Komatsu Bulldozers D60-, D65- Series Workshop Repair & Service Manual

Catalog:

Model:

Complete digital official shop manual contains service, maintenance, and troubleshooting information for the Komatsu Bulldozer D60A-6, D60P-6, D60PL-6, D60A-8, D60E-8, D60P-8, D60PL-8, D65A-6, D65P-6, D65A-8, D65E-8, D65P-8, D65E-8A, D65P-8A, D65E-12, D65P-12, D65EX-12, D65EX-12 (EU SPEC.), D65PX-12, D65PX-12 (EU SPEC.), D65EX-15, D65PX-15, D65WX-15, D65EX-15E0, D65PX-15E0, D65WX-15E0, D65WX-15E0, D65EX-16, D6PX-16, D6WX-16, D65EX-17, D65PX-17, D65WX-17. Diagnostic and repair procedures are covered in great detail to repair, maintain, rebuild, refurbish or restore your bulldozer like a professional mechanic in local service/repair workshop. This cost-effective quality manual is 100% complete and intact as should be without any missing pages. It is the same factory shop manual used by dealers that guaranteed to be fully functional to save your precious time.

This manual for Komatsu Bulldozer D60A-6, D60P-6, D60PL-6, D60A-8, D60E-8, D60P-8, D60PL-8, D65A-6, D65P-6, D65A-8, D65E-8, D65P-8, D65E-8A, D65P-8A, D65E-12, D65P-12, D65EX-12, D65EX-12 (EU SPEC.), D65PX-12, D65PX-12 (EU SPEC.), D65EX-15, D65PX-15, D65WX-15, D65EX-15E0, D65PX-15E0, D65WX-15E0, D65WX-15E0, D65EX-16, D6PX-16, D6WX-16, D65EX-17, D65PX-17, D65WX-17 is divided into different sections. Each section covers a specific component or system and, in addition to the standard service procedures, includes disassembling, inspecting, and assembling instructions. A table of contents is placed at the beginning of each section. Pages are easily found by category, and each page is expandable for great detail. It is in the cross-platform PDF document format so that it works like a charm on all kinds of devices. You do not need to be skilled with a computer to use the manual.

FILE LIST (1.4 GB PDF):

TFN00512-02 - Bouteur D65EX,PX,WX-17 Manuel d'utilisation et d’entretien (SN1001&up).pdf

TEN00512-04 - Bulldozer D65EX,PX,WX-17 Operation & Maintenance Manual (SN1001&up).pdf

TEN00488-03 - Bulldozer D65EX,PX,WX-16 Operation & Maintenance Manual (SN80159&up).pdf

TEN00404-00 - Bulldozer D65EX,PX,WX-16 Operation & Maintenance Manual (SN80012&up).pdf

TEN00330-02 - Bulldozer D65EX,PX,WX-16 Operation & Maintenance Manual (SN80001&up).pdf

TEN00276-02 - Bulldozer D65EX,PX,WX-15E0 Operation & Maintenance Manual (SN69105&up).pdf

TEN00103-06 - Bulldozer D65EX,PX,WX-15E0 Operation & Maintenance Manual (SN69001&up).pdf

TEN00061-01 - Bulldozer D65E,P-12 Operation & Maintenance Manual (SN65001&up).pdf

TEN00057-03 - Bulldozer D65EX,PX,WX-15 Operation & Maintenance Manual (SN67001&up).pdf

TEN00013-00 - Bulldozer D65EX,PX,WX-15 Operation & Maintenance Manual (SN67001&up).pdf

SRBM001910 - Бульдозер D65E,P-12 D65E,P-12 Заводская инструкция (SN60001 и выше).pdf

SRAM001202 - Бульдозер D65E-12 Технический паспорт.pdf

SEN05536-02 - Bulldozer D65EX,PX,WX-17 Shop Manual (SN1001&up).pdf

SEN05536-01 - Bulldozer D65EX,PX,WX-17 Shop Manual (SN1001&up).pdf

SEN04887-10 - Bulldozer D65EX,PX,WX-16 Shop Manual (SN80001&up).pdf

SEN00046-09 - Bulldozer D65EX,PX,WX-15E0 Shop Manual (SN69001&up).pdf

SEN00046-02 - Bulldozer D65EX,PX,WX-15E0 Shop Manual (SN69001&up).pdf

SEBM01440809 - Bulldozer D60A,E,P,PL-8 & D65A,E,P-8 & D65E,P-8A Shop Manual (SN45001&up).pdf

SEBM040800 - Bulldozer GALEO D65WX-15E0 Power Angle Power Tilt Dozer Shop Manual (SN69001&up).pdf

SEBM029508 - Bulldozer D65EX,PX,WX-15 Shop Manual (SN67001&up).pdf

SEBM027202 - Bulldozer D65EX-12 & D65PX-12 (EU SPEC.) Shop Manual (SN65209&up).pdf

SEBM001923 - Bulldozer D65E,P-12 & D65EX,PX-12 Shop Manual (SN60001&up).pdf

SEBM001922 - Bulldozer D65E,P-12 & D65EX,PX-12 Shop Manual (SN60001&up).pdf

SEBM001921 - Bulldozer D65E,P-12 & D65EX,PX-12 Shop Manual (SN60001&up).pdf

SEBM0144B01 - Bulldozer D60A,P,PL-6 & D65A,P-6 Shop Manual (SN31001&up).pdf

SEAM01440805 - Bulldozer D65A,E,P-8 Operation & Maintenance Manual (SN45001&up).pdf

SEAM026600P - Bulldozer D65E,P-12 Operation & Maintenance Manual (SN62781&up).pdf

SEAM007209T - Bulldozer D65EX,PX-12 Operation & Maintenance Manual (SN65001&up).pdf

SEAM007207T - Bulldozer D65EX,PX-12 Operation & Maintenance Manual (SN63304&up).pdf

SEAM007102 - Bulldozer D65E-12, D65P-12 Operation & Maintenance Manual).pdf

SEAM001202 - Bulldozer D65E,P-12 & D65EX,PX-12 Operation & Maintenance Manual (SN60001&up).pdf

SEAM001202 - Bulldozer D65E-12, D65P-12, D65EX-12, D65PX-12 Operation & Maintenance Manual (SN60001&up).pdf

SEAD007205 - Bulldozer D65EX,PX-12 Operation & Maintenance Manual.pdf

SEAD007204 - Bulldozer D65EX,PX-12 Operation & Maintenance Manual (SN61369&up).pdf

SEAD007202 - Bulldozer D65EX,PX-12 Operation & Maintenance Manual (SN60915&up).pdf

SEAD007104 - Bulldozer D65E,P-12 Operation & Maintenance Manual (SN61365&up).pdf

SEAD007102 - Bulldozer D65E,P-12 Operation & Maintenance Manual (SN60891&up).pdf

SEAD001202 - Bulldozer D65E,P-12 & D65EX,PX-12 Operation & Maintenance Manual (SN60001&up).pdf

EEAM024400 - Bulldozer D65EX,PX-15E0 Operation & Maintenance Manual (SN69001&up).pdf

CEAWD01701 - Crawler Dozer D65EX-12 PAT Field Assembly Manual (SN62745&up).pdf

SEBD001920 - Bulldozer D65E,P-12 & D65EX,PX-12 Shop Manual (SN60001&up).pdf

SEBM0141C01 - Bulldozer D60S-7 & D65S-7 Shop Manual (SN40001&up).pdf

EXCERPT:

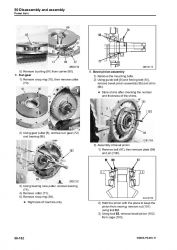

50 Disassembly and assembly

Engine and cooling system

Removal and installation of fuel tank assembly

- Place the machine on a level ground and apply the parking brake.

- Lower the work equipment to the ground, and stop the engine.

- Disconnect the cable from the negative (-) terminal of the battery.

Removal

1. Remove cover (1) under the fuel tank.

2. Drain the fuel from the fuel tank from the fuel valve at the fuel tank bottom.

3. Disconnect fuel outlet hose (2).

- Plug the hoses and adapters to prevent the fuel from flowing out.

4. Open battery cover (3) on the left side of the machine and fix it with the lock.

- Lock the opened cover securely.

5. Disconnect connector CN-FTK (4) of the fuel level sensor wiring harness.

6. Disconnect fuel return hose (5).

- Plug the hoses and adapters to prevent the fuel from flowing out.

7. Sling the fuel tank assembly.

8. Remove three mounting bolts (6) each on the right and left sides of the fuel tank from under the fenders at the rear portion of the machine.

9. Sling and remove fuel tank assembly (7).

- Check that all the wiring and piping are disconnected before lifting off the operator cab assembly.

4 Fuel tank assembly: 240 kg (when empty)

Installation

• Carry out installation in the reverse order to removal.

• Refilling of fuel (fuel tank)

5 Fuel tank (diesel fuel): 415 l

(For details, see "List of lubricant and water")

• Checking for fuel leakage (fuel system)

Check the fuel system for leakage. For details, see Testing and adjusting, "Checking fuel system for leakage".

• Bleeding air (fuel system)

Bleed air from the fuel circuit. For details, see Testing and adjusting, "Bleeding air from fuel circuit".

Removal and installation of KDPF assembly

- Place the machine on a level ground and apply the parking brake.

- Lower the work equipment to the ground and stop the engine.

- Set the disconnect switch to the OFF position and remove the key.

- The temperature of KDPF increases above 500 °C . Accordingly, wait until the piping around the engine cools down after the engine is stopped, and then start the removal work.

Removal

1. Remove the engine hood assembly. For details, see "Removal and installation of engine hood assembly".

2. Disconnect wiring connectors PDPF (1) and TDPF (2) according to the following procedure.

1) Slide the lever (red) of the connector in the direction of the arrow to unlock it.

2) Pull out the connector in the direction of the arrow while pressing the knob.

3. Remove eye-joint (3). [*1]

4. Remove cover (4).

5. Using tool A9, remove V-clamp (5). [*2]

- Since tube (6) is a datum location for installation, do not loosen it.

- Make match marks on the KDPF and tube (6). [*3]

...