John Deere 490D & 590D Excavator Repair Technical Manual (TM1390)

Catalog:

Model:

Complete service repair manual for John Deere Excavators 490D, 590D, with service information to maintain, repair, and rebuild like professional mechanics.

John Deere Excavators 490D, 590D workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

TM1390 - John Deere 490D and 590D Excavator Technical Manual - Repair.pdf

omat126018 English - 490D, 590D EXCAVATOR Operator's Manual

omat126031 French - Excavatrice 490D Excavatrice 590D John Deere

Total Pages: 711 pages

File Format: PDF (bookmarked, ToC, Searchable, Printable)

Language: English

MAIN SECTIONS

Foreword

General Information

Safety

General Specifications

Torque Values

Fuels And Lubricants

Tracks

Track System

Axles And Suspension Systems (Propel)

Axle Shaft, Bearings, And Reduction Gears

Hydraulic System

Engine

Removal And Installation

Engine Auxiliary Systems

Cold Weather Starting Aids

Cooling System

Speed Controls

Intake System

External Fuel Supply Systems

Dampener Drive (Flex Coupling)

Elements

Electrical System

Batteries, Support, And Cables

Alternator, Regulator And Charging System Wiring

Wiring Harness And Switches

Motors And Actuators

Frame Or Supporting Structure

Frame Installation

Chassis Weights

Operator’s Station

Removal And Installation

Operator Enclosure

Seat And Seat Belt

Heating And Air Conditioning

Sheet Metal And Styling

Hood Or Engine Enclosure

Excavator

Buckets

Frames

Hydraulic Systems

Swing Or Pivoting System

Mechanical Drive Elements

Hydraulic System

Dealer Fabricated Tools

TABLE OF CONTENTS

Section I: General Information...14

Group I: Safety...14

Follow Safe Procedures...18

Prepare for Emergencies...19

Prevent Acid Burns...20

Handle Chemical Products Safely...22

Handle Fluids Safely-Avoid Fires...23

Avoid High-Pressure Fluids...24

Warn Others of Service Work...25

Support Machine Properly...26

Operate Only from Operator's Seat...27

Park Machine Safely...28

Stay Clear of Moving Parts...29

Avoid Power Lines...30

Use Handholds and Steps...31

Keep Riders Off Machine...32

Move and Operate Machine Safely...33

Wear Protective Clothing...34

Protect Against Flying Debris...35

Protect Against Noise...36

Illuminate Work Area Safely...37

Service Machines Safely...38

Remove Paint Before Welding or Heating...39

Avoid Heating Near Pressurized Fluid Lines...40

Beware of Exhaust Fumes...41

Use Proper Lifting Equipment...42

Service Cooling System Safely...43

Dispose of Waste Properly...44

Work in a Clean Area...45

Use Tools Properly...46

Replace Safety Signs...47

Live With Safety...48

Group II: General Specifications...666

490D Specifications...666

490D Working Ranges...53

490D Drain And Refill Capacities...55

490D...56

490D Bucket Selection Chart-2.5 M (98 In.) Arm...58

490D Bucket Selection Chart-3.0 M (118 In.) Arm...59

490D Bucket Specifications...666

490D with 2.5 m (8 ft 2 in.) Arm Lift Capacity-Kg (Lb)...61

490D with 3.0 m (9 ft 10 in.) Arm Lift Capacity-Kg (Lb)...62

590D Specifications...666

590D Working Ranges...66

590D Operating Specifications...666

590D Drain And Refill Capacities...68

590D Engine and Hydraulic Specifications...666

590D Bucket Selection Chart-2.6 M (8 Ft 6 In.) Arm...71

590D Bucket Selection Chart-3.1 M (10 Ft. 2 In.) Arm...72

590D Bucket Specifications...666

590D Lift Capacity-Kg (Lb)...74

590D Lift Capacity-Kg (Lb)-Continued...76

Group III: Torque Values...15

Hardware Torque Specifications...666

Check Track Shoe Torque...79

Inch Cap Screw Torque Values...80

Metric Cap Screw Torque Values...82

Additional Metric Cap Screw Torque Values...84

Service Recommendations for O-Ring Boss Fittings...86

Service Recommendations For Flat Face O-Ring Seal Fittings...88

Service Recommendations For Flared Connections-Straight or Tapered Threads...90

SAE Four Bolt Flange Fitting Service Recommendations...92

Group IV: Fuels And Lubricants...15

Fuel Specifications...666

Fuel Storage...96

Engine Oil...97

Hydraulic Oil...98

Swing Gearbox, Propel Gearbox And Pump Gearbox Oils...99

Track Rollers And Idlers Oil...100

Swing Gear Grease...102

Grease...102

Lubricant Storage...103

Alternative Lubricants...104

Section 01: Tracks...105

Group 0130: Track System...105

Service Equipment And Tools...664

Other Material...665

Specifications...666

Measure Lower Track Roller Wear...110

Remove And Install Lower Track Roller...111

Disassemble And Assemble Lower Track Roller...113

Inspect Metal Face Seals...221

Measure Upper Track Roller Wear...122

Remove And Install Upper Track Roller...123

Assemble Upper Track Roller...126

Measure Track Shoe Grouser Wear...128

Remove And Install Track Shoe...129

Measure Track Link Wear...130

Measure Track Bushing Wear...131

Measure Track Pitch...132

Remove Track Chain...133

Install Track Chain...135

Disassemble And Assemble Track Chain...137

Adjust Track Sag...138

Measure Sprocket Wear...140

Remove And Install Sprocket...141

Measure Front Idler Wear...143

Remove And Install Front Idler...144

Disassemble Front Idler...145

Assemble Front Idler...148

Remove And Install Track Adjuster...151

Disassemble Track Adjuster...154

Assemble Track Adjuster...161

Section 02: Axles And Suspension Systems (Propel)...166

Group 0250: Axle Shaft, Bearings, And Reduction Gears...166

Service Equipment And Tools...664

Other Material...665

Specifications...666

Towing The Excavator-490D...171

Towing The Excavator-590D...174

Remove And Install Propel Gearbox-490D...178

Disassemble Propel Gearbox-490D...181

Assemble Propel Gearbox-490D...191

Remove And Install Propel Gearbox-590D...201

Disassemble Propel Gearbox-590D...205

Assemble Propel Gearbox-590D...214

Inspect Metal Face Seals...221

Group 0260: Hydraulic System...166

Essential Tools...495

Service Equipment And Tools...664

Other Material...665

Specifications...666

Remove And Install Propel Motor-490D...228

Disassemble Propel Motor-490D...233

Inspect Propel Motor-490D...243

Assemble Propel Motor-490D...247

Remove And Install Propel Motor-590D...257

Disassemble Propel Motor-590D...260

Assemble Propel Motor-590D...269

Remove And Install Propel Hydraulic Lines...276

Remove And Install Rotary Manifold...278

Disassemble And Assemble Rotary Manifold...281

Rotary Manifold Air Test...283

Section 04: Engine...284

Group 0400: Removal And Installation...284

4276 John Deere Engine Repair-Use CTM-4...286

Essential Tools...495

Other Material...665

Specifications...666

Remove And Install Engine-490D...292

Remove And Install Engine-590D...297

Remove And Install Oil Pan...301

Remove Fuel Injection Pump...302

Install Fuel Injection Pump...304

Remove And Install Fuel Injection Nozzles...306

Bleed Fuel System...309

Remove And Install Water Pump...311

Remove And Install Turbocharger-590D...313

Section 05: Engine Auxiliary Systems...315

Group 0505: Cold Weather Starting Aids...315

Other Material...665

Specifications...666

Remove And Install Starting Aid Solenoid And Nozzle...319

Remove And Install Engine Coolant Heater...321

Group 0510: Cooling System...315

Service Equipment And Tools...664

Specifications...666

Remove And Install Fan...326

Remove And Install Fan Belt...327

Fan Belt Tension Adjustment...328

Remove And Install Radiator...329

Group 0515: Speed Controls...315

Other Material...665

Specifications...666

Remove And Install Speed Control Assembly...333

Engine Speed Adjustment...334

Speed Control Linkage Adjustment...337

Speed Control Lever Tension Adjustment...340

Group 0520: Intake System...315

Service Equipment And Tools...664

Specifications...666

Remove And Install Air Cleaner-490D...344

Remove And Install Air Cleaner-590D...345

Air Intake System Leakage Test...346

Group 0560: External Fuel Supply Systems...315

Specifications...666

Remove And Install Fuel Tank...350

Remove And Install Fuel Filter...352

Section 07: Dampener Drive (Flex Coupling)...354

Group 0752: Elements...354

Other Material...665

Specifications...666

Disassemble And Assemble Flex Coupling-490D...358

Disassemble And Assemble Flex Coupling-590D...361

Section 16: Electrical System...363

Group 1671: Batteries, Support, And Cables...363

Specifications...666

Handle Batteries Safely...366

Test Batteries Using Coolant And Battery Tester...367

Test Batteries Using High Rate Discharge Test...368

Prevent Fire Hazards When Using Booster Batteries...369

Charge Battery...370

Remove And Install Batteries...371

Group 1672: Alternator, Regulator And Charging System Wiring...363

John Deere Engine Accessories-Alternator Repair-Use CTM-11...373

Service Equipment And Tools...664

Specifications...666

Remove And Install...376

Group 1674: Wiring Harness And Switches...363

Remove And Install Dome Light Switch...379

Remove And Install Control Panel Switches...380

Remove And Install Relay Starter Solenoid...381

Remove And Install Engine Hourmeter Switch...382

Remove And Install Engine Overheat Alarm Switch...383

Remove And Install Air Cleaner Restriction Indicator...384

Remove And Install Battery Relay...386

Remove And Install Battery Relay...386

Remove And Install Buzzer Stop Switch...387

Remove And Install Travel Alarm-590D...388

Changing Travel Alarm Volume...389

Group 1677: Motors And Actuators...363

John Deere Starting Motor Repair Use CTM-11...391

Service Equipment And Tools...664

Specifications...666

Remove And Install Starting Motor...394

Section 17: Frame Or Supporting Structure...395

Group 1740: Frame Installation...395

Welding Repair Of Major Structure...397

Group 1749: Chassis Weights...395

Essential Tools...495

Specifications...666

Remove And Install Counterweight...401

Section 18: Operator’s Station...402

Group 1800: Removal And Installation...402

Other Material...665

Specifications...666

Remove And Install Cab And Cab Floor...406

Remove And Install Cab (Without Floor)...413

Group 1810: Operator Enclosure...402

Service Equipment And Tools...664

Other Material...665

Remove And Install Windowpane And Two Piece Molding...418

Remove And Install Windowpane And One Piece Molding...420

Remove And Install Sliding Windows...421

Windowpane Dimensions...423

Remove And Install Cab Door...424

Remove And Install Door Latch...425

Remove And Install Inside Assist Handle...426

Remove, Disassemble, Assemble, And Install Windshield Wiper...427

Remove And Install Defroster Fan...428

Disassemble And Assemble Defroster Fan...429

Group 1821: Seat And Seat Belt...402

Disassemble And Assemble Seat...431

Group 1830: Heating And Air Conditioning...402

Disassemble And Assemble Blower Motor...433

Remove And Install 13,500 BTU Heater...434

Remove And Install 13,500 BTU Cab Heater Lines And Controls...436

Remove And Install 19,000 BTU Heater...438

Remove And Install 19,000 BTU Cab Heater Lines And Controls...439

Remove And Install 40,000 BTU Heater...441

Remove And Install 40,000 BTU Cab Heater Lines And Controls...442

Section 19: Sheet Metal And Styling...444

Group 1910: Hood Or Engine Enclosure...444

Specifications...666

Remove And Install Hood...447

Adjust Hood Latch Catch...448

Remove And Install Service Doors...449

Remove And Install Top Cover...450

Section 33: Excavator...451

Group 3302: Buckets...451

Service Equipment And Tools...664

Specifications...666

Remove And Install Bucket And Linkage...458

Remove And Install Bushings...492

Inspect Bucket Linkage Pins And Bushings...465

Adjust Bucket Pivot End Play...466

Disassemble And Assemble Bucket...467

Remove And Install Tooth Tip...468

Remove Tooth Shank...469

Install Tooth Shank...470

Group 3340: Frames...451

Service Equipment And Tools...664

Other Material...665

Specifications...666

Remove Arm...477

Install Arm...481

Remove Boom...484

Install Boom...488

Inspect Arm And Boom Pins And Bushings...491

Remove And Install Bushings...492

Group 3360: Hydraulic Systems...451

Essential Tools...495

Service Equipment And Tools...664

Other Material...665

Specifications...666

Hydraulic Cylinder Bleed Procedure...583

Release Pressure In Hydraulic System...502

Remove And Install Hydraulic Pump...504

Hydraulic Pump Start-Up Procedure...506

Disassemble Hydraulic Pump...507

Assemble Hydraulic Pump...511

Remove And Install Hydraulic Pump Regulator...514

Disassemble Pump Regulator...515

Assemble Pump Regulator...520

Remove And Install Pilot Pump...524

Disassemble And Assemble Pilot Pump...525

Remove And Install Solenoid Valve And Pilot Pressure Regulating Valve...527

Disassemble And Assemble Solenoid Valve And Pilot Pressure Regulating Valve...530

Remove And Install Engine Speed Mode Selection Cylinders...533

Disassemble And Assemble Engine Speed Mode Selection Cylinders...534

Remove And Install Hydraulic Control Valve...535

Disassemble Hydraulic Control Valve...542

Assemble Hydraulic Control Valve...553

Remove And Install Reservoir...564

Remove And Install Return Filter And Suction Filter...569

Remove And Install Oil Cooler Restriction Valve...572

Disassemble And Assemble Oil Cooler Restriction Valve...573

Remove And Install Oil Cooler Bypass Valve...574

Disassemble And Assemble Oil Cooler Bypass Valve...575

Remove And Install Oil Cooler...576

Remove And Install Bucket Cylinder...577

Remove And Install Arm Cylinder...579

Remove And Install Boom Cylinder...581

Hydraulic Cylinder Bleed Procedure...583

Disassemble Bucket, Arm And Boom Cylinders...584

Inspection Of Cylinder Rod...589

Assemble Bucket, Arm, And Boom Cylinders...590

Inspection Of Cylinder Pins And Bushings...596

Remove And Install Auxiliary Shut-Off Valve...597

Disassemble And Assemble Auxiliary Shut-Off Valve...599

Remove And Install Propel Function Ler Valve...601

Disassemble Propel Function Pilot Controller Valve...603

Assemble Propel Function Pilot Controller Valve...606

Remove And Install Dig Function Pilot Controller Valve...609

Disassemble Dig Function Pilot Controller Valve...612

Assemble Dig Function Pilot Controller Valve...615

Remove And Install Pilot Shut-Off Valve...618

Pilot Shut-Off Valve Linkage Adjustment...620

Disassemble And Assemble Pilot Shut-Off Valve...621

Disassemble And Assemble Pilot Filter...623

Inspect Pilot Filter Relief Valve...624

Remove And Install Flow Control Valve...625

Disassemble And Assemble Flow Control Valve...627

Remove And Install Check Valve Block...629

Disassemble And Assemble Check Valve Block...631

Section 43: Swing Or Pivoting System...632

Group 4350: Mechanical Drive Elements...632

Service Equipment And Tools...664

Other Material...665

Specifications...666

Remove And Install Swing Gearbox...637

Disassemble And Assemble Swing Gearbox...639

Remove And Install Swing Bearing...648

Disassemble And Assemble Swing Bearing...657

Install Swing Bearing Seals...662

Group 4360: Hydraulic System...632

Service Equipment And Tools...664

Other Material...665

Specifications...666

Remove And Install Swing Motor...667

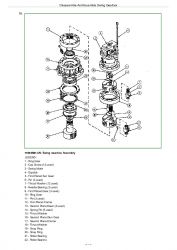

Disassemble Swing Motor...669

Assemble Swing Motor...676

Disassemble And Assemble Crossover Relief Valves...682

Remove And Install Make-Up Valves...686

Disassemble And Assemble Swing Brake Release Valve...687

Section 99: Dealer Fabricated Tools...691

Group 9900: Dealer Fabricated Tools...691

DF1036 Propel Gearbox Nut Wrench-490D...693

DFT1070 Propel Gearbox Nut Wrench-590D...694

DF1038 Torque Adapter...695

Rotary Manifold Lifting Tool...696

ST4920 Track Recoil Spring Disassembly And Assembly Tool...697

DFT1087 Track Recoil Spring Disassembly And Assembly Guard Tool...701

John Deere 490D and 590D Excavator Repair Technical Manual (TM1390)