John Deere 17D Excavator Operation & Test Manual (TM10258)

Catalog:

Model:

Complete technical Operation & Test Manual with electrical wiring diagrams for John Deere 17D Excavator. It's the same service manual used by dealers that guaranteed to be fully functional and intact without any missing page.

This John Deere 17D Excavator Operation & Test Manual (including maintenance, overhaul, disassembling & assembling, adjustment, tune-up, operation, inspecting, diagnostic & troubleshooting…) is divided into different sections. Each section covers a specific component or system with detailed illustrations. A table of contents is placed at the beginning of each section. Pages are easily found by category, and each page is expandable for great detail. The printer-ready PDF documents work like a charm on all kinds of devices.

TM10258 - John Deere 17D Excavator Operation & Test Manual.pdf

tm10260 - John Deere Excavatrice 17D.pdf

tm10262 - John Deere Excavadora 17D.pdf

Category: Operation and Test

Language: English Spanish French

Published on 2019/03/21

EXCERPT:

Table of Contents (exploded views)

TM10258 - John Deere 17D Excavator Operation & Test Manual

Foreword

9000 - General Information

01 - Safety

Add and Operate Attachments Safely

Add Operator's Station Guarding for Special Uses

Avoid Backover Accidents

Avoid High-Pressure Fluids

Avoid High-Pressure Oils

Avoid Machine Tip Over

Avoid Unauthorized Machine Modifications

Avoid Work Site Hazards

Beware of Exhaust Fumes

Dispose of Waste Properly

Drive Metal Pins Safely

Follow Safety Instructions

Handle Chemical Products Safely

Inspect Machine

Keep Riders Off Machine

Make Welding Repairs Safely

Operate Only If Qualified

Park and Prepare for Service Safely

Prepare for Emergencies

Prevent Battery Explosions

Prevent Fires

Prevent Unintended Machine Movement

Recognize Safety Information

Remove Paint Before Welding or Heating

Service Cooling System Safely

Start Only From Operator's Seat

Stay Clear of Moving Parts

Use and Maintain Seat Belt

Use Special Care When Lifting Objects

Use Steps and Handholds Correctly

Wear Protective Equipment

9005 - Operational Checkout Procedure

10 - Operational Checkout Procedure

Operational Checkout

9010 - Engine

Air Intake System Leakage Test

Bleed Fuel System

Cooling System Pressure Test

Diagnose Engine Malfunctions

Engine Component Location

Engine Compression Pressure Test

Engine Cooling System Operation

Engine Fuel System Operation

Engine Lubrication System Operation

Engine Oil Pressure Test

Engine Speed Check

Engine Speed Control Lever and Cable Adjustment

Engine Thermostat Test

Engine Valve Lash (Clearance) Check and Adjustment

Fan Belt Tension Adjustment

Fuel Injection Nozzle Check

Fuel Transfer Pump Pressure Test

Head Gasket Failure Check

Injection Pump Timing Check and Adjustment

JT05801 Clamp-On Electronic Tachometer Installation

Radiator Cap Test

9015 - Electrical System

05 - System Information

Component Identification Table

Electrical Diagram Information

Fuse (Blade-Type) Color Codes

10 - System Diagrams

Battery and Ground Cables (W6 and W7) Component Location

Boom Work Light Harness (W3) Component Location

Boom Work Light Harness (W3) Wiring Diagram

Engine Harness (W2) Component Location

Engine Harness (W2) Wiring Diagram

Fuse Specifications

Platform Harness (W1) Component Location

Platform Harness (W1) Wiring Diagram

System Functional Schematic and Section Legend

System Functional Schematic, Wiring Diagrams, and Component Locations Master Legend

15 - Sub-System Diagnostics

Fuel Shutoff Circuit Theory of Operation

Monitor Panel Circuit Theory of Operation

Pilot Control Shutoff Circuit Theory of Operation

Start and Charge Circuits Theory of Operation

Travel Speed Control and Travel Alarm Circuit Theory of Operation

20 - References

Alternator and Starting Motors

Alternator Test

Electrical Component Specifications

Install WEATHER PACK 342204242 Contact

Remove Connector Body from Blade Terminals

Replace DEUTSCH 342204242 Rectangular or Triangular Connectors

Replace WEATHER PACK 342204242 Connector

9020 - Power Train

Diagnose Undercarriage Components Malfunctions

Measure Swing Bearing Wear

Track Adjuster and Recoil Spring Operation

Travel Gearcase Operation

9025 - Hydraulic System

05 - Theory of Operation

Arm Regenerative Valve Operation

Auxiliary Selector Valve Operation

Blade, Boom Swing, and Auxiliary Pilot Controller Operation

Blade Circuit Operation

Bucket, Boom, and Boom Swing Anticavitation Valve Operation

Circuit Relief Valve Operation

Control Valve Operation

Flow Combiner Valve Operation

Hydraulic Cylinder Operation

Hydraulic Oil Return Filter Operation

Hydraulic Pump 1 and 2 Operation

Hydraulic Pump 3 Operation

Hydraulic Pump Regulator Operation

Hydraulic System Circuit Symbols

Hydraulic System Diagram

Hydraulic System Schematics

Pilot Controller Operation

Pilot Filter Bypass Operation

Pilot

Pilot Pump Operation

Pilot System Diagram

Rotary Manifold Operation

Swing Motor Anticavitation Valve Operation

Swing Motor Crossover Relief Valve Operation

Swing Motor Operation

Swing Motor Park Brake Release Circuit Operation

System Relief Valve Operation

Travel Motor Counterbalance Valve Operation

Travel Motor Operation

Travel Motor Park Brake Operation

Travel Motor Speed Change Valve Operation

Travel Pilot Controller Operation

15 - Diagnostic Informtion

Blade Hydraulic System Line Identification

Diagnose Dig Circuit Malfunctions

Diagnose Hydraulic System Malfunctions

Diagnose Pilot Circuit Malfunctions

Diagnose Swing Circuit Malfunctions

Diagnose Travel System Malfunctions

Diagnostic Procedure

Main Hydraulic Pilot System Line Identification

Main Hydraulic Working System Line Identification

Major Component Location

Pilot Controller to Pattern Conversion Valve Line Connection

Travel Hydraulic System Line Identification

20 - Adjustments

25 - Tests

Circuit Relief Valve Test and Adjustment

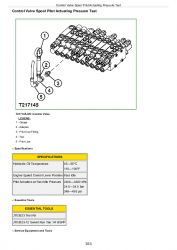

Control Valve Spool Pilot Actuating Pressure Test

Cylinder Drift Test342200224Boom, Arm, Bucket, and Blade

Hydraulic Oil Cleanup Procedure Using Portable Filter Caddy

Hydraulic Pump 1 and 2 Flow Test

Hydraulic Pump 3 Flow Test

Hydraulic Pumps 1, 2, and 3 System Relief Valve Test and Adjustment

Hydraulic Pumps 1 and 2 Regulator Test and Adjustment342200224Engine Pulldown

Hydraulic System Warmup Procedure

JT02156A Digital Pressure _ Temperature Analyzer Installation

JT05800 Digital Thermometer Installation

Pilot Pressure Regulating Valve Test and Adjustment

Swing Motor Crossover Relief Valve Test and Adjustment

Swing Motor Leakage Test

Travel Motor Leakage Test

...

John Deere 17D Excavator Operation & Test Manual (TM10258)