Takeuchi Compact Excavator TB125, TB135, TB145 Factory Service & Shop Manual

Catalog:

Model:

Complete service repair manual with electrical wiring diagrams for Takeuchi Compact Excavator TB125, TB135, TB145, with all the shop information to maintain, diagnose, repair, and rebuild like professional mechanics.

Takeuchi Compact Excavator TB125, TB135, TB145 workshop service & repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 1,087 pages

File Format: PDF (bookmarked, ToC, Searchable, Printable, high quality)

Language: English

TABLE OF CONTENTS

Takeuchi Compact Excavator TB125, TB135, TB145 Workshop Manual; 1,087 pages; Serial Number TB125: 12510003~, TB135: 13510004~, TB145: 14510004~.

I . GENERAL

II . SPECIFICATIONS

III. MACHINE CONFIGURATION

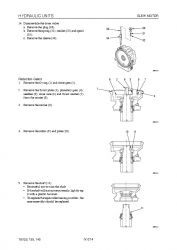

IV. HYDRAULIC UNITS

V . TROUBLESHOOTING VI. ENGINE

FOOT OF THE PAGE............5

I . GENERAL............9

II . SPECIFICATIONS............25

III . MACHINE CONFIGURATION............91

IV . HYDRAULIC UNITS............287

V . TROUBLESHOOTING............613

VI . ENGINE............665

Cover TNE series............666

CONTENTS............668

Cover 3TNV/4TNV series............801

History of Revision............802

PREFACE............803

SAFETY LABELS............804

CONTENTS............812

1. General............817

1.1 Engine nomenclature............817

1.2 Specifications............817

1.3 Fuel oil, lubricating oil and cooling water............830

1.3.1 Fuel oil............830

1.3.2 Lubricating oil............831

1.3.3 Cooling water............832

1.4 Engine external views............833

1.5 Structural description............834

1.6 Exhaust gas emission regulation............835

1.6.1 The emission standard in USA............835

1.6.2 Engine identification............836

1.6.3 Guarantee conditions for the EPA emission standard............837

2. Inspection and adjustment............839

2.1 Periodic maintenance schedule............839

2.2 Periodic inspection and maintenance procedure............840

2.2.1 Check before daily operation............840

2.2.2 inspection after initial 50 hours operation............842

2.2.3 Inspection every 50 hours............845

2.2.4 Inspection every 250 hours or 3 months............849

2.2.5 Inspection every 500 hours or 6 months............852

2.2.6 Inspection every 1,000 hours or one year............854

2.2.7 Inspection every 2000 hours or 2 years............863

2.3 Adjusting the no-load maximum or minimum speed............867

2.4 Sensor inspection............868

2.4.1 Oil pressure switch............868

2.4.2 Thermo switch............868

2.5 Water leak check in cooling water system............868

2.6 Radiator cap inspection............869

2.7 Thermostat Inspection............869

2.8 Adjusting operation............870

2.9 Long storage............870

3. Troubleshooting............871

3.1 Preparation before troubleshooting............871

3.2 Quick reference table for troubleshooting............872

3.3 Troubleshooting by measuring compression pressure............875

4. Disassembly, inspection and reassembly of engines............877

4.1 Complete disassembly and reassembly............877

4.1.1 Introduction............877

4.1.2 Special service tools............878

4.1.3 Complete disassembly............883

4.1.4 Precautions before and during reassembly............887

4.1.5 Adjusting operation............887

4.2 Cylinder head: Disassembly, inspection and reassembly............888

4.2.1 Components (2-valve cylinder head)............888

4.2.2 Disassembly procedure:............888

4.2.3 Reassembly procedure:............889

4.2.4 Servicing points............890

4.2.5 Parts Inspection and measurement............894

4.2.6 Valve seat correction............898

4.2.7 Valve guide replacement............899

4.2.8 Valve stem seal replacement............900

4.3 Gear train and camshaft............901

4.3.1 Components............901

4.3.2 Disassembly procedure:............901

4.3.3 Reassembly procedure:............901

4.3.4 Servicing points............902

4.3.5 Parts inspection and measurement............905

4.3.6 Oil seal replacement (Gear case side)............907

4.3.7 Camshaft bushing replacement............907

4.4 Cylinder block............908

4.4.1 Components............908

4.4.2 Disassembly procedure:............908

4.4.3 Reassembly procedure:............908

4.4.4 Servicing points............909

4.4.5 Parts inspection and measurement............913

4.4.6 Cylinder bore correction............924

4.4.7 Piston pin bushing replacement............925

4.4.8 Oil seal replacement (Flywheel housing side)............925

5. Lubrication system............926

5.1 Lubrication system diagram............926

5.2 Trochoid pump components............927

5.3 Disassembly (Reverse the procedure below for assembly)............927

5.4 Servicing points............927

5.5 Parts Inspection and measurement............929

5.5.1 Trochoid pump inspection and measurement............929

5.6 Lube oil filter............931

5.6.1 Lube oil filter construction............931

5.6.2 Lube oil filter replacement............931

6. Cooling system............932

6.1 Cooling water system............932

6.2 Cooling water pump components............932

6.3 Disassembly (Reverse the procedure below for assembly)............933

6.4 Servicing points............933

7. Fuel injection pump / Governor............934

7.1 Introduction............934

7.2 Fuel injection pump............934

7.2.1 Fuel system diagram............934

7.2.2 External view and components............935

7.2.3 Disassembly procedure:............935

7.2.4 Assembly procedure............936

7.2.5 Servicing points............936

7.2.6 C.S.D. (Cold Start Device)............937

8. Turbocharger: Disassembly, inspection and reassembly............938

8.1 Structure and functions............938

8.1.1 Main specifications............938

8.1.2 Construction............938

8.1.3 Structural and functional outline............939

8.1.4 Components............940

8.2 Service standards and tightening torque............941

8.2.1 Service standards............941

8.2.2 Tightening torque............942

8.3 Periodic inspection procedure............943

8.3.1 Periodic inspection intervals............943

8.3.2 Inspection procedure............944

8.3.3 Waste gate valve adjustment procedure............945

8.4 Disassembly procedure............947

8.4.1 Preparation for disassembly............947

8.4.2 Inspection before disassembly............948

8.4.3 Disassembly............948

8.5 Washing and inspection procedure............950

8.5.1 Washing............950

8.5.2 Inspection procedure............951

8.6 Reassembly procedure............954

8.6.1 Preparation for reassembly............954

8.6.2 Reassembly............954

8.7 Handling after disassembly and reassembly............957

8.7.1 Instructions for turbocharger installation............957

8.8 Troubleshooting............958

8.8.1 Excessively exhaust smoke............958

8.8.2 White smoke generation............958

8.8.3 Sudden oil decrease............959

8.8.4 Decrease in output............959

8.8.5 Poor (slow) response (starting) of turbocharger............959

8.8.6 Abnormal sound or vibration............959

9. Starting motror............960

9.1 For 4TNV94L/ 98............960

9.1.1 Specifications............960

9.1.2 Components............961

9.1.3 Troubleshooting............962

9.1.4 Names of parts and disassembly procedure............963

9.1.5 Inspection and maintenance............967

9.1.6 Service standards............972

9.1.7 Assembly............973

9.1.8 Characteristic test............975

9.2 For 4TNV106 (T)............976

9.2.1 Specifications............976

9.2.2 Congiguration drawing............976

9.2.3 Troubleshooting............977

9.2.4 Component names and disassembly procedure............978

9.2.5 Disassembly procedure............979

9.2.6 Inspection and maintenance............987

9.2.7 Assembly............993

9.2.8 Adjustment............994

9.2.9 Service standards............995

9.3 For 3TNV82A to 3/4TNV88............996

9.3.1 Specifications............996

9.3.2 Characteristics............996

9.3.3 Disassembly drawing............997

9.3.4 Connecting diagram of a starting motor............997

10. Alternator............998

10.1 The 40A alternator for 3TNV84 and other models............998

10.1.1 Components............998

10.1.2 Specifications............999

10.1.3 Wiring diagram............999

10.1.4 Standard output characteristics............1000

10.1.5 Inspection............1000

10.1.6 Troubleshooting............1001

11. Electric wiring............1002

11.1 Electric wiring diagram............1002

11.2 Precaution on electric wiring............1003

11.2.1 Alternator............1003

11.2.2 Starter............1004

11.2.3 Current limiter............1005

11.2.4 Section area and resistance of electric wire............1006

12. Service standards............1007

12.1 Engine tuning............1007

12.2 Engine body............1009

12.2.1 Cylinder head............1009

12.2.2 Gear train and camshaft............1012

12.2.3 Cylinder block............1013

12.3 Lubricating oil system (Trochoid pump)............1018

13. Tightening torque for bolts and nuts............1019

13.1 Tightening torques for main bolts and nuts............1

13.2 Tightening torques for standard bolts and nuts............0

Back cover............1021

YPD-MP2/YPD-MP4............1022

CONTENTS............1024

Takeuchi Compact Excavator TB125, TB135, TB145 Repair Service Manual