Kobelco SK100, SK100L, SK100LV, SK100V, SK100W-2, SK120, SK120LC, SK120LCV, SK120V Workshop Repair & Service Manual

Catalog:

Model:

Complete digital workshop manual contains service, maintenance, and troubleshooting information for the Kobelco SK100, SK100L, SK100LV, SK100V, SK100W-2, SK120, SK120LC, SK120LCV, SK120V Hydraulic Excavators. Diagnostic and repair procedures are covered in great detail to repair, maintain, rebuild, refurbish or restore your excavator like a professional mechanic in local service/repair workshop. This cost-effective quality manual is 100% complete and intact as should be without any missing pages. It is the same factory shop manual used by dealers that guaranteed to be fully functional to save your precious time.

This manual for Kobelco SK100, SK100L, SK100LV, SK100V, SK100W-2, SK120, SK120LC, SK120LCV, SK120V, Hydraulic Excavator is divided into different sections. Each section covers a specific component or system and, in addition to the standard service procedures, includes disassembling, inspecting, and assembling instructions. A table of contents is placed at the beginning of each section. Pages are easily found by category, and each page is expandable for great detail. It is in the cross-platform PDF document format so that it works like a charm on all kinds of devices. You do not need to be skilled with a computer to use the manual.

“SK100,SK120(LC) (S5LP0004E).pdf”

Kobelco SK100, SK120, SK120LC Hydraulic Excavator Shop Manual; 1,041 pages

“SK100,SK120(LC) (S5LP0005E).pdf”

Kobelco SK100, SK120, SK120LC Hydraulic Excavator Shop Manual; 810 pages

“SK100(L),SK120(LC) (S5LP0006E).pdf”

Kobelco SK100, SK100L, SK120, SK120LC Hydraulic Excavator Shop Manual; 918 pages

“SK100V,SK120(LC)V (S5LP0007E).pdf”

Kobelco SK100V, SK120V, SK120LCV Hydraulic Excavator Shop Manual; 712 pages

“SK100(L)V,SK120(LC)V (S5LP0008E).pdf”

Kobelco SK100V, SK100LV, SK120V, SK120LCV Hydraulic Excavator Shop Manual; 856 pages

“SK100 (S5YW0002E).pdf”

Kobelco SK100 Hydraulic Excavator Shop Manual; 754 pages

“SK100W-2 (S5YE0002E).pdf”

Kobelco SK100W-2 Hydraulic Excavator Shop Manual; 888 pages

EXCERPT:

TABLE OF CONTENTS

1. SPECIFICATION

2. OPERATION AND CONTROLS (Refer to Operators Manual)

3. LOCATION AND WEIGHT OF COMPONENTS

4. MAINTENANCE STANDARDS AND TEST PROCEDURES

5. TROUBLESHOOTING

6. PREVENTIVE MAINTENANCE (Refer to Operators Manual)

7. WORKING STANDARDS

...

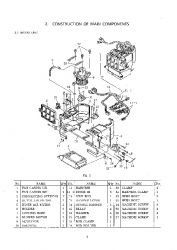

3. DISASSEMBLY AND ASSEMBLY

3.2 PREPARATION BEFORE DISASSEMBLY

1) Before disassembling the pump, read through the instructions.

2) The figures in parentheses after part names correspond to those in construction drawing (Fig. 2)

3.3 DISASSEMBLY

1) Selecting a place for disassembly.

• Choose a clean place.

• Place a rubber sheet or cloth on a work bench so as not to damage parts.

• Do not loosen the nuts (808) marked * in valve block (312). Otherwise, the flow setting will change.

• The figures in the parentheses after part names in the instructions correspond to those in Fig. 2.

2) Drain out the oil in the pump casing by removing drain port plug (466 ).

3) Remove socket head cap-screws (412,413) and take off the regulator.

• For the disassembly of the regulator, refer to the regulator manual.

4) Separate valve block (312) from pump casing (271) by removing capscrews (401).

• Execute this operation after removing the gear pump.

5) Draw out cylinder (141) out of pump casing (271) in parallel to drive shaft (111). Then draw out piston (151), shoe (152), retainer (153), spherical bush (156), cylinder spring (157) and spacer (158) as well.

• Use care so as not to score the sliding surface of the cylinder. spherical bush (156). shoe (152) and the swash plate (212).

6) Loosen the socket head capscrew (406) fastening seal cover (F) (261) and remove seal cover (F) (261).

• The seal cover (F) (261) can easily be removed if cap screws are put into the extracting holes (tapped holes M6) to draw out the seal cover.

• The seal cover (F) (261) is fitted with 0 ring (710) and oil seal (774). Exercise

care so the oil seal is not scored when disassembled.

7) Separate pump casing (271) by lightly tapping the flange fastening swash plate support (251) on the pump casing side, using a plastic mallet.

• An 0 ring (717) is attached to swash plate support (251).Use care so the 0 ring is not scored when removed.

8) Separate shoe plate (211) and swash plate (212) from pump casing (271).

...