John Deere 130G and 130GLC Excavator Diagnosis and Test Service Technical Manual (TM14288X19)

Catalog:

Model:

Complete Diagnosis & Tests Technical Manual with electrical wiring diagrams for John Deere 130G and 130GLC Excavator, with workshop information to maintain, diagnose, and rebuild like professional mechanics.

John Deere 130G and 130GLC Excavator workshop Diagnosis & Tests technical manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

TM14288X19 - John Deere 130G and 130GLC Excavator Technical Manual.pdf

tm14288x54 - John Deere Escavadeiras 130G e 130GLC.pdf

tm14288x63 - John Deere Excavadora 130G y 130GLC.pdf

PRODUCT DETAILS:

Total Pages: 1,205 pages

File Format: PDF (bookmarked, ToC, Searchable, Printable)

Category: Operation and Test

Language: English Spanish Portuguese

Published on 2019/04/25

Models: John Deere - Excavator - 1F9130GX_ _D040001-

TABLE OF CONTENTS

Section 9000: General Information................22

Group 01: Safety................22

Recognize Safety Information................25

Follow Safety Instructions................26

Operate Only If Qualified................27

Wear Protective Equipment................28

Protect Against Noise................29

Avoid Unauthorized Machine Modifications................30

Control Pattern................31

Inspect Machine................32

Stay Clear of Moving Parts................33

Avoid High-Pressure Fluids................34

Avoid High-Pressure Oils................35

Work In Ventilated Area................36

Avoid Static Electricity Risk When Refueling................37

High Debris Applications................38

Prevent Fires................39

In Case of Machine Fire................40

Prevent Battery Explosions................41

Handle Chemical Products Safely................42

Handle Starting Fluid Safely................43

Decommissioning — Proper Recycling and Disposal of Fluids and Components................44

Prepare for Emergencies................45

Clean Debris from Machine................46

Add Cab Guarding for Special Uses................47

Use Steps and Handholds Correctly................48

Start Only From Operator's Seat................49

Use and Maintain Seat Belt................50

Heated and Ventilated Operator’s Seat................51

Prevent Unintended Machine Movement................52

Avoid Work Site Hazards................53

Keep Riders Off Machine................55

Avoid Backover Accidents................56

Avoid Machine Tip Over and Machine Damage................57

Use Special Care When Lifting Objects................59

Use Care When Swinging Machine................60

Operate Boom With Care................61

Avoid Power Lines................62

Use Special Care When Operating................63

Inspect and Maintain ROPS................64

Travel Safely................65

Prevent Acid Burns................66

Add and Operate Attachments Safely................68

Park and Prepare for Service Safely................69

Service Machines Safely................70

Service Cooling System Safely................71

Remove Paint Before Welding or Heating................72

Make Welding Repairs Safely................73

Drive Metal Pins Safely................74

Use Proper Lifting Equipment................75

Section 9001: Diagnostics................76

Group 10: Main Controller (MCZ) Diagnostic Trouble Codes................82

Main Controller (MCZ) Diagnostic Trouble Codes................82

Controller Area Network 0 (CAN 0) Circuit Diagnostics................83

Controller Area Network 1 (CAN 1) Circuit Diagnostics................84

Interface Controller Area Network (N-CAN) Diagnostics................85

011000.02 - Abnormal EEPROM................76

011001.02 - Abnormal RAM................76

011002.02 - Abnormal A/D Converter................76

011003.03 - Abnormal Sensor Voltage................76

011006.02 - Engine Controller Communication Error................76

011007.02 - (CAN 0) Data Converter Communication Error 1................76

011008.02 - (CAN 1) Data Converter Communication Error 2................76

011009.02 - (CAN 0) Monitor Controller Communication Error 1................76

011010.02 - (CAN 1) Monitor Controller Communication Error 2................76

011100.02 - Abnormal Engine Speed................76

011101.03 - Engine Speed Dial Sensor Circuit High Input................76

011101.04 - Engine Speed Dial Sensor Circuit Low Input................76

011200.03 - Pump 1 Delivery Pressure Sensor Circuit High Input................76

011200.04 - Pump 1 Delivery Pressure Sensor Circuit Low Input................76

011202.03 - Pump 2 Delivery Pressure Sensor Circuit High Input................76

011202.04 - Pump 2 Delivery Pressure Sensor Circuit Low Input................76

011206.03 - Pump 1 Flow Control Pressure Sensor Circuit High Input................76

011206.04 - Pump 1 Flow Control Pressure Sensor Circuit Low Input................76

011208.03 - Pump 2 Flow Control Pressure Sensor Circuit High Input................76

011208.04 - Pump 2 Flow Control Pressure Sensor Circuit Low Input................76

011301.03 - Swing Pilot Pressure Sensor Circuit High Input................76

011301.04 - Swing Pilot Pressure Sensor Circuit Low Input................76

011302.03 - Boom Up Pilot Pressure Sensor Circuit High Input................76

011302.04 - Boom Up Pilot Pressure Sensor Circuit Low Input................76

011303.03 - Arm Roll-in Pilot Pressure Sensor Circuit High Input................76

011303.04 - Arm Roll-in Pilot Pressure Sensor Circuit Low Input................76

011304.03 - Travel Pilot Pressure Sensor Circuit High Input................76

011304.04 - Travel Pilot Pressure Sensor Circuit Low Input................77

011307.03 - Front Attachment Pilot Pressure Sensor Circuit High Input................77

011307.04 - Front Attachment Pilot Pressure Sensor Circuit Low Input................77

011400.02 - Pump 2 Flow Rate Limit Solenoid Feedback Abnormal................77

011400.03 - Pump 2 Flow Rate Limit Solenoid Feedback High Current................77

011400.04 - Pump 2 Flow Rate Limit Solenoid Feedback Low Current................77

011401.02 - Torque Control Solenoid Abnormal Feedback................77

011401.03 - Torque Control Solenoid Feedback High Current................77

011401.04 - Torque Control Solenoid Feedback Low Current................77

011402.02 - Dig Regenerative Solenoid Feedback Current Abnormal................77

011402.03 - Dig Regenerative Solenoid Feedback Current High................77

011402.04 - Dig Regenerative Solenoid Feedback Current Low................77

011403.02 - Arm Regenerative Solenoid Feedback Current Abnormal................77

011403.03 - Arm Regenerative Solenoid Feedback Current High................77

011403.04 - Arm Regenerative Solenoid Feedback Current Low................77

011407.02 - Power Boost/Travel Speed Solenoid Feedback Current Abnormal................77

011407.03 - Power Boost/Travel Speed Solenoid Feedback Current High................77

011407.04 - Power Boost/Travel Speed Solenoid Feedback Current Low................77

011408.02 - 2-Spool Solenoid Valve Unit (SJ) Abnormal Feedback................77

011408.03 - 2-Spool Solenoid Valve Unit (SJ) Feedback High Input................77

011408.04 - 2-Spool Solenoid Valve Unit (SJ) Feedback Low Input................77

011409.02 - 2-Spool Solenoid Valve Unit (SZ) Abnormal Feedback................77

011409.03 - 2-Spool Solenoid Valve Unit (SZ) Feedback High Input................77

011409.04 - 2-Spool Solenoid Valve Unit (SZ) Feedback Low Input................77

011428.02 - Arm 2 Flow Rate Control Solenoid Valve Feedback Abnormal................77

011428.03 - Arm 2 Flow Control Solenoid Valve Feedback High Input................77

011428.04 - Arm 2 Flow Control Solenoid Valve Feedback Low Input................77

011434.02 - Attachment Relief 1 (Upper) Proportional Solenoid Valve Abnormal Feedback................77

011434.03 - Attachment Relief 1 (Upper) Proportional Solenoid Valve Feedback High Current................77

011434.04 - Attachment Relief 1 (Upper) Proportional Solenoid Valve Feedback Low Current................77

011435.02 - Attachment Relief 2 (Lower) Proportional Solenoid Valve Abnormal Feedback................77

011435.03 - Attachment Relief 2 (Lower) Proportional Solenoid Valve Feedback High Current................77

011435.04 - Attachment Relief 2 (Lower) Proportional Solenoid Valve Feedback Low Current................77

011436.02 - Breaker Relief Proportional Solenoid Valve Abnormal Feedback................78

011436.03 - Breaker Relief Proportional Solenoid Valve Feedback High Current................78

011436.04 - Breaker Relief Proportional Solenoid Valve Feedback Low Current................78

011457.02 - 2-Speed Activation Solenoid Disconnected or Not Present................78

011458.02 - Selector Valve Solenoid Valve Disconnected or Not Present................78

011459.02 - Idle Stop Relay Circuit Malfunction................78

011810.03 - Electrical Lever Control Pressure 1 Sensor High Input................78

011810.04 - Electrical Lever Control Pressure 1 Sensor Low Input................78

011901.03 - Hydraulic Oil Temperature Sensor Circuit High Input................78

011901.04 - Hydraulic Oil Temperature Sensor Circuit Low Input................78

020010.02 - Abnormal Exhaust Filter................78

020062.02 - Hydraulic Oil Temperature Alarm................78

Group 20: Engine Control Unit (ECU) Diagnostic Trouble Codes................251

Engine Control Unit (ECU) Diagnostic Trouble Codes................251

000158.01 - System Voltage Low................78

000647.05 - Variable Speed Fan Solenoid Open Circuit................78

000647.31 - Variable Speed Fan Solenoid Short Circuit................78

000898.09 - Engine Speed Request Not Received or Timed Out................78

001075.05 - Low-Pressure Fuel Pump Circuit has High Resistance................78

001638.09 - Hydraulic Oil Temperature Message Not Received or Timed Out................78

Group 30: Monitor Controller (DSZ) Diagnostic Trouble Codes................260

Monitor Controller (DSZ) Diagnostic Trouble Codes................260

013000.02 - Flash Memory Failure 1................78

013001.02 - Flash Memory Failure 2................78

013002.02 - ECU Communication Error................78

013003.02 - Main Controller (MCZ) Communication Error 1................78

013004.02 - Main Controller (MCZ) Communication Error 2................78

013005.02 - Monitor Controller (DSZ) Communication Error 1................78

013006.02 - Monitor Controller (DSZ) Communication Error 2................78

013007.02 - Machine Controller (BCZ) Communication Error................78

Group 40: Information Controller (ICZ) Diagnostic Trouble Codes................270

Information Controller (ICZ) Diagnostic Trouble Codes................270

013303.02 - Abnormal Monitor Internal Temperature Sensor................78

013304.02 - Alternator Alarm................79

013305.02 - Abnormal Manual Glow EXT Output................79

013310.03 - Coolant Temperature Sensor Short Circuit................79

013311.03 - Fuel Level Sensor Open Circuit................79

013311.04 - Fuel Level Sensor Shorted Circuit................79

013334.02 - Radiator Coolant Error................79

014001.02 - Flash Memory Read/Write Error................79

014002.02 - External RAM Read/Write Error................79

014003.02 - Abnormal EEPROM................79

014006.02 - Communication Terminal: Communication Error................79

014008.02 - Abnormal Internal RAM................79

014009.02 - CAN Communication Error 2................79

014021.02 - Communication Terminal Security Error................79

014022.02 - SIM Card Error................79

014023.02 - Security Error................79

020100.02 - Overheat Alarm................79

020101.02 - Engine Warning Alarm................79

020102.02 - Engine Oil Pressure Alarm................79

020103.02 - Alternator Alarm................79

020105.02 - Hydraulic Oil Filter Restriction Alarm................79

020106.02 - Air Cleaner Restriction Alarm................79

020107.02 - Water Separator Alarm................79

020109.02 - Pilot Control Shutoff Lever Alarm................79

020110.02 - Fuel Filter Restriction Alarm................79

020113.02 - System Error Alarm................79

020114.02 - Overheat Alarm (Immediately After the Key is Turned ON)................79

020133.02 - Crane Function Alarm................79

020135.02 - Exhaust Filter Regeneration Unnecessary Warning................79

020137.02 - Exhaust Filter Alarm................79

020141.02 - Exhaust Temperature Alarm................79

020142.02 - Intake Air Temperature Alarm................79

020145.02 - Boost Temperature Increase Alarm................79

020146.02 - Fuel Temperature Increase Alarm................79

020149.02 - EGR Gas Temperature Alarm................80

020150.02 - Coolant Level Alarm................80

020151.02 - Engine Warning Alarm................80

020152.02 - Engine Oil Pressure Alarm................80

020153.02 - Air Cleaner Restriction Alarm................80

020154.02 - Fuel Filter Restriction Alarm................80

020155.02 - Engine Output Reduction Alarm................80

020156.02 - Cooling Performance Decrease Alarm................80

020157.02 - Cooling Performance Decrease Alarm................80

Group 50: Air Conditioner Controller (ACF) Diagnostic Trouble Codes................321

Air Conditioner Controller (ACF) Diagnostic Trouble Codes................321

11 - Open Circuit in Air Recirculation Sensor................80

12 - Short-Circuited Air Recirculation Sensor................80

13 - Open Circuit in Ambient Air Temperature Sensor................80

14 - Short-Circuited Ambient Air Temperature Sensor................80

18 - Short-Circuited Solar Radiation Sensor................80

21 - Open Circuit in Air Conditioner Freeze Control Switch................80

22 - Short-Circuited Air Conditioner Freeze Control Switch................80

43 - Abnormal Air Conditioner and Heater Blower Port Change Servomotor................80

44 - Abnormal Air Conditioner and Heater Mixer Servomotor................80

51 - Abnormal High/Low Refrigerant Pressure................80

91 - Communication Error................80

92 - CAN Bus Off Error................80

Section 9005: Operational Checkout Procedure................354

Group 10: Operational Checkout Procedure................354

Operational Checkout................417

Section 9010: Engine................479

Group 05: Theory of Operation................695

Engine Identification................483

John Deere Engine................501

Engine Fuel System Component Location................487

Engine Cooling System Component Location................488

Cold Weather Starting Aid................489

Engine Speed Control System Operation................695

Group 15: Diagnostic Information................479

John Deere Engine................501

Group 20: Adjustments................479

John Deere Engine................501

Group 25: Tests................479

John Deere Engine................501

Section 9015: Electrical System................502

Group 05: System Information................502

Electrical Diagram Information................514

Group 10: System Diagrams................502

Explanation of Wire Markings................523

Fuse and Relay Specifications................524

System Functional Schematic, Component Location, and Wiring Diagram Master Legend................528

System Functional Schematic................535

Cab Harness (W1) Component Location................542

Cab Harness (W1) Wiring Diagram................546

Machine Harness (W2) Component Location................551

Machine Harness (W2) Wiring Diagram................553

Monitor Harness (W3) Component Location................555

Monitor Harness (W3) Wiring Diagram................556

Engine Harness (W4) Component Location................558

Engine Harness (W4) Wiring Diagram................561

Engine Interface Harness (W5) Component Location................563

Engine Interface Harness (W5) Wiring Diagram................564

Pump Harness (W8) Component Location................566

Pump Harness (W8) Wiring Diagram................568

Pilot Shutoff Switch Harness (W11) Component Location................570

Pilot Shutoff Switch Harness (W11) Wiring Diagram................571

Heated Air Seat Harness (W14) Component Location................572

Heated Air Seat Harness (W14) Wiring Diagram................574

Multi-Function Pilot Control Lever Harness (W15) Component Location................575

Multi-Function Pilot Control Lever Harness (W15) Wiring Diagram................577

Travel Alarm Cancel Switch Harness (W16) Component Location................578

Travel Alarm Cancel Switch Harness (W16) Wiring Diagram................579

Attachment Harness (W17) Component Location................580

Attachment Harness (W17) Wiring Diagram................581

Alternator Harness (W18) Component Location................582

Alternator Harness (W18) Wiring Diagram................583

Rear Camera Harness (W19) Component Location................584

Rear Camera Harness (W19) Wiring Diagram................585

Alternator Jumper Harness (W20) Component Location................586

Alternator Jumper Harness (W20) Wiring Diagram................587

Pilot Shutoff Valve Harness (W21) Component Location................588

Pilot Shutoff Valve Harness (W21) Wiring Diagram................589

Auxiliary 3-Button Cancel Switch Harness (W22) Component Location................590

Auxiliary 3-Button Cancel Switch Harness (W22) Wiring Diagram................591

Travel Alarm Harness (W26) Component Location................592

Travel Alarm Harness (W26) Wiring Diagram................593

Starter Harness (W27) Component Location................594

Starter Harness (W27) Wiring Diagram................595

Starter Switch Harness (W29) Component Location................597

Starter Switch Harness (W29) Wiring Diagram................598

Attachment Pressure Sensor Harness (W31) Component Location................599

Attachment Pressure Sensor Harness (W31) Wiring Diagram................600

2-Speed Harness (W32) Component Location—If Equipped................601

2-Speed Harness (W32) Wiring Diagram—If Equipped................603

Fuel Injector Harness (W38) Component Location................605

Fuel Injector Harness (W38) Wiring Diagram................606

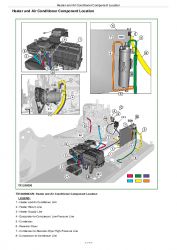

Heater and Air Conditioner Harness (W41) Component Location................608

Heater and Air Conditioner Harness (W41) Wiring Diagram................609

Starter Protection Jumper Harness (W42) Component Location................610

Starter Protection Jumper Harness (W42) Wiring Diagram................611

Cab Roof Light Harness (W44) Component Location................612

Cab Roof Light Harness (W44) Wiring Diagram................613

Cab Roof Light Jumper Harness (W45) Component Location................614

Cab Roof Light Jumper Harness (W45) Wiring Diagram................615

Cab Roof Light 1 Relay Harness (W46) Component Location................616

Cab Roof Light 1 Relay Harness (W46) Wiring Diagram................617

Cab Roof Light 2 Relay Harness (W47) Component Location................618

Cab Roof Light 2 Relay Harness (W47) Wiring Diagram................619

Heater and Air Conditioner Relay Harness (W51) Component Location................620

Heater and Air Conditioner Relay Harness (W51) Wiring Diagram................621

Auxiliary Solenoid Harness (W61) Component Location................623

Auxiliary Solenoid Harness (W61) Wiring Diagram................625

Modular Telematics Gateway (MTG) Harness (W6002) Component Location................627

Modular Telematics Gateway (MTG) Harness (W6002) Wiring Diagram................628

Satellite (SAT) Harness (W6003) Component Location................629

Satellite (SAT) Harness (W6003) Wiring Diagram................630

Group 15: Sub-System Diagnostics................504

Controller Area Network (CAN) Circuit Theory of Operation................695

Starting and Charging Circuit Theory of Operation................695

Monitor Controller (DSZ) Circuit Theory of Operation................695

Engine Control Unit (ECU) Circuit Theory of Operation................695

Main Controller (MCZ) Circuit Theory of Operation................695

Machine Controller (BCZ) Circuit Theory of Operation................695

Windshield Wiper and Washer Circuit Theory of Operation................695

Lighting Circuit Theory of Operation................695

Travel Alarm Circuit Theory of Operation................695

Pilot Shutoff Circuit Theory of Operation................695

Attachment Control Circuit Theory of Operation................695

Group 16: Monitor Operation................695

Service Menu................684

Troubleshooting................685

Monitoring................686

Controller Version................693

Issued Warning Record................694

Operation................695

Machine Setting................696

Monitor Setting................703

Maintenance Mode................706

Rear View Camera Troubleshooting................707

Group 20: References................504

Reading Diagnostic Trouble Codes with Monitor Display................711

Service ADVISOR™ Diagnostic Application................712

Service ADVISOR™ Connection Procedure................713

Reading Diagnostic Trouble Codes with Service ADVISOR™ Diagnostic Application................715

MPDr Application................718

MPDr Connection Procedure................719

Controller Area Network (CAN) Circuit Test................721

Electrical Component Specifications................727

Alternator Test................730

Electrical Component Checks................732

Battery Remove and Install................740

Rear Cover Remove and Install................742

Main Controller (MCZ) Remove and Install................744

Machine Controller (BCZ) Remove and Install................746

Engine Control Unit (ECU) Remove and Install................749

Data Converter Remove and Install................751

Monitor Controller (DSZ) Remove and Install................752

Air Conditioner Controller (ACF) Remove and Install................754

Key Switch Remove and Install................755

Right Switch Console Remove and Install................756

Left Switch Console Remove and Install................758

Travel Alarm Remove and Install................760

Section 9020: Power Train................761

Group 05: Theory of Operation................695

Track Adjuster and Recoil Spring Operation................764

Travel Gear Case Operation................766

Group 15: Diagnostic Information................761

Noisy or Loose Track Chain................761

Tight Track Chain................761

Frequent Track Chain Sag Adjustment Required................761

Excessive Oil Leakage From Front Idler, Track Rollers, or Carrier Rollers................761

Bent Track Shoes................761

“Popping” of Track................761

Cracked Track Link................761

Chipped Link Rails................761

Individual Undercarriage Component Wear................761

Measure Swing Bearing Wear................783

Section 9025: Hydraulic System................787

Group 05: Theory of Operation................695

Hydraulic System Operation................792

Pilot System Operation................793

Pilot Pump, Pressure Regulating Valve, and Filter Operation................794

Pilot Shutoff Solenoid Valve Operation................796

Pilot Control Valve Operation................828

Travel Pilot Control Valve Operation................828

Pilot Operation of Control Valve Operation................828

Pilot Signal Manifold Operation................807

Pump 1, Pump 2, and Drive Gear Case Operation................815

Pump 1 and Pump 2 Regulator Operation................818

Engine Speed Sensing Control Circuit Operation................826

Control Valve Operation................828

Control Valve Check Valves Identification and Operation................840

Main Relief Valve Circuit Operation................844

Circuit Relief and Anticavitation Valve Operation................848

Travel Flow Combiner Valve Operation................850

Auxiliary Flow Combiner Valve and Bypass Shutoff Valve Operation................854

Boom Lower Meter-In Cut Valve Operation................859

Boom Regenerative Valve Circuit Operation................862

Dig Regenerative Valve Circuit Operation................864

Arm Regenerative Valve Circuit Operation................870

Bucket Regenerative Valve Circuit Operation................875

Boom and Arm Reduced Leakage Valves Operation................877

Arm 1 Flow Rate Control Valve Circuit Operation................880

Arm 2 Flow Rate Control Valve Circuit Operation................885

Bucket Flow Rate Control Valve Circuit Operation................890

Boom Flow Rate Control Valve Circuit Operation................896

Auxiliary Flow Rate Control Valve Circuit Operation................902

Swing Reduction Gear Case Operation................908

Swing Motor, Crossover Relief Valve, and Make-Up Check Valve Operation................909

Swing Motor Park Brake Release Circuit Operation................912

Center Joint Operation................914

Travel Motor and Park Brake Valve Operation................916

Travel Motor Speed Circuit Operation................922

Cylinder Operation................926

Return Filter Operation................928

Auxiliary System Operation................929

Auxiliary Pilot Control Valve Operation................930

Flow Rate Select Solenoid Valve Operation................935

Flow Rate Pressure Reducing Valve Operation................937

Selector Valve Solenoid Valve Operation................938

Selector Valve Operation................939

Auxiliary Shuttle Valve Operation................940

Auxiliary High Flow Line Kit Operation................942

Two Way Solenoid Kit Operation................945

Two Pump Combined Flow Kit Operation................948

Group 15: Diagnostic Information................788

All Hydraulic Functions Slow................788

Hydraulic Oil Overheats................788

No Hydraulic Functions................788

No Hydraulic Functions—Electrical Checks................788

Function Does Not Stop When Control Lever Released................788

Load Drifts Down When Control Lever is in Neutral Position................788

Load Falls When Control Valve is Actuated to Raise Load................788

H/P (High Power) Function Does Not Operate, PWR (Power) Mode is Normal................788

Boom Down Does Not Function, Moves Slowly, or is Erratic, All Other Functions Normal................788

Arm In Does Not Function, Moves Slowly, or is Erratic, All Other Functions Normal................788

Swing Speed Slow During Arm In Function................788

Boom Cannot Raise Track Off Ground................788

Swing Function Does Not Operate in Both Directions................788

Swing Speed Slow in Both Directions................788

Swing Speed Slow or Does Not Operate in One Direction................788

Upperstructure Drift with Swing Valve in Neutral................788

Machine Freewheels Down an Incline................788

Track Will Not Move in Either Direction................789

Machine Mistracks................789

Machine Mistracks Left During Combined Travel and Dig Functions................789

Machine Will Not Shift Into Fast (rabbit) Speed................789

Pump 1, Pump 2, and Pilot Pump Line Identification................1015

Control Valve Line Identification................1017

Swing Motor Line Identification................1020

Pilot Control Valve-to-Pilot Signal Manifold Component Location—Excavator Pattern................1022

Pilot Control Valve-to-Pilot Signal Manifold Component Location—Backhoe Pattern................1024

Pilot Signal Manifold-to-Control Valve Line Connection................1026

Travel System Component Location................1029

Travel Hydraulic System Line Connection................1031

Auxiliary Attachment Schematic................1033

Auxiliary System Line Connections................1038

Hydraulic System Schematic................1040

Hydraulic System Component Location................1049

Hydraulic System Line Connections................1051

Group 25: Tests................789

JT05800 Digital Thermometer Installation................1053

JT02156A Digital Pressure and Temperature Analyzer Kit Installation................1054

General Hydraulic Oil Cleanup Procedure................1055

Hydraulic Component Failure Cleanup Procedure................1058

Hydraulic Oil Tank Pressure Release Procedure................1061

Hydraulic Oil Warm-Up Procedure................1062

Pilot Pressure Regulating Valve Test and Adjustment................1065

Control Valve Spool Actuating Pilot Pressure Test................1069

Dig Regenerative Solenoid Valve Test and Adjustment................1072

Arm Regenerative Solenoid Valve Test and Adjustment................1077

Power Dig/Travel Speed Solenoid Valve Test and Adjustment................1082

Arm 2 Flow Control Solenoid Valve Test and Adjustment................1087

Torque Control Solenoid Valve Test and Adjustment................1092

Pump Control Pilot Pressure Signal Test................1097

Main Relief and Power Dig Valve Test and Adjustment................1100

Circuit Relief Valve Test and Adjustment................1107

Swing Motor Crossover Relief Valve Test and Adjustment................1113

Travel Motor Crossover Relief Valve Test and Adjustment................1117

Pump Regulator Test and Adjustment—Minimum Flow................1123

Pump Regulator Test and Adjustment—Maximum Flow................1127

Pump Flow Test................1130

Comprehensive Pump Flow Test................1134

Swing Motor Leakage Test................1140

Travel Motor Leakage Test................1143

Cylinder Drift Test—Boom, Arm, and Bucket................1147

Upperstructure Drift Test................1150

Section 9031: Heating and Air Conditioning................1153

Group 05: Theory of Operation................695

Air Conditioning System Cycle of Operation................1156

Group 15: Diagnostic Information................1153

Air Conditioning System Does Not Operate................1153

Air Conditioning System Does Not Cool Interior of Cab................1153

Air Conditioning System Runs Constantly, Too Cold................1153

Heating System Does Not Operate................1153

Heating System Does Not Warm Interior of Cab................1153

Interior Windows Continue to Fog................1153

Heater and Air Conditioner Component Location................1180

Group 25: Tests................1153

R134a Refrigerant Cautions and Proper Handling................1183

R134a Oil Charge Capacity................1184

R134a Refrigerant Charge Capacity................1185

Heater and Air Conditioner Operational Checks................1186

Air Conditioner Compressor Clutch Test................1189

R134a Refrigerant Leak Test................1190

R134a Refrigerant Hoses and Tubing Inspection................1191

Air Conditioner High/Low-Pressure Switch Test................1192

Air Conditioner Freeze Control Switch Test................1195

Air Conditioner Compressor Belt Check................1196

Air Conditioning System Test................1197

Operating Pressure Diagnostic Chart................1200

Section 9900: Dealer Fabricated Tools................1202

Group 99: Dealer Fabricated Tools................1202

DFT1218 Split Flange Hose Cap................1204

John Deere 130G and 130GLC Excavator Diagnosis and Test Service Technical Manual (TM14288X19)