International/Navistar Truck & Bus 2014 Workshop Repair & Service Manual

Catalog:

Model:

Complete digital official workshop manual contains service, maintenance, and troubleshooting information for the 1986-2014 International/Navistar Trucks & Buses (All Models). Diagnostic and repair procedures are covered in great detail to repair, maintain, rebuild, refurbish or restore your vehicle like a professional mechanic in local service/repair workshop. This cost-effective quality manual is 100% complete and intact as should be without any missing pages. It is the same factory shop manual used by dealers that guaranteed to be fully functional to save your precious time.

Service Information for International trucks, IC Bus chassis and MaxxForce engines helps facilitate vehicle uptime by aiding in rapid and accurate diagnostics, ease of repairs and improved vehicle maintenance. This manual [ver. 07.2014] contains:

- Master Service Manual

- Technical Letters

- Diagnostic Trouble Code Indexes

- Troubleshooting Guides

- Circuit Diagram Manuals

- New Vehicle Processing Manual

- Repair Times

- Help

MAKE: International/Navistar

YEAR: 1986 1987 1988 1989 1990 1991 1992 1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 2013 2014 (MY2015 2016 applicable)

LANGUAGE: English French Spanish

OS: Windows

SIZE: 6.79 GB

FORMAT: DVD ISO image

MODELS:

International 1000

International 2000

International 3000 FE

International 3000 RE

International 3000

International 3100

International 3200

International 3200 IM

International 3300

International 3400

International 3600

International 3700

International 3800

International 3900

International 4100

International 4200

International 4300

International 4400

International 4700

International 4800

International 4900

International 5000

International 5000i

International 7100

International 7300

International 7400

International 7500

International 7600

International 7700

International 8100

International 8200

International 8300

International 8500

International 8600

International 9000

International 9000i

International 9100

International 9100i

International 9200

International 9200i

International 9300

International 9400

International 9400i

International 9600

International 9700

International 9800

International 9900i

International BE BUS

International CE BUS

International CF 500

International CF 600

International CityStar

International CXT

International DuraStar

International FC BUS

International FE BUS

International HC BUS

International IC BUS

International LC BUS

International LoneStar

International MXT

International PayStar

International ProStar

International RE BUS

International RXT

International TerraStar

International TranStar

International WorkStar

VENDORS:

Aeroquip

AKW

ALLISON

ANCHORLOK

BENDIX

BOSCH

Kumin$

DANA SPICER

DAYCO

DELCO

DELCO-REMY

DETROIT DIESEL

DOW CORNING

EATON

EATON FULLER

FABCO

FULLER

GOLD SEAL

gunite

HALDEX / EATON

HENDRICKSON

HOLSET

HORTON

KYSOR

Leece NEVILLE

LUCAS VARITY

LUK

MERITOR

MGM

MIDLAND

MODINE

MOR / RYDE

MOTOROLA

MPSI

NEWAY

PRESTOLITE

REYCO

ROCKWELL

SHEPPARD

SIKKENS

SPICER

STOPMASTER

TRW

VICKERS

WABCO

WACKER

YORK

ENGINES:

MaxxForce DT

MaxxForce 5

MAXXFORCE 7

MAXXFORCE 9

MAXXFORCE 10

MAXXFORCE 11

MAXXFORCE 13

MAXXFORCE 15

N13

DT 360

DT 408

DT 466

DT 466E

DT 530

DT 530E

DT 570

DTA 360

DTA 466

HT 530

HT 570

T 444E

VT 365

VT 275

530

530E

7.3L

MWN Acteon

Caterpillar

Kumin$

MAJOR GROUPS:

01 Frame

02 Front Axle

03 Springs

04 Brakes

05 Steering

06 Prop. Shaft

07 Exhaust

08 Electrical

09 Front End

10 General

11 Clutch

12 Engine

13 Transmission

14 Rear Axle

15 Fuel Tanks

16 Cab

17 Wheels

47 Bus Body

90 Tools

What's New - July 2014 Update

This DVD no longer includes Recalls or AFCs. New or updated content provided on this Service Information DVD includes the following:

TSIs

TSI 14-12-05 R1

Induction Cleaning System Procedure

F14-12-05 R1 (French)

Procédure du système de nettoyage de l'induction

M14-12-05 R1(Spanish)

Procedimiento del Sistema de Limpieza por inducción

TSI 14-12-03

Turbo Oil Supply Tube Retrofit

F14-12-03 (French)

Rénovation du tube d'alimentation en huile du turbo

M14-12-03 (Spanish)

Reacondicionamiento del tubo de suministro de aceite del turbocargador

F14-07-01 (French)

Trousse d'outil de remplacement des filetages pour filtre à particules pour moteurs au diésel (FPD) et catalyseur à oxydation pour moteur diesel (DOC)

M14-07-01 (Spanish)

Kit de herramientas de sustitución de roscas de filtro de partículas diesel (DPF) o catalizador de oxidación diesel (DOC)

TSI 14-04-02

Air Compressor (2 Cylinder Yoo Sung) Removal / Installation

F14-04-02 (French)

Dépose / installation d'un compresseur d'air (Yoo Sung à 2 cylindres)

M14-04-02 (Spanish)

Desmontaje/instalación del compresor de aire (Yoo Sung de 2 cilindros)

TSI 13-12-12 R2

#5 and #6 Exhaust Manifold Gasket Removal and Installation

F13-12-12 R2 (French)

Procédure de dépose et de pose du joint d'étanchéité du collecteur d'échappement n° 5 et n° 6

M13-12-12 R2 (Spanish)

Desmontaje e instalación de las juntas n° 5 y n° 6 del múltiple de escape

TSI 12-12-03 R2

New Non-Serviceable Crankcase Breather

F12-12-03 R2 (French)

Nouveau reniflard de carter-moteur non réparable

M12-12-03 R2 (Spanish)

Nuevo respiradero del cárter no reemplazable

AFTERTREATMENT

0000003081

Aftertreatment Symptom-Based Diagnostic and Inspection Manual (EPA 10) Revision 3

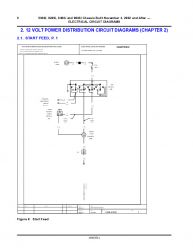

ELECTRICAL CIRCUIT DIAGRAM MANUALS

0000002122

ProStar® and LoneStar® Electrical Circuit Diagrams - Models Built June 14, 2010 and After (EPA 10) Revision 4 (Supersedes S08344 and S08371)

0000002441

PayStar® Electrical Circuit Diagrams (EPA 10) Revision 3 (Supersedes S08352)

0000002529

TerraStar® Electrical Circuit Diagrams (EPA 10) Revision 2 (Supersedes S08362)

0000002601

3200, RXT, DuraStar®, TranStar®, TranStar® Natural Gas, WorkStar® Electrical Circuit Diagrams Models Built May 17, 2010 and Later (EPA 10) Revision 5 (Supersedes S08343)

0000002843

IC Bus RE Model Body Electrical Circuit Diagrams Built November 2011 and After Revision 2 (Supersedes S08367)

0000003601

IC Bus BE / CE Models Body Electrical Circuit Diagrams Built May 11, 2011 and After Revision 3 (Supersedes S08377)

0000003922

DuraStar®, WorkStar®, TranStar® -- 4300, 4400, 7300, 7400, 7500, 7600, 7700, 8500, 8600 and 8600 Models for Latin America / Mexico Models Electrical Circuit Diagrams Built From November 22, 2010 (Supersedes S08353)

ENGINE SERVICE MANUALS

0000001835

MaxxForce® DT, 9 and 10 Engine Service Manual (EPA 10) Revision 4 (Formerly EGES-450)

0000001922 - Spanish

Manual de Servicio del Motor MaxxForce® 11 y 13 (EPA 10) Revision 6 (Reemplaza EGES-606)

0000003823

N13 with SCR Engine Service Manual (EPA 10)

0000004021

N9 & N10 Engine Service Manual

ENGINE DIAGNOSTIC MANUALS

0000003941 Spanish

Motor MaxxForce® 11 y 13 Manual de Diagnóstico

SERVICE MANUALS

0000003361

IC Bus BE / CE Series Radiator / Cooling System (EPA 10) Revision 2

Buy the best manual on the Internet from responsible merchant and get instant download without surprise.

INSTANT Delivery: A download link will be sent to you instantly after payment. Simply click on the link and save it to your computer. You can use this Manual as long as you wish with no restrictions.

PRINTABLE with Diagrams: Just print the manual out and start to work. You can also use the manual with your laptop in your garage.

Customer SATISFACTION: If there is any problem, just drop a quick email. Within hours the issue shall be taken care of.

REFUND Policy: We sell high quality products only. In case there is any problem with your purchase, a replacement link will be sent to you. If we are at fault, you get 100% refund.

EXCERPT:

Aftertreatment (AFT) System

The AFT System, part of the larger exhaust system, processes engine exhaust to meet emissions requirements. The AFT system traps particulate matter (soot) and prevents it from leaving the tailpipe.

AFT Control System

The control system performs the following functions:

• Monitors exhaust gases, the aftertreatment system, and controls engine operating

parameters for emission processing and failure recognition

• Cancels regeneration in the event of catalyst or sensor failure

• Monitors the level of soot accumulation in the Diesel Particulate Filter (DPF) and adapts engine operating characteristics to compensate for increased back pressure

• Controls engine operating parameters to make regeneration automatic.

• Maintains vehicle and engine performance during regeneration

Sensors

Sensors produce an electronic signal based on temperature and pressure. It is used by the control system to regulate the aftertreatment function.

The sensors measure the temperature and pressure at the center of the exhaust flow.

...

AIR COMPRESSOR: BENDIX TU-FLO 550 AND TU-FLO 750

APPLIES TO:

Vendor: BENDIX

Vendor Code: TU-FLO 550 TU-FLO 750

Model: 2000 3000 4000 5000 8100 8200 8300 9100 9200 9300 9400 9600 9700 9800

DESCRIPTION

The function of the air compressor is to provide and maintain air under pressure to operate devices in the air brake and/or auxiliary air systems. The Tu-Flo 550 compressor is a two-cylinder, single-stage, reciprocating compressor with a rated displacement of 13.2 cubic feet per minute at 1250 RPM. The 750 is similar, with a displacement of 16.5 cubic feet per minute at 1250 RPM.

The compressor assembly consists of two major subassemblies ( Figure 1 ): the cylinder head and the crankcase. The cylinder head is an iron casting which houses the inlet, discharge, and unloader valving ( Figure 2 ). The cylinder head contains the air inlet port and is designed with both top and side air discharge ports. Three water coolant ports provide a choice of coolant line connections. Governor mounting surfaces are provided at both the front and the rear of the cylinder head. The head is mounted on the crankcase and is secured by six capscrews. The Tu Flo-550 and 750 compressors are designed so that the cylinder head can be installed in one of two positions which are 180 degrees apart ( Figure 3 ). The crankcase houses the cylinder bores, pistons, crankshaft and main bearings, and provides the flange or base mounting surface ( Figure 4 ).

Figure 1. Bendix Tu-Flo Compressor

1. GOVERNOR MOUNTING PAD

2. WATER INLET

3. AIR DISCHARGE

4. CYLINDER HEAD

5. WATER OUTLET

6. AIR INLET

7. CRANKCASE

Figure 2. End View of Cylinder Head

1. CYLINDER HEAD

2. UNLOADER

3. INLET VALVE

4. INLET VALVE SEAT

5. INLET VALVE SPRING