS, TRACK ROLLERS, TOP CARRIER ROLLERS AND HYD.....174

FINAL DRIVE OIL SPECIFICATIONS....174

FUEL SYSTEM....174

COOLING SYSTEM....175

GENERAL....175

WATER....175

ANTIFREEZE....175

INHIBITORS/CONDITIONERS....176

SUPPLEMENTAL COOLANT ADDITIVES....176

STANDARD TIGHTENING TORQUES....180

INTRODUCTION OF NECESSARY TOOLS....180

BOLT IDENTIFICATION CHART....181

PERIODIC REPLACEMENT OF CRITICAL PARTS....182

MAINTENANCE SCHEDULE CHART....183

MAINTENANCE INTERVAL WHEN USING BREAKER....185

SERVICE PROCEDURE....186

INITIAL 250 HOURS SERVICE....186

FUEL FILTER CARTRIDGE....186

REPLACE ENGINE BYPASS FILTER CARTRIDGE....187

ENGINE VALVE CLEARANCE....188

WHEN REQUIRED....189

CHECK, CLEAN AND REPLACE AIR CLEANER ELEMENT....189

DRAIN, FLUSH AND REFILL COOLING SYSTEM....191

CHECK AND TIGHTEN TRACK SHOE BOLTS....193

CHECK AND ADJUST TRACK TENSION....193

CHECK ELECTRICAL INTAKE AIR HEATER....195

BUCKET TEETH REPLACEMENT....196

ADJUST BUCKET CLEARANCE....198

CHECK WINDOW WASHER FLUID, ADD FLUID....199

CHECK, MAINTAIN AIR CONDITIONER....199

REPLACE ADDITIONAL BREAKER FILTER ELEMENT....200

CLEAN IN LINE FILTERS....202

CHECK BEFORE STARTING....203

CHECK COOLANT LEVEL, ADD COOLANT....203

CHECK ENGINE OIL LEVEL, ADD OIL....203

CHECK FUEL LEVEL, ADD FUEL....204

CHECK OIL LEVEL IN HYDRAULIC TANK, ADD OIL....204

CHECK AIR CLEANER FOR CLOGGING....205

CHECK ELECTRIC WIRING....205

CHECK FUNCTION OF HORN....205

CHECK FOR WATER/SEDIMENT IN FUEL FILTER, DRAIN....206

EVERY 50 HOURS SERVICE....207

GREASE LUBRICATION....207

EVERY 100 HOURS SERVICE....209

PREVIOUS MAINTENANCE....209

LUBRICATION....209

CHECK OIL LEVEL IN SWING MACHINERY CASE, ADD OIL....210

DRAIN WATER AND SEDIMENT FROM FUEL TANK....210

EVERY 250 HOURS SERVICE....211

PREVIOUS MAINTENANCE....211

CHECK OIL LEVEL IN FINAL DRIVE CASE, ADD OIL....211

CHECK LEVEL OF BATTERY ELECTROLYTE....211

CHANGE ENGINE OIL, REPLACE FILTER CARTRIDGE....212

LUBRICATE SWING CIRCLE (3 POINTS)....214

CHECK FAN BELT TENSION, ADJUST....214

CHECK, ADJUST TENSION OF A/C COMPRESSOR BELT....215

EVERY 500 HOURS SERVICE....216

PREVIOUS MAINTENANCE....216

FUEL FILTER CARTRIDGE....216

CHECK SWING PINION GREASE LEVEL, ADD GREASE....217

CLEAN AND INSPECT RADIATOR, OIL COOLER AND CONDENSER FINS....217

CLEAN FILTERS OF AIR CONDITIONER....218

REPLACE HYDRAULIC TANK BREATHER ELEMENT....218

REPLACE HYDRAULIC FILTER ELEMENT....219

EVERY 1000 HOURS SERVICE....220

CHANGE OIL IN SWING MACHINERY CASE....220

CHECK OIL LEVEL IN DAMPER CASE, ADD OIL....220

REPLACE CORROSION RESISTOR CARTRIDGE....221

REPLACE HYDRAULIC TANK RELIEF VALVE ELEMENT....222

CHECK TIGHTENING PARTS OF TURBOCHARGER....222

CHECK PLAY OF TURBOCHARGER ROTOR....222

EVERY 2000 HOURS SERVICE....223

CHANGE OIL IN FINAL DRIVE CASE....223

CLEAN HYDRAULIC TANK STRAINER....223

CLEAN ENGINE BREATHER....224

CLEAN, CHECK TURBOCHARGER....224

CHECK ALTERNATOR, STARTING MOTOR....224

CHECK ENGINE VALVE CLEARANCE, ADJUST....224

CHECK VIBRATION DAMPER....224

CHECK, ADJUST FUEL INJECTION NOZZLES....224

EVERY 4000 HOURS SERVICE....225

CHECK WATER PUMP....225

REPLACE FUEL INJECTION NOZZLE TIPS....225

EVERY 5000 HOURS SERVICE....226

CHANGE OIL IN HYDRAULIC TANK....226

SPECIFICATIONS....230

SPECIFICATIONS AND DIMENSIONS....231

SPECIFICATIONS....231

DIMENSIONS....233

PC400LC-6LK....233

PC400HD-6LK....245

OPTIONS, ATTACHMENTS....254

GENERAL PRECAUTIONS....255

PRECAUTIONS RELATED TO SAFETY....255

PRECAUTIONS WHEN INSTALLING ATTACHMENTS....256

BUCKET WITH HOOK....257

CHECKING FOR DAMAGE....257

PROHIBITED OPERATIONS....257

PRECAUTIONS DURING OPERATIONS....257

MACHINES READY FOR ATTACHMENT....258

GENERAL LOCATIONS....258

HYDRAULIC CIRCUIT....261

SWITCHING TO FILTER CIRCUIT....261

CONNECTING HYDRAULIC CIRCUIT....261

PATH OF OIL FLOW....262

ATTACHMENT REMOVAL AND INSTALLATION....263

PROCEDURE FOR REMOVAL....263

PROCEDURE FOR INSTALLATION....263

OPERATION....264

WHEN USING BREAKER....264

WHEN USING GENERAL ATTACHMENT....264

LONG TERM STORAGE....265

SPECIFICATIONS....265

INTRODUCTION OF ATTACHMENTS....266

ATTACHMENT INSTALLATION COMBINATION TABLE....266

BUCKET SELECTION....267

STANDARD DUTY PLATE BUCKET....267

HEAVY DUTY PLATE BUCKET....267

HEAVY DUTY CAST BUCKET....267

DITCH CLEANING BUCKET....267

SELECTION OF TRACK SHOES....268

EXTENDING MACHINE SERVICE LIFE....269

HYDRAULIC BREAKER....269

MAIN FIELDS OF APPLICATION....269

MISTAKEN METHODS OF USE....270

GREASING POSITION FOR HYDRAULIC BREAKER....272

POWER RIPPER....273

MAIN FIELDS OF APPLICATION....273

MISTAKEN METHODS OF USE....273

GRAB FORK....275

MAIN FIELDS OF APPLICATION....275

MISTAKEN METHODS OF USE....275

GRAPPLE BUCKET....276

MAIN FIELDS OF APPLICATION....276

MISTAKEN METHODS OF USE....276

SCRAP GRAPPLE....278

MAIN FIELDS OF APPLICATION....278

MISTAKEN METHODS OF USE....278

CRUSHER AND CUTTER....280

MAIN FIELDS OF APPLICATION....280

MISTAKEN METHODS OF USE....280

HYDRAULIC PILE DRIVER....281

MAIN FIELDS OF APPLICATION....281

MISTAKEN METHODS OF USE....281

MULTIPURPOSE CRANE....283

MAIN FIELDS OF APPLICATION....283

MISTAKEN METHODS OF USE....283

CEBM002502 - Hydraulic Excavator PC400LC-6LK, PC400HD-6LK avance Shop Manual....288

COVER....288

CONTENTS....289

FOREWORD....300

SAFETY....300

SAFETY NOTICE....300

IMPORTANT SAFETY NOTICE....300

GENERAL PRECAUTIONS....300

PREPARATIONS FOR WORK....300

PRECAUTIONS DURING WORK....300

GENERAL....302

HOW TO READ THE SHOP MANUAL....303

VOLUMES....303

DISTRIBUTION AND UPDATING....303

FILING METHOD....303

REVISED EDITION MARK....303

REVISIONS....303

SYMBOLS....303

HOISTING INSTRUCTIONS....304

HOISTING....304

WIRE ROPES....304

COATING MATERIALS....305

STANDARD TIGHTENING TORQUE....307

STANDARD TIGHTENING TORQUE OF BOLTS AND NUTS....307

TIGHTENING TORQUE OF HOSE NUTS....308

TIGHTENING TORQUE OF SPLIT FLANGE BOLTS....308

TIGHTENING TORQUE FOR FLARED NUTS....308

ELECTRIC WIRE CODE....309

CLASSIFICATION BY THICKNESS....309

CLASSIFICATION BY COLOR AND CODE....309

CONVERSION TABLES....310

METHOD OF USING THE CONVERSION TABLE....310

01 GENERAL....316

SPECIFICATION DRAWINGS....317

MACHINE....317

WORK EQUIPMENT....319

SPECIFICATIONS....321

WEIGHT TABLE....323

FUEL COOLANT AND LUBRICANTS....325

10 STRUCTURE AND FUNCTION....326

PARTS RELATED TO ENGINE....330

ENGINE MOUNT TORQUES....332

RADIATOR, OIL COOLER....334

RADIATOR AND OIL COOLER SPECIFICATIONS AND TORQUES (1/4)....335

RADIATOR AND OIL COOLER SPECIFICATIONS AND TORQUES (2/4)....336

RADIATOR AND OIL COOLER SPECIFICATIONS AND TORQUES (3/4)....337

RADIATOR AND OIL COOLER SPECIFICATIONS AND TORQUES (4/4)....339

POWER TRAIN....340

FINAL DRIVE....342

FINAL DRIVE SPECIFICATIONS AND TORQUES....343

SWING CIRCLE....345

SWING CIRCLE SPECIFICATIONS AND TORQUES....346

SWING MACHINERY....348

SWING MACHINERY SPECIFICATIONS AND TORQUES....349

TRACK FRAME, RECOIL SPRING....351

PC400LC-6LK....351

TRACK FRAME, RECOIL SPRING TORQUES PC400LC-6LK....352

PC400LC-6LK - VARIABLE GAUGE....353

TRACK FRAME, RECOIL SPRING TORQUES PC400LC-6LK - VARIABLE GAUGE....354

PC400HD-6LK....355

TRACK FRAME, RECOIL SPRING TORQUES PC400HD-6LK....356

TRACK SHOE....358

TRACK SHOE SPECIFICATIONS....361

CARRIER ROLLER....362

IDLER....363

TRACK ROLLER....365

HYDRAULIC PIPING DRAWING....367

HYDRAULIC CIRCUIT DIAGRAM....369

HYDRAULIC TANK, HYDRAULIC FILTER....370

HYDRAULIC PUMP....371

HPV 160 + 160....371

HYDRAULIC PUMP TORQUES....374

TVC, LS VALVE....378

LS VALVE - OPERATION....381

TVC VALVE - OPERATION....385

HYDRAUIC CYLINDER....393

BOOM, BUCKET CYLINDER - THREADED PISTON....393

BOOM, BUCKET CYLINDER - CLAMPED PISTON....393

ARM CYLINDER - THREADED PISTON....393

ARM CYLINDER - CLAMPED PISTON....393

CONTROL VALVE....395

10 SPOOL VALVE - STD. AND 3 SERVICE VALVES....395

9 SPOOL VALVE - STD AND 2 SERVICE VALVES....401

8 SPOOL VALVE - STD AND 1 SERVICE VALVES....402

7 SPOOL VALVE - STD....403

CONTROL VALVE SPECIFICATIONS AND TORQUES....405

10 SPOOL VALVE....405

SELF REDUCING PRESSURE VALVE....411

SELF REDUCING PRESSURE VALVE SPECIFICATIONS....411

SUCTION SAFETY VALVE....417

FOR SERVICE....417

SUCTION SAFETY VALVE SPECIFICATIONS AND TORQUES....418

CLSS....419

OUTLINE OF CLSS....419

BASIC PRINCIPLE....420

CONTROL OF PUMP SWASH PLATE ANGLE....420

PRESSURE COMPENSATION....421

OPERATION FOR EACH FUNCTION OF CLSS....422

SYSTEM DIAGRAM....423

WHEN UNLOAD VALVE IS ACTUATED....424

OPERATION OF RELIEF VALVE....425

CUT-OFF CONTROL ACTUATED....425

CUT-OFF CANCELED....425

INTRODUCTION OF LS PRESSURE....426

LS BYPASS VALVE....427

PRESSURE COMPENSATION VALVE....428

SHUTTLE VALVE INSIDE PRESSURE COMPENSATION VALVE....431

VARIABLE TYPE PRESSURE COMPENSATION VALVE (FOR SERVICE VALVE)....433

VARIABLE PRESSURE COMPENSATION VALVE SPECIFICATIONS AND TORQUES....434

BOOM REGENERATION CIRCUIT....435

ARM REGENERATION CIRCUIT....437

MERGE FLOW DIVIDER VALVE....439

LS SELECT VALVE....441

2-STAGE SAFETY VALVE (INSTALLED TO BOOM CYLINDER HEAD)....442

OPERATION OF CLSS SYSTEM AS A WHOLE....443

WHEN ALL WORK EQUIPMENT IS AT NEUTRAL....443

WHEN PUMP FLOW MERGED, BUCKET CURL OPERATED INDEPENDENTLY....444

WHEN PUMP FLOW MERGED, BOOM RAISE OPERATED INDEPENDENTLY....444

WHEN PUMP FLOW MERGED, ARM IN OPERATED INDEPENDENTLY....444

WHEN PUMP FLOW MERGED, ARM OUT OPERATED INDEPENDENTLY....445

WHEN PUMP DIVIDED, TRAVEL OPERATED INDEPENDENTLY....445

WHEN PUMP FLOW MERGED, ARM IN + BOOM RAISE OPERATED SIMULTANEOUSLY....445

WHEN PUMP FLOW MERGED, SWING + BOOM RAISE OPERATED SIMULTANEOUSLY....446

WHEN PUMP FLOW DIVIDED, TRAVEL + BOOM RAISE OPERATED SIMULTANEOUSLY....446

WHEN PUMP FLOW DIVIDED, TRAVEL + ARM IN OPERATED SIMULTANEOUSLY....446

SWING MOTOR....447

SWING MOTOR SPECIFICATIONS AND TORQUES....449

SUCTION-SAFETY VALVE....450

SWING BRAKE....451

CENTER SWIVAL JOINT....452

CENTER SWIVEL JOINT SPECIFICATIONS....453

TRAVEL MOTOR....455

MOTOR OPERATION....459

AT LOW SPEED....459

AT HIGH SPEED....460

PARKING BRAKE OPERATION....461

BRAKE VALVE OPERATION....461

SAFETY VALVE....463

VALVE CONTROL....466

WORK EQUIPMENT PPC VALVE....467

OPERATION....469

AT NEUTRAL....469

DURING FINE CONTROL (NEUTRAL Æ FINE CONTROL)....469

DURING FINE CONTROL (WHEN LEVER IS RETURNED)....470

AT FULL STROKE....470

WORK EQUIPMENT AND SWING PPC VALVE SPECIFICATIONS AND TORQUES....471

TRAVEL PPC VALVE....472

OPERATION....474

AT NEUTRAL....474

FINE CONTROL (NEUTRAL --> FINE CONTROL)....474

FINE CONTROL (CONTROL LEVER RETURNED)....475

AT FULL STROKE....475

TRAVEL PPC VALVE SPECIFICATIONS AND TORQUE....477

SERVICE PPC VALVE....479

SERVICE PPC VALVE SPECIFICATIONS AND TORQUES....481

PPC SAFETY LOCK VALVE....482

PPC ACCUMULATOR....483

PPC SHUTTLE VALVE, TRAVEL JUNCTION VALVE....484

PPC SHUTTLE VALVE....485

TRAVEL JUNCTION VALVE....488

STRAIGHT-TRAVEL SYSTEM....489

PPC SHUTTLE VALVE, TRAVEL JUNCTION VALVE SPECIFICATIONS AND TORQUES....491

LS-EPC VALVE....492

LS-EPC VALVE SPECIFICATIONS AND TORQUES....495

SOLENOID VALVE....496

SOLENOID VALVE TORQUES....498

BOOM HOLDING VALVE....499

BOOM HOLDING VALVE SPECIFICATIONS AND TORQUES....502

WORK EQUIPMENT....504

WORK EQUIPMENT SPECIFICATIONS....505

DIMENSIONS OF WORK EQUIPMENT....507

ARM....507

BUCKET....509

AIR CONDITIONER....512

A/C PIPING....512

A/C ELECTRICAL WIRING DIAGRAM....513

ENGINE CONTROL....517

OPERATION....518

STARTING ENGINE....518

ENGINE SPEED CONTROL....518

STOPPING ENGINE....518

COMPONENTS....519

FUEL CONTROL DIAL....519

GOVERNOR MOTOR....521

GOVERNOR, PUMP CONTROLLER....523

INPUT OUTPUT SIGNALS....524

ELECTRONIC CONTROL SYSTEM....526

CONTROL FUNCTION....526

TOTAL SYSTEM DIAGRAM....526

PUMP AND ENGINE CONTROL SYSTEM....527

PUMP AND VALVE CONTROL FUNCTION....530

CUT-OFF FUNCTION....531

CUT-OFF CANCEL FUNCTION....531

FINE CONTROL MODE FUNCTION....532

POWER MAX. FUNCTION, SWIFT SLOW-DOWN FUNCTION....533

AUTO DECELERATION SYSTEM....534

AUTOMATIC WARMING-UP AND ENGINE OVERHEAT PREVENTION FUNCTION....536

SWING CONTROL SYSTEM....539

TRAVEL CONTROL SYSTEM....541

ACTIVE MODE FUNCTION....543

INCREASE IN ENGINE SPEED....544

COMPONENTS OF SYSTEM....545

ENGINE SPEED SENSOR....545

PPC HYDRAULIC SWITCH....545

PUMP PRESSURE SENSOR....546

TVC PROLIX RESISTOR....547

MACHINE MONITOR SYSTEM....549

MONITOR PANEL....550

MONITOR DISPLAY....551

CONTENT OF DISPLAY....552

OIL MAINTENANCE FUNCTION....553

MODE SELECTION SWITCHES....555

SWITCH ACTUATION TABLE....555

SENSORS....556

20 TESTING, ADJUSTING AND TROUBLESHOOTING....560

STANDARD VALUE TABLES....562

ENGINE RELATED PARTS....562

CHASSIS RELATED PARTS....563

ELECTRICAL PARTS....568

TESTING AND ADJUSTING....574

SERVICE TOOLS....576

ENGINE....577

BLOW BY PRESSURE....577

BOOST PRESSURE....577

COMPRESSION PRESSURE....577

ENGINE OIL PRESSURE....577

ENGINE SPEED SENSOR....577

ENGINE SPEED (rpm)....577

EXHAUST COLOR....577

FUEL INJECTION TIMING....577

VALVE CLEARANCE....577

GOVERNOR MOTOR LEVER S TROKE....578

FAN BELT TENSION....579

A/C COMPRESSOR BELT....579

WORK EQUIPMENT, SWING, TRAVEL CIRCUIT....580

TVC VALVE OUTPUT PRESSURE....583

LS VALVE OUTPUT PRESSURE....585

LS DIFFERENTIAL PRESSURE....585

CONTROL CIRCUIT OIL PRESSURE....588

SOLENOID VALVE OUTPUT PRESSURE....589

PPC VALVE OUTPUT PRESSURE....592

PPC SHUTTLE VALVE....592

WORK EQUIPMENT, SWING PPC VALVE....594

WORK EQUIPMENT....596

HYDRAULIC DRIFT - LOCATIONS CAUSING....596

CYLINDER PACKING....596

BOOM LOCK VALVE....597

PPC VALVE....597

OIL LEAKAGE....598

WORK EQUIPMENT CYLINDER....598

SWING MOTOR....599

TRAVEL MOTOR....599

RELEASING REMAINING PRESSURE....600

TESTING CLEARANCE OF SWING CIRCLE BEARING....601

SPROCKET WEAR....602

TRACK SHOE TENSION....603

BLEEDING AIR....604

BLEEDING AIR FROM HYDRAULIC CYLINDERS....605

BLEEDING AIR FROM SWING MOTOR....605

BLEEDING AIR FROM TRAVEL MOTOR....605

TROUBLESHOOTING GENERAL....606

POINTS TO REMEMBER WHEN TROUBLESHOOTING....608

SEQUENCE OF EVENTS IN TROUBLESHOOTING....610

POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE....611

POINTS TO REMEMBER WHEN HANDLING ELECTRIC EQUIPMENT....611

HANDLING WIRING HARNESSES AND CONNECTORS....611

REMOVING, INSTALLING, AND DRYING CONNECTORS AND WIRING HARNESSES....613

HANDLING CONTROL BOX....616

POINTS TO REMEMBER WHEN TROUBLESHOOTING ELECTRIC CIRCUITS....617

POINTS TO REMEMBER WHEN HANDLING HYDRAULIC EQUIPMENT....617

CHECKS BEFORE TROUBLESHOOTING....619

CONNECTOR TYPES AND MOUNTING LOCATIONS....620

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS....626

EXPLANATION OF CONTROL MECHANISM FOR ELECTRICAL SYSTEM....636

EXPLANATION OF MACHINE CONTROL FUNCTIONS....636

DISPLAY METHOD AND SPECIAL FUNCTION OF MONITORING PANEL....637

DISPLAY ON MACHINE MONITOR....637

RECORDING OF SERVICE CODES AND USER CODE DISPLAY FUNCTION....637

METHOD OF DISPLAYING TROUBLE DATA....638

MACHINE DATA MONITORING FUNCTION....639

METHOD OF DISPLAYING MONITORING CODE....639

TABLE OF MACHINE MONITORING CODES....640

BIT PATTERN CHART....641

GOVERNOR MOTOR ADJUSTMENT MODE....643

TIME ADJUSTMENT MODE....643

WORKING MODE DEFAULT SETTING MODE....644

METHOD OF USING JUDGEMENT TABLE....645

METHOD OF USING TROUBLESHOOTING CHARTS....647

METHOD OF USING TROUBLESHOOTING TABLE FOR EACH TROUBLESHOOTING MODE....647

DETAILS OF TROUBLESHOOTING AND TROUBLESHOOTING PROCEDURE....651

PROCEDURE FOR CHECKING MONITOR PANEL OUTPUT SIGNAL....653

CHECKING INPUT SIGNAL OF GOVERNOR, PUMP CONTROLLER....654

PUMP CONTROL SYSTEM....654

GOVERNOR CONTROL SYSTEM....657

SERVICE CODE TABLE....658

TROUBLESHOOTING ELECTRICAL SYSTEM ON GOVERNOR PUMP CONTROLLER (C-MODE)....660

POINTS TO REMEMBER WHEN TROUBLESHOOTING SYSTEM....662

POINTS TO REMEMBER IF A PROBLEM RETURNS TO NORMAL BY ITSELF....662

USER CODE MEMORY RETENTION FUNCTION....662

INFORMATION CONTAINED IN TESTING PROCEDURES....663

(C-1)....665

CONTROLLER POWER SOURCE (LED) IS OFF....665

(C-2)....667

SHORT IN FRONT PUMP (TVC) SOLENOID SYSTEM....667

(C-3)....669

OPEN IN FRONT PUMP (TVC) SOLENOID SYSTEM....669

(C-4)....671

SHORT IN REAR PUMP (TVC) SOLENOID SYSTEM....671

(C-5)....673

OPEN IN REAR PUMP (TVC) SOLENOID SYSTEM....673

(C-6)....675

SHORT IN (LS) SELECT SOLENOID SYSTEM....675

(C-7)....676

OPEN IN (LS) SELECT SOLENOID SYSTEM....676

(C-8)....677

SHORT IN SWING BRAKE SOLENOID SYSTEM....677

(C-9)....679

OPEN IN SWING BRAKE SOLENOID SYSTEM....679

(C-10)....681

SHORT IN PUMP MERGE DIVIDER SOLENOID SYSTEM....681

(C-11)....683

OPEN IN PUMP MERGE DIVIDER SOLENOID SYSTEM....683

(C-12)....685

SHORT IN TRAVEL SPEED SOLENOID SYSTEM....685

(C-13)....687

OPEN IN TRAVEL SPEED SOLENOID SYSTEM....687

(C-14)....689

SHORT IN ACTIVE MODE, SWING, SOLENOID SYSTEM....689

(C-15)....691

OPEN IN ACTIVE MODE, SWING, SOLENOID SYSTEM....691

(C-16)....693

ABNORMAL INPUT FOR MODEL CODE....693

(C-17)....695

SHORT IN (LS-EPC) SOLENOID SYSTEM....695

(C-18)....696

OPEN IN (LS-EPC) SOLENOID SYSTEM....696

(C-19)....697

ABNORMAL FRONT PUMP PRESSURE SENSOR SIGNAL....697

(C-20)....699

BINOMIAL REAR PUMP PRESSURE SENSOR SIGNAL....699

(C-21)....701

ABNORMAL PRESSURE SENSOR POWER SUPPLY....701

(C-22)....703

ABNORMAL ENGINE RPM SIGNAL IN GOVERNOR PUMP CONTROLLER....703

(C-23)....705

MACHINE PUSH-UP SOLENOID HAS NO RESPONSE....705

TROUBLESHOOTING ELECTRICAL SYSTEM ON GOVERNOR PUMP CONTROLLER (E-MODE)....708

POINTS TO REMEMBER WHEN TROUBLESHOOTING SYSTEM....710

POINTS TO REMEMBER IF A PROBLEM RETURNS TO NORMAL BY ITSELF....710

USER CODE MEMORY RETENTION FUNCTION....710

INFORMATION CONTAINED IN TESTING PROCEDURES....711

(E-1)....713

CONTROLLER POWER SOURCE (LED) IS OFF....713

(E-2)....715

INCORRECT FUEL CONTROL DIAL VALUE DISPLAYED....715

(E-3)....717

OPEN IN MOTOR DRIVE SYSTEM....717

(E-4)....719

SHORT IN MOTOR DRIVE SYSTEM....719

(E-5)....721

INCORRECT FEEDBACK IN POTENTIOMETER DISPLAYED....721

(E-6)....723

SHORT IN BATTERY RELAY OUTPUT SYSTEM....723

(E-7)....725

ABNORMALITY IN STEP OUT MOTOR SYSTEM....725

(E-8)....727

ENGINE WILL NOT CRANK....727

(E-9)....729

ENGINE SPEED IRREGULAR....729

ENGINE SPEED IS HUNTING....731

(E-10)....733

ENGINE OUTPUT IS LOW....733

(E-11)....735

ENGINE WILL NOT SHUT DOWN....735

(E-12)....737

FAULTY OPERATION OF RELAY OUTPUT SYSTEM....737

TROUBLSHOOTING GOVERNOR, PUMP CONTROLLER, INPUT SIGNAL (F-MODE)....740

POINTS TO REMEMBER WHEN TROUBLESHOOTING SYSTEM....741

POINTS TO REMEMBER IF A PROBLEM RETURNS TO NORMAL BY ITSELF....741

USER CODE MEMORY RETENTION FUNCTION....741

INFORMATION CONTAINED IN TESTING PROCEDURES....742

(F-1)....744

SWING OIL PRESSURE SWITCH DOES NOT LIGHT UP....744

(F-2)....745

TRAVEL OIL PRESSURE SWITCH DOES NOT LIGHT UP....745

(F-3)....746

BOOM (LOWER) PRESSURE SWITCH DOES NOT LIGHT UP....746

(F-4)....747

BOOM (RAISE) PRESSURE SWITCH DOES NOT LIGHT UP....747

(F-5)....748

ARM (IN) PRESSURE SWITCH DOES NOT LIGHT UP....748

(F-6)....749

ARM (OUT) PRESSURE SWITCH DOES NOT LIGHT UP....749

(F-7)....750

BUCKET (CURL) PRESSURE SWITCH DOES NOT LIGHT UP....750

(F-8)....751

BUCKET (DUMP) PRESSURE SWITCH DOES NOT LIGHT UP....751

(F-9)....752

SWING LOCK SWITCH DOES NOT LIGHT UP....752

(F-10)....753

MODE CONNECTION DOES NOT LIGHT UP....753

(F-11)....755

LEFT KNOB SWITCH DOES NOT LIGHT UP....755

TROUBLESHOOTING HYDRAULIC AND MECHANICAL SYSTEM (H-MODE)....758

PUMP MERGE DIVIDER LOGIC....760

SOLENOID ACTUATION TABLE....760

TABLE OF FAILURE MODES AND CAUSES....761

H-1....765

SPEEDS OF ALL WORK EQUIPMENT, SWING, TRAVEL ARE SLOW OR LACK POWER....765

H-2....767

THERE IS EXCESSIVE DROP IN ENGINE SPEED, OR ENGINE STALLS....767

H-3....768

NO WORK EQUIPMENT, TRAVEL, SWING MOVEMENT....768

H-4....769

ABNORMAL NOISE GENERATED AROUND PUMP....769

H-5....770

AUTO DECELERATION DOES NOT WORK WHEN PPC SHUTTLE VALVE IS CAUSE....770

H-6....770

FINE CONTROL ABILITY IS POOR OR RESPONSE IS POOR....770

H-7....771

BOOM IS SLOW OR LACKS POWER....771

H-8....773

ARM IS SLOW OR LACKS POWER....773

H-9....775

BUCKET IS SLOW OR LACKS POWER....775

H-10....777

WORK EQUIPMENT; BOOM, ARM, BUCKET, DOES NOT MOVE, BUT TRAVEL AND SWING ARE NORMAL....777

H-11....777

EXCESSIVE HYDRAULIC DRIFT, BOOM, ARM, BUCKET....777

EXCESSIVE HYDRAULIC DRIFT OF BOOM....777

EXCESSIVE HYDRAULIC DRIFT OF ARM OR BUCKET....777

H-12....778

EXCESSIVE TIME LAG, ENGINE AT LOW IDLING....778

H-13....778

OTHER EQUIPMENT MOVES WHEN SINGLE CIRCUIT IS RELIEVED....778

H-14....779

IN L/O, F/O MODES, WORK EQUIPMENT SPEED IS FASTER THAN SPECIFIED SPEED....779

H-15....779

MALFUNCTION OF MACHINE PUSH UP FUNCTION....779

H-16....779

IN COMPOUND OPERATIONS, WORK EQUIPMENT WITH LARGER LOAD IS SLOW....779

H-17....780

IN SWING PLUS BOOM RAISE, BOOM RAISE IS SLOW....780

IN ACTIVE MODE....780

IN OTHER MODE....780

H-18....780

IN SWING PLUS ARM, ARM IS SLOW....780

H-19....780

IN SWING PLUS TRAVEL, TRAVEL SPEED DROPS EXCESSIVELY....780

H-20....781

TRAVEL DEVIATION....781

WHEN THERE IS A DEVIATION IN NORMAL TRAVEL....781

EXCESSIVE DEVIATION WHEN STARTING....781

H-21....783

TRAVEL SPEED IS SLOW....783

H-22....785

STEERING DOES NOT TURN EASILY OR LACKS POWER....785

H-23....787

TRAVEL SPEED DOES NOT SWITCH OR IS FASTER THAN SPECIFIED SPEED....787

H-24....787

TRAVEL DOES NOT MOVE, ONE SIDE ONLY....787

H-25....788

DOES NOT SWING....788

DOES NOT SWING TO EITHER LEFT OR RIGHT....788

DOES NOT SWING IN ONE DIRECTION....788

H-26....789

SWING ACCELERATION IS POOR OR SWING SPEED IS SLOW....789

H-27....791

EXCESSIVE OVERRUN WHEN STOPPING SWING....791

ONE DIRECTION ONLY....791

BOTH DIRECTIONS....791

H-28....792

EXCESSIVE SHOCK WHEN STOPPING SWING, ONE DIRECTION ONLY....792

H-29....792

EXCESSIVE ABNORMAL NOISE WHEN STOPPING SWING....792

H-30....793

EXCESSIVE HYDRAULIC DRIFT OR SWING....793

WHEN SWING HOLDING BRAKE IS RELEASED....793

WHEN SWING HOLDING BRAKE IS APPLIED....793

H-31....794

SWING SPEED IS FASTER THAN SPECIFIED SWING SPEED....794

TROUBLESHOOTING MACHINE MONITOR SYSTEM (M-MODE)....796

POINTS TO REMEMBER WHEN TROUBLESHOOTING SYSTEM....798

POINTS TO REMEMBER IF A PROBLEM RETURNS TO NORMAL BY ITSELF....798

USER CODE MEMORY RETENTION FUNCTION....798

INFORMATION CONTAINED IN TESTING PROCEDURES....799

(M-1)....801

ERROR IN DATA HISTORY....801

(M-2)....803

SHORT IN BUZZER OUTPUT DISPLAY....803

(M-3)....805

AIR CLEANER CLOG INDICATOR FAILURE....805

(M-4)....807

ABNORMAL ENGINE (HI) OIL PRESSURE....807

(M-5)....809

ENGINE COOLANT INDICATING OVERHEAT CONDITION....809

(M-6)....811

THREE SECOND DELAY ON MONITOR WHEN IGNITION KEY IS TURNED “ON”....811

(M-7)....813

WHEN IGNITION SWITCH IS TURNED “ON” ALL PANEL LAMPS STAY ILLUMINATED....813

(M-8)....813

WHEN IGNITION SWITCH IS TURNED “ON” PANEL LIGHTS DO NOT MATCH THE MACHINE....813

(M-9)....815

ABNORMAL FLUID LEVEL INDICATIONS....815

ENGINE COOLANT LEVEL FLASHES....815

ENGINE OIL LEVEL FLASHES....817

HYDRAULIC OIL LEVEL FLASHES....818

(M-10)....819

PREHEATING INDICATION IS “ON” WHEN SYSTEM IS OFF....819

(M-11)....821

WHEN ENGINE IS STARTED BASIC CHECK ITEMS FLASH....821

ALTERNATOR SYSTEM....821

ENGINE OIL PRESSURE....823

(M-12)....825

WHEN ENGINE IS STARTED CAUTION ITEMS FLASH....825

ALTERNATOR SYSTEM....825

ENGINE OIL PRESSURE....827

(M-13)....829

WHEN THE ENGINE IS STARTED CAUTION AND EMERGENCY ITEMS FLASH....829

ENGINE OIL PRESSURE FLASHES....829

COOLANT LEVEL FLASHES....829

BATTERY CHARGE INDICATOR FLASHES....829

COOLANT TEMPERATURE FLASHES....830

FUEL LEVEL FLASHES....831

AIR CLEANER CLOG INDICATOR FLASHES....832

(M-14)....833

WARNINGS FLASH BUT BUZZER IS DELAYED....833

(M-15)....835

BUZZER SOUNDS CONTINUOUSLY....835

(M-16)....837

NIGHT LIGHT ON MONITOR PANEL DOES NOT LIGHT-UP....837

(M-17)....839

ENGINE COOLANT TEMPERATURE DOES NOT RISE....839

(M-18)....841

ENGINE COOLANT TEMPERATURE GIVES NO DISPLAY....841

(M-19)....843

FUEL LEVEL GAUGE ALWAYS SHOWS “FULL”....843

(M-20)....844

FUEL LEVEL GAUGE DOES NOT DISPLAY....844

(M-21)....845

SWING LOCK NOT INDICATED ON MONITOR WHEN “ON”....845

(M-22)....847

SWING PROLOX NOT INDICATED ON MONITOR....847

(M-23)....849

SERVICE METER DOES NOT ADVANCE WHILE ENGINE IS RUNNING....849

(M-24)....850

WITH IGNITION SWITCH “OFF”, WHEN THE TIME SWITCH IS PRESSED THE TIME AND SERVICE ARE NOT DISPLAYED....850

(M-25)....851

FAULTY FUEL LEVER SENSOR SYSTEM....851

(M-26)....852

COOLANT TEMPERATURE SENSOR SYSTEM....852

(M-27)....853

FAULTY ENGINE OIL LEVEL SENSOR SYSTEM....853

(M-28)....855

FAULTY ENGINE COOLANT LEVEL SENSOR SYSTEM....855

(M-29)....857

FAULTY HYDRAULIC OIL LEVEL SENSOR SYSTEM....857

(M-30)....859

WIPER DOES NOT WORK, OR REMAINS “ON”....859

WIPER DOES NOT WORK....859

WIPER SWITCH IS IN THE "OFF" POSITION BUT WIPERS REMAIN ON....862

(M-13)....865

WASHER MOTOR WORKS WHEN SWITCH IS NOT BEING USED OR WASHER MOTOR DOES NOT WORK....865

TROUBLESHOOTING COMMUNICATION SYSTEM (N-MODE)....868

POINTS TO REMEMBER WHEN TROUBLESHOOTING SYSTEM....869

POINTS TO REMEMBER IF A PROBLEM RETURNS TO NORMAL BY ITSELF....869

USER CODE MEMORY RETENTION FUNCTION....869

INFORMATION CONTAINED IN TESTING PROCEDURES....870

(N-1)....872

COMMUNICATION ABNORMALITY....872

30 DISASSEMBLY AND ASSEMBLY....874

METHOD OF USING MANUAL....876

PRECAUTIONS DURING OPERATION....877

PRECAUTIONS WHEN CARRYING OUT REMOVAL WORK....877

PRECAUTIONS WHEN CARRYING OUT INSTALLATION WORK....878

PRECAUTIONS WHEN COMPLETING THE OPERATIONS....879

OTHER PRECAUTIONS....879

SPECIAL TOOL LIST....880

SKETCHES OF SPECIAL TOOLS....885

ENGINE....893

AFTERCOOLER....893

ALTERNATOR....893

CYLINDER HEAD....893

ENGINE OIL COOLER....893

ENGINE REAR SEAL....893

FUEL INJECTION PUMP....893

NOZZLE HOLDER....893

STARTING MOTOR....893

THERMOSTAT....893

TURBOCHARGER....893

WATER PUMP....893

GOVERNOR MOTOR....894

OIL COOLER....895

RADIATOR, OIL COOLER....897

ENGINE, MAIN HYDRAULIC PUMP....900

DAMPER....905

FUEL TANK....906

CENTER SWIVEL JOINT....907

FINAL DRIVE....909

TRAVEL MOTOR....920

SPROCKET....934

SWING MOTOR....935

SWING MACHINERY....945

REVOLVING FRAME....954

SWING CIRCLE....956

IDLER AND RECOIL SPRING....957

IDLER....958

RECOIL SPRING....962

TRACK ROLLER....964

CARRIER ROLLER....970

TRACK CHAIN....975

HYDRAULIC TANK....976

MAIN HYDRAULIC PUMP....978

DISASSEMBLY....980

PUMP ASSEMBLY....980

FRONT PUMP....980

REAR PUMP....985

ASSEMBLY....988

FRONT PUMP....988

REAR PUMP....996

MAIN PUMP OIL SEAL....1007

CONTROL VALVE....1008

PUMP MERGE DIVIDER VALVE....1022

PRESSURE COMPENSATION VALVE....1023

FRONT PUMP SERVO VALVE....1024

REAR PUMP SERVO VALVE....1025

LS-EPC SOLENOID VALVE....1026

SOLENOID VALVE....1027

WORK EQUIPMENT PPC VALVE....1029

TRAVEL PPC VALVE....1031

PPC SHUTTLE VALVE....1034

BOOM LOCK VALVE....1037

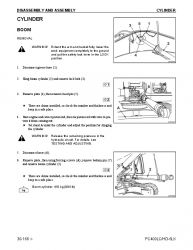

CYLINDER....1039

BOOM....1039

ARM....1041

BUCKET....1043

HYDRAULIC....1045

BOLT ON TYPE PISTON....1045

THREADED STYLE PISTON....1049

WORK EQUIPMENT....1055

BUCKET....1057

ARM....1059

BUCKET AND ARM....1061

BOOM....1063

OPERATORS CAB....1065

COUNTERWEIGHT....1067

AIR CONDITIONER....1068

COMPRESSOR....1068

CONDENSER....1069

RECEIVER TANK....1070

AIR CONDITIONER UNIT....1071

GOVERNOR, PUMP CONTROLLER....1073

MONITOR PANEL....1074

CONTROL STAND CASE....1075

90 OTHERS....1078

ELECTRICAL....1080

FOLDOUT 1 - CIRCUIT DIAGRAM SHEET 1 (Part 1 of 3)....1080

FOLDOUT 2 - CIRCUIT DIAGRAM SHEET 1 (Part 2 of 3)....1082

FOLDOUT 3 - CIRCUIT DIAGRAM SHEET 1 (Part 3 of 3)....1084

FOLDOUT 4 - CIRCUIT DIAGRAM SHEET 2 (Part 1 of 2)....1086

FOLDOUT 5 - CIRCUIT DIAGRAM SHEET 2 (Part 2 of 2)....1088

FOLDOUT 6 - CIRCUIT DIAGRAM SHEET 3 (Part 1 of 1)....1090

FOLDOUT 7 - ELECTRONIC CONTROL SYSTEM - TOTAL SYSTEM DIAGRAM....1092

HYDRAULIC....1094

FOLDOUT 8 - CIRCUIT DIAGRAM (Sheet 1 of 4)....1094

FOLDOUT 9 - CIRCUIT DIAGRAM (Sheet 2 of 4)....1096

FOLDOUT 10 - CIRCUIT DIAGRAM (Sheet 3 of 4)....1098

FOLDOUT 11 - CIRCUIT DIAGRAM (Sheet 4 of 4)....1100

CLSS OPERATION FOR EACH FUNCTION....1102

FOLDOUT 12 - HYDRAULIC CIRCUIT DIAGRAM....1102

FOLDOUT 13 - WHEN ALL WORK EQUIPMENT IS AT NEUTRAL....1104

FOLDOUT 14 - WHEN PUMP FLOW MERGED, BUCKET CURL OPERATED INDEPENDENTLY....1106

FOLDOUT 15 - WHEN PUMP FLOW MERGED, BOOM RAISE OPERATED INDEPENDENTLY....1108

FOLDOUT 16 - WHEN PUMP FLOW MERGED, ARM IN OPERATED INDEPENDENTLY....1110

FOLDOUT 17 - WHEN PUMP FLOW MERGED, ARM OUT OPERATED INDEPENDENTLY....1112

FOLDOUT 18 - WHEN PUMP DIVIDED, TRAVEL OPERATED INDEPENDENTLY....1114

FOLDOUT 19 - WHEN PUMP FLOW MERGED, ARM IN + BOOM RAISE OPERATED SIMULTANEOUSLY....1116

FOLDOUT 20 - WHEN PUMP FLOW MERGED, SWING + BOOM RAISE OPERATED SIMULTANEOUSLY....1118

FOLDOUT 21 - WHEN PUMP FLOW DIVIDED, TRAVEL + BOOM RAISE OPERATED SIMULTANEOUSLY....1120

FOLDOUT 22 - WHEN PUMP FLOW DIVIDED, TRAVEL + ARM IN OPERATED SIMULTANEOUSLY....1122

Komatsu Hydraulic Excavator PC400LC-LK, PC400HD-LK Series Repair Service Manuals